CHAPTER 10

Geothermal Energy – Power from the Deep

When planet Earth came into being more than four billion years ago, its form was considerably different from what it is now. At that time Earth was in a partially melted state. It was not until about three billion years ago that the temperature of the Earth's surface dropped to below 100 °C and the Earth's crust gradually began to harden.

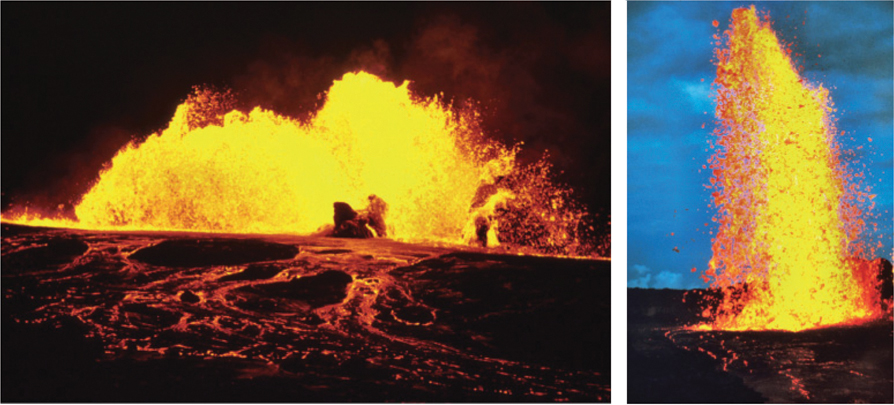

It may not seem like it in the depths of a northern winter, but today our planet is anything but a cold ball. About 99% of the Earth is hotter than 1000 °C and 90% of the rest has temperatures of over 100 °C. Fortunately for us, these high temperatures are almost exclusively found in the Earth's interior. Every so often volcanoes produce impressive eruptions spewing molten matter from depths of up to 100 km. Different geothermal energy technologies enable us to tap the heat of the Earth's interior in a controlled way so that we can satisfy some of our heat and electricity demands (Figure 10.1).

Figure 10.1 Volcanic eruptions bring the energy from the Earth's interior to the surface in a spectacular fashion. Source: D.W. Peterson and R.T. Holcomb, US Geological Survey.

10.1 Tapping into the Earth's Heat

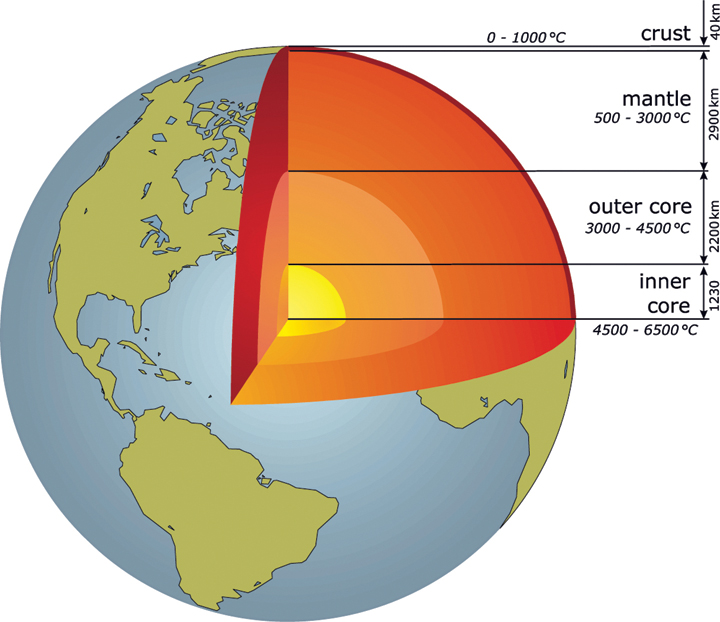

The Earth itself is made up of concentric bands (Figure 10.2) comprising the core, the mantle, and the crust. The Earth's core has a diameter of around 6900 km (4290 mi). A differentiation is made between the outer, liquid core, and the inner core, which is made of solid matter. Maximum temperatures in the Earth's core reach 6500 °C, which is hotter than the surface of the sun.

Figure 10.2 The structure of the Earth.

Why the Earth's Inner Core is Not Liquid

Why the Earth's Inner Core is Not Liquid

The Earth's inner core, which essentially consists of iron and nickel, has temperatures of up to 6500 °C. Under normal environmental conditions with an ambient pressure of one bar, these temperatures would make iron and nickel gaseous. The pressure rises as the depth into the Earth's interior increases. This pressure reaches maximum values of four million bars. This extremely high pressure ensures that the outer core is liquid, and the inner core is solid.

Eighty percent of the Earth's core consists of iron. A small amount of the heat in the Earth's interior comes from residual heat from the time the Earth was formed but a major part consists of radioactive decaying processes. The Earth's mantle is around 2900 km thick. We are only able to reach the top part of the Earth's crust.

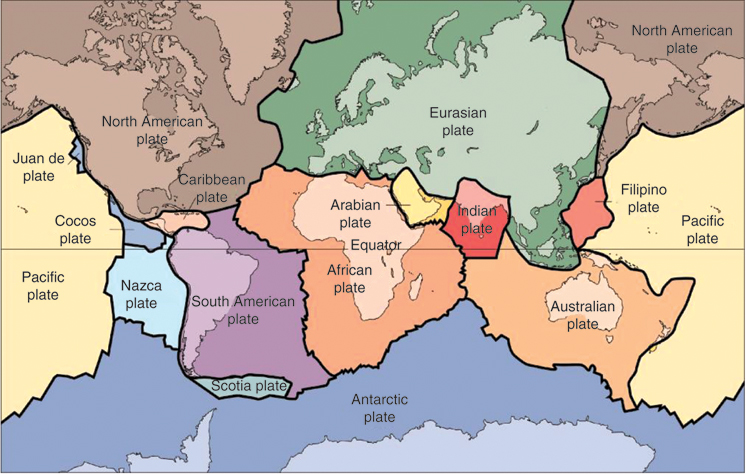

The Earth's crust and the uppermost part of the Earth's mantle together form the lithosphere. The thickness of the lithosphere varies from a few kilometres to more than 100 km. It consists of seven large and some smaller lithosphere plates (Figure 10.3). These rather brittle plates float in the asthenosphere, where matter is no longer solid. The plates are constantly in motion. Earthquakes and volcanoes frequently occur in areas where two plates collide. Thermal anomalies can also frequently be observed in these areas, where high temperatures can occur, even at shallow depths, creating conditions that enable us to make particularly effective use of the Earth's heat.

Figure 10.3 Tectonic plates on Earth. Source: US Geological Survey.

Regions like Central Europe, that are not near the borders of tectonic plates do not have optimal geothermal resources. This does not mean that high temperatures do not exist underground. However, compared to regions like Iceland where geothermal conditions are favourable, it takes drilling at greater depths to reach the same temperatures.

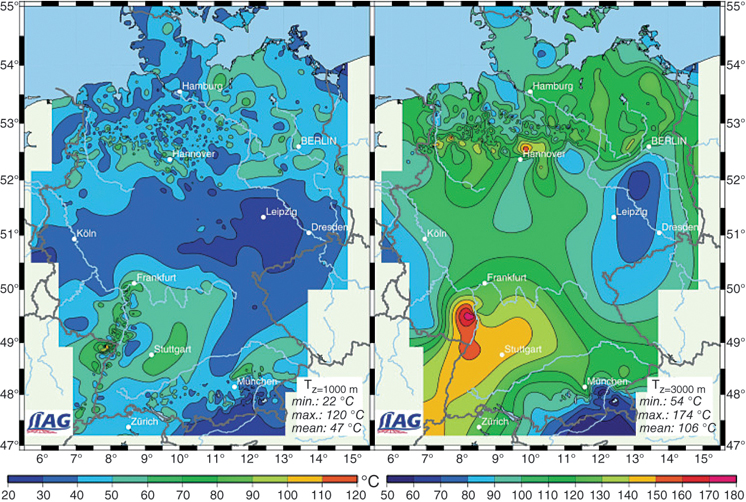

The best geothermal conditions in Germany are in the Rhine Rift Valley (Figure 10.4). In this region temperatures of 150 °C or more can be found at depths of 3000 m. The average thermal depth gradient is around 3 °C per 100 m. On this basis, a temperature increase of 90 °C could be expected at depths of 3000 m. In Iceland, temperatures like this occur at depths of just a few hundred metres.

Figure 10.4 Temperatures in Germany at depths of 1000 and 3000 m. Source: http://www.liag-hannover.de [Sch02].

Deep drilling is required to exploit the high temperatures. The technique for this type of drilling has long been familiar from oil extraction. Rotary drilling methods are employed, whereby motors drive a diamond bit into the depths. At very great depths, a drill bit cannot be driven in the conventional way over a drill string due to the increased strain caused by turning and friction. An electric motor or turbine therefore directly drives the drill bit.

The actual derrick (Figure 10.5) that holds the drill pipe is all that can be seen from the surface. Water is pressed into the borehole at pressures of up to 300 bars through the inside of the drill. Crushed rock material in the outer area between the bit and the borehole is forced to the surface by the flushed mud, which at the same time cools the drill. The drilling drive can also be used to change the bore from its vertical position. This enables the boreholes that are sited close together on the surface to exploit a larger area underground.

Figure 10.5 Left: New and used drill bits. Right: Structure of a derrick. Photos: Geopower Basel AG.

Depending on the conditions underground, the walls of a borehole can become unstable. Steel tubes are inserted at large intervals and stabilized with a special cement to prevent the walls from collapsing. The drilling is then continued with a smaller drill bit. For many years the very high salt content of thermal water caused serious problems at many drilling sites. Salt attacks metal and very quickly causes corrosion. Today, the use of specially coated materials has eliminated this problem.

The deepest drilling ever carried out was for research purposes on the Kola peninsula in Russia. This bore hole had a depth of 12 km. In Germany, the continental deep geothermal drilling project in the Oberpfalz region reached a depth of 9.1 km. These drilling depths represent the current technical limit. The conditions at depths of 10 km are extreme, with temperatures of more than 300 °C and pressures of 3000 bar. Under these conditions rock becomes plastic and viscous.

Much shallower depths are sufficient for geothermal use. The maximum drilling depth currently planned for large-scale facilities is around 5 km. However, the techniques employed even at these depths are complex and therefore expensive.

A distinction is made between the following in the exploitation of geothermal deposits:

- hot steam deposits

- thermal water deposits

- Hot Dry Rock (HDR)

Hot steam and thermal water sources can be used directly for heating purposes or to generate electricity. If the ground consists only of hot rock, this can heat up cold water that is compressed into the depths.

10.2 Geothermal Heat and Power Plants

10.2.1 Geothermal Heat Plants

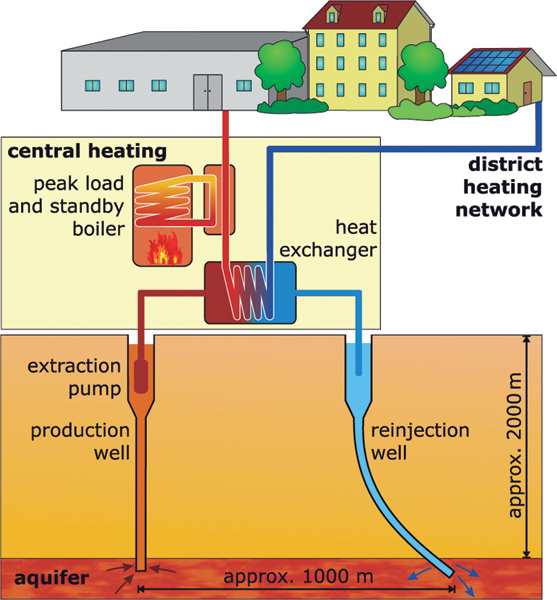

If boreholes already exist in a thermal water area, it is comparatively easy to develop a geothermal heat supply. In geothermal heat plants a feed pump fetches hot thermal water from a production well to the surface (Figure 10.6). As thermal water often has a high salt content, along with certain natural radioactive impurities, it cannot be used directly to provide heat. A heat exchanger extracts the heat from the thermal water and transfers it to a district heating grid. A reinjection well injects the cooled thermal water back into the earth.

Figure 10.6 Principle of a geothermal heat plant.

Relatively low temperatures of 100 °C or less are sufficient for heating purposes. Drilling depths of about 2000 m are often sufficient in suitable regions.

A central heating plant controls the flow rate depending on the heat demand. If the heat demand is particularly high, a peak-load boiler can cover the heat peaks. A backup boiler is also helpful to guarantee reliable heat supply in case problems occur with the extraction pump or the well.

10.2.2 Geothermal Power Plants

Using geothermal energy to generate electricity is somewhat more complex than providing thermal heat. The relatively low temperatures that are available call for innovative power plant concepts such as:

- Direct steam use

- Flash power plants

- ORC (Organic Rankine Cycle) power plants

- Kalina power plants

Normal steam turbine systems can be used in geothermally optimal locations with temperatures between 200 and 300 °C. If hot steam deposits exist underground, they can be used directly to drive the turbines.

If hot thermal water is under pressure, it can be evaporated through an expansion stage. The steam from the water that is still hot can in turn be transferred directly to a steam turbine. This technique is called a flash process.

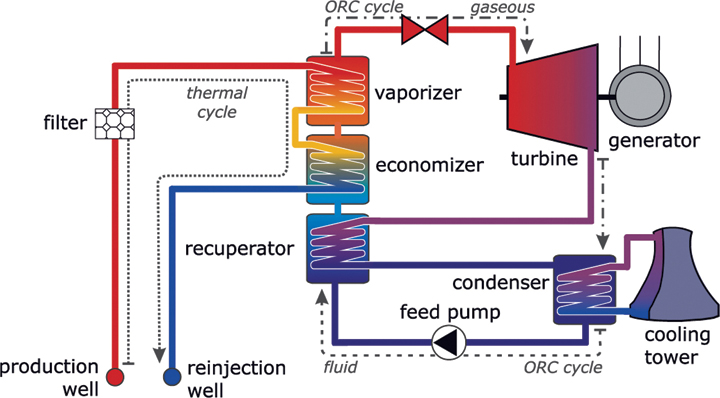

At temperatures of 100 °C or less geothermal water is not hot enough to vaporize water. A normal steam turbine using water as the work medium is not suitable in this case. An ORC system can be used instead (Figure 10.7).

Figure 10.7 Principle of a geothermal ORC plant.

A steam turbine also forms the core of this kind of system. However, instead of water, the steam turbine uses an organic material such as Isopentan or PF5050. A heat exchanger transfers the heat from the geothermal cycle to the organic working fluid. This material also evaporates under high pressure at temperatures lower than 100 °C. The steam from the organic material drives the turbine and expands in the process. The organic material is liquefied again in a condenser. A cooling tower dissipates the residual heat. A feed pump again puts the organic material under pressure and the heat exchanger completes the cycle.

The disadvantage of ORC systems is that they are relatively inefficient. At temperatures of 100 °C the efficiency is well below 10%. This means that at best 10% of the geothermal heat energy can be converted into electric energy. The Kalina process promises slightly higher efficiency. With this process a mixture of water and ammonia acts as the working material. However, not even the laws of physics can make this process a viable option. Generating electricity from geothermal energy is basically preferable and offers higher efficiency.

The first geothermal power plant in Germany was in Neustadt-Glewe between Hamburg and Berlin (Figure 10.8). This ORC plant, which was built in 2003, had an electrical output of 230 kW. A geothermal heat plant, which was put into operation in 1995 with geothermal heat output of 4 MW, is located at the same site. After a technical defect in 2010, power generation was discontinued. Since then, the plant has only supplied heat.

Figure 10.8 The Neustadt-Glewe geothermal heat power plant was the first plant to generate electricity from geothermal energy in Germany.

In late 2007 the second geothermal power plant in Germany came into operation in Landau. It uses two boreholes to access 155 °C hot thermal water from a depth of 3300 m. An ORC process designed for continuous all-year-round power generation uses this supply to generate around 3 MW of electricity.

The next power plant was built a short time later in Unterhaching near Munich. Hot thermal water with a temperature of 122 °C is extracted here from a depth of 3350 m. This geothermal cogeneration plant with an electricity output of around 3.36 MW is the first one to use the Kalina process. In addition, the plant feeds heat with a thermal capacity of 38 MW into a district heating grid.

In the meantime, numerous other projects have been developed or are in the planning and construction stages. Information on these projects can be found on the websites provided below.

![]()

|

Geothermal Information System German Geothermal Energy Assn. Deep Geothermal Energy Information Portal |

10.2.3 Geothermal HDR Power Plants

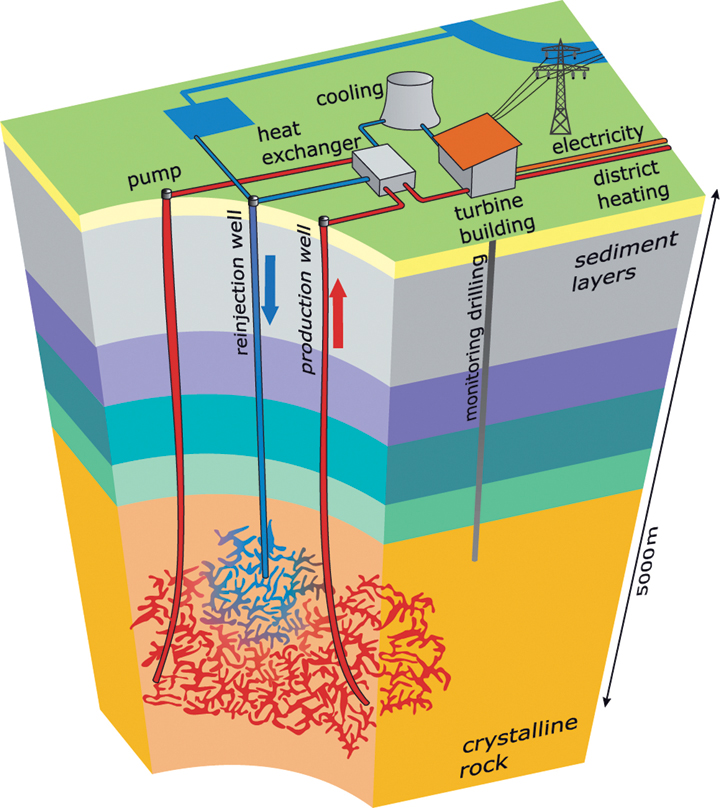

The aim of drilling at depths of up to 5000 m is almost always geothermal power generation. At such depths, temperatures are around 200 °C, even in regions that do not benefit from optimal geothermal conditions, such as Germany, France, and Switzerland. As a result, quite reasonable efficiency is achieved in power generation provided the depth is great enough.

Thermal water cannot usually be exploited at such great depths. What is mainly found is HDR. Artificial shafts are created in which water can be heated to extract the heat from the rocks. These shafts are made by compressing water at high pressure into a borehole. The heat expands the borehole, creates new fissures and expands existing cracks. This produces an underground fracture system that can extend to several cubic kilometres. The activities are monitored via a dedicated auxiliary borehole.

This direct tapping of hot water deposits is also referred to as hydrothermal geothermal energy, whereas hot-dry-rock technology is also called petrothermal geothermal energy.

To generate geothermal energy, a pump transports cold water through an injection well down to depth. There, the water disperses into the cracks and fissures of the crystalline rock and heats up to temperatures of 200 °C. The hot water reaches the surface again through production wells and delivers the heat over a heat exchanger to a power plant process and district heating network (Figure 10.9).

Figure 10.9 Diagram of an HDR power plant.

During the 1970s the Los Alamos laboratory in the USA conducted the first tests of the HDR method. A European research project on HDR technology has been underway in Soultz-sous-Fôrets in Alsace since 1987. The power plant started a trial operation in 2008.

In 2004 Geopower Basel AG was founded in Switzerland with the aim of building the first commercial HDR power plant. However, work on the project was stopped in 2007 when small tremors occurred during the creation of the underground fractures.

10.3 Planning and Design

The most important factor in planning geothermal power plants is the temperatures that can be achieved. The design of the heat exchangers, district heating grids and plant processes are all based on projected temperatures. Geologists try to determine in advance at which depths the desired temperatures can be found. To an extent, they are able to rely on the knowledge gained from existing boreholes.

In addition to achievable temperatures, extractable water quantities also play a major role. Large volumes of water are needed to achieve high output. The diameter of the borehole as well as the pumps both have to be designed accordingly. Last but not least, it is important that the temperature of the thermal water is not allowed to drop too significantly during the extraction process. Large-scale power plants usually extract more heat from the depth than regularly flows back into an exploited area. Therefore, a slow cooling of the exploited area cannot really be prevented. The goal is to plan the intervals between the drilling so that the desired temperatures can be sustained for about 30 years. After this period the temperatures drop below the desired target values, and, as a result, the geothermal plant performance also decreases. A new site, which should not be more than a few kilometres from the existing site, must be developed if any further exploitation is planned.

10.4 Economics

Drilling is by far the biggest cost factor with deep geothermal energy. Yet, it is not only the cost of the drilling itself that is the problem. The risks associated with it, especially on commercial projects, are something that should not be underestimated. Even the best geologists can never accurately predict what conditions will be like underground. Drilling costs shoot up immediately if drills unexpectedly hit crystalline hard rock instead of soft sedimentary rock. If, in addition, the temperatures underground are well below what was projected, a geothermal project can fail at an early stage. At Bad Urach, for example, a rather promising geothermal project was repeatedly suspended for financial reasons.

Underground conditions can often spring other surprises. For example, during work on a geothermal project in Speyer in Germany, drillers not only found the thermal water they were hoping for but also discovered an oilfield 2000 m below the surface Now oil is being produced there instead of geothermal heat.

Even when drilling is successful, geothermal power plants have to spend up to half of all investment on the drilling activities. Therefore, the cost of geothermal power is often considerably higher than that of electricity from wind and hydropower systems.

In Germany, the Renewable Energy Sources Act (EEG) also promotes geothermal power generation. In 2018, the statutory payment for geothermal power plants was 25.2 cents kWh−1. The payments for new plants are to be reduced by 5% per year from 2021.

The costs in countries with good geothermal conditions are considerably lower than those in Germany. At drilling depths of a few hundred metres the drilling costs in those areas end up being very low. If, in addition, high temperatures exist close to the surface, some countries such as Iceland can even use geothermal heat to keep their pavements free of ice in winter (Figure 10.10).

Figure 10.10 The Nesjavellir geothermal power plant in Iceland. Photo: Gretar Ívarsson.

10.5 Ecology

Geothermal co-generation plants have little ecological impact. Most of the plant is located underground and is not visible, and therefore does not have a direct negative impact on people or landscape. Only the power plant complex is above ground. Like other heat plants, these also require cooling water for the plant processes. However, water is readily available at most geothermal sites.

What can cause problems are some of the working materials used in the generation of power. For instance, the material PF5050 used in ORC processes has a very high greenhouse potential. If 1 kg of this material reaches the atmosphere, it produces the same greenhouse effect there as 7.5 tons of carbon dioxide. However, alternatives, such as Isopentan, are available.

In the long term, geothermal systems can cause a certain cooling of some localized areas under the ground. However, as far as we are currently aware, this has no effect on the surface.

Relatively little research has been done on the risk of seismic activities. Small tremors with an intensity of up to 3.4 on the Richter scale occurred in 2006 after geothermal drilling for an HDR power plant to a depth of 5000 m in Basel, Switzerland. The tremors caused small cracks to buildings in the region, so work on the project was halted. The geothermal company involved paid compensation for most of the damage.

As long as scientists are unable to predict accurately whether and when tremors can occur during the compression of water, HDR projects will pose a certain risk in densely inhabited regions. Hydrothermal geothermal projects that do not require fissures and cracks to be artificially created are comparatively safe with regards to earthquake risk.

10.6 Geothermal Markets

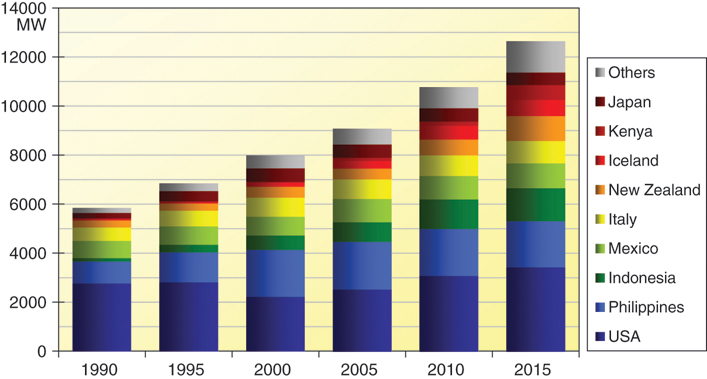

China, the USA, Iceland, and Turkey are the outright leaders when it comes to geothermal heat use. The USA and the Philippines have the highest power plant output from geothermal electricity generation (Figure 10.11). Providing more than 60% of the country's energy needs, geothermal energy in Iceland constitutes the highest relative share of any country's total primary energy supply. However, since the population of Iceland is only 300 000 and the country is not exactly densely populated, its absolute installed capacity is nevertheless lower than that in other countries.

Figure 10.11 Installed geothermal power plant capacity worldwide. Data: IGA, http://www.geothermal- energy.org.

The use of geothermal energy in Germany is considerably more modest than in the countries already mentioned. The main reasons are the comparatively low geothermal resources and the associated great drilling depths for tapping suitable temperatures. However, this disadvantage is also an incentive for technological developments. Germany is one of the leading nations in geothermal power generation in the low-temperature range between 100 and 200 °C.

10.7 Outlook and Development Potential

Many countries are starting to develop the use of geothermal energy, but compared to other renewable energy technologies, such as wind power and photovoltaics, the annual growth rates for this energy source are quite modest.

The share of geothermal energy in the worldwide energy supply is therefore currently very low. But this technology has great potential. Another advantage of geothermal energy is its constant availability. Compared to the fluctuations in certain renewable energy sources – such as solar energy, wind power, and hydropower – geothermal energy is not subject to any unpredictable daily or yearly changes in available supply. This makes geothermal energy an important building block in a carbon-free energy supply. Additionally, supply reliability will become a big factor, as the share that renewable energies have within the overall energy demand increases. This will help to raise interest in building new geothermal plants.

For economic reasons, countries with large geothermal resources will remain the leaders in the field. As prices for fossil fuels continue to rise, geothermal energy will also become more interesting to countries with moderate geothermal resources. Germany could benefit not only from the use of geothermal energy in its own country, but also from the export of technologies developed there.