CHAPTER 14

Sunny Prospects – Examples of Sustainable Energy Supply

The previous chapters covered the large spectrum of renewable energies available. Renewable energies will largely have to replace conventional energy sources during the next 20 years to keep the consequences of climate change within manageable limits. The modern use of these energies does not have decades of tradition to fall back upon. Their applications are often new and unusual. Yet climate-compatible energy supply is not pie in the sky. A life beyond fossil and nuclear energy sources is already possible today. This chapter illustrates this based on impressive examples from different areas. Despite the pressing need to protect the climate, low-energy dwellings such as ‘three-litre’ houses or passive houses meeting the German KfW 55 or KfW 40 standards are still the exception rather than the rule. Most buildings that undergo restoration or renovation also fall short of meeting the standard for climate compatibility. It is technically as well as economically easy to incorporate energy supplies that are low or neutral in carbon dioxide into new buildings in particular. It is far simpler to do this at the building stage rather than adapting the finished house in the future. Energy-saving adaptations are usually postponed until windows, roofs, and outside walls are due for refurbishment anyway. However, with well-constructed new buildings this can take many years. If energy prices continue to rise over the next few years, then even new-builds with unnecessarily high requirements in energy will become very costly to run. Investing in high quality insulation and renewable energy supply when a house is being built or renovated means not having to worry about increases in energy prices in the years to come. Most of the climate-protecting measures available in building construction are relatively unspectacular. The first example shows an ordinary single-family home in Berlin with about 150 m2 of living space. It was built in 2005 using timber frame construction. Compared to solid construction, wood frame construction offers good insulation values even with thinner walls. In this particular house, the wall thickness was increased to 32 cm by adding 8 cm of insulation on the outside, to reduce further heat losses through the walls. The standard thermal windows were replaced using triple-glazed windows with a high insulation value. A controlled ventilation system with heat recovery reduces ventilation losses and increases comfort levels. These measures alone will enable this building to reach the standards of a 3-l house (Figure 14.1). Figure 14.1 Left: Family home in Berlin with carbon-neutral energy supply. Right: Boiler room with buffer storage tank, solar cycle pump, controlled heat recovery system and wood pellet boiler. A wood pellet boiler and a 4.8 m2 solar thermal system cover the remaining space heating and hot water demand. A pellet store 5 m2 in size has capacity for around 6 tonnes of wood pellets. This covers heat energy demand for around three years and is even enough to bridge periods when fuel prices are particularly high. A photovoltaic (PV) system with a capacity of 1 kW peak, which was later expanded to 10.7 kW peak, generates around twice as much electricity per year as is consumed in the house. The additional costs for the measures described compared to the minimum newbuild standard in 2005 amounted to around €30 000. Retrofitting of the PV system added another €15 000. The cost of wood pellets is around €500 yr−1. The payments for the solar electricity fed into the grid are significantly higher, so that overall the space heating and electricity consumption costs for this house are virtually zero. A green power supplier covers the electricity demand at times of low sunshine in a carbon dioxide-free manner. Since the PV system generates significantly more electricity than is consumed in the house, the house is not only carbon dioxide-neutral during operation, it even provides an additional reduction in greenhouse gases. If the entire roof area of an optimally insulated house is fitted with solar systems, a carbon dioxide-neutral house can be turned into a plus-energy solar house. An example is the house shown in Figure 14.2, located in Fellbach near Stuttgart. Optimal heat insulation using cellulose, triple-glass solar glazing, a ventilation system with heat recovery and preheated air supplied from the ground reduce the heat energy needs by about 80% compared to a standard new-build. Figure 14.2 Plus-energy solar house in Fellbach near Stuttgart. The PV system feeds more electricity into the public grid each year than the house needs to cover its own space heating and electricity demand.

Source: Reinhard Malz, www.fellbach-solar.de. A brine-water heat pump with an electrical capacity of 1.1 kW covers the remaining space heating demand of the house. The low-temperature heat comes from two vertical ground probes sunk 40 m into the ground. A 0.50 kW heat pump would have been sufficient but was not available on the market. The PV system with a capacity of 8 kW peak feeds more than 8000 kWh into the public grid each year. This is more than the electricity demand of the house, including the ventilation system and the heat pump. As a result, the energy supplied in this house is not only carbon-neutral but actually saves carbon dioxide elsewhere due to the solar electricity fed into the grid. Houses that produce an energy surplus over the year and feed it into the grid do not have to be an exception. This is demonstrated by the Schlierberg solar housing estate in Freiburg in southern Germany. The architect Rolf Disch designed 50 plus-energy houses for this estate. He has been integrating ecological enhancements and renewable energies into his projects for more than 30 years. All houses in this development of terraced houses are orientated towards the south. The gaps between the terraces are designed so that the heat from the sun can stream into the houses through large south-facing windows in the winter. Balconies that jut out prevent the houses from heating up too much in the summer. These simple and cheap measures could reduce the energy needs of many new-build houses. Optimal insulation that exceeds the standard and controlled living space ventilation with heat recovery are standard features of this particular housing estate. These features are designed to keep heat energy needs to an absolute minimum (Figure 14.3). Figure 14.3 Schlierberg solar housing estate in Freiburg, Germany, with 50 plus-energy houses.

Source: Rolf Disch SolarArchitektur, www.solarsiedlung.de. A woodchip combined heat and power (CHP) plant covers the rest of the remaining space heating demand and provides a climate-neutral energy supply. A local heating network transports the heat to the individual houses. The PV systems feed into the public electricity grid. The solar energy surplus produced by the houses makes them plus-energy homes. The building materials were also chosen with ecology and sustainability in mind. The wood has not been chemically treated, solvent-free paints and varnishes have been used throughout and the water pipes and electric cables are PVC-free. Many houses use solar thermal systems only to heat water in the summer and at best to provide heating support during the transitional seasons. It is hard to imagine that houses in countries with cold winters could be heated with solar energy alone. But in recent years many single-family houses have proven that the heating demand can be covered by the sun even in Central Europe. The first multiple-family home in Europe to be heated 100% with solar thermal heat was built in Burgdorf near Bern, Switzerland, in 2007 (Figure 14.4). Figure 14.4 Left: First multiple-family home in Europe with 100% solar heating. Right: Installation of 276 m2 roof-integrated solar collector.

Photos: Jenni Energietechnik AG, www.jenni.ch. High-quality heat insulation and a ventilation system with heat recovery ensure that heat losses in this building are relatively low. The large 276 m2 roof is completely covered with solar collectors. An enormous hot water storage tank with a capacity of 205 000 l is located in the centre of the building. The seasonal storage tank extends from the basement to the loft. The collectors heat the storage tank with solar heat in the summer. In winter, when the collectors cannot supply sufficient heat, the heat from the storage keeps the building cosy. No auxiliary heating is required. Less than 10% of the total construction cost of around 1.8 million euros for the building was spent on the solar system. Yet aside from the small expenditure for electricity for the solar and heating circuit pumps, no additional heating-related costs are incurred. Heating costs are included in the rent, so that residents of the block do not have to worry about constant rises in energy bills. Since the house exceeded all expectations during actual operation, two further solar-heated multi-family houses were built on the same site. Practically all technical options can be incorporated into new-builds without a problem. The situation is considerably more complex with existing buildings that date from a time before protecting the environment was considered important. Building renovations or the installation of a new heating system present the ideal opportunity to make enormous reductions in carbon dioxide. One example is the zero-heating cost apartment block in Ludwigshafen, Germany, which was built in the 1970s and then renovated in 2007 to a technical standard comparable to today's levels (Figure 14.5). Figure 14.5 Constant hikes in energy bills are a thing of the past for this zero heating-cost house in Ludwigshafen, Germany.

Photos: LUWOGE, www.luwoge.de. As a result, space heating demand is reduced by around 80%, which now amounts to only around 20 kWh m−2 of living space per year. 30 cm thick outer wall insulation and triple-glazed thermal windows provide optimal building insulation. Controlled living space ventilation with heat recovery reduces ventilation heat losses. Solar thermal façade collectors provide for the hot water supply and a large grid-coupled PV system is located on the roof. The minimal residual space heating demand is covered electrically. The yield from the PV system should be roughly the same as the heating electricity costs. As a result, the tenants have zero heating costs. Constant rises in heating costs are therefore a thing of the past for this building. Taking into account all costs including upkeep and vacancy rates, the modernization measures have also turned out to be very lucrative for the investor. Both sides benefited from the climate-protection measures that were taken. The ‘Sonnenschiff’ (Sun Ship) is located near the housing estate in Freiburg presented above. The Sonnenschiff is a solar service centre that houses shops, offices, medical practices, and penthouse flats. The plus-energy design for the building complex was developed by the architect Rolf Disch. Optimal insulation incorporating advanced vacuum insulation material and intelligent ventilation with heat recovery help reduce the heating demand. In winter the sun streams through large windows right into the heart of the building, providing some of the heating. In summer canopies and blinds prevent the building from overheating (Figure 14.6). Figure 14.6 The ‘Sonnenschiff’ (Sun Ship) in Freiburg contains two shops, a bistro, offices, and medical practices.

Photo: Rolf Disch SolarArchitektur, www.solarsiedlung.de. A woodchip CHP plant covers the small residual heating demand. PV systems are not simply mounted on the roof but are actually used instead of a conventional roof. As a result, the entire roof surface generates electricity. An intelligent solution has also been devised for transport connections. The complex has its own tram stop and conveniently sited parking areas for bicycles, thereby offering alternatives to motor car use. The electric cars of a car-sharing firm are allocated preferential parking spaces and can be charged using solar power generated by the complex itself. The Sonnenschiff complex has put into practice the concept of working and living carbon-free and contributing to climate-compatible mobility. It is also relatively easy for factories to operate without emitting carbon dioxide. An example is the Solvis zero-emissions factory in Braunschweig, Germany, which produces solar and pellet systems. High-quality heat insulation and waste air recovery in the factory have resulted in energy savings as high as 70% compared to conventional structures. Optimal use of daylight and low-energy office machines have halved electricity needs. Solar collectors and PV systems generate 30% of the electricity and heating required. A rapeseed oil CHP plant covers the remaining energy needs, thereby ensuring that all energy supply is completely carbon-free. Large amounts of heat often escape through the open shed doors of factories during the loading and unloading of heavy goods vehicles. This factory keeps heat losses at a minimum because the loading and unloading zones are situated inside the building. A direct connection to local public transport, parking facilities for bicycles, and showers for cyclists provide employees with a climate-compatible workplace (Figure 14.7). Figure 14.7 Solvis zero-emissions factory in Braunschweig, Germany.

Photo: SOLVIS, www.solvis.de. The ‘factory of the future’, completed in May 2000 by Wasserkraft Volk AG, is the first energy self-sufficient carbon-free heavy equipment factory built in Germany. The administration building is mainly built of timber from the Black Forest area. The entire building including the factory floor is very well insulated. The offices are orientated towards the south, and the factory has large roof lights. This construction enables maximum use of daylight and the incoming sunlight covers some of the heating demand. A 30 m2 solar collector on the administration building actively utilizes solar energy. At the heart of the factory's energy supply is its own hydropower plant with a capacity of 320 kW. The turbines integrated into the building use natural water from the Elz River nearby. The waste heat from the generator covers about 10% of the heat demand. Three heat pumps with a heat output of 130 kW extract heat from the groundwater and cover the remaining heat demand. The hydropower plant generates an annual surplus of around 900 000 kW h of electric energy, which the factory feeds into the public grid. This makes it not only a carbon-free factory, but also a plus-energy one that supplies additional green electricity (Figure 14.8). Figure 14.8 The administration building at the Wasserkraft Volk AG factory of the future in Gutach, Germany, has its own hydropower plant, which generates carbon-free electricity.

Photos: WKV AG, www.wkv-ag.de. The buildings of Juwi AG in Wörrstadt, Rhine-Hesse, prove that even large company headquarters can be completely supplied by renewable energies. The company complex was commissioned in 2008 and subsequently extended several times. The buildings mainly use timber as an environment-friendly building material. Optimum insulation and a sophisticated ventilation system with heat recovery reduce the energy demand of the buildings. A roof-mounted solar thermal system, two wood pellet boilers with a total capacity of 590 kW, a biogas cogeneration plant, and several ground heat wells cover the heating demand in a carbon dioxide-neutral manner. Cooling is supplied by an absorption chiller (Figure 14.9). Figure 14.9 Energy-efficient, purely renewably supplied company headquarters of Juwi AG in Wörrstadt with building-integrated PV system and battery storage.

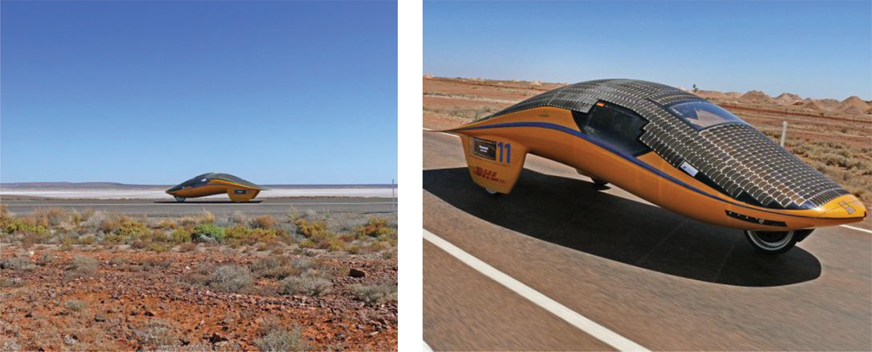

Photos: Mosler for JUWI, www.juwi.de. When purchasing the electrical equipment, attention was always paid to maximum efficiency, so that the electrical energy demand could also be considerably reduced. Several PV systems integrated into the building and carports with solar roofs cover a large proportion of the electricity demand. Together with the biogas CHP plant, the company complex generates more electricity than it consumes. The company's own shuttle service and numerous electric vehicles in the company's fleet reduce transport-related carbon dioxide emissions. The company's own canteen relies on regional organically grown food and thus rounds off the company's sustainability ethos. The colourful, glossy brochures produced by leading car manufacturers are full of impressive assertions about how much they are doing to protect the environment. However, with many manufacturers it is difficult to discern any real innovation in creating carbon-free means of transport. Cars that run on natural gas and hybrid cars make only a marginal difference in reducing carbon dioxide emissions, and electric cars that can be charged with green electricity are only slowly entering the market. The sustainable cultivation potential with biomass fuels is too low to meet total needs and there is simply not enough carbon-free hydrogen being produced to advance the innovation of hydrogen cars. For a long time, the US pioneer Tesla was the only one to launch purely electric cars with a range suitable for everyday use in the luxury segment, but now other manufacturers are also following suit. In the short term, only plug-in hybrids or pure electric cars can offer an alternative for climate protection. Plug-in hybrid vehicles are normally recharged through a power point and for emergencies have a combustion engine that can run on biofuel. Pure electric cars only run on electricity. If the electricity is supplied by renewable power plants, no carbon dioxide is emitted while the vehicle is being driven. The potential of electric cars is demonstrated by some impressive examples. Solar cars have a reputation of being only suitable for short distances. They are usually not trusted to be driven for long distances, and under challenging conditions (Figure 14.10). Figure 14.10 In July 2007 Louis Palmer of Switzerland began his trip around the world in a solar energy-operated vehicle.

Photos: www.solartaxi.com. To highlight the problems of climate change, Louis Palmer of Switzerland set off on the first trip around the world in a solar-power taxi on 3 July 2007. Palmer had been dreaming about a solar taxi since 1986. In 2005 he finally succeeded in implementing the project, thanks to the help of numerous sponsors and technical support from the Swiss Federal Institute of Technology (ETH) in Zurich. His route took him more than 50 000 km through 50 countries on 5 continents over 15 months. On the trip he and his team took advantage of numerous stops and events to introduce solar technology and provide impetus for the use of new climate-friendly technologies. Allowing people to test drive it enthused many people in the countries it toured. The solar taxi is designed as an electric car. It has a 5-m trailer that is covered with 6 m2 of solar cells. A new type of battery stores the electricity, thereby enabling the car to be driven at night and when there is no sun. The daily range is about 100 km. The World Solar Challenge proves that solar cars are already capable of extremely high performance. This event has taken place regularly in Australia since 1987 and is the most demanding solar car race in the world. The race follows a route on public roads for around 3000 km right across Australia: from Darwin in the north, to Adelaide on the south coast. The racing teams try to cover maximum distances between the hours of eight in the morning and five in the afternoon (Figure 14.11). Figure 14.11 In 2007 the solar car from Bochum University reached an average speed of 73 km h−1 during the 3000 km race.

Photos: Bochum University of Applied Sciences, www.hs-bochum.de/ solarcar.html. The vehicles battling for first place in the race are technical masterpieces. The size of the batteries is restricted by the rules and the only energy allowed is what is supplied by solar modules that are mounted directly onto the vehicles. Powerful solar cells with efficiencies of well over 20% provide the necessary drive energy. The cars are optimized for aerodynamics and trimmed to a minimal weight. As a result of constant technical advances and more and more efficient solar cells, the average speeds of the winners have been increasing steadily. In 2005 it was 102.7 km h−1. As Australia imposes speed limits on public roads, it will not be possible from a practical standpoint to increase this speed much further. Therefore, in 2007 the rules were changed to limit the size of the solar generator and stipulate a seated position for the driver. Teams from all over the world have been participating in the competition for many years. In 2007 the Solarworld No. 1 racing car from Bochum University of Applied Sciences reached fourth place. It took the team from Bochum around 41 hours of pure driving time to cover the 3000 km distance. In 2012, after the World Solar Challenge the Bochum team circumnavigated the globe in its optimized solar car, like Louis Palmer before, covering almost 30 000 km. Thanks to optimized solar technology, they no longer needed a solar trailer or a power socket. If you think about it, there is nothing less suitable for inner-city delivery traffic than a vehicle with a diesel engine. It does not like frequent starts and stops, contributes significantly to air pollution in cities and also causes a high level of noise pollution. With daily journeys of around 100 km, end-customer delivery traffic is therefore predestined for the use of electric vehicles. That's what Deutsche Post thought, too. But it could not find a manufacturer that could or wanted to supply suitable vehicles. As a result, and without further ado, Deutsche Post bought StreetScooter GmbH in December 2014. The company had previously developed a prototype for an electrically powered van as a privately organized research initiative at RWTH Aachen University. In 2016, StreetScooter started series production and expanded its annual production capacity to 20 000 vehicles by 2018. The basic version has a service load of 650 kg and achieves a nominal range of 118 km and a maximum speed of 85 km h−1 with a 20 kWh lithium-ion battery. StreetScooter now also cooperates with conventional car manufacturers in the marketing of vehicles and the development of larger vans (Figure 14.12). Figure 14.12 Environment-friendly electric vehicles are predestined for inner-city delivery traffic.

Photos: StreetScooter GmbH, www.streetscooter.eu. The major car manufacturers have now realized that they need to review their lack of commitment to clean mobility, having lost much credibility with their conventional business model. The Munich-based startup Sono Motors is a good example for understanding why conventional car manufacturers have tried to avoid electric mobility for a long time, preferring instead to adhere to the internal combustion engine by hook or by crook, sometimes by unfair means. At the beginning of 2016, three friends with a vision founded the company because they had grown impatient with the slow pace of the departure from oil in the transport sector. Through crowdfunding, they collected the necessary money to build a prototype called Sion, which they presented to the public in 2017. They were able to inspire many test drivers with the vehicle. The car has a nominal range of 320 km and, among many other technical refinements, has a PV system integrated into the body. This allows the car to gain up to 30 km d−1 in additional range directly from the sun, without having to connect to a power outlet. The estimated retail price is €16 000 plus the cost of the battery, which is likely to add another €4000–6000. Whether the company will be successful in the long term remains to be seen. But the mere fact that three newcomers succeeded in designing a fully-functional, production-ready car is impressive. The essential components for such a car are freely available to everyone on the supply market; plus, compared to complex petrol or diesel engine technology, the integration of batteries and electric motors is simple. So, if an electric car can in principle be developed and built by anyone, it poses enormous problems for the major car manufacturers. With the combustion engine they lose their main know-how and their unique selling point (Figure 14.13). Figure 14.13 Electric cars are much easier to build than cars with combustion engines.

Photos: Sono Motors, www.sonomotors.com. Since electric cars require considerably less maintenance, have far fewer wearing parts and don't need oil changes, the lucrative car repair shop business also collapses. No wonder then, that the car companies have, for many years, avoided the electric car like the plague. But they can no longer stop its triumphal advance. Electric cars will soon be cheaper than comparable cars with combustion engines. They are more environment-friendly and can actually be more fun to drive. The smartphone has shown us what rapid upheavals await us in the automotive sector. In a few years' time we will ask ourselves why we drove vehicles that relied on combustion for so long. If we accelerate the expansion of electricity generation from renewables at the same time, it is also an opportunity for the rapid development of climate-neutral road transport. As a result of globalization, goods are being shipped over ever-longer distances. A large part of the increase in transport is being handled by commercial shipping. The carbon dioxide emissions per transport kilometre are significantly lower for shipping compared to air freight. Nevertheless, shipping is also contributing noticeably to the greenhouse effect. Around 3% of all global carbon dioxide emissions are attributed to shipping – and the rate is rising. Until the middle of the nineteenth century, sailing ships dominated freight and passenger traffic at sea. Steamships then came along and had the advantage that they did not have to depend on wind conditions to keep to their timetables. They gradually replaced sailing ships, which today are used almost exclusively for leisure and sporting activities. There are various new concepts that make wind power available in combination with conventional ship propulsion systems. The German inventor Anton Flettner developed a cylindrical rotor to propel ships in the 1920s. However, this propulsion method did not catch on at the time. New ship prototypes are currently in development, including the Flettner rotor combined with a conventional ship diesel drive, aimed at reducing fuel requirements from 30% to 40%. Another interesting concept is based on modern towing kites (Figure 14.14). A starting and landing system automatically lowers and raises the power kite and the cabling rope. The kite flies at a height between 100 and 300 m. The wind at this height is stronger and more consistent than on the deck of a conventional sailing ship. The towing cable, which is made of modern synthetic material, is attached to the foreship, and the towing force is transferred through to the ship. The steering of the kite is completely automated. Through a shortening or lengthening of the steering lines, a power kite can be controlled like a paraglider and orientated with optimal precision depending on wind direction, wind intensity and a ship's course. With a sail surface of up to 5000 m2, the power output could reach up to 5000 kW or 6800 hp. As an annual average, a towing kite should be able to reduce fuel requirements, and consequently carbon dioxide emissions, by 10–35%. Under optimal conditions savings of up to 50% may be possible. Modern wind-based propulsion can therefore make a considerable contribution towards reducing carbon dioxide emissions. Emissions in shipping can even be eliminated completely if biofuel or renewably produced hydrogen is used to cover the residual fuel requirements of conventional ship engines. Solar boats offer climate-compatible travel on water even if there is no wind, especially for short distances. The Helio solar ferry on Lake Constance has been connecting the German town of Gaienhofen to Steckborn in Switzerland since May 2000 (Figure 14.15). Figure 14.14 Advanced, automatically controlled towing kites can reduce the fuel consumption of conventional ships by up to 50% and, when combined with biofuels, even make it CO2-free.

Photos: SkySails, www.skysails.de. The 20 m ferry can carry up to 50 passengers. Two 8 kW electric motors can provide a maximum speed of 12 km h−1. The boat batteries ensure a range of 60–100 km. The roof of the boat consists of an optically very successful PV system that produces an output of 4.2 kW, which provides most of the power needed for charging the batteries. In addition to its climate-compatibility, this solar boat also offers other environmental benefits. It runs very quietly and, unlike conventional diesel engine ships, does not emit unpleasant exhaust fumes. The construction of the ship only causes minimal waves and, as a result, does not contribute towards any further erosion on the lake's shores. Figure 14.15 The Helio solar ferry has been crossing Lake Constance since 2000.

Photos: Bodensee-Solarschifffahrt, www.solarfaehre.de. Hot-air balloons were the first flying machines people used. Fire from firewood or straw produced the hot air needed for the carbon-neutral powering of a balloon. Today hot-air balloons are usually powered by natural gas burners. However, these balloons are highly unsuitable for freight transport or regular services. Without exception, propeller and jet-powered aeroplanes rule commercial aviation. The kerosene used is produced from oil, so the prospect of climate-friendly air travel is still a long way off (Figure 14.16). Figure 14.16 NASA's Helios aeroplane, powered only by solar cells, set a new world record for altitude in 2001.

Photos: NASA, www.dfrc.nasa.gov. But an unmanned light aeroplane called Helios, after the Greek sun god, showed that fossil fuels and flying do not have to be inextricably linked. The plane, developed by NASA and the California company AeroVironment, had its maiden flight in 1999. A total of 62 130 silicon solar cells with an efficiency of 19% were located on the wings, which have a span of 75.3 m and a depth of 2.4 m. These solar cells delivered the power for 14 electric motors with a total output of 21 kW. High-performance lithium batteries enable the plane to fly even after sunset. Due to the low power output, the flight speed at low altitudes was less than 45 km h−1. However, the performance of this aeroplane is not attributed to its speed but to its flying altitude. Flying over Hawaii at an altitude of 29 524 m on 13 August 2001, this plane set a world record for non-rocket-operated planes. The maiden flight of Helios took place in 1999. Sadly, on 29 May 2003 it broke apart during a test flight and plunged into the Pacific Ocean near Hawaii. The Swiss psychiatrist, scientist, and adventurer Bertrand Piccard is hoping to have more luck with his solar aeroplane. He is mainly known for his trip around the world in a hot-air balloon in 1999. With his successor project, Solar Impulse, he wanted to circumnavigate the world in a glider powered solely by solar energy. Unlike the NASA Helios aeroplane, this was a manned flight. The project started in 2003, and a prototype was developed and tested for the first time in 2009. In 2011, construction of a second plane started, which had a pressurized cabin and other technical improvements. With a wingspan of 72 m, it is wider than a Boeing 747. It weighs just 2300 kg and is designed for an average speed of 60–90 km h−1. The wings are equipped with 17 000 solar cells. They supply enough energy to power the aeroplane without the need for any additional energy. During the day high-performance batteries store some of the solar energy so that the plane can also fly at night. Due to the low speed, some of world circumnavigation stages lasted several days, for example to cross the Pacific. During the day, the solar propulsion brought the aircraft to altitudes of up to 12 000 m. Powered by the solar energy stored in the batteries, the aircraft was then able to maintain an altitude of around 3000 m until the morning hours. After numerous test flights, the round-the-world flight started in Abu Dhabi in March 2015. After the 4-day flight from Japan to Hawaii, which was over 8000 km long, the batteries were damaged by overheating. The repair took several months, so that the successful round-the-world flight could only be celebrated in Abu Dhabi in July 2016. With technical advances in batteries and a resulting anticipated reduction in weight, similar planes could be used for longer flights with two pilots. Then even a non-stop round-the-world flight in a solar plane would be possible, and even passenger planes are conceivable in the long term (Figure 14.17). Figure 14.17 Bertrand Piccard of Switzerland aimed to fly the aeroplane Solar Impulse round the world in 2011.

Photos: Solar Impulse/EPFL Claudio Leonardi. Based on current technology, it does not seem likely that solar aeroplanes will ever be able to replace large conventional planes. Even with highly efficient solar cells, the space available on the surface of the wings is not large enough to provide sufficient driving energy for planes carrying loads of several hundred tonnes. With the exception of a very limited possible use of biofuels, there are no options offering complete climate-compatible air travel. In the long term renewal production of hydrogen offers an alternative to fossil fuels. Until then the only carbon-free alternative available is to not travel by air at all. Modern communication technologies and more and more interesting leisure activities in close proximity to where people live are helpful alternative options to travel. But the solarium around the corner is not really a substitute for a winter break in a sunny resort. It makes it even more difficult to stick to one's principles if cheap flights are offered at the same price as a ticket on the local city train. Section 3.5 of this book showed that, as an interim solution, investments in other areas can reduce as much carbon dioxide as is, for example, created by an unavoidable flight. The carbon dioxide emissions of a flight from Berlin to New York and back can be offset for around €100. As part of its programme, the non-profit company Atmosfair offers measures designed to compensate for emissions and at the same time recommends considering videoconferencing and travel by train as alternatives (Figure 14.18). Figure 14.18 Solar-mirror systems financed through contributions from environmental protection funds replace conventional diesel burners in large kitchens in India.

Photos: atmosfair, www.atmosfair.de. For example, Atmosfair had large solar thermal systems installed in temples, hospitals, and schools in different projects at 18 locations in India. One of the projects is a solar kitchen for the Hindu place of pilgrimage, Sringeri Mutt. Diesel burners had been supplying the energy to prepare meals for thousands of pilgrims until modern solar mirrors replaced them as part of the project. The mirrors bundle sunlight onto a pipe and heat the water, which is then fed to the kitchen. A cleverly devised steam system ensures that the kitchens can still function even after sunset. Another aim of the project is to implement a transfer of technology to local enterprises. The systems for all 18 projects were made by an Indian manufacturer and by 2012 should be offsetting a total of around 4000 tonnes of carbon dioxide emissions from air travel. Energy supply throughout Germany is still heavily dependent on fossil fuels. All over Germany? No! A village populated by indomitable Brandenburgers has managed to establish an independent electricity and heat supply system that is completely based on renewable energies. The village of Feldheim (more precisely the district of Feldheim within the town of Treuenbrietzen) with 145 inhabitants and 37 households is located about 60 km south-west of Berlin. Households, companies and the local administration have joined forces and operate their own electricity and heat supply network, which was set up with financial support from the state of Brandenburg and the EU. The heat and electricity generated locally is transmitted directly to the consumers via the local grid. Traditional energy suppliers, and thus dependence on fossil fuels, are sidelined (Figure 14.19). Figure 14.19 Biogas plant, windfarm, and visitor centre of Germany's first energy self-sufficient village at Feldheim in Brandenburg.

Photos: Förderverein des Neue Energien Forum Feldheim e.V., www.nef-feldheim.info. The heat demand is met by a biogas plant that can supply 560 kW of heat and simultaneously feed up to 526 kW of electricity into the public grid. In cases of particularly high heat demand, a woodchip heating system provides additional heat. A large heat store compensates for fluctuations in demand. Feldheim also has a large windfarm consisting of 55 wind turbines with a total a capacity of 122.6 MW. Since the windfarm can supply up to 65 000 households with electricity, it feeds 99% of the electricity it generates into the public grid. The village therefore not only supplies itself, but also makes an important contribution to the energy transition in other places. A 2.25 MW PV system on a former military site has been supplying electricity to 600 households since 2008. In 2015, a storage system based on lithium-ion batteries with a capacity of 10 500 kWh was added. The battery storage provides balancing energy for the public grid and can thus take on tasks previously performed by fossil power plants. By combining the various renewable systems and storage facilities, Feldheim is impressively demonstrating that renewable energies alone can already ensure a climate-neutral supply of heat and electricity today. A hybrid power plant, which opened near Prenzlau in Brandenburg at the end of 2011, proved for the first time in Germany that a reliable energy supply can function with the help of wind power and hydrogen storage (Figure 14.20). Figure 14.20 Hybrid power plant near Prenzlau.

Photos: ENERTRAG/Tom Baerwald, www.enertrag.com. Three 2 MW wind turbines feed electricity into the grid. If surpluses arise that are not needed in the grid, an electrolysis system generates hydrogen, which is stored in pressure tanks. If the wind turbines supply too little electricity, two CHP plants bridge the gap. These use the stored hydrogen or biogas from the connected biogas plant to generate electricity. An integrated hydrogen filling station enables climate-neutral refuelling of hydrogen cars. The hybrid power plant at Prenzlau shows that a combination of fluctuating regenerative energies such as solar or wind power, in combination with storage and controllable regenerative energies such as biogas, can provide a reliable power supply. Further hybrid power plants are already planned in Germany. What is demonstrated here on a small scale can quite easily be transferred to our entire energy supply system. A sustainable and secure energy supply based on renewable energies by 2040 is therefore anything but a utopia. The variety of possibilities for using renewable energies described in this book, not least the examples in this chapter, have shown that it is actually unnecessary to endanger our future existence through an unrestrained use of crude oil, natural gas, coal, and nuclear energy. The effects of fossil energy on the world's climate are already noticeable. The consequences of climate change will soon be beyond our control if we do not take the bull by the horns and radically restructure our energy supply. Figure 14.21 The future belongs to renewable energies. By 2040 they could secure our entire energy supply in a climate-neutral manner and thus secure the livelihoods of future generations. Renewable energies are already able to cover our energy demand in an affordable and climate-compatible manner. There is no basis for the widespread fear that the lights will go out if we cannot use oil, natural gas, coal, and nuclear energy. On the contrary, increasing the use of renewable energies will make us increasingly more independent of the conventional energy sources that are steadily becoming scarcer and more expensive. The use of renewable energies will also help to end some of the conflicts that are taking place at the moment. The question that remains is why are we still using renewable energies on such a small scale? There are many reasons for this. First of all, the wider public is not being made sufficiently aware of the possibilities offered by renewable energies. It is hoped that an increase in information sources such as this book will gradually close this gap in knowledge. On the other hand, everyone is hoping that the problem will somehow solve itself; many people do not really feel responsible or they have already lost hope. However, it is up to each and every one of us to make a contribution and to demand our politicians implement the necessary measures. If, right now, we all begin taking any opportunities to save energy and use renewable sources more seriously, we can still stop global warming and establish a truly sustainable energy supply system (Figure 14.21).14.1 Climate-Compatible Living

14.1.1 Carbon-Neutral Standard Prefabricated Houses

14.1.2 Plus-Energy Solar House

14.1.3 Plus-Energy Housing Estate

14.1.4 Heating Only with the Sun

14.1.5 Zero Heating Costs After Redevelopment

14.2 Working and Producing in a Climate-friendly Manner

14.2.1 Offices and Shops in the ‘Sonnenschiff’

14.2.2 Zero-Emissions Factory

14.2.3 Carbon-free Heavy Equipment Factory

14.2.4 Plus-Energy Head Office

14.3 Climate-Compatible Driving

14.3.1 Travelling Around the World in a Solar Car

14.3.2 Across Australia in 33 hours

14.3.3 Emission-free Deliveries

14.3.4 Electric Cars for All

14.4 Climate-Compatible Travel by Water or Air

14.4.1 Advanced Sailing

14.4.2 Solar Ferry on Lake Constance

14.4.3 World Altitude Record with a Solar Aeroplane

14.4.4 Flying Around the World in a Solar Plane

14.4.5 Flying for Solar Kitchens

14.5 Everything Becomes Renewable

14.5.1 A Village Becomes Independent

14.5.2 Hybrid Power Plant for Secure Renewable Supply

14.6 Everything will Turn Out Fine