Synchronous, permanent magnet and reluctance motors and drives

Abstract

This increasingly important group of motors (that includes the so-called ‘brushless d.c.’) have the potential to eclipse the induction motor in terms of efficiency because, like the d.c. machine, the ‘excitation’ or flux-producing mechanism is separate from the work producing part. We cover fixed-frequency and inverter-fed operation of excited rotor, permanent magnet, reluctance, and salient PM. For each type we also discuss the field orientation techniques that not only provide high dynamic performance but also ensure self-synchronisation, thereby eliminating the danger of stalling.

Keywords

Synchronous motors; Permanent magnet (PM); Salient; Field oriented control; Field weakening; Reluctance motor; Reluctance torque; Performance

9.1 Introduction

Chapters 6–8 have described the virtues of the induction motor and how, when combined with power electronic control, it is capable of meeting the performance and efficiency requirements of many of the most demanding applications. In this chapter another group of a.c. motors is described. In all of them the electrical power that is converted to mechanical power is fed into the stator, so, as with the cage induction motor, there are no sliding contacts in the main power circuits. The majority have stators that are identical (or very similar) to the induction motor, but some new constructional and winding techniques involving segmented construction are being applied at the lower power end: these will be introduced later.

It has to be admitted that the industrial and academic communities have served to make life confusing in this area by giving an array of different names to essentially the same machine, so we begin by looking at the terminology. The names we will encounter include:

- (a) Conventional Synchronous Machine with its rotor field winding (excited-rotor). This is the only machine that may have brushes, but even then they will only carry the rotor excitation current, not the main a.c. power input.

- (b) Permanent Magnet Synchronous Machine with permanent magnets replacing the rotor field winding.

- (c) Brushless Permanent Magnet Synchronous Motor (same as (b)). The prefix ‘brushless’ is superfluous.

- (d) Brushless a.c. Motor (same as (b).

- (e) Brushless d.c. Motor (same as (b) except for detailed differences in the field patterns). This name was coined in the 1970s to describe ‘inside out’ motors that were intended as direct replacements for conventional d.c. motors, and in this sense it has some justification.

- (f) Permanent Magnet Servo Motor (same as (b)).

The Reluctance motor is fundamentally different from all the above types. Whilst it rotates at synchronous speed, it does not have any form of excitation on the rotor and the method of torque production is somewhat different. It is nonetheless an increasingly important type of electrical machine.

Traditionally, as their name implies, synchronous motors were designed for operation directly off the utility supply, usually at either 50 Hz or 60 Hz. They then operate at a specific and constant speed (determined by the pole-number of the winding) over a wide range of loads, and therefore can be used in preference to induction motors when precise (within the tolerance of the utility frequency) constant speed operation is essential: there is no load-dependent slip as is unavoidable with the induction motor. These machines are available over a very wide range from tiny single-phase versions in domestic clocks and timers to multi-megawatt machines in large industrial applications such as gas compressors. (The clock application means that utility companies have a responsibility to ensure that the average frequency over a 24 h period always has to be precisely the rated frequency of the supply in order to keep us all on time. Ironically, in order to do this, they control the speed of very large, turbine-driven, synchronous machines that generate the vast majority of the electrical power throughout the world.)

To overcome the fixed-speed limitation that results from the constant frequency of the utility supply, inverter-fed synchronous motor drives are widely used. We will see that all forms of this generic technology use a variable-frequency inverter to provide for variation of the synchronous speed, but that in almost all cases, the switching pattern of the inverter (and hence the frequency) is determined by the rotor position and not by an external oscillator. In such so called ‘self-synchronous’ drives, the rotor is incapable of losing synchronism and stalling (which is one of the main drawbacks of the utility-fed machine). Field oriented control can be applied to synchronous machines to achieve the highest levels of performance and efficiency with machines which have higher inherent power densities than the equivalent induction motors.

9.2 Synchronous motor types

In the synchronous motor, the stator windings are essentially the same as in the induction motor, so when connected to the 3-phase supply, a rotating magnetic field is produced. However, instead of having a cylindrical rotor with a cage winding which automatically adapts to the pole number of the stator field, the synchronous motor has a rotor with either a d.c. excited winding (supplied via sliprings, or on larger machines an auxiliary exciter1), or permanent magnets, designed with the same pole number as the stator. The rotor is thus able to ‘lock-on’ or ‘synchronise with’ the rotating magnetic field produced by the stator. Once the rotor is synchronised, it will run at exactly the same speed as the rotating field despite load variation, so under constant-frequency operation the speed will remain constant as long as the supply frequency is stable.

As previously shown, the synchronous speed (in rev/min) is given by the expression

where f is the supply frequency and p is the pole-number of the winding. Hence for 2, 4 and 6-pole industrial motors the running speeds on a 50 Hz supply are 3000, 1500, and 1000 rev/min, while on a 60 Hz supply they become 3600, 1800, and 1200 rev/min respectively. At the other extreme, the little motor in a time switch with its cup-shaped rotor with 20 axially projecting fingers and a circular coil in the middle is a 20-pole reluctance (synchronous) motor that will run at 300 rev/min when fed from a 50 Hz supply. Users who want speeds different from these discrete values will be disappointed, unless they are prepared to invest in a variable-frequency inverter.

With the synchronous machine, we find that there is a limit to the maximum (pull-out) torque (see Section 9.3) which can be developed before the rotor is forced out of synchronism with the rotating field. This ‘pull-out’ torque will typically be 1.5 times the continuous rated torque but can be designed to be as high as 4 or even 6 times higher in the case of high performance PM motors where, for example, high accelerating torques are needed for relatively short periods. For all torques below pull-out the steady running speed will be absolutely constant. The torque-speed curve is therefore simply a vertical line at the synchronous speed, as shown in Fig. 9.1. We can see that the vertical line extends into quadrant 2, which indicates that if we try to force the speed above the synchronous speed the machine will act as a generator.

Traditionally, utility-fed synchronous motors were used where a constant speed is required, high efficiency desirable, and power factor controllable. They were also used in some applications where a number of motors were required to run at precisely the same speed. However, a group of utility-fed synchronous motors could not always replace mechanical shafting2 because whilst their rotational speed would always be matched, the precise relative rotor angle of each motor would vary depending on the load on the individual motor shafts.

9.2.1 Excited-rotor motors

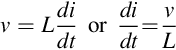

The rotor of a conventional synchronous machine carries a ‘field’ or ‘excitation’ winding which is supplied with direct current either via a pair of sliprings on the shaft, or via an auxiliary brushless exciter on the same shaft. The field winding is designed to produce an air-gap field of the same pole-number and spatial distribution (usually sinusoidal) as that produced by the stator winding. The rotor may be more-or-less cylindrical, with the field winding distributed in slots (Fig. 9.2A), or it may have projecting (‘salient’) poles around which the winding is concentrated (Fig. 9.2B).

A cylindrical-rotor motor has little or no reluctance (self-aligning) torque (discussed later), so it can only produce torque when current is fed into the rotor. On the other hand, the salient-pole type also produces some reluctance torque even when the rotor winding has no current. In both cases, however, the rotor ‘excitation’ power is relatively small, since all the mechanical output power is supplied from the stator side.

Excited rotor motors are used in sizes ranging from a few kW up to many MW. The large ones are effectively alternators (as used for power generation) but used as motors. Wound rotor induction motors (see Chapter 6) can also be made to operate synchronously by supplying the rotor with d.c. through the sliprings.

As we will see later, an advantage of the excited rotor type is that the power factor can be controlled over a wide range by varying the rotor excitation current.

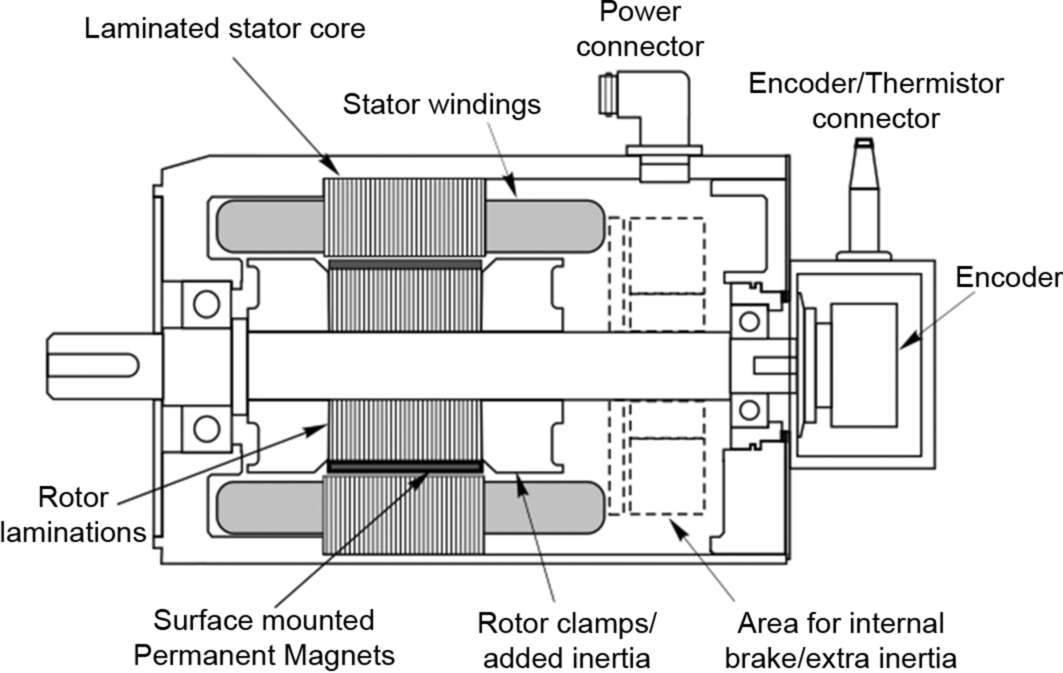

9.2.2 Permanent magnet motors

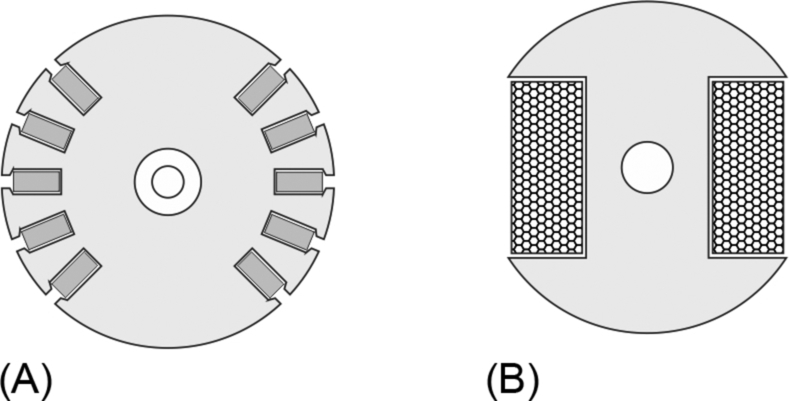

The synchronous machines considered so far require two electrical supplies, the first to feed the field/excitation and the second to supply the stator. Brushless permanent magnet (Brushless PM) machines have magnets attached to the rotor to provide the field, and so only a stator supply is required. The principle is illustrated for 4-pole surface-mounted and 10-pole buried/interior types in Fig. 9.3. Motors of this sort have typical output ranging from about 100 W up to perhaps 500 kW, though substantially higher ratings have been made.

The advantages of the permanent magnet type are that no supply is needed for the rotor and the rotor construction can be robust and reliable. The disadvantage is that the excitation is inherently fixed, so the designer must either choose the shape and disposition of the magnets to match the requirements of one specific load, or seek a general-purpose compromise. Control of power-factor via excitation is of course no longer possible. Within these constraints the Brushless PM synchronous motor behaves in very much the same way as its excited-rotor sister.

9.2.3 Reluctance motors

The reluctance motor is arguably the simplest synchronous motor of all, the rotor consisting simply of a set of laminations shaped so that it tends to align itself with the field produced by the stator. This ‘reluctance torque’ action is discussed in Section 9.3.3.

Until recently reluctance motors were intended for use from the utility supply, so in order to get the rotor up to a speed close enough to the synchronous speed for the rotor to make the final leap and lock onto the rotating stator field, the rotor also carries a cage winding which provides accelerating torque for the run-up, but thereafter carries no current. The rotor therefore resembles a cage induction motor, with parts of the periphery cut away in order to force the flux from the stator to enter the rotor in the remaining regions where the air-gap is small, as shown in Fig. 9.4A. Alternatively, the ‘preferred flux paths’ can be imposed by removing iron inside the rotor so that the flux is guided along the desired path, as shown in Fig. 9.4B and C, the latter being for an inverter-fed motor, where a starting cage is not required. All these rotor types can be seen to have “salient” poles.

The rotor will tend to align itself with the field, and hence is able to remain synchronised with the travelling field set up by the 3-phase winding on the stator in much the same way as a permanent-magnet rotor. Early reluctance motors were invariably one or two frame sizes bigger than an induction motor for a given power and speed, and had low power-factor and poor pull-in performance. As a result they fell from favour except for some special applications such as textile machinery where large numbers of cheap synchronised motors driven from a single variable frequency inverter were used. Understanding of reluctance motors is now much more advanced, though their fundamental performance still lags the induction motor as regards power-output, power factor and efficiency. Recently, there is renewed interest in rotors that exploit both permanent magnet and reluctance torque, and this is discussed in Section 9.3.5.

9.2.4 Hysteresis motors

Whereas most motors can be readily identified by inspection when they are dismantled, the hysteresis motor is likely to baffle anyone who has not come across it before. The rotor consists simply of a thin-walled cylinder of what looks like steel, while the stator has a conventional single-phase or three-phase winding. Evidence of very weak magnetism may just be detectable on the rotor, but there is no hint of any hidden magnets as such, and certainly no sign of a cage. Yet the motor runs up to speed very sweetly and settles at exactly synchronous speed with no sign of a sudden transition from induction to synchronous operation.

These motors (the operation of which is quite complex) rely mainly on the special properties of the rotor sleeve, which is made from a hard steel which exhibits pronounced magnetic hysteresis. Normally in machines we aim to minimise hysteresis in the magnetic materials, but in these motors the effect (which arises from the fact that the magnetic flux density B depends on the previous ‘history’ of the m.m.f.) is deliberately accentuated to produce torque. There is actually also some induction motor action during the run-up phase, and the net result is that the torque remains roughly constant at all speeds.

Small hysteresis motors were once used extensively in office equipment, fans, etc. The near constant torque during run-up and the very modest starting current (of perhaps 1.5 times rated current) means that they are also suited to high inertia loads such as gyro compasses and small centrifuges.

Hysteresis motors are used in niche areas, and so we will not consider them any further.

9.3 Torque production

The aim of this section is to present physical pictures of the torque production mechanism in the various types of synchronous motor. We deliberately concentrate on the same ‘BIl’ approach that we have followed in relation to the d.c. and the induction motor, in order to highlight the fundamental similarities between the three types of motor.

We start with the excited-rotor motor in order to establish a general approach to the interaction between stator and rotor currents and fields, and to develop qualitative expressions for torque. A relatively simple adaptation is then made to deal with the permanent-magnet type, and with a further twist, we can throw light on the torque in a reluctance motor (which has neither winding nor magnets on the rotor). Finally we look briefly at salient pole synchronous motors, which develop both excitation torque and reluctance torque.

The spatial images developed in this section will help later in the chapter when we link them to the voltages and currents in the steady-state time phasor diagram. Readers who are familiar with the theory of electrical machines will be aware that books often omit the material in this section in favour of the coupled-circuit approach that we discussed briefly in Section 8.3; however, we believe that the physical approach will be preferred by our target readership.

9.3.1 Excited rotor motor

In explaining the mechanism of torque production in the induction motor (Chapter 5) we chose to focus on the ‘BIl’ force (and hence the torque) resulting from the interaction between the rotor current wave and the resultant radial flux density wave (i.e. the resultant flux due to the combined effect of the stator and rotor m.m.f.'s), both of which are sinusoidally distributed in space.

For the synchronous machine we could use the same approach for the excited rotor type, but the PM rotor and reluctance versions don't have current on the rotor when running synchronously, so we consider the torque on the stator instead. We assume here that the reader is happy to accept that electromagnetic torque on the rotor will always be accompanied by an equal and opposite torque on the stator.

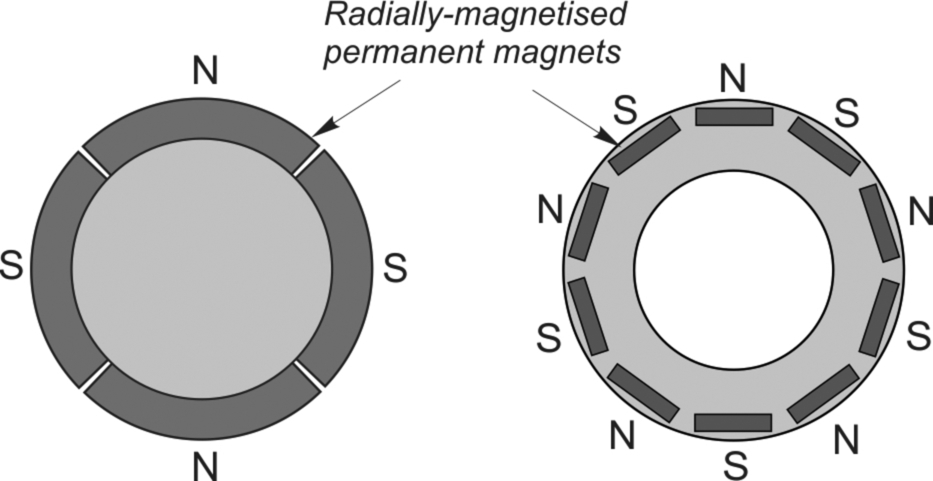

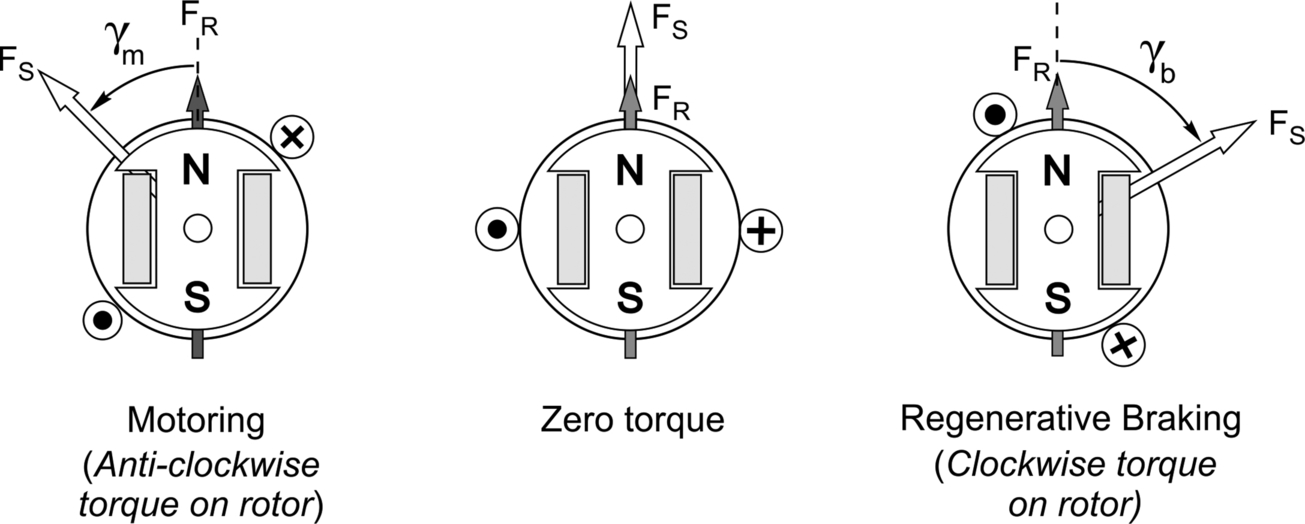

We will explore the torque mechanism by looking first at the static condition (which is equivalent to taking a snapshot of the running condition), as shown in Fig. 9.5. This represents a model of a smooth rotor machine with sinusoidally distributed currents on both stator and rotor: the stator current is fixed in all five sketches, and the rotor current is fixed relative to the rotor. The blue flux lines represent in simplified form the sinusoidal m.m.f. and flux density produced by the rotor current, and so when the rotor turns, they follow; only a few lines are shown for the sake of clarity. The drum on the rotor carries a rope to which weights can be attached to apply mechanical torque to the rotor.

The ‘rule of thumb' relating to the torque produced by the interaction of rotor and stator fields is that the torque always acts so as to move the two fields into alignment. The flux pattern produced by the stator winding is not shown in Fig. 9.5 in order to avoid overcrowding, but it would be similar to the rotor flux, and in all three sketches it would be directed upwards.

Hence if the rotor is free to move, and there is no external torque applied, it will come to rest as shown in the centre sketch, with zero torque. We can confirm that the resultant torque is zero in this position by considering the ‘BIl’ forces on the stator conductors caused by interaction with the rotor flux. Because of the symmetry there is no resultant force on the group of stator conductors carrying positive current, because any in the upper half exposed to positive (outward) flux will experience a clockwise force, while those in the lower half will be exposed to negative (inward) flux, and therefore will experience an equal anticlockwise force. By the same token, there is no resultant force on the conductors carrying negative current, and there is therefore no torque on the stator, and hence none on the rotor.

However, when the rotor is turned in a clockwise direction by a load, as in the two right-hand sketches, more stator conductors carrying positive current are exposed to positive rotor flux, and those carrying negative current are exposed to negative flux. Application of Fleming's left hand rule shows that there is a clockwise torque on the stator, and therefore an equal anti-clockwise torque on the rotor, the torque increasing with angle. When the rotor torque equals the load torque, the rotor is at rest, in a stable equilibrium: If it is displaced in either direction, and then released, it will settle back at the same angle.

The unloaded case shown in the centre sketch is also a stable equilibrium, with any clockwise displacement leading to an anti-clockwise restoring torque, and vice-versa. Beyond 90°, however, the rotor is unstable, and so although there is theoretically another zero torque at 180°, the unloaded rotor could not remain at rest there because the slightest nudge would cause it to flip round in the direction it had been disturbed, and come to rest as in the centre sketch.

The right hand sketch shows the position of maximum torque, the rotor flux being horizontal and aligned with the stator current distribution. Recalling that the flux produced by the stator current is vertical, we see that the condition for maximum torque is that the two fields are perpendicular.

The theoretical torque-angle curve is shown below the three sketches in Fig. 9.5, and is a sinusoidal function of rotor angle. The beginnings of the unstable regions are indicated by dotted lines. The peak torque is, as expected, proportional to the product of the stator current and the rotor current (or flux). For obvious reasons, the angle between the rotor and stator fields is known as the torque angle.

We have considered the stator current to be constant in order to explore the mechanism of torque production, and the mental picture of the two fields always tending to align themselves is a useful one, which we can easily extend to the running condition. We now imagine that the rotor is running in the steady-state at the synchronous speed, with the amplitude and frequency of the stator current kept constant, the rotor being ‘locked onto’ or dragged along by the rotating stator field. The variation of the ‘torque angle’ with load on the shaft is then the same as we have seen in the static case, the angle increasing as the load torque increases. Clearly, if the load torque exceeds the point at which the torque angle is 90°, the rotor will lose synchronism and stall. However it is important to stress that in practice ‘constant stator current’ is not a normal operating condition. When the motor is operated from the utility supply, for example, it is the stator voltage (and frequency) that are constant, while in an inverter-fed drive with field-oriented control (see later), the system will always control the magnitude, speed and instantaneous position of the stator current distribution relative to the rotor position in order to provide the torque required.

Torque—Excited rotor motor

Hitherto, when we have invoked the ‘BIl’ picture to explain the production of torque we have always taken the B to be the resultant flux density, resulting from the combined effect of both stator and rotor currents, but in the discussion above we only considered the torque produced on the stator by the rotor flux. We will now see that if the windings are sinusoidally distributed, and the rotor surface is smooth (i.e. it may have slots, but no major saliencies), there are several ways of expressing the torque, not all involving the resultant flux, and we can choose which suits best according to the circumstances.

We saw in Section 8.2.1 that sinusoidally space-distributed quantities can be represent by space phasors or vectors, so we can represent an m.m.f. (or its corresponding flux density distribution) by a vector whose length is proportional to the m.m.f. (and hence to the current), and whose direction is determined by the instantaneous angular position of the current wave.

The general case is shown in Fig. 9.6, where FS, FR, and F are the stator, rotor and resultant m.m.f.'s respectively. The angle between stator and rotor m.m.f's (the torque angle), is λ, and the angle between the rotor m.m.f. and the resultant m.m.f. (δ) is the load angle (see later). The rotor m.m.f. in this space phasor diagram has been chosen deliberately to be horizontal in order to be consistent with the time phasor diagrams of pm motors that we will discuss later in this chapter.

We have already established that the torque is proportional to the product of the stator and rotor m.m.f.'s, and to the sine of λ, i.e.

The expression FSFR sin λ is the area of the triangle defined by the sides FS and FR, so we see that the area provides an immediate visual indication of the torque. We can also see that when the stator and rotor m.m.f.'s are aligned, the torque is zero, and when they are perpendicular, we get maximum torque.

Readers who are familiar with vector calculus will recognise the expression for the area of a triangle as the amplitude term of the so-called ‘cross product’ of two vectors (i.e. if the vectors are of magnitudes A and B and the angle between them is γ, their cross product is AB sin γ).

The triangles defined by the sides F and FR, and F and FS, both have the same area as the triangle defined by FS and FR, so the torque can equally well be expressed in two further ways, leading to the three equivalent cross-product formulations shown below:

We have used the first of these in slightly modified form in previous chapters, where instead of resultant m.m.f. we talked of resultant flux density, and instead of rotor m.m.f. we used rotor current distribution, but as both are proportional to their respective m.m.f.'s, and we are not being quantitative, there is no inconsistency. In fact, we will often substitute ‘flux density’ or (for a given machine) ‘flux’ in place of m.m.f. later in this chapter when we are discussing what determines the torque.

In the excited rotor case it turns out that the first version is the simplest way of picturing the torque mechanism when the currents are specified (as in an inverter-fed drive), and in particular it defines what we mean by the torque angle, λ. We should also note what many readers may think is obvious, which is that if the rotor m.m.f. is zero, and the only source of excitation is on the stator, the stator flux will not produce any torque. However, this is only true for smooth rotor machines, and things are different for rotors with salient poles, as we will see later.

When we move on to consider steady-state operation from the utility supply, the second torque formulation will prove more fruitful for our discussions, and we will make use of the load-angle (δ) rather than the torque angle.

It is worth mentioning that an alternative way of looking at a cross product is that it can be obtained by taking the product of the first vector with the component of the second that is perpendicular to the first, and we will make use of this later in this chapter, where we refer to the axis of the rotor flux as the ‘direct axis’ and to the perpendicular component as the ‘quadrature axis’ component.

Physically, we picture maximum torque when stator and rotor m.m.f.'s or fluxes are in quadrature, and zero torque when they are aligned. At other angles, we recognise that it is only the quadrature component of the second vector that contributes to torque.

9.3.2 Permanent magnet motor

The permanent magnet (PM) motor (Fig. 9.3) behaves in a similar way as the excited rotor one, with the obvious exception that the ‘strength’ of the flux produced by the magnet cannot be varied once it has been magnetised.

To avoid going deeply into the properties of permanent-magnets, we can picture the magnet as an m.m.f. source, whose external magnetic circuit comprises three reluctances in series, viz. the ‘iron’ part of the rotor body; the stator iron; and the air-gap between rotor and stator iron. The latter term is dominant in any machine, but it is even more so here because the “airgap” is at least equal to the radial thickness of the magnets, and so is much larger than in the excited rotor version. Despite this, the high magnet m.m.f. produces the required flux density at the stator. There is no variation in the reluctance ‘seen’ by the magnet as the rotor turns, so we can picture a rotor flux wave that remains constant and whose instantaneous position is determined by the rotor angle: in future, we will denote this by the symbol φmag.

Looked at from the stator side we might wonder how the magnet material influences the reluctance seen by the stator m.m.f. Again, we can take a simplified view and, as far as an externally applied field is concerned, we treat the magnet material as if it had the same permeability as air. The stator m.m.f. therefore sees a high reluctance because the effective air-gap is much larger than usual due to the radial depth of the magnets. This means the stator self-inductance is much lower than that of a similar excited rotor motor, which is advantageous as far as rapid current control is concerned.

Torque—Permanent magnet motor

In line with our discussion above, if we denote the stator (or, to use the traditional word ‘armature’) flux wave by φarm and the angle between the magnet and stator flux waves (the torque angle) by λ, the torque is expressed by

i.e. the torque depends on product of the rotor and stator fluxes and the sine of the angle between them. Note that we could equally have chosen to use the respective m.m.f.'s in the torque expression rather than the fluxes, in which case the torque expression would be identical to that for the excited rotor case.

9.3.3 Reluctance motor

The reader who absorbed Chapter 1 will recall that the word reluctance is used in the context of magnetic circuits to define the analogous quantity to resistance in an electric circuit, i.e. the ratio of m.m.f. to flux. Given that all motors have magnetic circuits, and involve reluctance, it may seem odd that the same word also describes a particular type of motor, but the justification for doing so should soon become clearer.

Up to now in this chapter we have seen how to picture torque from the ‘BIl’ interaction between the rotor component of the resultant flux density and the stator current. However, the rotor of a reluctance motor has no current-carrying conductors (apart from, perhaps, a starting cage, which only functions below synchronous speed), so clearly the only source of excitation is the stator winding. Nevertheless, torque is produced, so it would not be unreasonable to suppose that an entirely different mechanism is responsible, and that our trusted friend ‘BIl’ will not provide an explanation. (This impression would be reinforced if we looked at the literature on reluctance motors, which concentrates on the circuit modelling approach.) However, as we will see, the ‘BIl’ approach not only illuminates the physical basis for understanding reluctance torque, but it also allows us to obtain a simple expression for torque in terms of stator current.

We begin with a hypothetical set up of no practical use but which will help our later discussion.

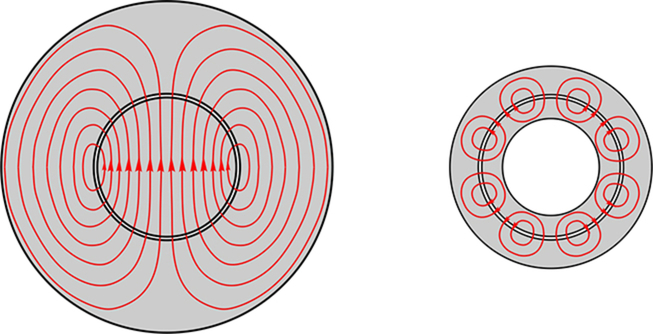

Fig. 9.7 shows an idealised machine with a smooth air-gap and infinitely permeable stator and rotor cores, and an ideal sinusoidal distribution of stator current. As we have seen previously, this idealised model leads to a close approximation of the resultant field produced by a real machine with three-phase sinusoidally distributed windings fed from a three-phase sinusoidal supply.

The rotor is non-salient, i.e. a uniform homogeneous cylinder, and has no current carrying conductors.

The flux produced by the stator current is shown by the hand-sketched red lines. In this instance, sketching is aided by the fact that for this idealised situation, an analytical solution is available that shows that the flux density inside the rotor is uniform, say B. The sketch is too small to show the air-gap flux density in any detail, but we can find the radial flux density at any angle θ measured from the vertical axis by resolving B, which yields the radial air-gap flux density as

This is what is expected: the gap is uniform, so the radial flux density wave is proportional to, and in phase with the stator m.m.f., which in turn is in quadrature with the stator current distribution. Maximum air-gap flux density is at the top, and maximum current is on the horizontal axis, and there is therefore no resultant torque.

If the previous paragraph fails to convince, we can look directly at the forces on the stator conductors, using ‘BIl’. First, consider the topmost conductor on the left: it carries a current out of the paper, and is exposed to a radially outward air-gap flux density, so it experiences a force to the left, and the rotor therefore experiences an equal and opposite force to the right. The corresponding conductor on the right carries current into of the paper, and is exposed to the same outward flux density, so its force is to the right, and the reaction on the rotor is to the left. Because of the symmetry, there is no resultant torque on the rotor, regardless of its angular position. (If we had taken the circuit viewpoint, where torque is linked to the change of inductance with position, we would have deduced that the torque was zero because the magnetic circuit ‘seen’ by the stator winding does not vary as the rotor turns, so the inductance is constant.)

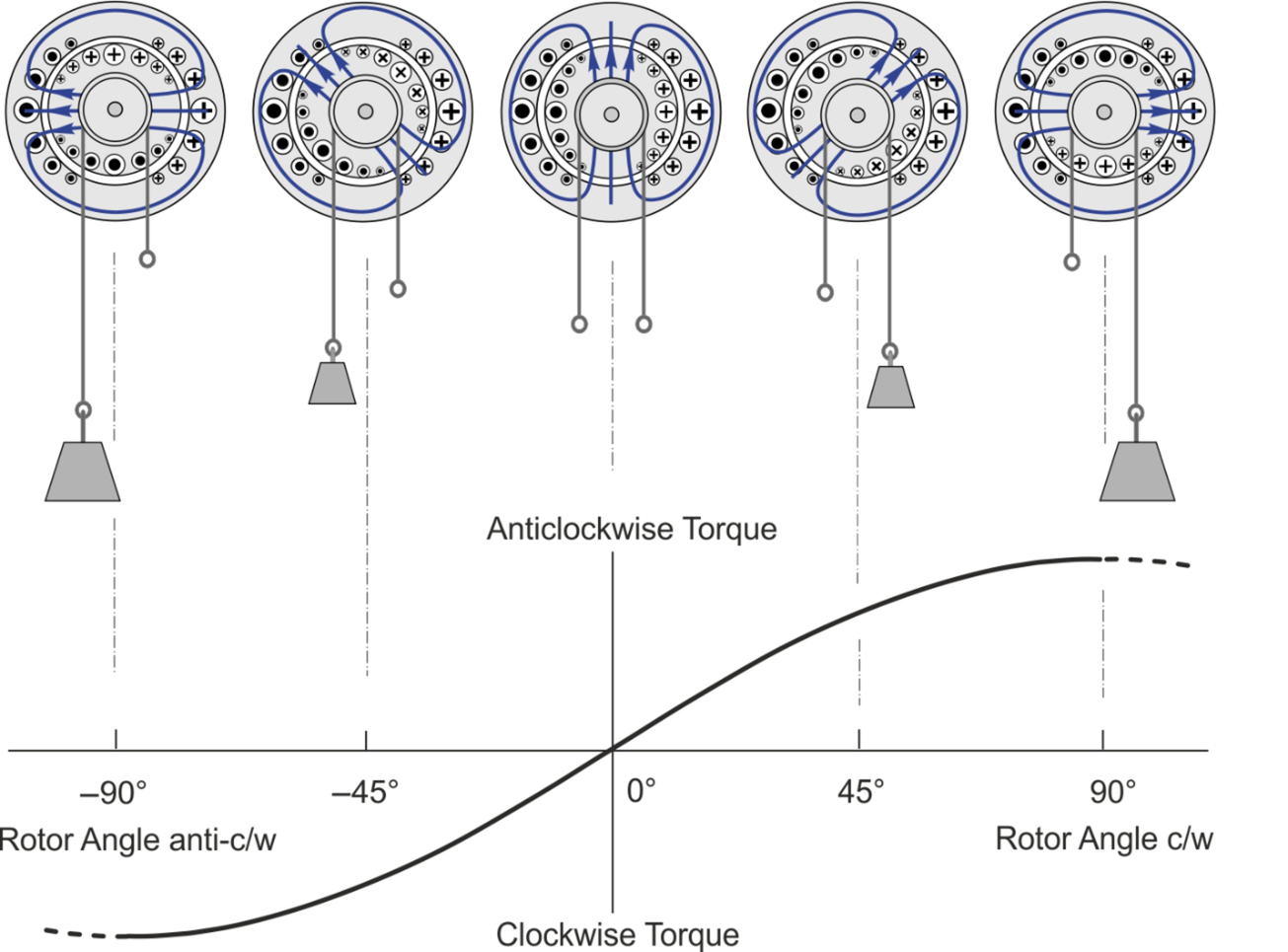

Now we turn to the ‘salient’ rotor shown in the four sketches in Fig. 9.8. Two segments of the original cylindrical rotor have been removed to leave two projecting poles or ‘saliencies’, thereby forming the rotor of a 2-pole reluctance motor. (We have deliberately chosen a simple shape for illustrating the principle: a real rotor would probably look more like a 2-pole version of those shown in Fig. 9.4. The grey dot on the rotor is there to allow us to correlate sketches (a) to (d) with the torque plot below.

When the rotor is aligned as in (a) the sinusoidal stator m.m.f. acts on a relatively low-reluctance path, so the flux is relatively large, (but not as high as it was when the rotor was cylindrical because the overall reluctance is now higher). When the flux takes the low-reluctance path as in (a) it is said to be flowing along the ‘direct axis’. Recalling that inductance is the ratio of flux linking the stator winding to the current producing it, the inductance in case (a) is known as the direct-axis inductance, Ld: we will return to this later.

At the other extreme, when the rotor is aligned as in (c), the same m.m.f. now acts on a relatively high reluctance path (the ‘quadrature axis’) and the flux is low: the inductance in this situation is the quadrature-axis inductance (Lq), which is of course much less than Ld.

The terms direct axis and quadrature axis define mutually perpendicular axes fixed to the rotor, and will be used extensively later in this chapter, especially when we talk about the control of these machines with a variable frequency inverter.

It should be clear that because of the non-uniform air gap, the flux density wave will no longer be sinusoidal, which might suggest that our previous simple approach to torque (via the product of two displaced sine waves) would no longer apply. In fact, as we will see next, as long as we focus on the fundamental component of the flux density wave, we can obtain torque as before.

An important property of any winding that we have not mentioned previously is the reciprocal relationship between the m.m.f. and flux density produced by a winding, and the reaction of that winding to its own internal or another external field. By ‘reaction to’ we mean both the e.m.f. induced in the winding by either the self-produced field or the external field, and/or the torque produced on it when it is carrying current. For example, if the winding m.m.f. consisted of only a fundamental and fifth space harmonic, the winding would only react to external fields of fundamental and fifth space harmonic. (To emphasis the point, if we were to put a 4-pole permanent magnet rotor into a 2-pole stator carrying current, there would be ‘BIl’ forces on the individual conductors of the stator, some positive and some negative, but the resultant force would be zero.)

In the present context, we have a sinusoidally distributed winding but a non-sinusoidal flux density wave, so as long as we restrict consideration to the fundamental component of the flux density wave, we can continue to explore the mechanism of torque production as we have done so far.

When we apply ‘BIl’ to find the forces on the stator windings, we find that in both (a) and (c), the symmetry results in zero net torque on the stator windings, and thus zero torque on the rotor, as shown in the graph in Fig. 9.8.

When we displace the rotor as shown in (b), the stator conductors that overlap the top of the rotor all carry current into the paper, and thus experience forces to the right, while those at the bottom carry current out of the paper and experience a force to the left: the reaction forces on the rotor therefore give rise to anticlockwise torque which tends to return the rotor to position (a). Not surprisingly, if we displace the rotor anticlockwise instead (see (d)), the rotor torque becomes clockwise, again tending to restore the rotor to position (a). Position (a) is therefore one of stable equilibrium, i.e. any displacement in either direction brings a restoring torque into play, and the greater the displacement, the greater the restoring torque.

In practice we find that there is a maximum torque, and it occurs at 45°, as shown. Beyond that point the torque diminishes to zero at 90°, before reversing and reaching a peak again at 135°. At 90°, the torque is zero, but any displacement of the rotor not only results in a torque that tries to increase the angle further, but also the torque increases with the displacement. The 90° position is therefore an unstable equilibrium (marked by a star): if we put the rotor there, any tiny disturbance will cause it to flip away, and settle (after oscillating) at a stable equilibrium point such as (a), marked with a dot.

We have considered the stator current wave to be stationary in order to simplify the discussion, but in practice the field will be rotating synchronously at a speed determined by the frequency of the stator currents. Under such steady-state conditions the rotor torque must match the load torque, so under ideal no-load conditions the rotor direct axis will be aligned with the applied field (as in Fig. 9.8a) and no torque will be produced. When the load torque is increased, causing a momentary deceleration, the rotor axis drops back relative to the field, thereby producing a motor torque that increases with angle until it equals the load torque, whereupon the speed is again synchronous. It is also worth noting that, once synchronised, a reluctance machine will operate as a generator, in which case the load angle becomes negative.

Torque—Reluctance motor

For the non-salient rotors looked at in the previous two sections we were able to obtain very simple expressions for the torque because the amplitudes of the stator and rotor fields remained constant as the rotor angle varied. Here, things are more complex, because the amplitude of the stator field varies with rotor position (the variation being governed by the change in reluctance with angle), and as a result it is a bit more tricky to obtain an expression for torque in terms of the stator current. The exercise is useful however, because it introduces some ideas that are taken up again later when we discuss torque in salient-pole excited motors.

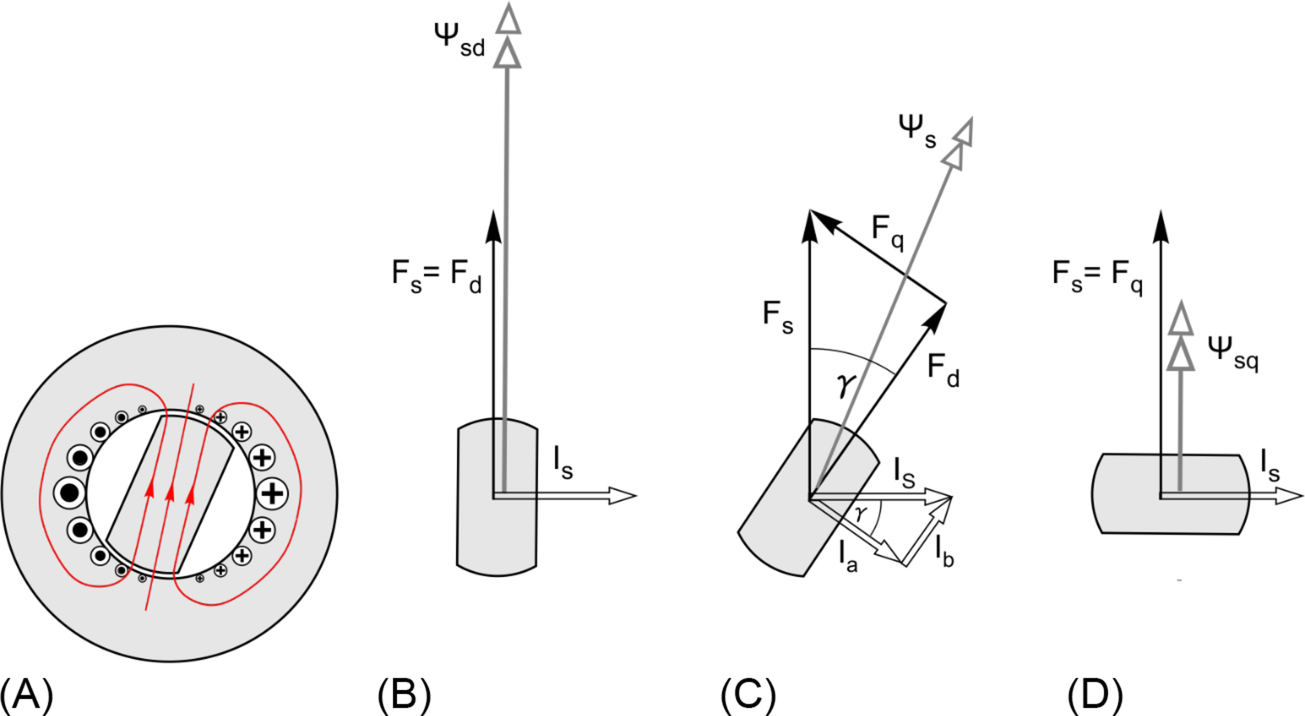

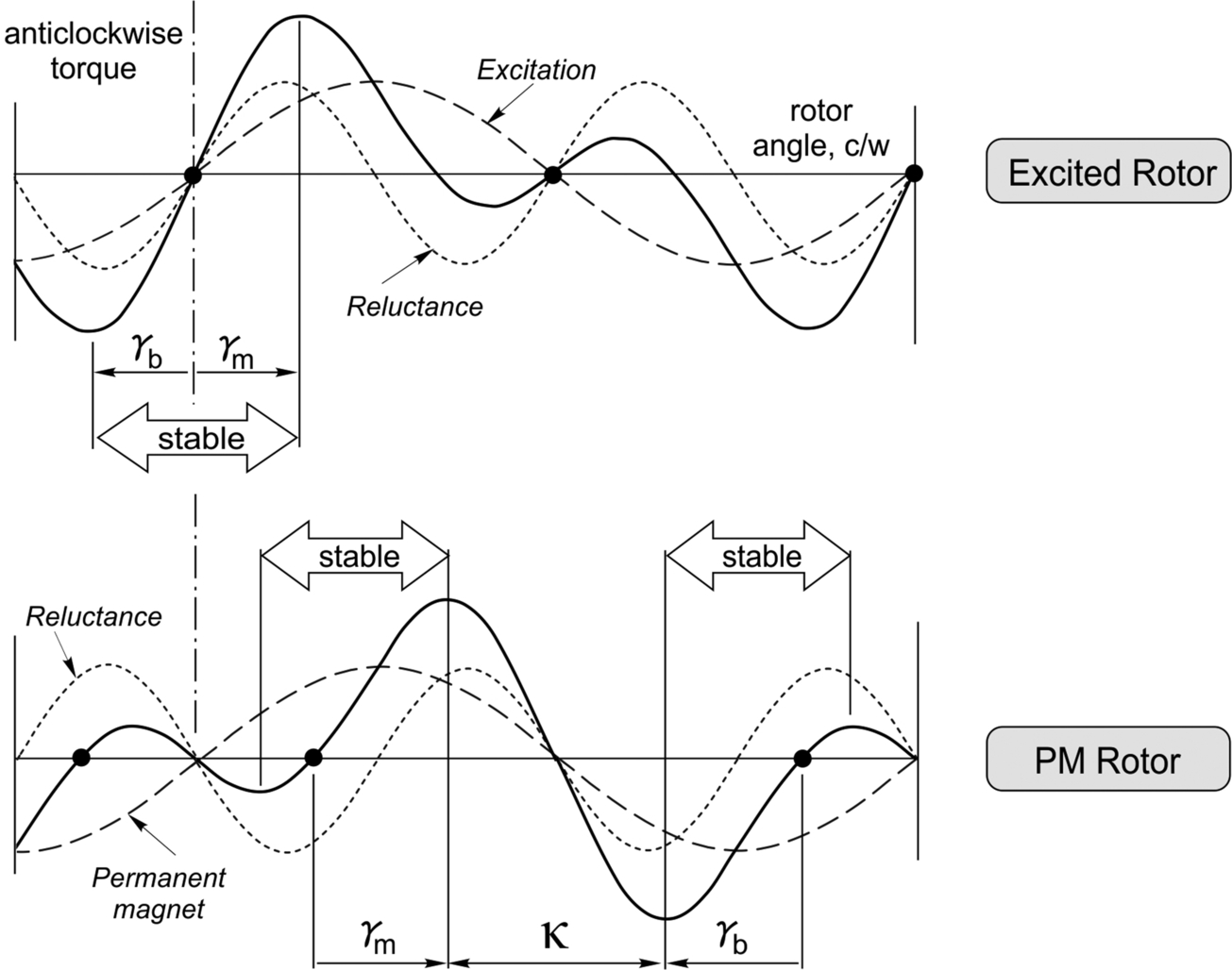

The sketches in Fig. 9.9 relate to the basic reluctance motor shown in Fig. 9.8. Fig. 9.9A is a reminder that we are dealing with a salient-pole rotor and a stator winding carrying a sinusoidally distributed current, while diagrams (B), (C), and (D) are space vector diagrams corresponding to various rotor positions. (We explained in Chapter 8 that it is very convenient to represent currents, m.m.f.'s and fluxes that are sinusoidally distributed in space by vectors, and the following discussion will underline the value of this approach.)

What we want to find is how the magnitude and phase of the stator flux linkage varies with the position of the rotor: if we know this, we can find the torque by applying the familiar ‘BIl’ approach used hitherto. The general position is shown in sketch (C), but it is best for us to establish some general ideas first by considering the limiting cases shown in sketches (B) and (D).

The peak of the stator current distribution (Is) lies on the horizontal axis, so the vector that represents the stator current distribution is horizontal and pointing to the right: this vector remains constant in all three sketches. The corresponding m.m.f. wave (Fs) is directed vertically upwards, and again it is constant in all three sketches.3 The suffices d and q refer to the direct and quadrature axes of the rotor, d being the low-reluctance axis, and q being the high reluctance path.

In sketch (B), for example, the stator m.m.f. Fs is directed along the rotor direct axis, and so it has been labelled Fd. The reluctance along the direct axis is low, so the stator flux linkage ψsd will be large. In contrast, in sketch (D) the same stator m.m.f. Fs is directed along the rotor's quadrature axis: it is therefore labelled Fq; and because the reluctance is relatively high, the corresponding stator flux linkage ψsq is relatively small.

In sketch (C), the stator m.m.f. vector has been resolved into direct and quadrature axis components. If each m.m.f. component acted on the same reluctance, the resultant flux linkage would be in phase with Fs. But the d-axis reluctance is much lower than the q-axis reluctance, so the resultant stator flux linkage (ψs) is shifted towards the direct axis. There are some similarities here with our previous discussions, where we saw that torque production required two fields to be displaced by an angle. This condition is met to a varying degree for all rotor positions between sketches (B) and (D), with m.m.f. and flux misaligned; but at the extremes both fields become co-phasal and the torque falls to zero.

In order to obtain the variation of torque with rotor angle and stator current, we need to form an expression equivalent to the ‘BIl’ product at the stator winding. Hitherto we have worked in terms of the flux density (B), but we can equally well use the flux linkage vector because we have specified that all quantities are sinusoidally distributed.

The sketch on the left in Fig. 9.10 is a repeat of the space vector diagram (C) in the previous sketch, and it shows the stator current distribution (Is) resolved into components Ia and Ib that are responsible for producing the m.m.f. components Fd and Fq, respectively. (It is important to point out that the resolved components of the current distribution vector in Fig. 9.10 should not be confused with the direct and quadrature axis currents that we will meet later in this chapter: the former are spatial quantities, represented here by outline arrows, while the latter are sinusoidal time-varying quantities, and are represented in time phasor diagrams by solid grey arrows.)

We need to find the component of the resultant flux linkage that is co-phasal with the current so that we can apply ‘BIl’. That component is represented by the distance x, but we do not know the angle α, so instead we find the difference between z and y, yielding the flux linkage component (equivalent to the ‘B' in BIl) as (LdIa sinγ − LqIb cos γ). The ‘I' part of BIl is of course Is. So we find that the torque (or strictly the force, but here we are seeking a general qualitative expression applicable to a generic motor, so dimensions are not considered) is given by

If we now express the current distributions Ia and Ib in terms of Is, i.e. Ia = Is cosγ and Ib = Is sin γ, the torque is given by

This simple expression shows that the torque depends on the square of the current, and is therefore the same for both positive and negative current: the torque is also a double-frequency function of the rotor angle, as we saw earlier. We already knew that in order to work at all, the rotor had to have saliency, but we now see that the torque is directly proportional to the difference between the direct and quadrature axis inductances, so that, broadly speaking, the greater the difference, the better. However, we will see later that this is not the only criteria, and that the ratio of the inductances also has important consequences for steady-state running.

In practical reluctance machines, as the current is increased, the iron begins to saturate and the torque assumes a more linear relationship with the current. In view of the importance of saturation, reluctance torque is predicted at the design stage using computer-based finite element analysis of the magnetic field distribution at each rotor position, and then using ‘BIl’ or the Maxwell stress method to find the torque. Finite element analysis also enables inductance variation to be obtained, so that the ‘coupled circuit’ approach (see Section 8.3) can then be used to predict all aspects of performance.

9.3.4 Salient pole synchronous motor

Looking back at Fig. 9.2, it is obvious that both rotors exhibit saliency, although it is much more pronounced in the one on the right. It is therefore to be expected that in addition to the excitation torque that depends on the rotor current (Section 9.3.1), there will also be reluctance torque (Section 9.3.3) which will be there even when there is no rotor current.

If we ignore saturation, the torque-angle relationship is obtained by superposing the excitation torque term and the reluctance torque term, giving the typical torque-angle curve shown in Fig. 9.11. The region to the right of peak torque in Fig. 9.11 is of no practical interest because it represents an unstable condition, but it is included to show one full cycle of the reluctance torque.

The most noticeable effect of the reluctance component is to increase the ‘stiffness’ (i.e. the gradient of the torque-angle curve) about the zero torque position, but it also reduces the stable operating region lying to the left of the (in this case, slightly increased) peak torque. The increased stiffness is generally beneficial, while the reduction in the stable region is unlikely to be significant because operation at such large load angles would not be possible without exceeding the rated current.

The relative magnitude of the excitation torque and the reluctance torque is a critical design consideration. Today substantial research is being undertaken to reduce the use of permanent magnets, resulting in motor designs with an increasing proportion of the total torque being reluctance torque: this is discussed further in Section 9.8.

9.3.5 Salient permanent magnet motor (‘PM/Rel’ motor)

In Section 9.3.4 we saw that for an excited rotor motor with rotor saliency, the reluctance torque acting alone caused the unloaded rotor to come to rest with the rotor direct axis aligned with stator m.m.f., i.e. at the same position as it would if the excitation torque acted alone. This is because the low-reluctance axis is the same as the excitation direct axis. The ‘stiffness’ of the torque-angle characteristic is increased by the presence of the reluctance torque, and depending on the relative magnitudes of the two components, the peak torque may also be increased, as shown in Fig. 9.11, so the combination is an attractive proposition.

The idea of replacing the rotor excitation circuit with simpler permanent magnets while continuing to exploit reluctance torque is clear in principle, but in practice is not as straightforward as might be expected. In order for the magnet flux to flow along the rotor direct axis (i.e. along a salient pole), a gap has to be inserted to accommodate the magnet, and the stronger the magnet, the longer the gap. This greatly increases the reluctance of the direct axis, which is the opposite of what we want in order to maximise the reluctance torque.

However, we have already talked about the move by many industries to reduce their dependency on rare earth magnets because of concerns over the global security of supply. This uncertainty, together with the incentive to provide low-cost motors for the burgeoning mass market (notably in hybrid electric vehicles), has led to renewed interest in motors that combine PM and reluctance torque. Compared with a purely PM motor, the aim is to achieve comparable performance with less magnet material: the ratio of PM torque to reluctance torque varies considerably (typically from 4:1 to as low as 1:1) depending on the detailed motor design and application, but in very simplistic terms, and stating the obvious, the less magnet material the higher the proportion of reluctance torque.

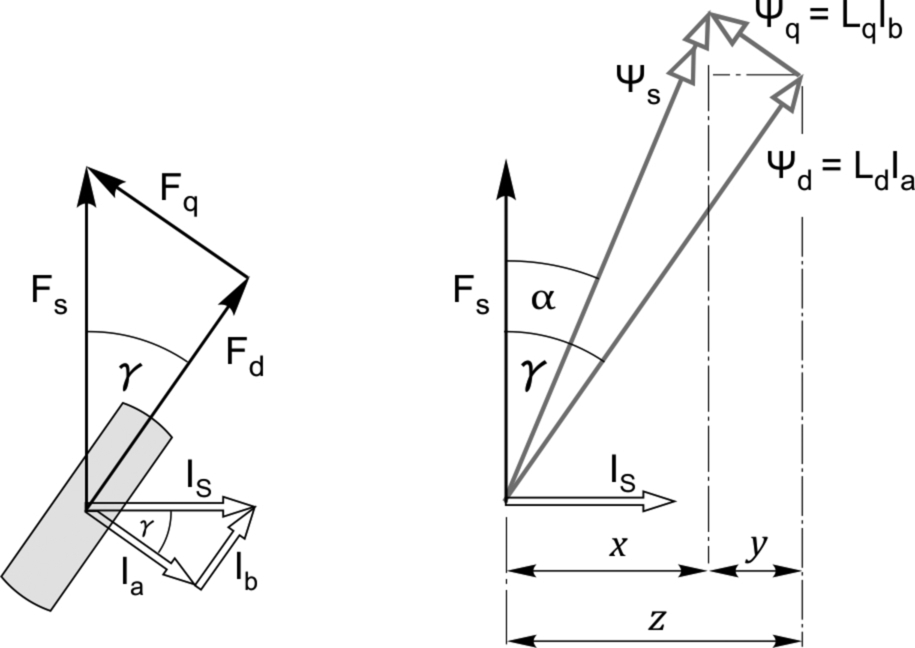

A typical six-pole rotor is shown in Fig. 9.12: it is basically a flux-guided reluctance motor rotor with buried permanent magnets sitting in the flux guides. Looking at the topmost N pole in Fig. 9.12 for example, its two magnets are effectively in series, and their direct (flux) axis is vertical. Apart from the air-gap, the main magnetic circuit external to each pair of magnets is of low reluctance through the core ‘iron’, so in this regard there is little compromise compared with PM-only design. However, for structural reasons there has to be a bridge of magnetic core material at the outer extremities of the flux guides, and this inevitably offers an attractive short-circuit for some of the magnet flux, which is thus diverted away from its useful path via the stator. This area remains saturated and unproductive in terms of torque.

As far as the reluctance aspect goes, the direct (low inductance) axis is shown by the chain-dotted lines, and the bridge referred to above again represents an unwanted short-circuit path for stator-produced flux, but in essence this is exactly as it would be in a flux-guided reluctance motor. If the reluctance torque acted alone, the unloaded rotor would come to rest with the stator m.m.f. aligned with the chain-dotted line, but if the PM acted alone, the unloaded rotor would come to rest with a N pole aligned with the stator m.m.f. So unlike the salient excited rotor motor, where the equilibrium positions coincided, we now have two distinct zero-torque positions, separated by 90° (elec.).

There is clearly potential confusion over which is the direct axis. On the face of it we have two rival contenders with conflicting claims: the reluctance camp would claim it was the chain-dotted line in Fig. 9.12, while the PM fans would argue it was an axis through the centre of the magnet poles. In practice the latter is usually preferred, i.e. the direct axis is defined in the same way as for a purely PM machine.

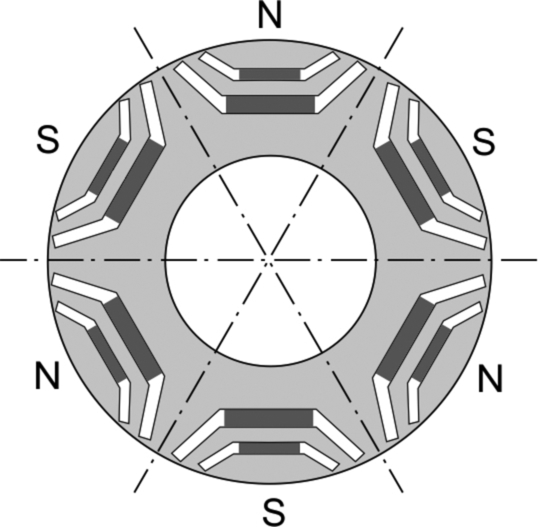

We can get a general idea of the shape of the overall torque-angle characteristic by superposing the separate reluctance and PM curves, as shown in Fig. 9.13, but we have to accept that this is only an approximation because it ignores the effects of saturation in the magnetic circuits.

The excited rotor case is included in Fig. 9.13 for comparison with the PM/Rel motor, and as we have already seen in Section 9.3.4, the resultant torque-angle curve for the excited rotor is stiffer about the stable zero-torque position, and the motoring and braking regions are symmetrically disposed, with equal maximum torque angles for motoring and braking of γm and γb, respectively.

Our aim is to highlight the fundamental differences between the torque-angle characteristics of the excited rotor motor and the PM/Rel motor, so we have arbitrarily chosen the reluctance and torque components to have the same amplitude. (In practice, an excited rotor motor would have much less reluctance torque, whereas the ratio of torque components for a PM/Rel motor could be higher or lower.)

The shift of 90° between the reluctance and PM curves results in different stable operating regions for the PM case, and also new zero-torque rest positions. The peak motoring and braking torques remain the same as for the excited rotor case, but they are no longer symmetrical about a single equilibrium rest position. The maximum motoring torque angle is indicated by γm, while the maximum braking torque is shown as γb. Hence when the drive requires the torque to change from maximum motoring torque to maximum braking torque, the control system (see Section 9.6) will reposition the stator current vector relative to the rotor by the angle κ shown in the lower diagram.

There is still a great deal of ongoing work and interest in this emerging technology, and it will be some time before optimised solutions for the various application areas finally emerge.

9.4 Utility-fed synchronous motors

Historically most synchronous machines were operated directly from the utility supply, so it is appropriate that we look first at the operation of synchronous machines assuming that the supply voltage and frequency are constant.

The physical picture involving spatially distributed m.m.f's, fluxes and current distributions in the previous section provided an explanation for the mechanism of torque production. We now shift attention into the time domain, and explore the steady-state behaviour when a synchronous motor is supplied from a balanced, constant voltage, sinusoidal supply. The stator current, which we held constant in the previous section, will now be one of the principal dependent variables, while the independent variables are the rotor excitation (if a wound rotor type) and the load on the shaft. The speed will be constant, so the power will be directly proportional to the torque.

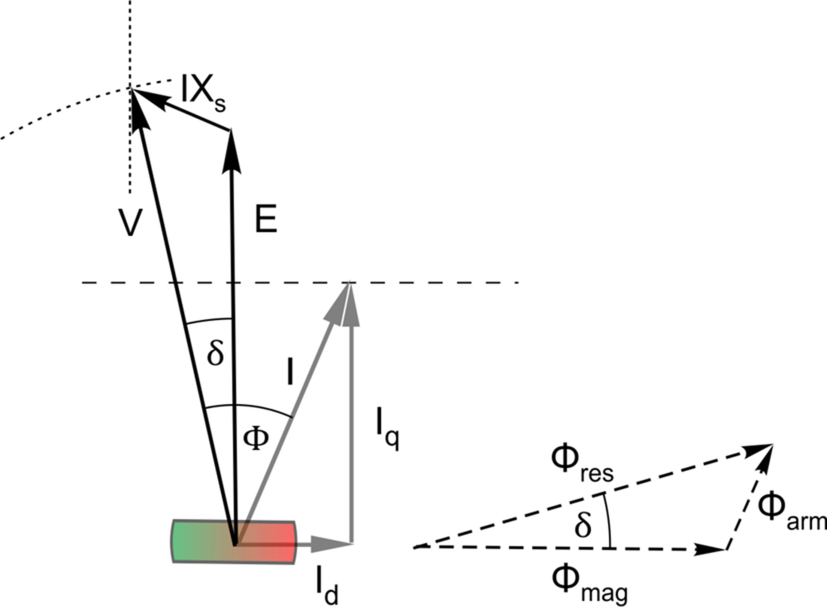

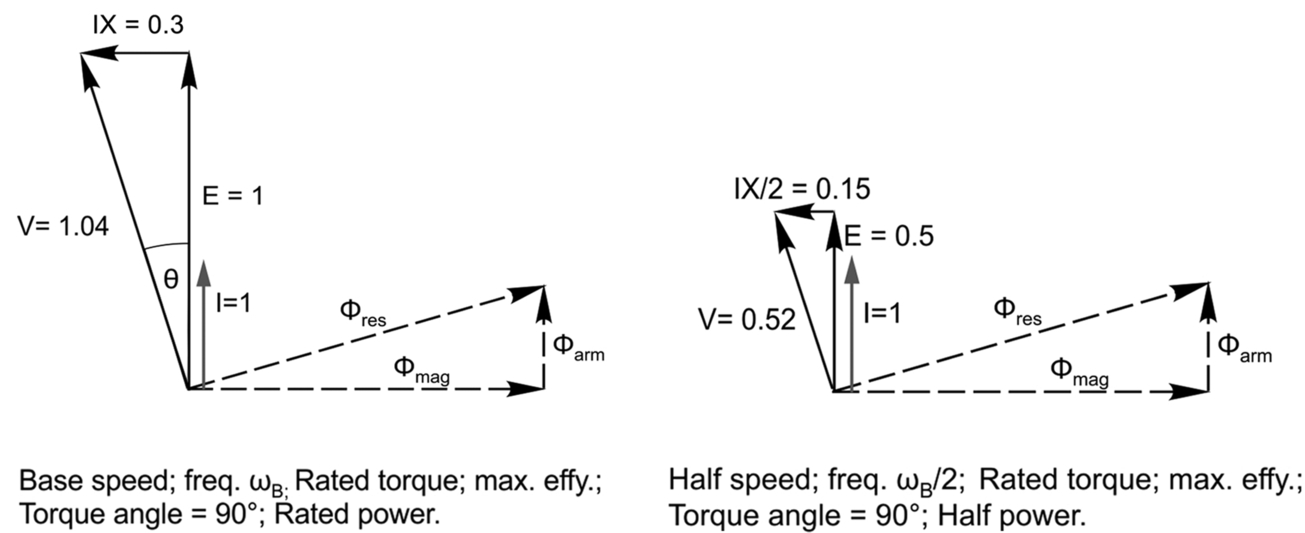

Fortunately, predicting the current and power-factor drawn from the supply by a cylindrical-rotor or PM synchronous motor supplied from a balanced three-phase supply is possible by means of the per-phase a.c. equivalent circuit shown in Fig. 9.14. To arrive at such a simple circuit inevitably means that approximations have to be made (notably in relation to saturation in the magnetic circuit), but we are seeking only a broad-brush picture, so the circuit is perfectly adequate.

In this circuit Xs (known as the synchronous reactance, or simply the reactance) represents the effective inductive reactance of the stator phase winding; R is the stator winding resistance; V is the applied voltage; and E is the e.m.f. induced in the stator winding by the rotating flux produced either by the d.c. current on the rotor or the permanent magnet.

The term ‘effective’ reactance applied to Xs reflects the fact that the magnitude of the flux wave produced by balanced currents in each of the three phase windings is 1.5 times larger than the flux that would be produced by the same current in only the one winding. The effective inductance of each phase (i.e. the ratio of flux linkage to current) is thus 1.5 times the self inductance of each phase winding, and consequently the synchronous reactance Xs = 1.5 X, where X is the reactance of one phase. For the benefit of readers who are familiar with the parameters of the induction motor, it should be pointed out that Xs is equal to the sum of the magnetising and leakage reactances, but because the effective air-gap in synchronous machines is usually larger than in induction motors, their per-unit synchronous reactance is usually lower than that of an induction machine with the same stator winding.

It may seem strange that in the previous section we were talking about both the rotor flux and the stator flux, but now, we refer to the e.m.f. induced by the rotor flux, and seem to have ignored the e.m.f. due to the rotating stator (armature) flux. Needless to say, we have not forgotten the stator flux, because we are following the conventional approach in which the self-induced e.m.f. due to the resultant stator flux (which is proportional to the stator current) is represented by the voltage (IXs) across the inductive reactance, Xs.

At this point, readers who are not familiar with a.c. circuits and phasor diagrams will inevitably be disadvantaged, because discussion of the equivalent circuit and the associated phasor diagram greatly assists the understanding of motor behaviour. We have included a brief resume of phasors in Section 9.4.3, but we have also summed up the lessons learned in each case, so that readers who have been unable to absorb the theoretical underpinning will not be seriously handicapped.

9.4.1 Excited rotor motor

Our aim is to find what determines the current drawn from the supply, which from Fig. 9.14 clearly depends on all the parameters therein. But for a given machine operating from a constant-voltage, constant-frequency supply, the only independent variables are the load on the shaft and the d.c. current (the excitation) fed into the rotor, so we will look at the influence of both, beginning with the effect of the load on the shaft.

The speed is constant and therefore the mechanical output power (torque times speed) is directly proportional to the torque being produced, which in the steady-state is equal and opposite to the load torque. Hence if we neglect all the losses in the motor (and in particular we assume that the resistance R is negligible), the electrical input power is also determined by the load on the shaft. The input power per phase is given by VI cos ϕ where I is the current and the power-factor angle is ϕ. But V is fixed, so the in-phase (or real) component of input current (I cos ϕ) is determined by the mechanical load on the shaft. We recall that, in the same way, the current in the d.c. motor (Fig. 3.6) was determined by the load. This discussion reminds us that although the equivalent circuits in Figs. 9.14 and 3.6 are very informative, they should perhaps carry a ‘health warning’ to the effect that one of the two independent variables (the load torque) does not actually appear explicitly on the diagrams.

Turning now to the influence of the d.c. excitation current, at a given supply frequency (i.e. speed) the utility-frequency e.m.f. (E) induced in the stator is proportional to the d.c. field current fed into the rotor. If we wanted to measure this e.m.f. we could disconnect the stator windings from the supply, drive the rotor at synchronous speed by an external means, and measure the voltage at the stator terminals, performing the so-called ‘open-circuit’ test. If we were to vary the speed at which we drove the rotor, keeping the field current constant, we would of course find that E was proportional to the speed. We discovered a very similar state of affairs when we studied the d.c. machine (Chapter 3): its induced motional or ‘back’ e.m.f. (E) turned out to be proportional to the field current, and to the speed of rotation of the armature. The main difference between the d.c. machine and the synchronous machine is that in the d.c. machine the field is stationary and the armature rotates, whereas in the synchronous machine the field system rotates while the stator windings are at rest: in other words, one could describe the synchronous machine, loosely, as an ‘inside-out’ d.c. machine.

We also saw in Chapter 3 that when the unloaded d.c. machine was connected to a constant voltage d.c. supply, it ran at a speed such that the induced e.m.f. was (almost) equal to the supply voltage, so that the no-load current was almost zero. When a load was applied to the shaft, the speed fell, thereby reducing E and increasing the current drawn from the supply until the motoring torque produced was equal to the load torque. Our overall conclusion was the simple statement that if E is less than V, the d.c. machine acts as a motor, while if E is greater than V, it acts as a generator.

The situation with the synchronous motor is similar, but now the speed is constant and we can control E independently via control of the d.c. excitation current fed to the rotor. We might again expect that if E was less than V the machine would draw-in current and act as a motor, and vice-versa if E was greater than V. But we are no longer dealing with simple d.c. circuits in which phrases such as ‘draw in current’ have a clear meaning in terms of what it tells us about power flow. In the synchronous machine equivalent circuit the voltages and currents are a.c., so we have to be more careful with our language and pay due regard to the phase of the current, as well as its magnitude. Things turn out to be rather different from what we found in the d.c. motor, but there are also similarities.

Phasor diagram and power-factor control

We will begin by looking at how the e.m.f. (E) influences the behaviour of the motor when it is running without any shaft load. By excluding one of the two independent variables (i.e. the load torque), we can highlight the role of the other independent variable (the rotor current) in relation to the excitation or flux producing requirement.

If we neglect winding resistance, iron loss and frictional losses, the input electrical power is equal to the mechanical output power, so in this case the input power will be zero, which means that the ‘real’ component of the phase current (i.e. the component in phase with V) will be zero, and the machine will therefore always be ‘reactive’ as viewed from the utility supply. The four sketches in Fig. 9.15 show how the input current (and thus the effective reactance) varies with the induced e.m.f. (E): they embody the result of applying Kirchoff's voltage law to the equivalent circuit in Fig. 9.14, i.e. V = E + IR + jIXs, but with R neglected, so the phasor diagram simply consists of the volt-drop IXs (which leads the current (I) by 90°) added to E to yield V.

In sketch (A), the rotor current (and hence E) is zero, so according to Fig. 9.14 the motor will look like a pure inductance when viewed from the supply, and the current (Io, the ‘o’ denoting no-load) will be given by V/Xs, where Xs is the synchronous reactance at the frequency of the supply. The large current (perhaps of the order of 60% of the full-load current in a large motor) is lagging by 90°, so the motor is therefore consuming reactive power only. In this extreme case the motor might be described as un-excited because there is no rotor current, but in fact a rotating field must be set up to induce an internal e.m.f. equal to the terminal voltage, and in this case all of the necessary m.m.f. is provided by the stator current in each phase. We discussed a similar state of affairs when we looked at the unloaded induction motor, where it emerged that the no load current lagged the voltage by almost 90°, and was called the ‘magnetising’ current, because it was responsible for setting up the rotating flux wave. Here the use of the term ‘excitation’ harks back to the d.c. machine, but the word ‘magnetising’ would be equally suitable.

In case (B), the rotor current is sufficient to produce a flux wave that in turn induces an e.m.f. of half the terminal voltage, so now the stator current is only half of that in (A) because it only has to make up the shortfall of excitation. The reactive power is now reduced, but it is still lagging. This condition, where the induced e.m.f. E is less that V, is usually referred to as ‘under-excited’.

In the special case shown in Fig. 9.15C, the induced e.m.f. is equal to the applied voltage, the current is zero, and the motor appears as an open circuit to the supply.

Finally, the ‘over-excited’ case is shown in sketch (D). The rotor excitation is now 50% larger than required to balance the voltage V, so the stator current reverses in phase and now opposes the rotor excitation. The current now leads by 90°, and the motor can equally well be viewed as exporting lagging VArs or consuming leading VArs, i.e. it looks capacitive. (When synchronous machines were operated with both ends of the rotor shaft sealed off, so that no mechanical power was involved, they were known as ‘compensators’, with the ability to ‘look like’ either an inductor or a capacitor, and until the advent of power electronics they were used for regulating purposes in power systems.)

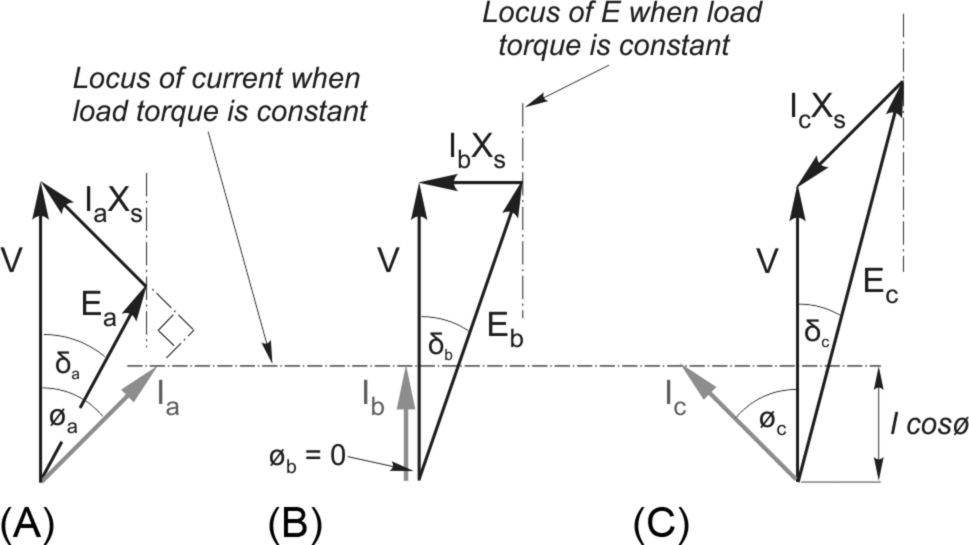

We now turn to the more important practical case where the motor is supplying mechanical output power, and again we will investigate how the magnitude of the e.m.f. influences behaviour, with the aid of the phasor diagrams in Fig. 9.16.

The first point to clarify is that our sign convention is that motoring corresponds to positive electrical input power to the machine. The power is given by VI cos ϕ, so when the machine is motoring (positive power) the angle ϕ lies in the range ± 90°. If the current lags or leads the voltage by more than 90° the machine will be generating.

The sketches in Fig. 9.16 correspond to low, medium and high values of the induced e.m.f. (E), the shaft load (i.e. mechanical power) being constant. As discussed above, if the mechanical power is constant, so is I cos ϕ, and the locus of the current is therefore shown by the horizontal dashed line. The load angle (δ), discussed earlier, is the angle between V and E in the phasor diagram.

Fig. 9.16A represents an under-excited condition where the field current has been set so that the magnitude of (E) is less than V, which leads to a relatively large lagging reactive current component. When the field current is increased (increasing the magnitude of E) the magnitude of the input current reduces and it moves more into phase with V: the special case shown in Fig. 9.16B shows that the motor can be operated at unity power-factor if the field current is suitably chosen.

A brief digression is appropriate at this point to relate the time phasor diagram to the space phasors in Fig. 9.6. We imagine the space phasors to be rotating at the synchronous speed, in which case each of them gives rise to an induced motional e.m.f. in the stator. The rotor space phasor (FR) produces E (proportional to the d.c. current in the rotor), and the stator space phasor (FS) produces an e.m.f. (which is proportional to the armature current) that we represent by the voltage IXs. The resultant of these two space phasors (F) produces the resultant flux linkage at the stator winding (ψs), which must induce the terminal voltage, V, so, depending on the magnitude of E, the armature current adjusts accordingly.

The unity power factor case shown in (B) represents the minimum current for the given power (or torque), when the terminal voltage V and frequency are fixed. The corresponding space phasor triangle will have an area determined by the torque, a resultant (F) that is fixed, and FR adjusted so as to minimise FS, which will be achieved when the angle α in Fig. 9.6 is 90° and FS is perpendicular to F. This represents the optimum condition for maximising torque when the resultant and rotor fluxes are specified, and the space phasor diagram will then be a scaled version of Fig. 9.16B.

Returning to Fig. 9.16C, the field current is considerably higher (the ‘over-excited’ case) which causes the current to increase again but this time the current leads the voltage and the power-factor is cosϕc, leading. We see that we can obtain any desired power-factor by appropriate choice of rotor excitation, and in particular we can operate with a leading power-factor, a freedom not afforded to users of induction motors.

When we studied the induction motor we discovered that the magnitude and frequency of the supply voltage V governed the magnitude of the resultant flux density wave in the machine, and that the current drawn by the motor could be considered to consist of two components. The real (in-phase) component represented the real power being converted from electrical to mechanical form, so this component varied with the load. On the other hand the lagging reactive (quadrature) component represented the ‘magnetising’ current that was responsible for producing the flux, and it remained constant regardless of load.

The stator winding of the synchronous motor is essentially the same as the induction motor, so, as discussed above, it is to be expected that the resultant flux will be determined by the magnitude and frequency of the applied voltage. This flux will therefore remain constant regardless of the load, and there will be an associated requirement for magnetising m.m.f. But as we have already seen, we have two possible means of providing the excitation m.m.f., namely the d.c. current fed into the rotor and the lagging component of current in the stator.

When the rotor is under-excited, i.e. the induced e.m.f. E is less than V (Fig. 9.16A), the stator current has a lagging component to make up for the shortfall in excitation needed to yield the resultant field that must be present as determined by the terminal voltage, V. With more field current (Fig. 9.16B), however, the rotor excitation alone is sufficient and no lagging current is drawn by the stator. And in the over-excited case (Fig. 9.16C), there is so much rotor excitation that there is effectively some reactive power to spare and the leading power-factor represents the export of lagging reactive power that could be used to provide excitation for induction motors elsewhere on the same system, thereby raising the overall system power factor. As might have been expected, these observations about the role of the excitation line up nicely with what we saw when we looked at the no-load behaviour.

To conclude our look at the excited rotor motor we can now quantify the torque. From Fig. 9.16, the real power is given by

The speed is constant, so the torque is also given by an expression of the form

This agrees with the conclusion we reached in Section 9.3.1, where we saw that the torque depended on the product of the resultant field (here represented by V), the rotor field (here represented by E) and the sine of the load angle between them (δ). We note that if the load torque is constant, the variation of the load-angle (δ) with E is such that E sin δ remains constant. As the rotor excitation is reduced, and E becomes smaller, the load angle increases until it eventually reaches 90o, at which point the rotor will lose synchronism and stall. This means that there will always be a lower limit to the excitation required for the machine to be able to transmit the specified torque. This is just what our simple mental picture of torque being developed between two magnetic fields, one of which becomes very weak, would lead us to expect.

9.4.2 Permanent magnet motor

Although the majority of permanent magnet motors are supplied from variable-frequency inverters, some are directly connected to the utility supply, and we can again explore their behaviour using the equivalent circuit shown in Fig. 9.14. Because the permanent magnet acts as source of constant excitation, we no longer have control over the magnitude of the induced e.m.f. (E), which now depends on the magnet strength and the speed, the latter being fixed by the utility frequency. So now we only have the load torque as an independent variable, and, as we saw earlier, because the supply voltage is constant, the load torque determines the in-phase or work component of the stator current (Icos ϕ) as indicated in the phasor diagrams in Fig. 9.16.

In order to identify which of the three diagrams in Fig. 9.16 applies to a particular motor we need to know the motional e.m.f. (E) with the rotor spinning at synchronous speed and the stator open-circuited. If E is less than the utility voltage, diagram (A) applies; the motor is said to be under-excited; and it will have a lagging power-factor that worsens with load. Conversely, if E is greater than V, (the over-excited case) diagrams (B) or (C) are typical, and the power factor will be leading.

9.4.3 Reluctance motor

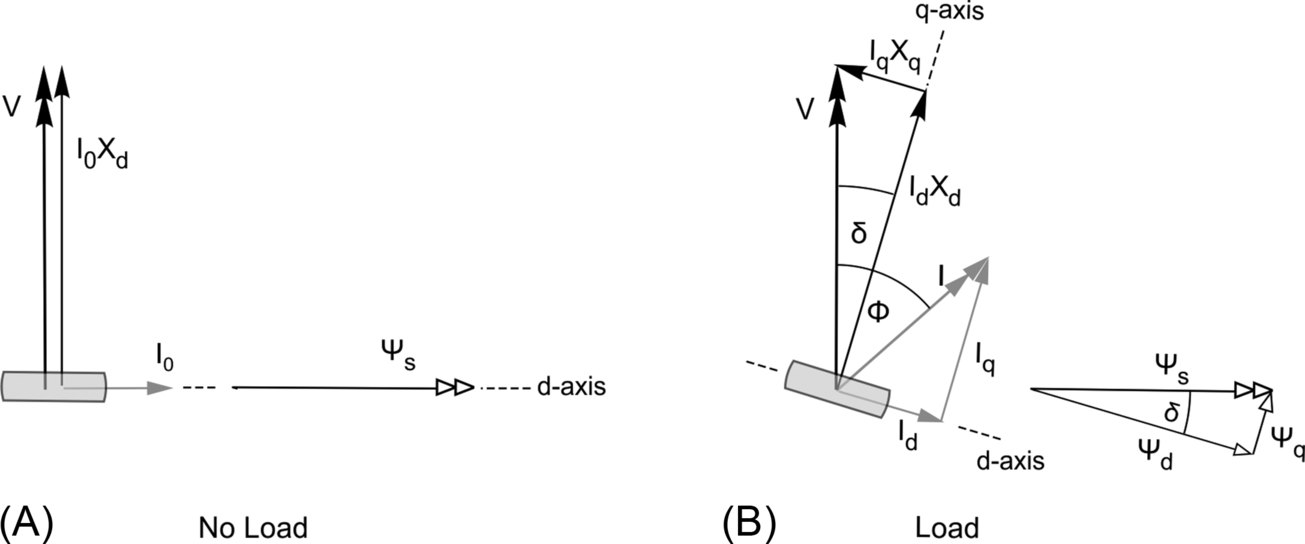

Time phasor diagrams for one phase winding under no-load and loaded conditions are shown in Fig. 9.17A and B, respectively, and in each case the time phasors of the flux linkage have been shifted to the right to avoid congestion with the voltages and current. These flux phasors can be compared with the space vectors shown in Fig. 9.10. Once again, resistance has been neglected in the interests of simplicity.

Two novel features of Fig. 9.17 are firstly the resolved current components Id and Iq, and secondly the incongruity of finding a sketch of a salient rotor in a diagram that supposedly represents time-varying electric circuit quantities. We will therefore break off from the specifics of the reluctance motor, firstly to refresh our understanding of the properties of time phasors, and secondly to justify the presence of the rotor in Fig. 9.17.

The purpose of a phasor diagram is to provide an efficient graphical way of representing the steady-state inter-relationship between quantities that vary sinusoidally in time. We picture all phasors to be rotating anticlockwise at a constant speed and completing one revolution per cycle of the supply. The length of each phasor is proportional to the amplitude (or more usually r.m.s. value) of the quantity represented, and its angular position represents its phase with respect to the other quantities. The projection of the tip of each phasor onto the vertical axis of the diagram then indicates its instantaneous value, which will, of course, vary sinusoidally in time: and if we were to arrange for a pen to be fixed to the tip of each phasor, and for the pen to bear on an endless strip of paper moving at a steady speed from left to right behind the rotating phasor, the trace on the paper would be a sinewave.

In this book, time phasor diagrams represent what is happening inside one of the stator windings, which by definition means that we are in a stationary reference frame, in which two distinct types of quantity may be represented. Firstly, there are the terminal voltages and currents (that we could measure with a voltmeter and ammeter), and the various ‘internal to the equivalent circuit’ voltages and currents that together make up the terminal quantities. These are single valued time functions which have no spatial meaning associated with them. But we also display quantities such as flux linkages that are sinusoidally distributed in space: this is justified because the rotating flux linkage space phasor manifests itself in the winding as a sinusoidally time-varying effect, the rate of change of which results in an induced voltage.

For the diagrams to be meaningful, it hardly needs saying that all quantities of the same kind (e.g. voltages) must be drawn to the same scale, while physically different quantities (e.g. currents) can be drawn to a different but consistent scale.

In the light of the above discussion, we would not expect to see the ghostly outline of a salient pole rotor superimposed on a diagram such as that in Fig. 9.17, and we are not about to argue that a rotor is a time-varying quantity. But the rotor does rotate by one pole-pair for each electrical cycle, and we have seen in the discussion of torque production (in Section 9.3.3) that in the steady state the rotor has a fixed angular relationship with the resultant flux phasor, so including it is not so fanciful after all, and as we will now see, it helps us to understand the phasor diagram by locating the direct and quadrature axes, and hence throwing light on the currents Id and Iq.

In Section 9.3.3 we defined the low reluctance path through the rotor as the direct axis, and the higher reluctance path as the quadrature axis. Hence when we include the rotor outline in a phasor diagram we implicitly define the direct axis (for example it is horizontal in Fig. 9.17A) and the quadrature axis (vertical). (We adopt the most widely-used convention, with the quadrature axis leading the direct axis by 90°, but readers should not be surprised to find textbooks that use alternatives.)

Returning now to the discussion of the reluctance motor phasor diagram in Fig. 9.17A that represents the unloaded motor, we choose the constant supply voltage V as reference, and follow the usual practice by drawing it vertical.

As we have seen for the induction and synchronous machines, the resultant flux linkage ψs is determined by the supply voltage and frequency, and the in-phase component of current (I cos ϕ), is solely determined by the load torque. The reluctance motor has no rotor excitation, so the stator current always has to draw an excitation or magnetising component.

At no load, (Fig. 9.17A, there is no in-phase component of current, and so the no-load current Io is all excitation or magnetising current, and it produces the flux linkage ψs which is in time phase with the current, and in turn induces the e.m.f. which must equal V. We have encountered these flux-e.m.f. relations several times already.

Where there is no saliency, we chose to represent the self-induced e.m.f. by means of the synchronous reactance voltage drop IXs. But with saliency, we have seen that for a given stator current, the self flux linkage (and hence the inductance) depends on the angular position of the rotor. We therefore introduced two new inductances Ld and Lq to assist analysis. Ld represents the inductance when the direct axis of the rotor is aligned with the m.m.f. axis of the stator phase, and Lq is the inductance when the rotor direct axis is perpendicular to the phase axis. The corresponding steady-state reactances are Xd and Xq, but it is not immediately obvious how these are to be reflected in the phasor diagram. This is where the rotor outline becomes invaluable.

Referring back to Fig. 9.10, we learned that torque is proportional to the sine of (twice) the space angle (δ) between the direct axis and the resultant flux, so we know that at no-load, the flux is along the direct axis. As the flux wave rotates, the rotor remains in synchronism with the flux, so we could legitimately add another ‘phasor arrow’ to the time diagram labelled ‘rotor direct axis’: in practice, it is more graphic to put a rotor outline, as shown in Fig. 9.17.

We now know that at no-load, the direct axis of the rotor is aligned with the flux wave, so this determines the rotor outline under no-load conditions as being in time phase with the flux, i.e. horizontal in Fig. 9.17A. The stator m.m.f. is thus entirely directed along the direct axis, and we therefore refer to the corresponding current as the ‘direct axis’ current. In this special (no-load) case all of the current is d-axis current (I0 = Id).

The flux produced by the d-axis current is determined by the d-axis inductance, and the e.m.f. induced by the flux is therefore related to the current by the d-axis reactance. The volt-drop that we choose to represent this e.m.f. is the phasor IdXd in Fig. 9.17A.

The phasor diagram when the motor is on load is shown in Fig. 9.17B, again with the voltage V as reference, and as at no load, the resultant flux remains the same because it has to induce an e.m.f. equal to V. The resultant flux is no longer on the direct axis, and the rotor is lagging the flux by the load angle (δ). The load torque determines the component of current that is in phase with V (i.e. IcosΦ—not shown), but the reactive component that finally determines the phase of the current depends on the two reactances, as explained below.

The significance of the current components Id and Iq should now be clear. The m.m.f. associated with Id acts along the direct axis of the rotor, and produces a flux linkage ψd that is given by LdId, and a corresponding self-induced e.m.f. given by Id Xd. We refer to Id as the flux producing, magnetising or excitation component of the current, and as we have seen, at no load, all of the input current is direct axis current.

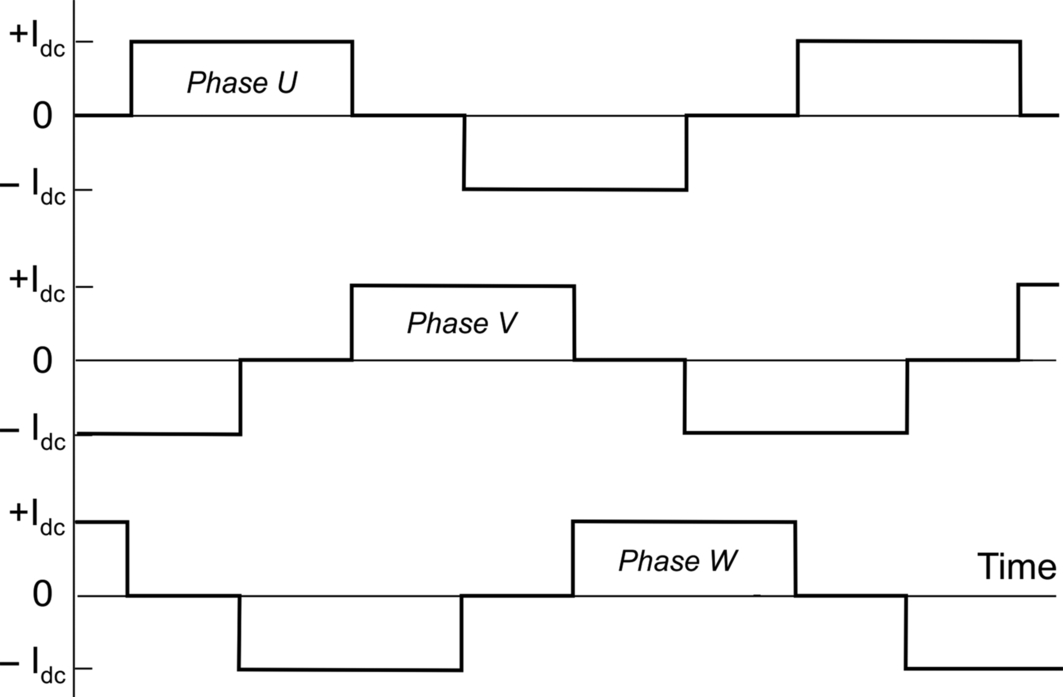

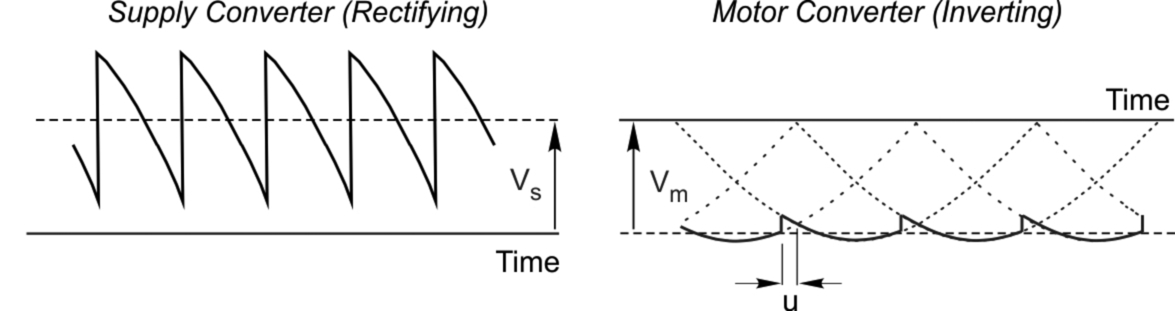

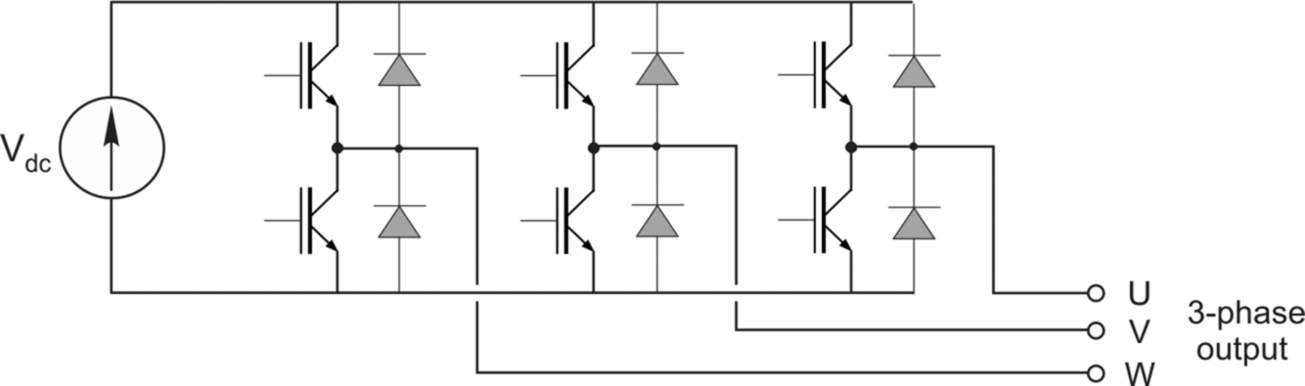

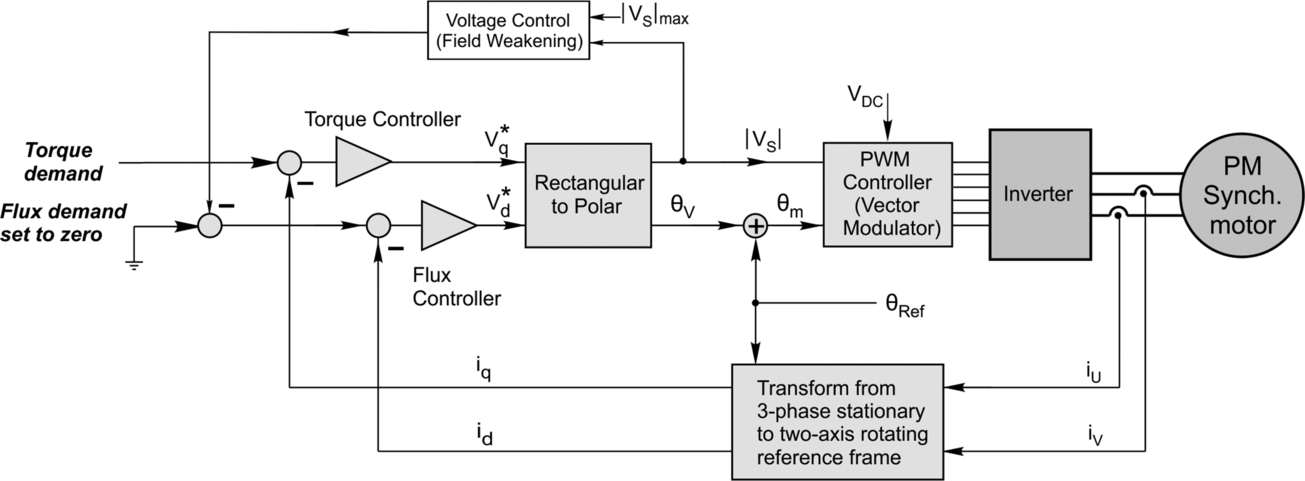

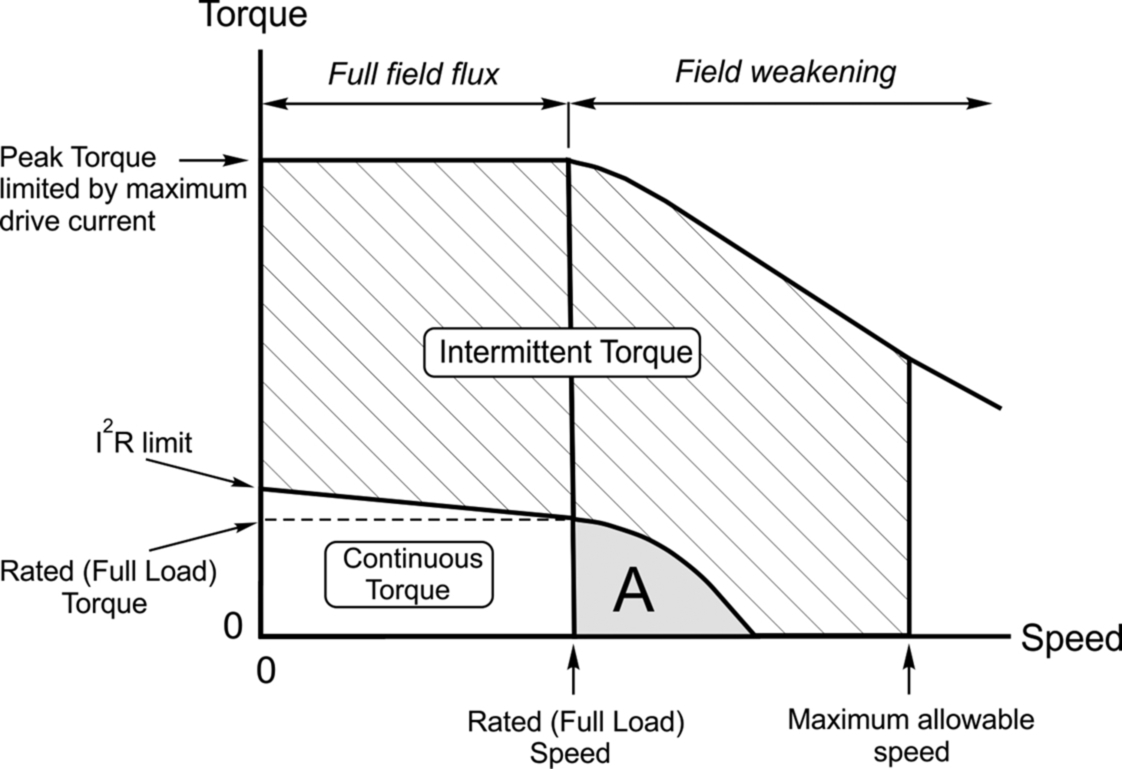

Conversely, Iq is the torque-producing component of current: its associated m.m.f acts along the quadrature axis, producing a flux linkage component ψq given by LqIq and a corresponding component of self-induced e.m.f. given by IqXq.