9.8. Fire Suppression Systems

According to the Fire Suppression Systems Association (FSSA) 43% of businesses closed by fire never reopen and another 29% fail within 3 years. These are stark statistics. Fire suppression systems are used in conjunction with smoke detectors and fire alarm systems to improve and increase public safety. Suppression systems are governed by the codes under the NFPA 13 handbook and include Fire sprinkler systems (wet, dry, preaction, and deluge), gaseous agents, and wet/dry chemical agents. When planning for fire protection, an integrated approach is needed in which system designers analyze the building’s components as a total package. To achieve an optimum symbiosis between these components, an experienced system designer, such as a fire-protection engineer, should be involved in the very early stages of the planning and design process. With the increasing number of high rise, high-performance buildings being built both nationwide and globally, the planning for fire protection has taken on a real urgency. Fire suppression design requires an integrated approach in which system designers need to analyze building components as a total package. As with other aspects of sustainable design, to achieve the most beneficial symbiosis between these components, an experienced system designer, such as a fire-protection engineer, should be involved early in the planning and design process and should be an integral part of the project team. Moreover, moving forward, we should start seeking out sustainable environmentally friendly fire-suppression approaches to reduce the environmental impacts during design and testing and also to help a project earn LEED credits.

Fire protection systems play an increasingly pivotal role in overall building design and construction and should never be comprised because they serve the purpose of life safety. Indeed, it is frequently argued that the life safety system is the most important system to be evaluated in a facility, particularly when it comes to high-rise structures. Furthermore, like any other building system, green concepts and specifications can be applied to their design, installation, and maintenance in a manner that reduces their harmful impacts on the environment. Moreover, there have been significant advances recently in fire-detection technology and fire suppression systems in addition to an ongoing development of international and national codes and standards all of which have made possible the “greening” of facility fire safety systems and which is taking on increasing importance for building owners and property developers.

For optimum efficiency, the various components of modern fire-protection systems should work in cohesion to detect, contain, control, and/or extinguish a fire in its early stages—and to survive during the fire. And the installation of environmentally friendly fire-protection technology can help earn credits under the U.S. Green Building Council’s LEED Green Building Rating System for new or retrofitted buildings. A facility’s type, size, and function will generally determine the complexity of the life safety system used.

In some of the smaller structures, the system may comprise of only smoke detectors and fire extinguishers. In other larger more complex buildings, a complete fire suppression system such as fire sprinklers is installed throughout the facility. An important aspect in the assessment of any life safety system includes verification that periodic maintenance, inspection, and testing of the main components of the system is being conducted. Fig. 9.29 illustrates several types of life safety systems normally employed to address fire safety requirements. Each of these gives rise to their own set of issues which need to be taken into account in facility surveys.

The extent of a life safety system survey and the expertise required to perform such an evaluation varies greatly from facility to facility depending on its size and complexity. Additionally, fire detection and prevention technologies have become increasingly sophisticated, intelligent, and powerful in recent years. Frank Monikowski and Terry Victor of SimplexGrinnell highlight some of the advances and emerging technologies that can be found in today’s Life/Safety systems such as:

• Suppression Sprinklers—operate quickly for high-challenge fires and are expected to extinguish a fire by releasing a high density of water directly to the base of the fire.

• Fast-Response Sprinklers—provide quicker response and are now required for all light-hazard installations.

• Residential Sprinklers—designed specifically to increase the survivability of an individual who is in the room where a fire originates.

• Extended coverage sprinklers—designed to reduce the number of sprinklers needed to protect a given area. These come in quick response, residential, and standard-response types and are also available for both light- and ordinary-hazard occupancies.

• Special sprinklers, such as Early Suppression Fast Response (ESFR)—designed for high-challenge rack storage and high-pile storage fires. In most cases, these sprinklers can eliminate the expense and resources needed to install in-rack sprinkler heads.

• Low-pressure sprinklers—provide needed water coverage in multistorey buildings where pressure may be reduced. These low-pressure sprinklers bring a number of benefits: reduced pipe size, reduction or elimination of a fire pump, and overall cost savings.

• Sprinkler system valves that are smaller, lighter, and easier to install and maintain and, therefore, less costly.

• A Fluid Delivery Time computer program that simulates water flowing through a dry system in order to accurately predict critical “water-to-fire” delivery time for dry-pipe systems.

• Cost-efficient CPVC piping for light-hazard and residential sprinkler systems.

• Advanced coatings on steel pipes, designed to resist or reduce Microbiologically Influenced Corrosion (MIC) and enhance sprinkler system life.

• Corrosion monitoring devices to alert users of potential problems.

• More efficient coordination in evaluating building sprinkler system need—including site surveys, accurate measurements, and the use of CAD and hydraulics software to ensure that fire sprinkler system designs respond to the specific risks and the physical layout of the premises.

According to the NFPA, more than 43 million Americans have a disability, which is partly why the NFPA recently developed and issued a new Emergency Evacuation Planning Guide for People with Disabilities. This document provides general information to assist designers in identifying the needs of people with disabilities related to emergency evacuation planning. This guide covers five general categories of disabilities which are mobility impairments, visual impairments, hearing impairments, speech impairments, and cognitive impairments. The four elements of evacuation information needed by occupants are notification, wayfinding, use of way, and assistance.

9.8.1. LEED Contributions

Fire sprinklers have been an essential component in stopping fire growth and minimizing greenhouse and toxic gas production for over a century. Yet they are not given any credit in the USGBC’s LEED certification program. In fact, fire suppression systems are only indirectly referenced in LEED certification documents. For example, LEED for New Construction (LEED-NC) V3 Energy and Atmosphere (EA) Credit 4, Enhanced Refrigerant Management, and LEED for Existing Buildings: Operations & Maintenance (LEED EBOM) V3 EA Credit 5, Refrigerant Management, the intent being reducing ozone depletion, supporting compliance with the Montreal Protocol and minimizing direct contributions to global warming.

It appears that credits can be earned with the installation/operation of fire suppression systems that do not contain ozone-depleting substances such as CFCs, HCFCs, and halons. Likewise, LEED credits in the Innovation in Design category can also be obtained for fire suppression systems. The LEED Reference Guide in the relevant category should be consulted, but generally, to earn those points, it is necessary to document and substantiate the innovation and design processes used. Dominick G. Kasmauskas who is with the National Fire Sprinkler Association says, “The fire sprinkler industry plans to work with the USGBC to develop a credit for fire sprinklers in future editions of LEED based on the environmental benefits of sprinkler systems.”

9.8.2. Sprinkler Systems

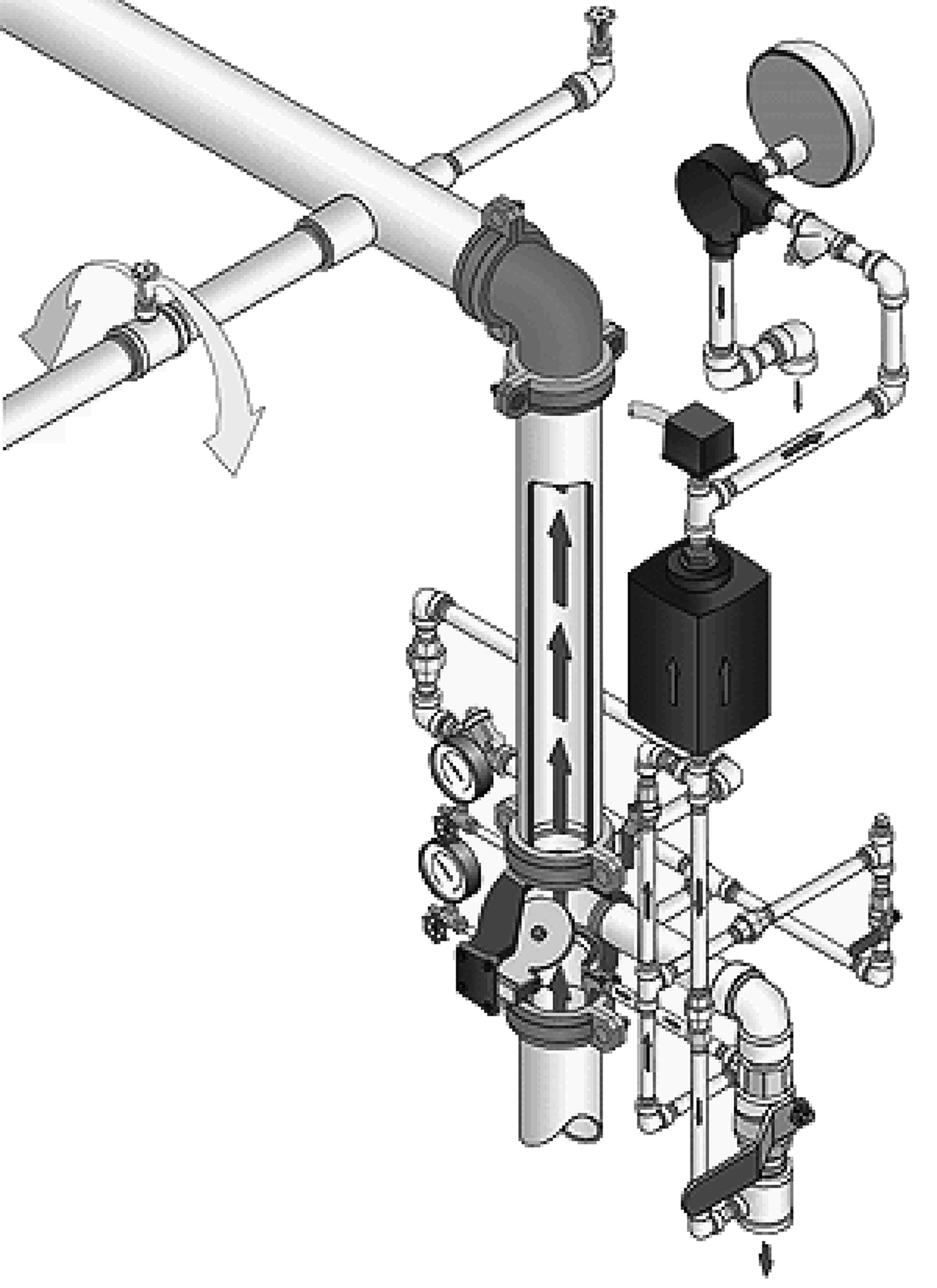

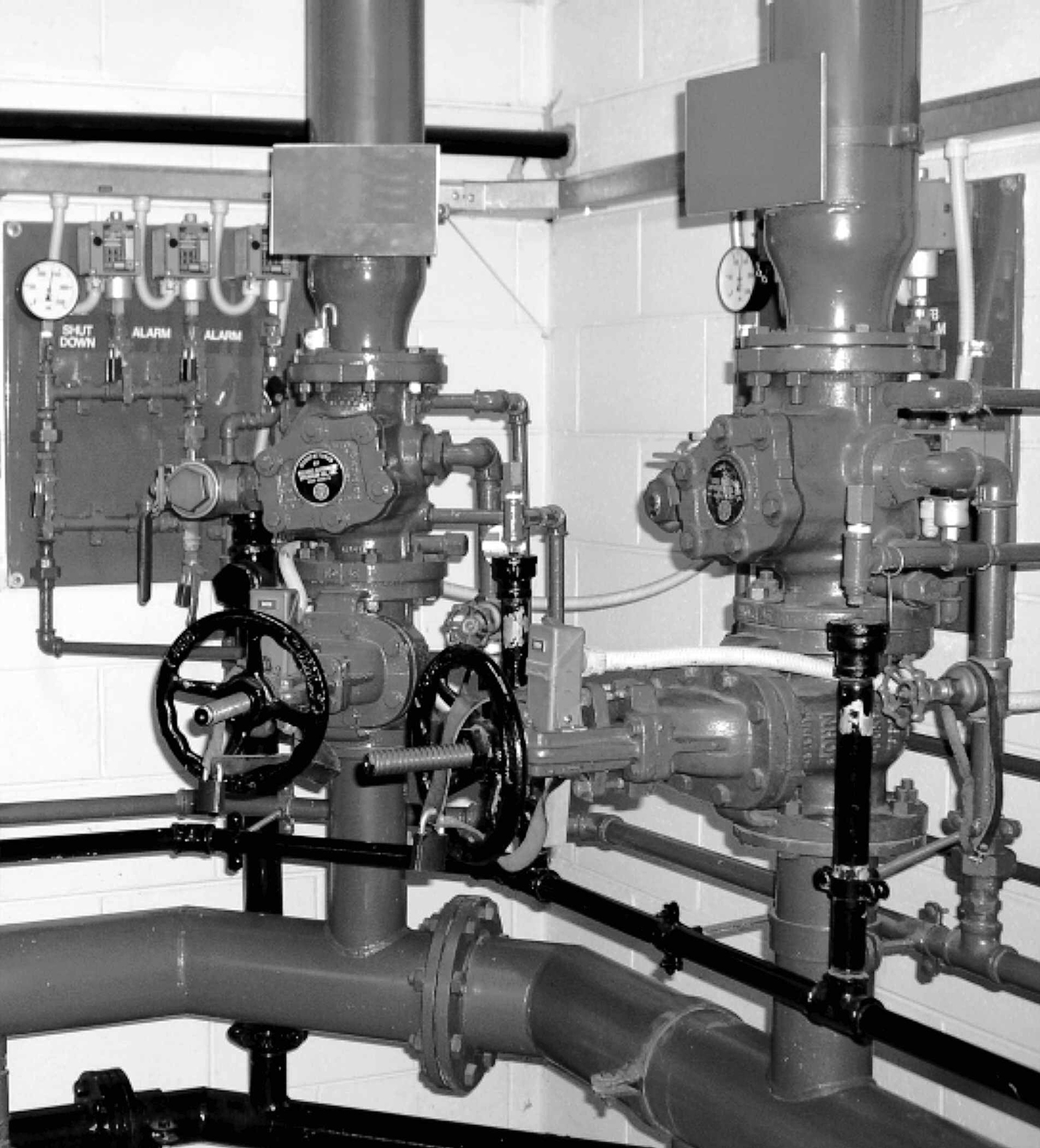

Since the dawn of history, people have used water as an extinguishing agent and today it is still the preferred choice for modern fire protection in the form of sprinklers and other methods. Sprinklers are the most common, widely specified and most effective fire suppression system in commercial facilities—particularly in occupied spaces. The various types of sprinkler systems are outlined next. However, in situations where the use of sprinklers is not feasible because of special considerations (e.g., water from sprinklers would damage sensitive equipment or inventory), alternative fire suppression systems might be decided upon, such as gaseous/chemical suppression. In the final analysis, the type of sprinkler system employed depends largely on a building’s function. When a system is operating as designed, fire sprinkler systems are highly reliable. However, like any other mechanical system, sprinkler systems need periodic maintenance and inspection in order to sustain proper operation. In the rare event a sprinkler system fails to control a fire, the root cause of failure is often the lack of proper maintenance (Fig. 9.30).

Automatic Sprinkler Systems

Optimized sprinkler system designs offer an effective means of addressing environmental impact and sustainability. Also, as they are the most widely specified, and most effective fire suppression system in commercial facilities, automatic sprinkler systems are now not only required in new high-rise office buildings, but in many American cities it is mandated by code that existing high rises be retrofitted with automatic sprinkler systems. There are several types of sprinkler systems that are commonly used, these include wet and dry pipes, preaction, deluge, and fire cycle systems. Of these, wet pipe and dry pipe are the most common. In a wet pipe system, the sprinklers are connected to a water supply, enabling immediate discharge of water at sprinkler heads triggered by the heat of the fire. In a dry pipe system, the sprinklers are under air pressure which, when the pressure is eased by the opening of the sprinkler heads, fills the system with water.

Figure 9.30 Typical fire sprinkler control valve assembly including pressure switches and valve monitors. Courtesy: Wikipedia.

Careful attention should be given to proper connections for flow and flow testing when designing automatic sprinkler systems. Likewise, flexible connections and arm overs may be employed to provide a means for facilitating the relocation of sprinklers with minimal need for additional materials if the system designer incorporates appropriate flow restrictions due to friction losses. In cases where employing water sprinklers are not feasible due to special considerations (e.g., water from sprinklers would damage sensitive equipment or inventory), alternative fire suppression systems such as gaseous/chemical suppression may be considered. But in the final analysis, the type of sprinkler system decided upon depends mainly on a building’s function. Of note, the majority of today’s fire sprinklers incorporate the latest advances in design and engineering technologies, thereby providing a very high level of life safety and property protection. The features and benefits now available are making fire sprinkler systems more efficient, reliable, and cost-effective. And as the benefits of sprinkler systems become better understood and more obvious, and the cost more affordable, their installation in residential structures is becoming more common. However, these sprinkler systems typically fall under a residential classification and not a commercial one.

The main difference between commercial and residential sprinkler systems is that a commercial system is designed to protect the structure and the occupants from a fire, whereas most residential systems are primarily designed to suppress a fire in a manner that allows for the safe escape of the building occupants. While these systems will often also protect the structure from major fire damage, this consideration nevertheless remains of secondary importance. In residential structures sprinklers are typically omitted from closets, bathrooms, balconies, and attics because a fire in these areas would not normally impact an occupant’s escape route. When a system is operating as intended, fire sprinkler systems are highly reliable, but like any other mechanical system, sprinkler systems require periodic maintenance and inspection in order to sustain proper operation. In the rare event a sprinkler system does fail to control a fire, the root cause of failure has often been found to be the lack of proper maintenance.

Wet pipe systems: Wet pipe sprinkler systems are the most common and have the highest reliability. Wet Systems are typically used in buildings where there is no risk of freezing. The systems are simple with the only operating component being the automatic sprinkler. A water supply provides pressure to the piping, and all of the piping is filled with water adjacent to the sprinklers. The water is held back by the automatic sprinklers (Fig. 9.31) until activated. When one or more of the automatic sprinklers is exposed to sufficient heat, the heat-sensitive element releases, allowing water to flow from that sprinkler. Each sprinkler operates individually. Sprinklers are manufactured to react to a specific range of temperatures, and only sprinklers subjected to a temperature at or above their specific temperature rating will operate. Fig. 9.32 shows a drawing of a typical wet pipe sprinkler system. The principal disadvantage of these systems is that they are not suited for subfreezing environments.

Dry Pipe Systems

This is the second most common sprinkler system type currently in use after the wet pipe system. A dry pipe sprinkler system is one in which pipes are filled with pressurized air or nitrogen, rather than water. This air holds a remote valve, known as a dry pipe valve, in a closed position. The dry pipe valve is located in a heated space and prevents water from entering the pipe until a fire causes one or more sprinklers to be activated. Once this happens, the air escapes and the dry pipe valve releases. To prevent the larger water supply pressure from forcing water into the piping system, the design of the dry pipe valve intentionally includes a larger valve clapper area exposed to the specified air pressure, as compared to the water pressure. Water then enters the pipe, flowing through open sprinklers onto the fire. However, regulations (NFPA 13 2007 ed. Sections 7-2 and A7-2) typically stipulate that these systems can only be used in spaces in which the ambient temperature may be cold enough to freeze the water in a wet pipe system, thus rendering it inoperable. For this reason we often find dry pipe systems used in unheated buildings and refrigerated coolers.

Activation (becomes operational) of the system takes place when one or more of the automatic sprinklers are exposed to sufficient heat, allowing the maintenance air to vent from that sprinkler. Each sprinkler operates individually. As the air pressure in the piping drops, the pressure differential across the dry pipe valve changes, allowing water to enter the piping system. Delays can be experienced in dry pipe systems, since the air pressure must drop before the water can enter the pipes and suppress the fire. Dry pipe systems are therefore not as effective as wet pipe systems in fire control during the initial stages of the fire although aid in faster activation, dry pipe valves may employ quick opening devices connected to them.

Deluge and Preaction Systems

These systems are less common and are used mainly in environments that require special sprinkler protection and are activated by fire detection systems. Deluge and preaction systems represent only a small percentage of market share of the total sprinkler systems currently in operation. The deluge fire sprinkler systems feature open-type sprinkler heads that are attached to a dry pipe which is connected to a main water supply. The utilization of an innovative detection system that recognizes smoke or heat, enables this fire suppression installation to activate a valve that releases water to all sprinklers.

Deluge systems are similar to preaction systems except that the sprinkler heads are open and the pipe is not pressurized with air. This means that in a Deluge system the heat sensing operating element is removed during installation, so that all sprinklers connected to the water piping system remain open by the operation of a smoke or heat detection system. These detection systems are normally installed in the same area as the sprinklers, so that when the detection system is activated, water readily discharges through all of the sprinkler heads in the system.

These systems are typically used in high hazards areas because they provide a simultaneous application of water over the entire hazard and where rapid fire spread is a major concern such as power plants, aircraft hangars, and chemical storage facilities. Water is not present in the piping until the system operates. Because the sprinkler orifices are open, the piping is at ambient air pressure. To prevent the water supply pressure from forcing water into the piping, a deluge valve is used in the water supply connection, which is a mechanically latched nonresetting valve that stays open once tripped. Because the heat-sensing elements present in the automatic sprinklers have been removed (resulting in open sprinklers), the deluge valve must be opened as signaled by a specialized fire alarm system. The type of fire alarm activation device used is based largely on the hazard (e.g., smoke detectors or heat detectors). The activation/initiation device signals the fire alarm panel, which in turn signals the deluge valve to open. Activation can also be achieved manually, depending on the system goals. Manual activation is usually via an electric or pneumatic fire alarm pull station, which signals the fire alarm panel, which in turn signals the deluge valve to open, allowing water to enter the piping system. Water flow effectively takes place from all sprinklers simultaneously.

Preaction sprinkler systems, on the other hand, are specialized systems that combine a fire detection system with a sprinkler system. They are typically used to ensure reliable protection against false alarms in locations where accidental activation is undesired, such as in museums containing rare art works, or computer suites, etc. These sprinkler systems employ the basic concept of a dry pipe system in that water is not normally contained within the pipes. It differs from the dry pipe system however, in that water is held from entering the piping by an electrically operated valve, known as a preaction valve. Valve operation is controlled by a signal from the fire detection system, not by a fall in pressure after a sprinkler has opened. If there is a fault on the fire detection system, a preaction system is switched over to operate as a normal dry system. Preaction systems are hybrids of wet, dry, and deluge systems, depending on the exact system goal.

Preaction systems can be either single interlock or double interlock. The operation of single interlock systems are similar to dry systems except that these systems require that a “preceding” and supervised event (typically the activation of a heat or smoke detector) takes place prior to the “action” of water introduction into the system’s piping due to opening of the preaction valve (i.e., a mechanically latched valve). The operation of double interlock systems is similar to a deluge system except that automatic sprinklers are used. Upon detection of the fire by the fire alarm system, it basically converts from a dry system into a wet system.

Water Mist Systems

Water mist systems consist of environmentally friendly systems that normally force water and pressurized gas together through stainless-steel tubes that are much narrower in diameter than pipes used in traditional sprinkler systems. The water mist system produces a fine mist with a large surface area that absorbs heat efficiently through vaporization. These systems are totally safe for humans because they utilize water as the extinguishing medium. With these systems, fires are suppressed using three main mechanisms:

1. As the water droplets contact the fire they convert to steam. This process absorbs energy from the surface of the burning material.

2. As the water turns into steam it expands greatly. This removes heat and lowers the temperature of the fire and the air surrounding it.

3. The water and the steam act to block the radiant heat and prevent the oxygen from reaching the fire (thus starving it of oxygen) so the fire smothers.

Water mist systems can be useful for suppressing fires in gas turbine enclosures, and machinery spaces and are FM (i.e., Factory Mutual) approved for such applications. Water mist systems are ideally suited for cultural heritage buildings where large amounts of water can potentially cause unacceptable damage to irreplaceable items and in retrofits where space is often limited. Water mist systems are also often used to protect passenger cruise ships, where the system’s excellent performance and low total system weight have made them very popular.

Foam–Water Sprinkler Systems

This type of sprinkler system is a special application system, discharging a mixture of water and low-expansion foam concentrate, resulting in a foam spray from the sprinkler. These systems are generally more economical than a water-only system, when evaluated for the same risk, and provide for actual extinguishment of the fire and a lower water demand. The conversion assists in the reduction of property loss, loss of life, and in many cases the reduction of insurance rates. But while foam concentrates and expanded foams are generally considered to be safe with regard to exposure to humans, they can unless specifically indicated, adversely impact the environment if allowed to flow freely into watershed areas. The base properties of typical foaming agents include nitrates, phosphorous, and organic carbon. It should be noted that the use of halons in fire suppression systems was phased out in the early 1990s to comply with the Montreal Protocol because they were determined to cause significant damage to the ozone layer. Moreover, halons have a long life in the atmosphere and a high GWP.

One of the characteristics of this system is that almost any sprinkler system—wet, dry, deluge, or preaction can be readily adapted to include the injection of AFFF foam concentrate in order to combat high risks situations. These systems are typically used with special hazards occupancies associated with high challenge fires, such as flammable liquids, and airport hangars. Added components to the sprinkler system riser include bladder tanks to hold the foam concentrate, concentrate control valves to isolate the sprinkler system from the concentrate until activation, and proportioners for mixing the appropriate amount of foam concentrate with the system supply water. The main standard that delineates the minimum requirements for the design, installation, and maintenance of foam–water sprinkler and spray system is NFPA 16 (National Fire Protection Association 16): Standard for the installation of Foam–Water Sprinkler and Foam–Water spray systems.

The checklist below is provided by the New York Property Insurance Underwriting Association to help identify general problems that may arise in typical sprinkler systems. This checklist is intended to identify what is required to be done and to assure that the sprinkler system is properly maintained:

• Are sprinkler heads free of paint, dust, and grease?

• Are the sprinkler heads obstructed by stored material? There should be no less than 18 inches of clearance at each head. Obstructions will diminish the operation of the head.

• Are the sprinkler pipes used to support lighting or other objects?

• Are there extra sprinkler heads and wrenches located at the control area for maintenance purposes?

• Is the O.S.&Y. valve chained in an open position to avoid disabling of the system?

• Are the sprinkler heads directed properly for their location?

• Is there a sprinkler contractor that supervises and inspects the system as required by N.F.P.A. and ISO? Is a service log maintained?

• Are the sprinkler alarms activated to protect your property in the event of accidental discharge or fire?

• Has the occupancy classification of the material in the building changed since its installation so that the sprinkler system is now ineffective?

• Is the heat supply in the premises adequate for the operation of a wet pipe system?

Fire Hose and Standpipe Systems

Michael O’Brian, president of Code Savvy Consultants says, “Standpipes are a critical tool that requires preplanning on first responding apparatus in order to be used effectively. The initial approval process for these systems is critical and the fire prevention bureau can assist responding crews by ensuring proper installation and maintenance of these systems. Standpipe systems vary in design, use, and location. These factors vary based on the adopted code; the use, size, and type of building they are installed in. Typically, model codes refer to NFPA 14, Standpipe and Hose Systems for the design, installation, and maintenance of these systems.”

Standpipe Systems consist of piping, valves, outlets, and related equipment designed to provide water at specified pressures and installed exclusively for the fire department or trained occupant use for the fighting of fires. These systems are used in conjunction with sprinklers or hoses, and basically consist of a water pipe riser running vertically through the building, although sometimes a building is provided with only piping for the standpipe system.

Standpipe systems can be wet or dry. Dry systems are normally empty and are not connected to a water source. A Siamese fitting is located at the bottom end of the pipe, allowing the fire department to pump water into the system. In a wet-type system, the pipe is filled with water and attached to a tank or pump. This type also contains Siamese fittings for the fire department’s use.

O’Brian says, “Many buildings are required to have an Automatic Class I standpipe system with a design pressure of 100 psi. Based on friction loss, municipal water supply, and pressure loss for the height of the standpipe a fire pump may need to be designed into the system. Due to the pressure requirements standpipes are limited to a maximum height of 275 ft. Those buildings over 275 ft in height will require the standpipe systems to be split in different pressure zones.”

Model fire and building codes stipulate among other things, the requirements for the installation of standpipe systems. The specific type of system is based on the occupancy classification and building height. The three main classifications of Standpipe systems are:

• Class I standpipe signifies that it equipped with a 2.5-inch (64 mm) fire hose connection for fire department use and those trained in handling heavy fire streams. These connections must match the hose thread utilized by the fire department and are typically found in stairwells of buildings. In high-rise buildings which do not have sprinklers and beyond the reach of fire department ladders, Class I systems provide water supply for the primary means of firefighting, i.e., manually.

• Class II standpipe system is one directly connected to a water supply and serves a 1.5-inch (38 mm) fire hose connection that provides a means for the control or extinguishment of incipient-stage fires. They are typically found in cabinets, are intended for trained occupant use, and are spaced according to the hose length. The hose length and connection spacing is intended for all spaces of the building.

• Class III standpipe system is a combined standpipe system (i.e., combining both Class I and II connections) directly connected to a water supply and is for the use of in-house personnel capable of furnishing effective water discharge during the more advanced stages of fire in the interior of workplaces. Many times these connections will include a 2.5-inch reducer to a 1.5-inch connection.

When a standpipe system control valve is located within a stairwell, the maximum length of hose should not exceed 100 ft. If the control valve is located in areas other than the stairwell, the length of hose should not exceed 75 ft. Code requires that fire hoses on Class II and Class III standpipe systems be equipped with a shutoff-type nozzle.

9.8.3. Handheld Fire Extinguishers

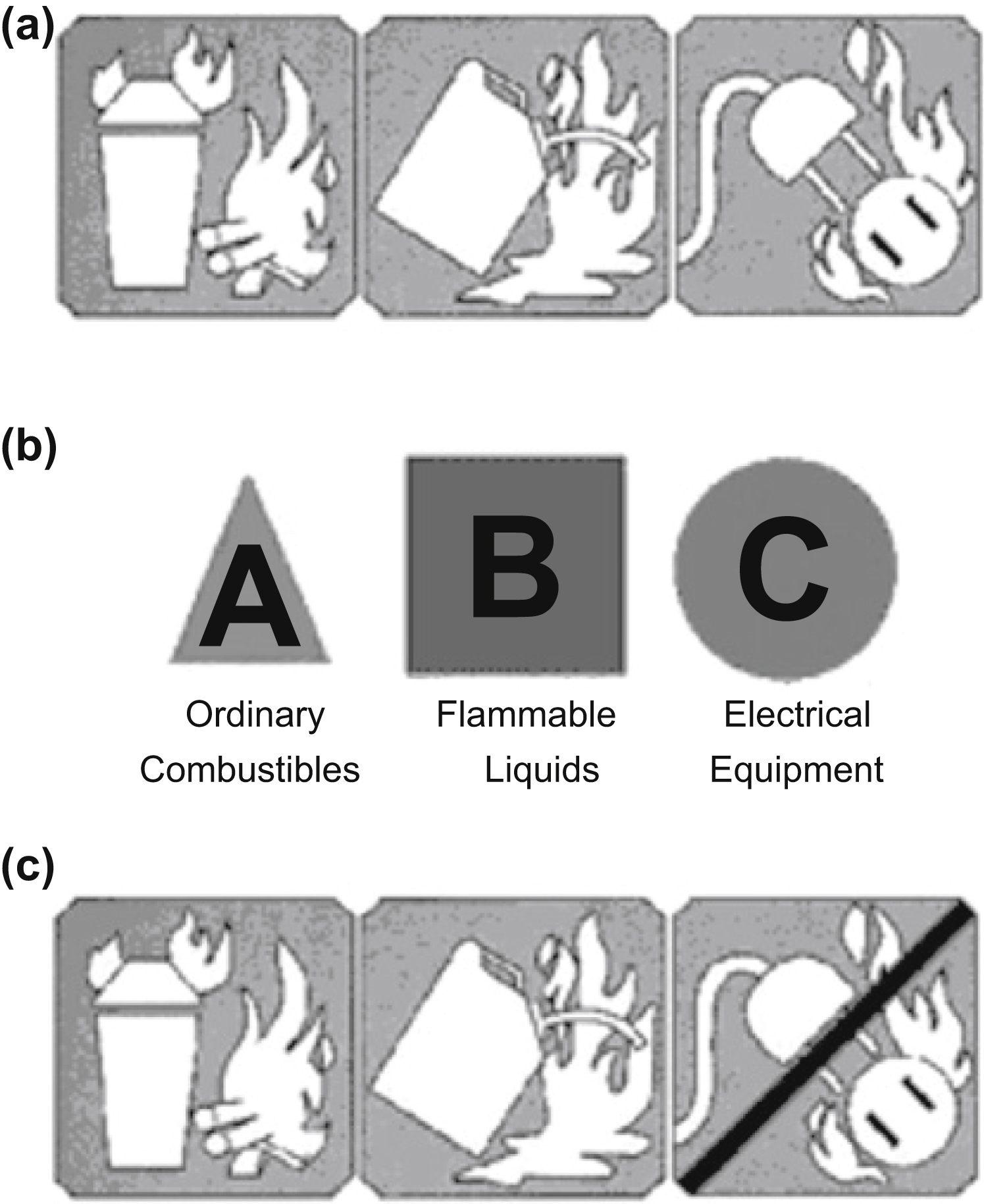

There are several different classifications of fire extinguishers, each of which extinguishes specific types of fire (Fig. 9.33). Newer fire extinguishers use a picture/labeling system to designate which types of fires they are to be used on, whereas older fire extinguishers are labeled with colored geometrical shapes with letter designations (Fig. 9.34).

Classification of HandHeld Fire Extinguisher

The U.S. Department of Labor says, “Portable fire extinguishers are classified to indicate their ability to handle specific classes and sizes of fires. Labels on extinguishers indicate the class and relative size of fire that they can be expected to handle.” These classifications are as follows:

Class A Fire Extinguishers are designed to put out fires caused by organic solids and ordinary combustibles like wood, textiles, paper, some plastic, and rubber. The numerical rating for this class of fire extinguisher refers to the amount of water the fire extinguisher holds and the amount of fire it will extinguish. To extinguish a Class A fire, extinguishers utilize either the heat-absorbing effects of water or the coating effects of certain dry chemicals. Class A fire extinguishers should be clearly marked with a triangle containing the letter “A.” If in color, the triangle should be green.

Class B Fire Extinguishers are used to put out fires involving Flammable and Combustible Liquids and Gases. They work by starving the fire of oxygen and interrupting the fire chain by inhibiting the release of combustible vapors. Class B fires include gasoline, oil, and paraffin. The numerical rating for this class of fire extinguisher states the approximate number of square feet of a flammable liquid fire that a nonexpert person can expect to extinguish. This includes all hydrocarbon- and alcohol-based liquids and gases that will support combustion. Class B fire extinguishers should be clearly marked with square containing the letter “B.” If in color, the square should be red.

Figure 9.33 Various types of fires extinguishers in common use: (1) MP series multipurpose dry chemical; (2) DC series regular dry chemical; (3) WC series wet chemical; (4) WM series water mist; (5) CD series carbon dioxide; (6) HT series Halotron I. Source: Larsen’s Manufacturing Co.

Figure 9.34 New and old style labeling systems indicating suitability for use on Class A, B, and C fire extinguishers.

Class C Fire Extinguishers are most effective for use on fires that involve live electrical equipment where a nonconducting material is required. This class of fire extinguishers does not have a numerical rating, but the presence of the letter “C” indicates that the extinguishing agent is nonconductive. Class C fire extinguishers should be clearly marked by a circle containing the letter “C.” If in color, the circle should be blue.

Class D Fire Extinguishers are special types designed and approved for specific combustible materials (metals) such as magnesium, titanium, zirconium, potassium, sodium, etc., which require an extinguishing medium that does not react with the burning metal. Class D fire extinguishers should be clearly marked by a five-point painted star containing the letter “D.” If in color, the star should be colored yellow. These extinguishers generally have no rating nor are they given a multipurpose rating for use on other types of fires.

Class K Fire Extinguishers are effective for fighting fires involving cooking fats, grease, oils, etc., in commercial cooking environments. These fire extinguishers work on the principle of saponification, which takes place when alkaline mixtures such as potassium acetate, potassium citrate, or potassium carbonate are applied to burning cooking oil or fat. The alkaline mixture combined with the fatty acid creates soapy foam on the surface which holds in the vapors and steam and extinguishes the fire. Class K fire extinguishers should be clearly marked with the letter “K.”

Labeling

If a multipurpose extinguisher is being used and in order for users to be able to quickly identify the classification of a fire extinguisher in the event of an emergency, each unit should be clearly labeled. The approved marking system combines pictographs of both recommended and unacceptable extinguisher types on a single identification label. Many extinguishers available today can be used on different types of fires and will be labeled with more than one designator, e.g., A-B, B-C, or A-B-C. It should also be noted that British Standards and classifications differ slightly from American Standards and classifications.

Types of Fire Extinguishers

There are several types of fire extinguishers, the most important being:

Dry Chemical extinguishers come in a variety of types and are usually rated for multiple purpose use (class A, B, and C fires). They are filled with a foam or powder extinguishing agent and use a compressed, nonflammable gas as a propellant. One advantage a dry chemical extinguisher has over a CO2 extinguisher is that it leaves a nonflammable substance on the extinguished material, reducing the likelihood of reignition.

Water extinguishers or APW extinguishers (air-pressurized water) are filled with water and pressurized with oxygen. APW extinguishers should only be used on Class A (ordinary combustibles) fires and never on grease fires, electrical fires, or class D fires—the flames will only spread and likely make the fire bigger.

Carbon Dioxide (CO2) extinguishers contain carbon dioxide, a nonflammable gas, and are highly pressurized. They are most effective on Class B and C (liquids and electrical) fires. Since the gas disperses quickly, these extinguishers are only effective from 3 to 8 ft. The carbon dioxide is stored as a compressed liquid in the extinguisher; as it expands, it cools the surrounding air. The cooling will often cause ice to form around the “horn” where the gas is expelled from the extinguisher. However, they do not work very well on class A fires because they may not be able to displace enough oxygen to put the fire out, causing it to reignite. The advantage of CO2 extinguishers has over dry chemical extinguishers is that they do not leave a harmful residue and may therefore be a good choice for an electrical fire on a computer or other favorite electronic device such as a stereo or TV.

Halon extinguishers contain a gas that interrupts the chemical reaction that takes place when fuels burn. Halon is an odorless, colorless gas that can cause asphyxiation and halon extinguishers have a limited range, usually 4–6 ft. An advantage of halon is that it is a clean agent because it leaves no corrosive or abrasive residue after release, minimizing cleanup which makes it more suitable for valuable electrical equipment, computer rooms, telecommunication areas, theaters, etc. However, pressurized fire suppression system cylinders can be hazardous and if not handled properly are capable of violent discharge. Moreover, the cylinder can act as projectile, potentially causing injury or death. Halon has been banned from new production, except for military use, since January 1, 1994 because its properties contribute to ozone depletion and long atmospheric lifetime, usually 400 years. However, Halon reuse is still permitted in the United States.

NFPA Code 10 addresses all the issues pertaining to portable fire extinguishers and contains the clear, widely accepted rules for distribution and placement, maintenance, operation, inspection, testing, and recharging. Recognized as a first line of defense against fires, portable extinguishers when maintained and operated properly on a small containable fire, can prevent it from spreading beyond its point of origin. NFPA Code 10 requires owners of extinguishers to have monthly inspections performed and to maintain records of the inspections.

9.8.4. Smoke and Heat Detection Systems

Smoke and heat detection systems play a pivotal role in green buildings. Kate Houghton, Director of marketing for Kidde Fire Systems says, “By detecting a fire quickly and accurately (i.e., by not sacrificing speed or causing false alarms) and providing early warning notification, a fire-detection system can limit the emission of toxic products created by combustion, as well as global-warming gases produced by the fire itself. These environmental effects often are overlooked, but undoubtedly occur in all fire scenarios. Therefore, reducing the likelihood of a fire is an important part of designing a green building.”

A smoke detector or smoke alarm is a device that detects smoke and issues an alarm to alert nearby people of the threat of a potential fire. Smoke alarms that are properly installed and maintained play a critical role in reducing fire deaths and injuries. Household smoke detectors will typically be mounted in disk-shaped plastic enclosures about 150 mm in diameter and 25 mm thick, but the shape can vary by manufacturer (Fig. 9.35). Because smoke rises, most detectors are mounted on the ceiling or on a wall near the ceiling. It is imperative that smoke detectors are regularly maintained and checked that they operate properly. This will ensure early warning to allow emergency responses to occur well before a fire causes serious damage. It is not uncommon for modern types of systems to detect smoldering cables or overheating circuit boards. Smoke detectors are typically powered by one or more batteries but some can be connected directly to a building’s wiring. Often the smoke detectors that are directly connected to the main wiring system also have a battery as a power supply backup in case the facility’s wiring goes out. Batteries should be checked and replaced periodically to ensure appropriate protection. Early detection can save lives and help limit damage and downtime. Laws governing the installation of smoke detectors may differ from one jurisdiction to another.

Most smoke detectors work either by optical detection or by ionization, and in some cases both detection methods are used to increase sensitivity to smoke. A complete fire-protection system will typically include spot smoke detectors that can signal a fire control panel to deploy a fire suppression system. Smoke detectors can either operate alone or be interconnected to cause all detectors in an area to sound an alarm if one is triggered, or be integrated into a fire alarm or security system. Smoke detectors with flashing lights are also available for the deaf or hearing impaired. Smoke detector cannot detect carbon monoxide to prevent carbon monoxide poisoning unless they come with integrated carbon monoxide detectors.

Aspirating smoke detectors (ASD) can detect combustion at the early stages and are 1000 times more sensitive than conventional smoke detectors, giving early warning to building occupants and owners. An ASD consists of a central detection unit which draws air through a network of pipes to detect smoke, and in most cases requires a fan unit to draw in a representative sample of air from the protected area through its network of pipes. Although ASDs are extremely sensitive and are capable of detecting smoke before it is even visible to the human eye, their use is not recommended in environments that are unstable due to the wide range of particle sizes that are detected.

Optical Smoke Detectors are light sensors. When used as a smoke detector it includes a light source (infrared LED), a lens to collimate the light into a beam like a laser, and a photodiode or other photoelectric sensor at right angles to the beam as a light detector. Under normal conditions (i.e., in the absence of smoke) the sensor device detects no light signal and therefore produces no output. The source and the sensor device are arranged so that there is no direct “line of sight” between them. When smoke enters the optical chamber into the path of the light beam, some light is scattered by the smoke particles, and some of the scattered light is detected by the sensor, and the alarm is set off by the increased input of light into the sensor.

Projected beam detectors are not like traditional detection systems. Reflected Beam Smoke Detectors were designed for spacious rooms, open areas, and high ceilings; their innovative features make them popular choices for spaces like warehouses, atriums, arenas, and churches. They usually require only one device to install and align, thus saving time and money on open-area and high-ceiling applications. A unit on the wall typically transmits a beam, which is either received by a receiver, or reflected back via a mirror. When the beam is less visible to the “eye” of the sensor, it sends an alarm signal to the Fire alarm control panel (FACP). Optical smoke detectors are generally quick in detecting slow burning, smoky fires.

Ionization detectors are sometimes known as an ionization chamber smoke detector, is capable of quickly sensing flaming fires that produce little smoke. It employs a radioactive material (a very small amount of americium-241) to ionize the air in a sensing chamber; the presence of smoke affects the flow of the ions between a pair of electrodes, which triggers the alarm. While over 80% of the smoke detectors in American homes are of this type and although ionization detectors are less expensive than optical detectors, they are frequently rejected for projects seeking LEED certification for environmental reasons. The majority of residential models are self-contained units that operate on a 9-V battery, but construction codes in some parts of the country now require installations in new homes to be connected to the house wiring, with a battery backup in case of a power failure.

Heat Detectors can detect heat and can be either electrical or mechanical in operation. They are set to alarm when ambient temperatures reach a fixed point, typically indicating a fire. Fixed-temperature heat detectors are a very cost-effective solution for many property protection applications. There are also combination heat detectors which are employed to provide both fixed and rate-of-rise detection, thus enabling the heat detector to communicate an alarm to the central control panel prior to reaching its fixed set point for high rates of rise, thus providing a timely response to both rapid and slow temperature increases. Most heat detectors are designed to trigger alarms and notification systems before smoke even becomes a factor. The most common types of heat detectors are the thermocouple and the electropneumatic, both of which respond to changes in ambient temperature. Typically, if the ambient temperature rises above a predetermined threshold, an alarm signal is triggered.

Good detection has many benefits (beyond triggering the alarm system) the main one being that in many cases, there is a chance to extinguish a small, early blaze with a fire extinguisher. Also, intelligent smoke detectors can differentiate between different alarm thresholds. These systems typically have remote detectors located throughout the facility which are connected to a central alarm system.

9.8.5. Fire Doors

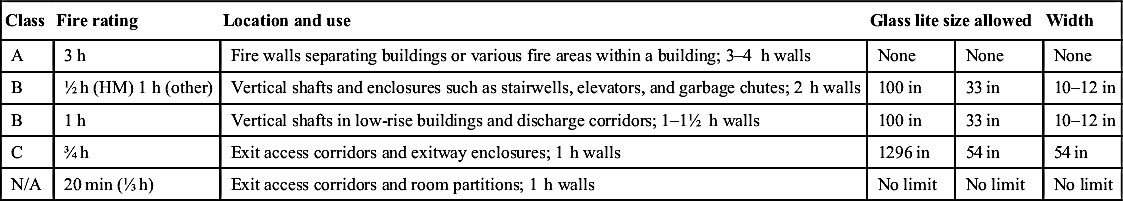

Fire doors form a vital component of a building’s passive fire protection system, and doors in a means of egress provide life safety by allowing people to exit quickly when necessary. Still, the requirements remain unclear for many architects and specifiers. Fire doors are essentially doors made of fire-resistant material that can be closed to prevent the spread of fire and are designed to provide extra fire-spread protection for certain areas of a building (Table 9.4). The fire rating classification of the wall into which a door is installed dictates the required fire rating of the door. The location of the wall in the building and prevailing building code establishes the wall’s fire rating. Fire doors are normally installed staircases from corridors or rooms, cross-corridor partition, to laboratories, plant rooms, workshops, storerooms, machine rooms, service ducts, and kitchens as well as to defined fire compartments. They are also employed in circulation areas which extend the escape route from the stair to a final exit or to a place of safety, and entrances and lobbies; at routes leading onto external fire escapes, and corridors that are protected from adjoining accommodation by fire-resisting construction.

Table 9.4

Fire-rated door and glass lites classification

| Class | Fire rating | Location and use | Glass lite size allowed | Width | |

| A | 3 h | Fire walls separating buildings or various fire areas within a building; 3–4 h walls | None | None | None |

| B | ½ h (HM) 1 h (other) | Vertical shafts and enclosures such as stairwells, elevators, and garbage chutes; 2 h walls | 100 in | 33 in | 10–12 in |

| B | 1 h | Vertical shafts in low-rise buildings and discharge corridors; 1–1½ h walls | 100 in | 33 in | 10–12 in |

| C | ¾ h | Exit access corridors and exitway enclosures; 1 h walls | 1296 in | 54 in | 54 in |

| N/A | 20 min (⅓ h) | Exit access corridors and room partitions; 1 h walls | No limit | No limit | No limit |

Fire door requirements are sometimes included within the applicable building or fire code, but NFPA 80 and 105 are typically referenced for many of the detailed requirements. According to the NFPA, doors are rated with respect to the number of hours they can be expected to withstand fire before burning through. There are 20-, 30-, 45-, 60-, 90-min rated fire doors as well as 2HR and 4HR rated fire doors that are certified by an approved laboratory such as Underwriters Laboratories (UL). Because Fire Doors are rated physical fire barriers that protect wall openings from the spread of fire, they are required to provide automatic closing in the event of fire detection. Fire doors should usually be kept closed at all times, although some fire doors are designed to stay open under normal circumstances, and are designed to close automatically or manually in the event of a fire. Fire Door release devices are electromechanical devices that enable automatic closing fire doors to respond to alarm signals from detection devices such as smoke detectors, heat detectors, and central alarm systems. This permits closing the door before high temperatures melt the fusible link. Fusible links should always be used as backup to the releasing device.

Fire-Rated Door Assemblies comply with NFPA 80 and are listed and labeled by UL, for the fire ratings indicated, based on testing according to NFPA 252. Assemblies must be factory-welded or come complete with factory-installed mechanical joints and must not require job fabrication on site.

Exit Routes

What is an exit route? As defined by OSHA, an exit route is a continuous and unobstructed path of exit travel from any point within a workplace to a place of safety. OSHA says that an exit route consists of three parts:

• Exit access—portion of an exit route that leads to an exit.

• Exit—portion of an exit route that is generally separated from other areas to provide a protected way of travel to the exit discharge.

• Exit discharge—part of the exit route that leads directly outside or to a street, walkway, refuge area, public way, or open space with access to the outside.

All buildings require fire exits which enable users to exit safely in the event of an emergency. Well-designed emergency exit signs are necessary for emergency exits to be effective. In the United States, fire escape signs often display the word “EXIT” in large, well-lit, green, or red letters. An exit route must be permanent and must be separated by fire-resistant materials. Construction materials used to separate an exit from other parts of the workplace must have a 1-h fire resistance rating if the exit connects three or fewer stories and a 2-h fire resistance rating if the exit connects four or more stories.

Unless otherwise stipulated by code, at least two exit routes must be provided in a workplace to permit prompt evacuation of employees and other building occupants during an emergency. The exit routes must be located as far away as practical from each other so that if one exit route is blocked by fire or smoke, employees can evacuate using the second exit route. More than two exit routes must be available in a workplace if the number of employees, the size of the building, its occupancy, or the arrangement of the workplace is such that all employees would not be able to evacuate safely during an emergency. Likewise, a single exit route is permitted where the number of employees, the size of the building, its occupancy, or the arrangement of the workplace is such that all employees would be able to evacuate safely during an emergency.

Exit routes must be free and unobstructed, and must be arranged so that employees are not required to travel toward a high hazard area, unless the path of travel is appropriately shielded from high hazard areas by suitable partitions or other physical barriers. No materials or equipment may be placed, either permanently or temporarily, along the exit route. The exit access must not go through a room that can be locked, such as a bathroom, to reach an exit or exit discharge, nor may it lead into a dead-end corridor. Where the exit route is not substantially level, it is necessary to have stairs or ramps.

OSHA requirements stipulate that each exit discharge must lead directly to the exterior or to a street, walkway, refuge area, public way, or open space with access to the outside. The street, walkway, refuge area, public way, or open space to which an exit discharge leads must be large enough to accommodate the building occupants likely to use the exit route. Exit stairs that continue beyond the level on which the exit discharge is located must be interrupted at that level by doors, partitions, or other effective means that clearly indicate the direction of travel leading to the exit discharge.

It is important to note that exit doors must not be locked from the inside, and each doorway or passage along an exit access that could be mistaken for an exit (such as a closet) must be marked “Not an Exit” or similar designation, or be identified by a sign indicating its actual use. Furthermore, exit route doors must be free of decorations or signs that obscure the visibility of the exit route door, and employees must be able to readily open an exit route door from the inside at all times without keys, tools, or special knowledge. A device such as a panic bar that locks only from the outside is permitted on exit discharge doors. Exit route doors may be locked from the inside only in mental, penal, or correctional facilities and then only if supervisory personnel are continuously on duty and the employer has a plan to remove occupants from the facility during an emergency.

Where a fall hazard exists in the use of an outdoor exit route, it must have guardrails to protect unenclosed sides. If snow or ice is likely to accumulate along the route it must be covered, unless it can be demonstrated that any snow or ice accumulation will be removed before it presents a slipping hazard. Also, the outdoor exit route must be reasonably straight and have smooth, solid, substantially level walkways, and must not have a dead-end that is longer than 20 ft (6.2 m).

To protect people and property during building fires requires the employment of three essential design elements:

• Alarms to provide early warnings,

• Automatic sprinklers or other suppression systems, and

• Fireproof compartments to contain flames and smoke.

These elements work together to give occupants time to escape and firefighters time to arrive. Eliminating any one of the three fire protection elements—detection, suppression, or compartmentation would compromise the integrity of the building.

Compartmentation

Building regulations in most jurisdictions stipulate that large buildings need to be divided into compartments and that these fire compartmentations must be maintained should a fire occur. In order to do this there are a range of fire-stopping products and methods available offering between 30 and 240 min fire compartmentation protection for construction movement joints and service penetrations. A fire compartment can therefore be defined as a space within a building extending over one or several floors that is enclosed by separating members such that the fire spread beyond the compartment is prevented during the relevant fire exposure. Fire compartments are sometimes referred to as Fire Zones. Compartmentation is critical to preventing a fire to spread into large spaces or into the whole building. It involves the specification of fire-rated walls and floors sealed with firestop systems, fire doors, and fire dampers, and the like. But to be effective the walls, floor, and ceiling need to contain flames and smoke within the compartment. These components must also provide sufficient insulation to prevent excessive heat radiating outside the compartment.

The division of the building into discrete fire zones offers perhaps the most effective means of limiting fire damage. Compartmentation techniques are designed to contain the fire to within the zone of origin, by limiting vertical and horizontal fire spread. Compartmentation also provides at least some protection for the rest of the building and its occupants even if first aid fire fighting measures are used and fail. It also provides protection for inventory and business operations and delays the spread of fire prior to the arrival of the fire brigade. But determining the required fire resistance for a compartment depends largely upon its intended purpose and on the expected fire. Either the separating members enclosing the compartment shall resist the maximum expected fire or contain the fire until occupants are evacuated. The load-bearing elements in the compartment must always resist the complete fire process or be classified to a certain resistance measured in terms of periods of time, which is equal or longer than the requirement of the separating members. The most important elements to be upgraded are the doors, floors, and walls, penetrations through floors and walls, and cavity barriers in the roof spaces. Halls and landings should typically be separated from staircases to prevent a fire from traveling vertically up or down the stairwell to the other floors. However, creation of new lobbies can have an unacceptable negative impact on the character of a fine historic interior. To be effective therefore, compartmentation needs to be correctly planned and implemented.

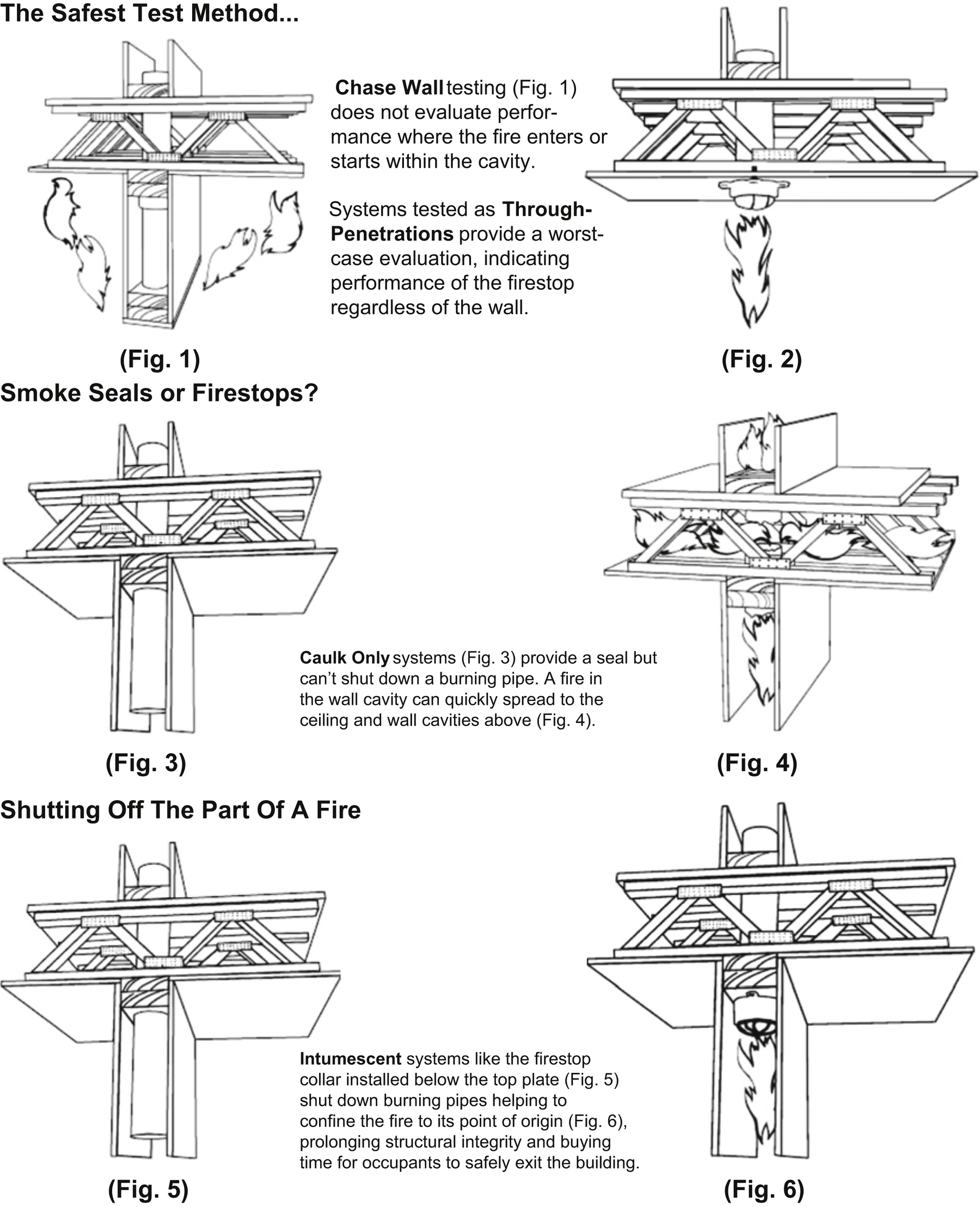

The main function of fire stopping is to stop the spread of fire between floors of a building. Flame retardant material is installed around floor openings designed to contain conduit and piping. A firestop is a product that when properly installed, impedes the passage of fire, smoke, and toxic gases from one side of a fire-rated wall or floor assembly to another. Typical firestop products include sealants, sprays, mechanical devices (firestop collar), foam blocks, or pillows. These products are installed primarily in two applications: (1) around penetrations that are made in fire-resistive construction for the passage of pipes, cables, or HVAC systems, and (2) where two assemblies meet, forming an expansion joint such as the top of a wall, curtain wall (edge of slab), or floor-to-floor joints. Typical opening types include the follwoing:

• Electrical through-penetrations

• Mechanical through-penetrations

• Structural through-penetrations

• Nonpenetrated openings (e.g., openings for future use)

• Reentries of existing firestops

• Control or sway joints within fire-resistance rated wall or floor assemblies

• Junctions between fire resistance-rated wall or floor assemblies

• “Head-of-wall” joints where nonload bearing wall assemblies meet floor assemblies.

Compliance with all applicable laws and regulations relating to a building is the owner’s responsibility including the adopted and enforced fire code within a specific jurisdiction. Fire codes govern the construction, protection, and occupancy details that affect the fire safety of buildings throughout their life span. Numerous different fire codes have been adopted throughout the United States—the vast majority of which are similar and based on one of the model codes available today or in the past. One requirement in all of these model codes is that fire safety features incorporated into a building at the time of its construction must be maintained throughout a building’s life. Therefore, this would require any fire resistance-rated construction to be maintained (Fig. 9.36).

Alarm Systems and Notification Systems

Fire alarm systems are essential to any facility, particularly in large buildings where there may be visitors or personnel who are unfamiliar with their surroundings. Bruce Johnson, Regional Manager for Fire Service Activities with the International Code Council says, “Fire alarm systems and smoke alarms are life safety systems that save countless lives each year, both civilians and firefighters. The International Residential Code requires interconnected, hardwired smoke alarms in all new construction (Section R313) and the International Building Code and International Fire Code (Section 907.2) call for manual or automatic fire alarm systems in most commercial buildings with high life occupancy or other hazards. In addition to new construction, the International Fire Code also has provisions for fire alarm systems and smoke alarms in existing structures (Section 907.3)”. Fire alarms alert building occupants of a fire that alert emergency public responders (police and fire) through a central station link to initiate appropriate responses.

FACPs, or fire alarm control units, comprise of electric panels that function as the controlling components of a fire alarm system (Fig. 9.37). The FACP panel receives information from environmental sensors designed to detect any changes associated with fire. It also monitors their operational integrity and provides for automatic control of equipment, and transmission of information necessary to prepare the facility for fire based on a predetermined sequence. An FACP panel may also supply electrical energy to operate any associated sensor, control, transmitter, or relay. There are currently four basic types of FACP panels on the market: coded panels, conventional panels, addressable panels, and multiplex systems.

Mass Notification systems (MNSs) are invaluable in the protection of a wide range of facilities, and MNSs use both audible and visible means to distribute potential life-saving messages. An MNS is much more than an alarm system. By using the technologies based on fire alarm codes and standards, fire system manufacturers are able to produce a robust life safety and security system.

The impact of increasingly sophisticated technology has had a significant impact on today’s alarm systems. For example, they now have the ability to provide more information to the fire department and first responders. In many cases, they can do more than just tell them that there has been an alarm in the building; they can be directed by the kind of alarm and where the alarm is. Moreover, many modern systems now include speakers that provide alerts in place of (or in addition to) traditional bell-type alarms. These speakers also can be used in emergencies other than fires to instruct and inform occupants of the situation. These voice-actuated systems can include prerecorded or live messages that play in the event of fire or another emergency. Typical prerecorded messages tell occupants that an alarm has been sounded and that they should remain in their designated area for further instruction. Building management can then manually use the system to deliver additional information and prepare occupants for an evacuation, if necessary. Alert systems can also close fire doors, recall elevators, and interface and monitor the installed suppression systems, such as sprinklers. It should be noted that when fire alarms systems are properly installed and maintained, they perform very well. But when they are not, the public and fire service may be subject to unnecessary “false alarms” that puts everyone at risk.

Figure 9.37 A Siemes MXL fire alarm control panel (top) and graphic annunciator (bottom) for Potomac Hall, at James Madison University. Photograph by Ben Schumin, (source: Wikipedia).

Alarm systems can also connect with a building’s ventilation, smoke management, and stairwell pressurization systems—all of which are critical to life safety. Again, these features are dependent on the building in which the particular system is installed. In addition, the integration of MNS and fire alarm control systems is a growing and positive trend that will hopefully continue and be applied in larger varieties of facilities and multibuilding properties, including schools, high-rise buildings, mass transit hubs, and even public gathering places such as places of worship, theaters, and restaurants.

An annunciator is basically a unit containing two or more indicator lamps, alpha-numeric displays, or other equivalent means in which each indication provides status information about a circuit, condition, or location. An annunciator panel is sometimes employed to monitor the status of the different areas in a designated fire zone, theft protection, and control of a facility’s alarm devices. There may be several fire zones in a building. Each fire zone is clearly marked on the panel. The annunciator panel identifies the different zones and their specific security status. Should a fire occur, an indicator light flashes on the panel and identifies the fire’s location. For example, the light on the panel might indicate that a fire has occurred in Fire Zone 4. This information allows the Fire Department to quickly locate the fire.

9.8.6. Codes and Standards

One of the most important objectives of any design must be Code compliance. There are a number of relevant national codes that relate to green building fire protection systems that are published by the NFPA. It should be noted that fire codes can vary substantially from one jurisdiction to another, and while these codes are not mandatory in all jurisdictions, they should nevertheless be adhered to whenever possible because they provide maximum safety for property and personnel and can help guide system design and installation:

NFPA 72, National Fire Alarm Code: Governs the design, installation, operation, and maintenance of fire detection and alarm systems. It includes requirements for detector spacing, occupant notification, and control panel functionality.

NFPA 750, Standard on Water Mist Fire Protection Systems: Governs water mist system classification and incorporates requirements for water mist system design, installation, operation, and maintenance.

NFPA 2001, Standard on Clean Agent Fire Extinguishing Systems: Governs the design, installation, operation, and maintenance of clean-agent systems. It additionally includes requirements for assessing design concentrations, safe personnel-exposure levels, and system-discharge times. The standard also stipulates that an agent be included on the U.S. Environmental Protection Agency’s (EPA’s) Significant New Alternatives Policy list.

Finally, green buildings today have numerous fire protection system options that can be employed. Careful consideration of a building and its anticipated hazards will help determine which areas require protection. Due to the recent advances in technology, fire detection and suppression systems can now adequately support and sustain a modern green building philosophy. The methodical selection of a clean-agent or water mist system can also help contribute to LEED certification credits for building owners and developers.

However, “The new methods and materials that are used to support green building concepts can result in specific fire hazards, just like in traditional building design,” says Craig Hofmeister, Vice President of engineering technology for RJA Group. “That means green concepts should be reviewed as part of a fire protection and life safety analysis.” The bottom line is that performance-based codes can be used as an excellent tool to resolve conflicts between progressive green design elements and prescriptive codes. Armin Wolski, Head of the San Francisco fire engineering group and Associate Principal at Arup says, “A particular design element might not comply with the letter of the code,” Wolski goes on to say, “but for a given use or intent, often the element can be analyzed from a performance perspective and shown to meet the intent of the code.”

..................Content has been hidden....................

You can't read the all page of ebook, please click here login for view all page.