21

A Low-Cost IoT Framework for Landslide Prediction and Risk Communication

Pratik Chaturvedi1,2, Kamal Kishore Thakur3, Naresh Mali4, Venkata Uday Kala4, Sudhakar Kumar5, Srishti Yadav4, and Varun Dutt5

1Applied Cognitive Science Laboratory, Indian Institute of Technology Mandi, Kamand, India

2Defence Terrain Research Laboratory, Defence Research and Development Organization, New Delhi, India

3Computer Science and Engineering Department, Thapar Institute of Engineering and Technology, Patiala, India

4School of Engineering, Indian Institute of Technology Mandi, Himachal Pradesh, India

5School of Computing and Electrical Engineering, Indian Institute of Technology Mandi, Himachal Pradesh, India

21.1 Introduction

Landslides are uncertain geological events and they pose great dangers to life and infrastructure (Parkash, 2011). In India, especially in the Himalayan region, landslides are more frequent than any other geological phenomena causing more than 200 deaths and, on average, $82 million in damages to infrastructure yearly (Chaturvedi et al., 2017; Chaturvedi and Dutt, 2015). Because of large costs and many deaths due to landslides, there is a need to design and develop frameworks that monitor landslides and alert people before they occur. To be effective, those frameworks should possess the following features: sense soil properties and soil movement at landslide-prone sites; log-sensed data at a remote site via a cloud infrastructure; allow analyses of logged data; and alert people via mobile applications before landslides occur.

Several techniques have been proposed for monitoring landslides. Some of these techniques include the use of stereoscopic aerial photographs (Casson et al., 2003); use of satellite and unmanned aerial vehicle (UAV)-based remote sensing (Guzzetti et al., 2012; Niethammer et al., 2012); use of digital elevation models (DEM) from airborne laser altimetry data (McKean and Roering, 2004); and use of Brillouin Optical Time-Domain Reflectometry method (Dan et al., 2004). Although these techniques provide effective landslide monitoring technologies, they only scan the terrain's surface and they are expensive to use.

IoT frameworks provide a foundation for connecting sensors, actuators, and other smart technologies and thus they help to improve automation and control in various operations (Borgia, 2014). These IoT frameworks could provide alternate solutions for monitoring landslides. In the past few years, researchers have designed and developed certain IoT frameworks for monitoring landslides and alerting people (Arnhardt and Neussner, 2013; Aziz and Kamarulzaman, 2011; Ramesh, 2009). These IoT frameworks involve data collection, transmission, preprocessing, machine learning, decision-making, and information dissemination via mobile applications (Khan et al., 2012). Thus, these IoT frameworks go beyond the typical wireless sensor networks (WSNs), which consist of only sensors that collect data and transmit it wirelessly (Othman and Shazali, 2012). However, these frameworks use costly sensing components like geophones, pore pressure transducers, and tilt meters (Arnhardt and Neussner, 2013; Aziz and Kamarulzaman, 2011; Ramesh, 2009). The high cost of sensing landslides via existing IoT frameworks limits their large-scale deployment across several landslide-prone areas in the world. Thus, there is a need to design and develop IoT frameworks that are low in cost, yet efficient.

One way of reducing cost is by using microelectromechanical systems (MEMS)-based sensors (Gupta and Ahmad, 2007) as a part of existing landslide-sensing IoT frameworks. MEMS is a technology that uses advances in fabrication techniques to embed an electromechanical system on a single chip (Mehregany and Roy, 1999). In MEMS-based sensors, mechanical elements like gears and beams are added on top of electrical systems, where this electromechanical combination allows one to sense the physical world (Mehregany and Roy, 1999). IoT frameworks involving MEMS-based sensors are likely to be useful for monitoring landslides. However, sensors used for landslide monitoring in the real world need to be first calibrated and tested at the lab scale.

In this chapter, the design and development of a low-cost IoT framework for monitoring landslide is discussed. This framework involved the use of MEMS-based sensors for monitoring landslides at the lab scale. The proposed framework can monitor soil moisture and movement and generate alerts based on predefined thresholds.

21.2 Background

As mentioned earlier, several technologies have been used for monitoring landslides (Guzzetti et al., 2012; Niethammer et al., 2012; McKean and Roering, 2004; Dan et al., 2004). Although these technologies provide different methods for landslide monitoring, they can only scan terrain's surface and are expensive to use. For example, in the city of Portland, where DEMs were used for landslide monitoring, the mapping cost itself was between $400 and $600 per square mile (Weinstein, 2010). This high-mapping cost was a reason why Portland was unable to afford a large-scale DEM implementation. Similarly, high costs and operating constraints have been associated with UAVs, which limits their usage (McKinnon, 2015).

The high cost of traditional landslide monitoring technologies calls for finding alternative technologies that are affordable and can look beneath the terrain's surface. MEMS-based sensors have been used across a wide range of applications involving healthcare, automotive, defense, and communication sectors (Crone, 2008). Recently, MEMS-based sensors have also drawn the attention of landslide researchers and IoT frameworks that use these sensors can provide promising low-cost solutions for monitoring landslides (Arnhardt and Neussner, 2013; Chaturvedi et al., 2017; Manconi and Giordan, 2016; Marciano et al., 2014; Martelloni et al., 2012). However, as the efficacy of the MEMS-based sensors has not been evaluated for landslide applications in the real world (Manconi and Giordan, 2016), more research is needed in designing and developing IoT frameworks that involve the use of these sensors. To design and develop such frameworks, it is important to first evaluate the capabilities of these sensors using controlled lab-scale simulations and then to test them in field applications. In the following section, the design and development of an IoT framework are presented where MEMS-based sensors were used at the lab scale.

21.3 System Design and Implementation

The design of the proposed landslide monitoring IoT framework consists of the following components: a sensing unit; a data-logging and thresholding unit; and an alert-generating unit (see Figure 21.1). In this section, a detailed description of each of these components is provided.

Figure 21.1 Design of the low-cost IoT framework for landslide monitoring.

21.3.1 Sensing Unit

In the proposed framework (see Figure 21.1), MEMS-based accelerometers and moisture sensors sense soil movement (accelerations) and soil moisture, respectively. The accelerometer measures accelerations (rate of change of velocity of an object) in three orthogonal directions (e.g., X, Y, and Z). When interfaced with a microcontroller, this sensor provides analog acceleration values. These analog units are converted to “m/s2” units by using an appropriate calibration procedure. The soil moisture sensor uses the resistance property to measure water content in the soil surrounding its electrodes. Resistance is inversely proportional to soil moisture and output voltage. When the sensor is dry, a high value of resistance is recorded. This resistance value results in a low-output voltage. In contrast, when the sensor's electrodes are moist, a low value of resistance is recorded and this resistance results in a high-output voltage.

The analog values from the accelerometer and soil moisture sensors are fed to the analog pins of the microcontroller, which is directly interfaced with these sensors. The sensor values received by the microcontroller are sent to the cloud via a Global System for Mobile (GSM) module (Rahnema, 1993). GSM is used for data transmission rather than Wi-Fi because in the real world the sensing unit will be installed on a remote hill where a Wi-Fi signal will not be present. However, GSM (mobile) networks are readily available in hilly terrain, especially in the Himalayas in Himachal Pradesh, where future deployment of the framework is planned.

21.3.2 Data Logging and Thresholding Unit

The GSM module receives sensor values from the microcontroller and then it transmits them to a database on the cloud. This setup is used in controlled lab-scale experiments, where certain critical values (i.e., threshold) are determined for soil moisture and soil movement. These threshold values when breached would cause landslides.

21.3.3 Alert-Generating Unit

The alert-generating unit compares sensor values with their predefined thresholds. Once the sensor values for soil moisture or soil movement cross their threshold values, this unit generates SMS alerts concerning landslides on mobile phones. The alert-generating unit also has the provision of preregistering mobile numbers for sending SMS alerts.

21.4 Testing the IoT Framework

In this section, a lab-scale experiment involving the proposed framework for monitoring landslides is discussed. The main purpose of the experiment was to test the capability of the framework for measuring soil moisture and soil movement. Also, a second objective of the experiment was to investigate the threshold values for soil moisture and soil movement, which were likely to trigger landslides. In the experiment, a soil sample from a hill was packed on a ramp. Next, the moisture level was increased in the soil sample until a landslide was triggered on the ramp. This experiment served as a proof of concept for testing the suitability of MEMS-based sensors for landslide monitoring as well as for gauging threshold values of soil moisture and soil movement.

21.4.1 Methodology

21.4.1.1 Soil Characteristics

To investigate thresholds for soil moisture and soil movement via the framework, an experiment was performed on a ramp involving soil with certain physical properties. First, soil tests were carried out where certain soil properties were determined using the Indian Standard (IS) procedures.

These IS procedures included tests for specific gravity (IS 2720-1, 1983), particle size distribution (IS 2720-4, 1985), compaction characteristics (IS 2720-8, 1983), and direct shear test (IS 2720-13, 1986). Specific gravity is the ratio of the density of the soil sample to the density of water at a specified temperature.

The soil sample was further analyzed in terms of its percentage constituents. To do this analysis, a grain size analysis test was performed that gave percentages of gravel sizes (particle diameter > 4.75 mm), sand sizes (particle diameter between 0.075 and 4.75 mm), silt sizes (particle diameter between 0.075 and 0.0002 mm), and clay sizes (particle diameter < 0.0002 mm) in the soil sample. As shown in Table 21.1, the soil sample mostly consisted of sand and silt particles and the sample was classified as a poorly graded sand. The angles of friction were greater between the sand particles compared to that between the sand particles and the ramp material. Also, the cohesion between sand particles was slightly greater compared to that between the sand particles and the ramp material. Overall, the sand particles bonded together much more compared to their bonding with the ramp material.

Table 21.1 Physical characteristics of soil sample.

| Property | Value for soil sample |

| Specific gravity(ratio) | 2.58 |

| Gravel size (%) | 4 |

| Sand size (%) | 46 |

| Silt size (%) | 47 |

| Clay size (%) | 3 |

| Soil classification | Poorly graded sand |

| Angle of internal friction between sand and sand, Φ (°) | 28 |

| Angle of internal friction between sand and ramp material, Φ (°) | 5 |

| Cohesion between sand and sand, C (kPa) | 5 |

| Cohesion between sand and ramp material, C (kPa) | 3 |

21.4.1.2 Lab-Scale Ramp Setup

A wooden ramp was prepared for performing an experiment with the framework (see Figure 21.2a). The dimensions of the ramp were as the following: length = 1 m; breadth = 0.3 m; and height = 0.3 m. In addition, the ramp was attached with supports on both sides so that it could be raised to a wide range of angles with the horizontal surface (between 1° and 90°; see Figure 21.2b). In the experiment, soil was packed in the ramp and moisture was added using a water sprinkler until soil moved and a landslide occurred.

Figure 21.2 The ramp used for the experiment and its specification drawing. (a) The ramp elevated to an angle with the horizontal surface for packing a soil sample. (b) The specification drawing of the ramp showing different dimensions and placement of sensors at ramp's toe-end.

As shown in Figure 21.2b, accelerometers and soil moisture sensors were placed at the base and at the top of a flexible pipe on the toe-end of the ramp. These sensors recorded soil movement and soil moisture values, respectively. One set of the accelerometer and soil moisture sensors were located at the base of the pipe and the second set of sensors were located at the top of the pipe. The pipe holding the two sensor sets was placed perpendicular to the ground level. The entire arrangement could sense soil movement and soil moisture and communicate the sensed values to the microcontroller. Subsequently, the sensor values received by the microcontroller were sent to a database via the cloud infrastructure and the GSM module.

21.4.1.3 Selection of Components for IoT Framework

Two MEMS-based accelerometers and moisture sensors were placed at the base and at the top of a flexible pipe on the toe-end of the ramp (see Figure 21.2b). The specifications of the different items used in this framework are discussed as follows:

- Accelerometer. A GY-61 accelerometer module1 is used in the framework (see Figure 21.3). This module measures triaxial accelerations in the range ±3 g (where g = 9.8 m/s2) across three orthogonal directions (see Figure 21.3). This sensor is a low-power device with an operating voltage between 1.8 and 3.6 V and an operating current of 350 μA. The accelerometer is calibrated by aligning each of its axis one by one with Earth's gravitational acceleration (= 9.8 m/s2). Thus, when the Z-axis is aligned with the Earth's gravitational acceleration, then the accelerometer gives +1 g acceleration in the Z-axis and 0 g acceleration in the X- and Y-axes. For the accelerometer placed at the top of the pipe, Ax, Ay, and Az refer to directions perpendicular to the base of the ramp (pointing upward), along the width of the ramp (from right to left), and sloping at an angle ϕ with the soil away from the ramp (ϕ is the angle that the ramp made with horizontal), respectively. Similarly, for the accelerometer at the base of the pipe, Ax, Ay, and Az refer to directions perpendicular to the base of the ramp (pointing downward), along the width of the ramp (from left to right), and sloping at an angle ϕ with the soil toward the ramp, respectively.

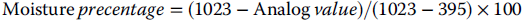

- Moisture Sensor. For sensing the percentage of the soil moisture, a YL-69 module2 is used in the framework (see Figure 21.4). The operating voltage for this sensor ranges between 3.3 and 5.0 V. Depending upon the level of moisture content in the close vicinity of the sensor, this sensor gives an analog value between 0 and 1023. Analog readings for soil moisture sensors in the dry state (0% moisture) and wet state (100% moisture) are 395 and 1023, respectively. To compute the percentage moisture corresponding to an analogue sensor value, the following equation is applied:

(1)

- Microcontroller. For reading and processing sensor values, an open-source microcontroller board, that is, Arduino MEGA 25603 is used (Barrett, 2013; see Figure 21.5). This microcontroller has 16 analog pins and 54 digital pins. The operating voltage and current of this microcontroller are 5 V and 500 mA, respectively.

- GSM Module. To transmit the sensor data to the cloud, a SIM900A GSM module4 is used (see Figure 21.6). The GSM module is connected to the microcontroller and it can operate on four different frequencies, namely, 850, 900, 1800, and 1900 MHz. Since the GSM module consumes up to 2 A current, an external power supply is used with an operating voltage and current of 5 V and 2 A, respectively. A SIM card is used in the GSM module for establishing a wireless connection between the microcontroller and the cloud.

Figure 21.3 GY-61 accelerometer sensor used in the framework.

Figure 21.4 YL-69 soil moisture sensor used in the framework.

Figure 21.5 Arduino MEGA 2560 module used in the framework.

Figure 21.6 SIM900A GSM module used in the framework.

In Figure 21.7, a GY-61 accelerometer, a YL-69 soil-moisture sensor, and a SIM900A GSM module are interfaced with an Arduino MEGA microcontroller board. Since GY-61 module has an on-board 5 V to 3.3 V converter, the VCC pin of this module is connected to the 5 V output pin of the Arduino MEGA microcontroller. Furthermore, the X, Y, and Z pins of GY-61 are connected to the analog input pins A1, A2, and A3 of Arduino microcontroller, respectively. As shown in Figure 21.7, the YL-69 module's VCC, GND, and SIG pins are connected to the 5 V output, ground, and analog A5 pins of the Arduino microcontroller, respectively. The SIM900A GSM module uses its TTL pins to connect with the Arduino microcontroller. Since this module is responsible for transmitting sensors values, its transmitter (SIM_TXD) and receiver (SIM_RXD) pins are connected with the receiver (digital pin 0) and transmitter (digital pin 1) pins of Arduino microcontroller, respectively. Lastly, the 5 V and RST pins of the GSM module are connected with the 5 V output and RESET pins of Arduino microcontroller, respectively.

Figure 21.7 Diagram showing all components connected to the microcontroller board.

21.4.2 Data Logging and Alerts

As mentioned already, once the microcontroller receives sensor values, these values are transmitted via the GSM module to a cloud database. A PHP script is written to perform the data saving action (Rahnema, 1993). Data stored in the database is later used for analyzing thresholds for different sensors. If sensor values crossed certain predefined thresholds, then an automated landslide SMS alert is sent to registered mobile numbers using a free service called Twilio5. Twilio is a cloud communications platform that uses an account identification number and a mobile number to send a custom SMS to that mobile number.

21.4.3 Experimental Procedure

Soil was packed in the ramp and the ramp was elevated at an angle slightly less than the soil's critical angle. The critical angle was the minimum angle calculated from soil properties at which soil movement would occur due to the gravitational force without the addition of moisture (see Figure 21.8a). For the soil used in the experiment, the critical angle was 5° (see Table 21.1). Next, moisture was added to the soil until the soil moved and a landslide occurred (see Figure 21.8b). During the experiment, raw data from sensors were stored in a cloud database. Subsequently, sensor values were analyzed statistically to determine thresholds at which soil became loose and a landslide occurred. If sensor values crossed predetermined thresholds, then the alert-generating unit automatically sent SMS alerts to registered mobile phones.

Figure 21.8 Pictures of the experiment with the ramp. (a) The sand was packed inside the ramp and the ramp was raised at an angle just below the critical angle. (b) Moisture was added to the soil using a water sprinkler till a landslide occurred.

21.5 Results

In this section, soil moisture and soil movement values recorded by different sensors are analyzed over time. Figure 21.9a–c show the plot of soil moisture, accelerometer, and cumulative displacement values, respectively, from sensors placed at the top of the pipe at the toe-end of the ramp. As seen in Figure 21.9a, the soil moisture sensor value increased and peaked at 18% when the landslide started occurring on the ramp (water was poured on the ramp at time t = 0 s). In addition, the changes in accelerations at the top of the pipe within the first 2 s of pouring water were the following: 0.7 to −1 g (X direction), 0.1 to −1.5 g (Y direction), and 0.15 to −2.5 g (Z direction), respectively. These accelerations and the corresponding displacements showed that the soil at the top of the pipe moved upward and outward when the landslide occurred. Furthermore, soil moisture values and acceleration values reached their peaks at the same time.

Figure 21.9 The value of accelerations (m/s2) and soil moisture (in percentage) on the pipe at the toe-end of the ramp. (a) Soil moisture at the top of the pipe. (b) Accelerometer values at the top of the pipe. (c) Displacement at the top of the pipe. (d) Soil moisture (in percentage) at the base of the pipe. (e) Accelerometer values at the base of the pipe. (f) Displacement at the base of the pipe.

Table 21.2 shows the values stored in the cloud database, where the stored values were collected from the sensors placed on the ramp. The first column in Table 21.2 shows the date and time at which data were collected. The second column shows the soil moisture percentage recorded from the sensor at the base of the pipe. The third column shows the accelerations in the three orthogonal directions recorded by the accelerometer put at the base of the pipe. Here, acceleration values have been represented in terms of g (1 g = 9.8 m/s2). Similarly, fourth and fifth columns show the soil moisture and acceleration values obtained from sensors placed at the top of the pipe.

Table 21.2 Sample data obtained from sensors on the pipe at the toe-end of the ramp.

| Time (in seconds) | Soil moisture at pipe's top (in %) | Accelerations at pipe's top (X, Y, and Z-axes) (in g) | Soil moisture at pipe's base (in %) | Accelerations at pipe's base (X, Y, and Z-axes) (in g) |

| 00 | 0.40 | 1.1, −0.2, 0.13 | 0.5 | 0.98, 0.2, 0.2 |

| 01 | 18.0 | 0.96, −1.57, −2.5 | 8.0 | −0.07, 0.08, 0.47 |

| 02 | 13.0 | 0.82, −1.29, −2.1 | 8.2 | −0.04, 0.1, 0.50 |

| 03 | 15.0 | 0.81, −1.37, −1.9 | 8.3 | 0.21, −0.01, 0.73 |

| 04 | 12.5 | 0.81, −1.32, −1.9 | 8.2 | 0.24, 0.02, 0.75 |

| 05 | 14.0 | 0.85, −0.8, −2.25 | 8.4 | 0.04, 0.1, 0.57 |

In this framework, the real-time sensor values are compared with their threshold values determined from the experiment above. If the sensed values are close to the critical soil movement and soil moisture thresholds, then SMS alerts are automatically sent to the registered mobile numbers. Figure 21.10 shows an SMS alert received on a mobile phone from the framework, as well as a web-based interface for landslide monitoring.

Figure 21.10 An SMS alert generated from the IoT landslide monitoring framework on a mobile phone. (a) The mobile interface showing the SMS alert. (b) The web-based interface for landslide monitoring.

Table 21.3 shows the cost of the components used in this IoT landslide monitoring framework for experimentation at the lab scale. The framework was assembled in the lab for only $32. If this framework was to be deployed on a real hill, then it would likely use 15 moisture sensors and 15 accelerometers at the crest-end, 10 moisture sensors and 10 accelerometers at the toe-end, 5 microcontrollers, and 2 GSM modules. The cost of this infrastructure would add up to $400 per crest-toe pair per hill. In summary, the proposed IoT framework provides a very cost-effective landslide monitoring and alerting solution to society.

Table 21.3 Cost of components used in the development of the IoT landslides monitoring framework for the laboratory experiment.

| Name of the component | Cost per unit(in USD) | Quantity | Total cost(in USD) |

| Accelerometer | 3.5 | 2 | 7.0 |

| Soil moisture sensor | 3.0 | 2 | 6.0 |

| Microcontroller board | 12.5 | 1 | 12.5 |

| GSM module | 13.5 | 1 | 13.5 |

| Breadboard + wires | 3.0 | 1 | 3.0 |

| Total | 32.0 |

21.6 Conclusions

In this chapter, a low-cost lab-scale IoT framework was proposed for monitoring landslides. MEMS-based sensors were used in this framework to measure soil moisture and soil movement on a ramp. Sensors' threshold values, derived from the experiment, were compared to real-time sensor data, and SMS alerts were sent to the registered mobile phones when sensor values exceeded their critical threshold levels.

The experimental results revealed that the base of the pipe experienced movement with only 8% moisture accumulation compared to the top of the pipe with 18% moisture accumulation. One likely reason for this observation is that the soil–soil bonding at the pipe's top was much stronger compared to the soil–wood bonding at the pipe's base. Second, it was found that the moisture sensor at the pipe's base experienced little variance in its moisture value over time. This result could be due to the pouring of water from the ramp's top. Thus, it did not accumulate as much at the pipe's base as compared to the accumulation at the pipe's top (pipe's top absorbed most of the moisture present).

Although this chapter reported only a single experiment involving lab-scale landslide monitoring, the results show the potential of using MEMS-based sensors for landslide monitoring in the real world. However, before scaling up the proposed framework for monitoring landslides in the real world, several challenges need to be overcome. This includes drilling on a hill with steep slopes, requiring a self-sustaining power source, 24 h monitoring of landslides, packaging of sensors so that they can withstand the rugged hilly terrain, and the use of other groundbreaking IoT technologies that enable rapid data collection.

Drilling on steep slopes requires state-of-the-art drilling equipment and interdisciplinary expertise in civil and geotechnical areas. For this purpose, it is encouraged to engage appropriate equipment and an interdisciplinary team of researchers. A self-sustaining and stable power source will be needed for real-world landslide monitoring. One way to provide such a power source is by using solar energy. However, if landslide monitoring system stays in an “on” state for 24 h a day, then the power requirements of such a system would be very large. Overall, this would increase the monitoring cost due to the investment in several solar panels and batteries.

One way to keep the monitoring cost low is to go for a passive monitoring system, which sleeps for 10–15 min, wakes-up to record sensor values, and then sleeps again for 10–15 min. If rain occurs during the time when the system is sleeping, then the rain wakes the system from sleep via a hardware interrupt. As revealed in the experiments, rain (or water) caused an increase in soil moisture over time. However, accumulation of moisture in the soil may not necessarily trigger a landslide, where the landslide trigger is also dependent upon the type of soil and its properties. Although only one soil type was tested in the experiment reported above, both soil properties and soil moisture were considered as causal factors in the experiment. The experiment's methodology could be easily adapted to monitor other soil types.

Another challenge is related to the packaging of the MEMS-based sensors that is crucial so that these sensors do not get damaged when used in the real world. One way of ensuring sensor durability is to mount them on a flexible rubber or plastic pipe while placing them on a hill. In fact, mounting these sensors on a flexible pipe is what was done in the experiment reported.

The proposed IoT framework is a whole, cost-effective solution, which requires no communication system beyond existing 2G telephony. However, this framework is currently at a prototypical level where it is planned to be deployed for landslide monitoring on a real hill in the future. Scaling up the system across many hills will allow for investigation of other groundbreaking IoT technologies, such as 5G broadband (Osseiran et al., 2014). These technologies will have bandwidth speeds more than 100 megabits per second and will enable gathering massive amounts of sensed data from hundreds of sensors in real time.

In conclusion, overall, the proposed IoT landslides monitoring framework helps to reduce the cost of monitoring landslides in the real world. In fact, once scaled up to a real hill, the framework is expected to cost less than 4% of the cost of conventional systems that are currently used for monitoring landslides. Given that there are 200 lives lost per year in the Himalayas alone due to landslides (Parkash, 2011), the cost-effectiveness of this IoT framework is expected to be only $1.3 per head. This low cost is expected to make the framework an affordable landslide monitoring system in the future—a system that is deployable at several landslide-prone sites across the world.

Acknowledgment

This research was supported by grants from the following agencies to Varun Dutt: State Council for Science, Technology & Environment, H.P. (IITM/HPSCSTE/VD/130); Defence Terrain Research Laboratory, Defence Research and Development Organisation (IITM/DRDO-DTRL/VD/179); and, National Disaster Management Authority (IITM/NDMA/VD/184).

Notes

References

- Arnhardt, C. and Neussner, O. (2013) Setup of a landslide monitoring system on the Philippine Island of Leyte near the village of Malinao (Municipality of St. Bernard). Landslide Science and Practice, Springer, Berlin Heidelberg, pp. 161–167.

- Aziz, N.A.A. and Kamarulzaman, A.A. (2011) Managing disaster with wireless sensor networks. 13th International Conference on Advanced Communication Technology, IEEE, 202–207.

- Barrett, S.F. (2013) Arduino microcontroller processing for everyone! Synthesis Lectures on Digital Circuits and Systems, 8(4), 1–513.

- Borgia, E. (2014) The Internet of Things vision: Key features, applications and open issues. Computer Communications, 54, 1–31.

- Casson, B., Delacourt, C., Baratoux, D., and Allemand, P. (2003) Seventeen years of the “La Clapiere” landslide evolution analysed from ortho-rectified aerial photographs. Engineering Geology, 68(1), 123–139.

- Chaturvedi, P. and Dutt, V. (2015) Evaluating the public perceptions of landslide risks in the Himalayan Mandi town. Proceedings of the Human Factors and Ergonomics Society Annual Meeting, 59(1), 1491–1495.

- Chaturvedi, P., Arora, A., and Dutt, V. (2017) Interactive landslide simulator: a tool for landslide risk assessment and communication. Advances in Applied Digital Human Modeling and Simulation, Springer International Publishing, 231–243.

- Chaturvedi, P., Shrivastava, S., and Kaur, P. (2017) Landslide early warning system development using statistical analysis of sensors' data at Tangni landslide, Uttarakhand, India. Advances in Intelligent Systems and Computing, Springer International Publishing, p. 547.

- Crone, W.C. (2008) A brief introduction to MEMS and NEMS. Springer Handbook of Experimental Solid Mechanics, Springer, US, pp. 203–228.

- Dan, Z., Bin, S., Hong-Zhong, X., Junqi, G., and Hong, Z. (2004) Experimental study on the deformation monitoring of reinforced concrete T-beam using BOTDR. Journal of Southeast University (Natural Science Edition), 4, 012.

- Gupta, A. and Ahmad, A. (2007) Microsensors based on MEMS technology. Defence Science Journal, 57(3), 225.

- Guzzetti, F., Mondini, A.C., Cardinali, M., Fiorucci, F., Santangelo, M., and Chang, Kang-T. (2012) Landslide inventory maps: new tools for an old problem. Earth-Science Reviews. 112(1), 42–66.

- IS 2720-1 (1983) Indian Standard Methods of Tests for Soils. Part 1 – Preparation of Dry Soil Samples for various tests. Available at https://law.resource.org/pub/in/bis/S03/is.2720.1.1983.pdf

- IS 2720-13 (1986) Indian Standard Methods of Tests for Soils. Part 13 – Direct Shear Test. Available at https://law.resource.org/pub/in/bis/S03/is.2720.13.1986.pdf

- IS 2720-4 (1985) Indian Standard Methods of Tests for Soils. Part 4 – Grain Size Analysis. Available at https://law.resource.org/pub/in/bis/S03/is.2720.4.1985.pdf

- IS 2720-8 (1983) Indian Standard Methods of Tests for Soils. Part 8 – Determination of Water Content-Dry Density Relation Using Heavy Compaction. Available at https://law.resource.org/pub/in/bis/S03/is.2720.8.1983.pdf

- Khan, R., Khan, S.U., Zaheer, R., and Khan, S. (2012) Future internet: the internet of things architecture, possible applications and key challenges. In Frontiers of Information Technology (FIT), 2012 10th International Conference on (pp. 257–260). IEEE.

- Manconi, A. and Giordan, D. (2016) Landslide failure forecast in near-real-time. Geomatics, Natural Hazards and Risk, 7(2), 639–648.

- Marciano, J.S., Hilario, C.G., Zabanal, M.A.B., Mendoza, E.V., Gumiran, B.L., Flores, B.F., Peña, M.O., and Razon, K.H. (2014) Monitoring system for deep-seated landslides using locally-developed tilt and moisture sensors: system improvements and experiences from real world deployment. Global Humanitarian Technology Conference (GHTC), 2014 IEEE, October, pp. 263–270.

- Martelloni, G., Segoni, S., Fanti, R., and Catani F. (2012) Rainfall thresholds for the forecasting of landslide occurrence at regional scale. Landslides, 9(4), 485–495.

- McKean, J. and Roering, J. (2004) Objective landslide detection and surface morphology mapping using high-resolution airborne laser altimetry. Geomorphology, 57(3), 331–351.

- McKinnon, A.C. (2015) 3D printing, drones and crowdshipping: city logistics game-changers or over-hyped curiosities. Urban Freight and Behavior Change (URBE) Roma Tre University, Rome, Italy.

- Mehregany M. and Roy S. (1999) Introduction to MEMS, in Helvajian, H., (ed.), Microengineering Aerospace Systems, Aerospace Press, Los Angeles, CA.

- Niethammer, U., James, M.R., Rothmund, S., Travelletti, J., and Joswig, M. (2012) UAV-based remote sensing of the Super-Sauze landslide: evaluation and results. Engineering Geology, 128, 2–11.

- Osseiran, A., Boccardi, F., Braun, V., Kusume, K., Marsch, P., Maternia, M., Queseth, O., Schellmann, M., and Schotten, H. (2014) Scenarios for 5G mobile and wireless communications: the vision of the METIS project. IEEE Communications Magazine. 52(5), 26–35. doi: 10.1109/MCOM.2014.6815890.

- Othman, M.F. and Shazali, K. (2012) Wireless Sensor Network Applications: A Study in Environment Monitoring System. Procedia Engineering, 41, 1204–1210.

- Parkash, S. (2011) Historical records of socio-economically significant landslides in India. Journal of South Asia Disaster Studies, 4(2), 177–204.

- Rahnema, M. (1993) Overview of the GSM system and protocol architecture. IEEE Communications magazine, 31(4), 92–100.

- Ramesh, M.V. (2009) Real-time wireless sensor network for landslide detection. 3rd International Conference on Sensor Technologies and Applications, IEEE, pp. 405–409.

- Weinstein, N. (2010) Lasers Help Identify Potential Landslides. Available at http://djcoregon.com/news/2010/08/10/lidar-helps-identify-potential-landslides/