PROTOTYPING SYSTEMS FOR Robotics

A bot-builder’s guide to bits and pieces.

Nate Van Dyke

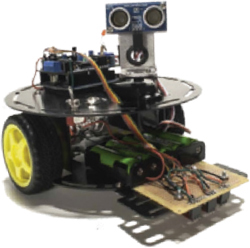

All-in-one robot kits, such as MAKE’s new Arduino-based Rovera series and Parallax’s Boe-Bot system, are designed to provide easy entry into hobby robotics. Popular with beginners as well as intermediate and advanced makers, they often employ fixed chassis components and simple drive trains that allow quick assembly and easy experimentation with sensors, plugin modules, and control components.

Prototyping systems, on the other hand, are not necessarily robotics -specific. They require more assembly, but allow for greater customization and are aimed at anyone looking to experiment with electromechanical systems in general. And, as it happens, they can be used to make some pretty sweet bots, too. Here are a few of my personal faves.

Vex Robotics

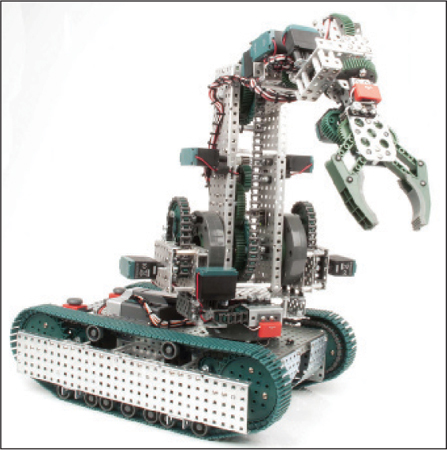

Like Mindstorms, the Vex Robotics Design System is an all-inclusive prototyping platform that includes structural components, drive train parts, actuators, sensors, a branded microcontroller, and remote control equipment. You can work entirely inside the Vex system, or use its structural and mechanical components as a base for third-party microcontrollers or other components.

Building mobile robot and machine prototypes from Vex components is fairly easy, though not Lego-easy. Lego is everywhere on the web, and naturally there are fewer photo galleries, build instructions, and other resources available for Vex, though the company itself does a good job of providing “Inventor’s Guides,” educational curricula, and other support materials. Add-on components include treads, chains, sprockets, gears, omni wheels, and many others, allowing for designs of great versatility and complexity.

The MAKE Rovera Arduino Robot Kit (2WD).

It’s possible to use Vex components with off-brand or improvised structural parts and hardware, but it’s usually much easier to stay in-system. Adapting Vex parts could be made simpler with the use of a 3D printer: Vex publishes 3D models for most of their products, enabling users to print individual components or compatible parts of their own design.

Mecanum wheels are among the more exotic components in the Vex system.

If you plan to use your own microcontroller, Vex’s $150 Clawbot Kit (276-2600) is a handy starting bundle. There’s also a Radio Control Starter Bundle (276-2310, discontinued but still available) for $300, which allows for quick mechanical prototyping without writing code.

Treaded prototype showing off Vex’s steel-beam framing system.

Makeblock

Many all-in-one commercial prototyping systems, like Lego and Vex, are proprietary and closed source — which is not necessarily a bad thing, but can make it more complicated for users to develop or commercialize their own designs past a certain point.

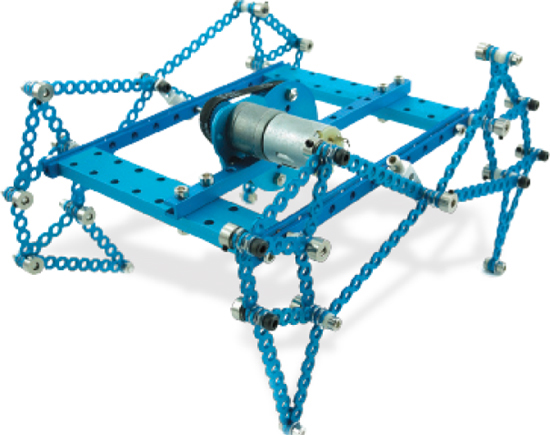

Personally, I like to create hodgepodge designs using just the components I want, without being locked into one system. Makeblock, a relatively new prototyping platform, seems to be one of the best mechanical design systems to allow this, short of working from scratch.

Makeblock’s mechanical and motion kits are designed from the ground up to be used with Arduino and other open source microcontrollers. The basic kits come with wheel assemblies and standard-sized 25mm gearmotors that can be easily controlled using an H-bridge circuit or motor shield. Larger kits include MXL belts and an assortment of timing pulleys for the creation of more advanced mechanisms.

Makeblock’s unique extruded-beam profile features a continuously threaded central channel.

Perhaps the most interesting aspect of Makeblock’s system is the aluminum structural beam design, which features two rows of evenly spaced holes and a middle channel with threaded walls. The threaded channel allows for structural components and other parts to be mounted anywhere along the length of the channel with just machine screws. Care must be used, with steel fasteners, to not damage these threads by overtightening. The latest beams are said to have stronger threads, but I still prefer nylon screws to minimize the risk of damage.

Lego

Although often thought of as toys, Lego products have established a strong reputation among roboticists. Lego elements are relatively inexpensive, commonplace, and highly modular, which makes them perfect for serious prototyping.

You may have already heard about Lego’s Mind-storms robot invention system, an all-in-one development kit that includes a powerful microcontroller, sensors, and servos. There has been an explosion of wondrous Mindstorms-based robotics in recent years — rovers, walkers, sorting machines, CNC foam milling machines, gripping arms, even a couple of underwater vehicles — that amply demonstrates how useful Legos can be at any level of robot design.

Lego also offers a classic line of Technic building sets and parts, which includes a vast selection of structural and mechanical components. Technic components are compatible with Mindstorms and other elements in the Lego system, including the Power Functions series of electric building components — various sizes and types of DC motors, LED lighting elements, switches, battery boxes, and wiring elements — which are all easy to interface with Arduino and other microcontrollers.

Technic vehicle sets usually feature mechanically realistic actuation and locomotion, making them excellent sources for drive train components, like gears and wheels, as well as linear actuators, pneumatic cylinders, shock absorbers, and of course structural parts. A Technic vehicle can also provide a quick means to get a mobile base working without much trial and error. If you find your design lacking one or more specific components, you can always head over to bricklink.com to buy parts a la carte.

There can be downsides to using Lego for building bots. First, Lego robots can be less robust and durable than those made from “serious” construction materials. It is possible to reinforce Lego builds with off-the-shelf parts using velcro, rubber bands, or more permanent means. But the time and effort saved by prototyping with Lego may or may not repay the time needed to convert a Lego-based prototype into a stronger, faster, or scaled-up construction using standard parts and components.

T-Slot Beams

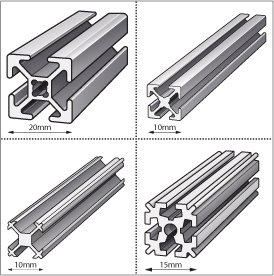

If you’re just looking for a structural prototyping system, T-slotted aluminum extrusions are a great way to go. There are several options on the market, with MicroRax, MakerBeam, and OpenBeam being the three notable small-scale systems, and 80/20 being the oldest, most well-established full-size brand.

Clockwise from upper left: 80/20 20-2020, MakerBeam, OpenBeam, and MicroRax extrusion profiles.

MicroRax and Maker-Beam extrusions have 10mm×10mm cross-sections, OpenBeam is 15mm×15mm, and 80/20 starts at 20mm×20mm. 80/20 also offers a smaller 12.5mm×25mm extrusion, but with only one T-slot.

Independent of size, T-slot beams are typically square or rectangular with built-in channels on all sides. The channels are shaped so that bolts and other fasteners must be slid in from an open end of the beam. This also means that fixtures can be loosened and slid into new positions on a beam without popping off.

Bolts are used to attach parts and devices directly to T-slots, and lengths of T-slot beam can be affixed to each other using metal brackets and joining plates. Extrusions often come in longer lengths that can be cut down to custom sizes, but it is also possible to purchase pre-cut beams for easier prototyping.

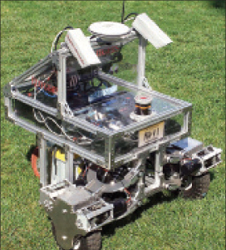

Rutgers University’s 2012 IGVC robot chassis uses 80/20 extrusions extensively.

80/20 is a very popular choice for larger mobile robot bases (even those you can ride on!), 3D printer frames, and CNC machines. Specialty fasteners and brackets allow for more complex configurations and designs, but these often require minor and sometimes multi-stepped machining operations.

T-slot systems, even the smaller-scale ones, require more advanced design skills and a better-equipped toolbox, so they’re not as beginner friendly as other prototyping options. Still, building with T-slotted beams is far quicker and easier than working with stock materials like aluminum channel or steel bar. ![]()

BIO

Stuart Deutsch enjoys reviewing the latest in hand and power tools at ToolGuyd.com. He has many maker interests, but is most passionate about robotics and computer casemodding.