CHAPTER 9

Why Communication Is Important?

There are five … basic operations in the work of the manager. …

A manager, in the first place, sets objectives. He determines what the objectives should be. He determines what the goals in each area of objectives should be. …

Secondly, a manager organizes. …

Next a manager motivates and communicates. He makes a team out of the people that are responsible for various jobs. He does that through the practices with which he manages. He does it in his own relation to the men he manages. He does it through incentives and rewards for successful work. He does it through his promotion policy. And he does it through constant communication, both from the manager to his subordinates, and from the subordinate to the manger. …

The fourth basic element in the work of the manager is the job of measurement. …

Finally, a manager develops people. …

Drucker recognizes that while companies may be complex systems, the systems consist of people who by performing their respective tasks help the company achieve its goals. Further, Drucker makes it clear that it is the managers’ job to ensure that all of the different people are everyone in their department—the department has to act as one. This makes communication one of management’s most important jobs. We therefore close this book with a chapter on communication (and how it creates action).

A very important need for communication is to share the company’s goals and targets with each person in the company. For these goals to be understood, management must do more than state the goals, it must interact with those they manage to be sure the goals are thoroughly understood and appropriate. Goals are typically transmitted from upper parts of the system to the lower parts of the system, and it is through this communication that the manager directs individuals to take actions to attain the goals. Communication from the bottom up (i.e., from the subordinate to the manager) is about the progress toward goals and the ability of the unit to achieve the goals. This bottom up communication includes information about the status of the process and should also include process knowledge or “know how.”

Lean Communication

A lean work design facilitates communication. Lean provides clear, effective channels for communication by creating an appropriate structure as discussed in the preceding chapter. But, creating clear communication channels is not enough to ensure effective communication. Communications within a company can suffer from the same problems that cause communication within a family or within any other groups of humans to be poor. Four rules of communication (adapted from Watzlawick, Beavin, and Jackson 1967) that need to be followed to avoid miscommunication and its problems are:

One cannot not communicate This means that everything we do communicates some information to observers. Even avoiding communication is communicating. For example, when a sales department manager has a problem with a sales clerk and this manager does not communicate to the sales clerk what the problem is, the manager may be inadvertently communicating to the sales clerk and to other clerks that there is no problem. Or if instead of directly having a conversation with the sales clerk, the manager only gives hints about a problem, it may be difficult for the sales clerk to interpret given that they had been receiving communication about there being no problem, so the sales clerk may take the wrong actions or no action at all. This first rule that “One cannot not communicate” means that communication is ongoing even when it is avoided. So, the need and structure for communication needs to be incorporated into the work design.

Communication consists of both content and relationship. Content refers to what is actually said and its relationship to how it is said. For example, a manager may seek to motivate an employee to achieve a goal (i.e., content) and do it with an animated expression (i.e., relationship). For example:

Wow Bob! You did well today. With a little more work you will be the master of this process and you will become the top performer in the company. Good job!

The content is that Bob is on target to become a top performer in the company and the relationship is that the manager would definitely welcome and support this, that is, the manager is very excited about this.

On the other hand, a manager who sets a stretch goal for an employee and does it without making eye contact with the employee and uses a disinterested tone, communicates to the worker that the manager is not serious about achieving the stretch goal. Further the manager might convey that they do not care about the employee.

“Bob. You should work harder to become a top producer in the company.”

The content of the message to Bob is to work harder with the goal of being a top producer. But the relationship suggests the manager does not care.

Another example of content and relationship is when the spoken words differ from the nonverbal communication or behavior of the communicator. For example, a manager might tell a worker to take work more seriously but do this while they are distracted by other things occurring in the workplace, such as reading a report or looking at their cell phone. In this type of communication, the worker receives both messages (i.e., content and relationship) and may act on the nonverbal message and not focus on the tasks they are to perform.

Each of us differs in how we interpret an ongoing sequence of events This means each of us may see different cause and effect relationships in the same sequence of events For example, in the year’s end inventory count, if the finished goods inventories are lower than the prior year, while raw materials inventories are slightly increased compared to the prior year, the operations manager may be very excited and state that lean design has reduced inventory stocks. However, the finance office may look at the same measurements and interpret them as a negative signal about company performance. They may argue that the asset level of the company has dropped.

Another example of this often occurs at the start of a lean transformation. The managers may see it as a challenge or an important intervention to keep the firm competitive. But, workers may interpret it as a signal that they are going to lose their positions.

Both symmetric and complementary communication procedures are used in human communications. Symmetrical interchange is an interaction based on equal power between communicators. Complementary interchange is an interaction based on differences in power. A complementary interchange could occur if you were a manager and you asked a worker whether the process was running without problems. The worker might simply respond “yes” even if there was a problem (thus hiding a problem) due to the power structure involved (see example on Crew Resource Management in Chapter 7). To reduce communication barriers due to complementary differences in power, people need to be able to speak freely without the fear of consequences. One technique to accomplish this is to have solutions to problems developed by a group rather than by imposing a solution from outside.

Example: Example of poor communication: A manager says to her workers: “I want independent thought from you, I am tired of doing all of the creative thinking and problem solving. You need to earn your paycheck.” A week later when a worker says: “I think I have a solution for the problem we are having in our department.” The manager then responds and says: “I am not paying you to think. I want you to get your work done. Stop wasting time dreaming. Am I clear?”

To build effective operational structure, lean work design has to improve communication. For example, Standard Operating Procedures and andon lights signal a problem and require a response by the supervisor and the worker. This enforces explicit communication about the status of that step of the process. Using an andon light recognizes the first axiom aforementioned—one cannot not communicate—that is, that everything one does is communication. If there are no signals, then the communication is that there is no problem. So, the andon light makes communication about the status of the process at that point explicit.

Both supervisor and worker have to show that they take the problem seriously. That means that the worker has to turn on the andon light when they see a problem and that the supervisor then has to respond to the andon light within the agreed amount of time. The first criterion for this to happen is that the supervisor has the capacity to do this. That means that the supervisor has to have some slack time in their schedule to be able to respond to a worker and that the supervisor has to be on the floor near the worker. The second point is that the supervisor has to communicate with the worker about the problem and listen to the explanation. If the problem is not solvable in the next cycle (e.g., maintenance must replace a part that requires constant adjustment), the supervisor must have counter measures prepared to isolate the problem, while other units respond. Third, the communication may have to be extended to explore and identify the root cause of the problem. This is facilitated by having standard problem solving techniques in place. Or, the supervisor can assign the problem to a team, which will then use standard problem solving techniques. Both actions require that the supervisor communicate both the content and the relationship. This recognizes the second axiom—Communication consists of both content and relationship.

The use of standard problem solving addresses the issue of different views of cause and effect, so that the individuals in the group develop a common view of cause-and-effect. This recognizes the third axiom—Each of us differs in how we interpret an ongoing sequence of events.

To obtain symmetrical communication, the supervisor uses coaching rather than imposing a solution. This recognizes the fourth axiom—both symmetric and complementary communication procedures are used in human communications—and is referred to as gembutsu in Japanese. Gembutsu means that the manager takes the time to see things as they really are. In this way, gembutsu helps managers avoid what Deming called tampering. Tampering refers to changing the system without understanding the system, which worsens the system’s performance.

Lean Action

“A little less conversation a little more action please” (Elvis Presley)

Standardizing work processes and the systems used in the process also improves communication, while the work is being performed, since the standards create a common understanding of what is to occur. The role of standards is explained by Spear and Bowen (1999), who suggested that all of Toyota’s efforts and system are the result of following four work design rules. These rules standardize the various aspects of the company’s management system.

Rule 1: “All work shall be highly specified as to content, sequence, timing, and outcome” cannot be implemented without clear communication from the support structure (often first-line supervisors or managers and engineers) to the line worker about what is to be done in each task, how it is to be done, how long it takes to be done, and what the outcome specifications are to be.

Rule 2: “Every customer-supplier connection must be direct, and there must be an unambiguous yes-or-no way to send requests and receive responses.” This rule ensures that the worker knows that their request for assistance was received and was either rejected or is being responded to by those responsible.

Rule 3: “The pathway for every product and service must be simple and direct” is concerned with communication about supplies, materials, and services that are used by a worker. It ensures that the worker knows who to contact about supplies, materials, and services and what needs to be in the communication message.

Rule 4: “Any improvement must be made in accordance with the scientific method at the lowest possible level in the organization facilitated by the next higher level of the organization” ensures that the scientific method guides the communication between the problem solvers and management.

The first rule standardizes the transformation processes. It also sets expectations for the detail of the work design. It shares with the designer and the worker the expectations of each. It also establishes a basis for communication about the work design. It creates a communication structure to revise the work design and to identify problems within it.

The second rule standardizes communication patterns and methods between departments. It establishes a relationship between workers and departments and between departments about what is clear communication. Was a clear request received? Was a clear request sent? This simplifies resolution of interdepartmental conflicts between supporting departments and using departments.

The third rule states that all supply functions are traceable. The movement of materials and information follows a known pathway. If there are problems with this pathway it can be traced and the problems can be identified and resolved.

The fourth rule ensures a structure for continuous improvement. The use of the structure created by these rules simplifies the communication between participants in the process. It establishes expectations for the continuous improvement process. The expectations include who authorizes it as well as who does it and how it is done.

The use of these four rules provides a structure that turns a request for action into a routine. Each rule is concerned with a different set of goals and there is a predefined boundary for the goals and resources.

Communication Cycle

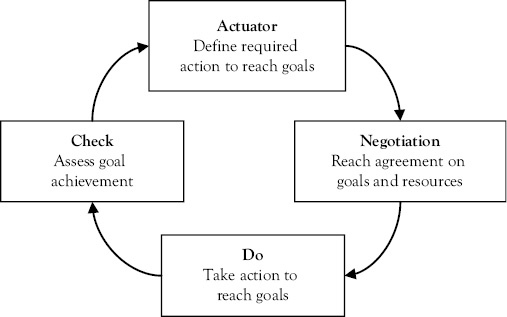

Successful communication is part of an ongoing cycle. Managers communicate to have someone take action or to have someone stop action. This is shown in Figure 9.1. An actuator (e.g., a manager) first decides what actions they need to reach their goals. They then approach whoever they want to take action and enter into a negotiation with them about the desired goals and the resources needed to achieve those desired goals. When there is agreement on the goals and required resources, the appropriate action is then taken to reach the goal. In the final step, there is a check or an assessment of whether the action that was taken actually achieved the goal.

Figure 9.1 Creating action through communication

For example, if there is a broken piece of equipment in a process, the manager or other actuator completes a standard request for help from maintenance. In this standard request, they specify what they see as the problem with the particular machine. When the appropriate supervisor or maintenance person arrives there may be a short negotiation about what is to be done. If it is a simple repair, maintenance can quickly state when they expect to have it operable. If it is more complex, the maintenance manager may request that they be given time to do a diagnosis before estimating what has to be done. If a diagnosis step is required, then the operations manager and maintenance supervisor agree on the time when that will be completed. The maintenance manager then assigns a worker to do this work, and then they report the diagnosis to the manager at the time agreed upon.

A follow up cycle to the repair could be a request by the maintenance manager to the operations manager to meet to discuss the use of Total Productive Maintenance (TPM) with the machine. The goal of the maintenance manager might be to reduce down time on the particular machine by involving the machine operators in routine maintenance such as lubrication and cleaning. The maintenance manager can meet with and negotiate with the operations manager about this and point out that while this will take some allocation of the operator’s time to lubrication and repair, the benefit will be higher machine uptime for the operations manager. Once they agree on the goals and resources needed for the TPM program, they can institute it with training and daily activities. At an agreed upon time they can evaluate whether they are achieving their goals.

Communication Standards Improves Performance

By establishing standard routines for problem identification and resolution, as well as standards for each operation, many process problems are avoided or measures to avoid problems identified, continuously improving the process. Through these structured actions work designs are created for the business processes and for the individual processes for each product or service.

Example: If you go to a coffee shop such as Starbucks and walk to the register, the barista takes action by asking: “What do you want?” Your decision will result in a standardized action by the barista and possibly by other staff. For example, if you answer that you want a skinny Frappuccino the barista will enter your order into the cash register, which will send a message to the labeler of the espresso machine. When it is printed, another barista will take the label, post it on a Frappuccino cup and then prepare the drink according to the Starbucks standards.

The process described in the Starbucks example, shows a routine communication structure. These communications are part of a routine to sequence actions. They also create an outline for training, because each employee is required to know how to perform their standard or routine actions. This training provides that the worker has the right knowledge to process the incoming information at the right time at the right place to take informed actions. The worker receiving the information is able to process the information according to the routine established in the work design, and so the desired actions occur.

To support leadership, and to take the right actions at the right time and the right place, the manager also needs support from the structure. The structure should provide him or her the right information at the right time and the right place, for example, via visual control.

Communication Breakdowns

When problems occur, visual controls or andon (indicator lights) show supervisors and others where the trouble is. That troubles are immediately visually communicated to everyone is a remarkable feature of the Toyota production system; but when troubles arise, it is the actual solutions to these problems that are most important. (Shingo 1989, p. 120)

Despite the best planning, there will be communication breakdowns. The company needs a process to identify and resolve these problems. A department may commit to have changes made by a certain date but the department may suddenly receive a more urgent request from another internal customer, which did not inform the department in advance. It is important that the department immediately signal its first customer with the less urgent request that it is unable to meet its commitment. By sending the signal immediately, the department is highlighting a problem for the entire organization to see, which is that it does not have the resources to meet a surge in demand. This allows time for an upper management intervention if the problem is seen to be serious enough. But it is also important to inform the other department that communication broke down.

The signaling of a communication breakdown is important. It is similar to an andon light on a machine. It lets everyone responsible know that there is a problem. Without a signal, the problem becomes noise which makes it harder for everyone to do their work.

References

Drucker, P.F. 1954. The Practice of Management. New York: Harper.

Shingo, S. 1989. A Study of the Toyota Production System from an Industrial Engineering Viewpoint. Cambridge, MA: Productivity Press.

Spear, S., and H.K. Bowen. 1999. “Decoding the DNA of the Toyota Production System.” Harvard Business Review, September–October, pp. 97–106.

Watzlawick, P., J.H. Beavin, and D.D. Jackson. 1967. Pragmatics of Human Communication: A Study of Interactional Patterns, Pathologies, and Paradoxes, 120. 1st ed. New York: Norton.