Chapter 4. Binary Column Distillation: Internal Stage-by-Stage Balances

4.0 Summary—Objectives

In this long chapter we develop the stage-by-stage balances for distillation columns and show how to solve these equations when molar flow rates in each section of the column are constant (called constant molal overflow [CMO]). When finished studying this chapter, you should be able to satisfy the following objectives:

1. Write mass and energy balances and equilibrium expressions for any stage in a column

2. Explain what CMO is, and determine if CMO is valid in a given situation

3. Derive the operating equations for CMO systems

4. Calculate the feed quality, and determine its effect on flow rates. Plot the feed line on a y-x diagram

5. Determine the number of stages required using the Lewis method and the McCabe-Thiele method

6. Develop and explain composition, temperature, and flow profiles

7. Solve any binary distillation problem where CMO is valid. This includes:

a. Open steam

b. Multiple feeds

c. Partial condensers and total reboilers

d. Side streams

e. Intermediate reboilers and condensers

f. Stripping and enriching columns

g. Total and minimum reflux

h. Overall and Murphree efficiencies

i. Simulation problems

j. Any combination of the above

8. Include the effects of subcooled reflux or superheated boilup

9. Use a computer process simulator for simulation of binary distillation

4.1 Internal Balances

In Chapter 3 we introduced column distillation and developed the external balance equations. In this chapter we look inside the column. The number of equilibrium stages required for the separation can be determined by solving mass and energy balances and equilibrium in a stage-by-stage fashion. We start at the top of the column and write the balances and equilibrium relationship for the first stage and then, once we have determined the unknown variables for the first stage, we write balances for the second stage. Utilizing the variables just calculated we can again calculate the unknowns. We can now proceed down the column in this stage-by-stage fashion until we reach the bottom. We could also start at the bottom and proceed upward. Methods for nonequilibrium stages are discussed in Section 4.11.

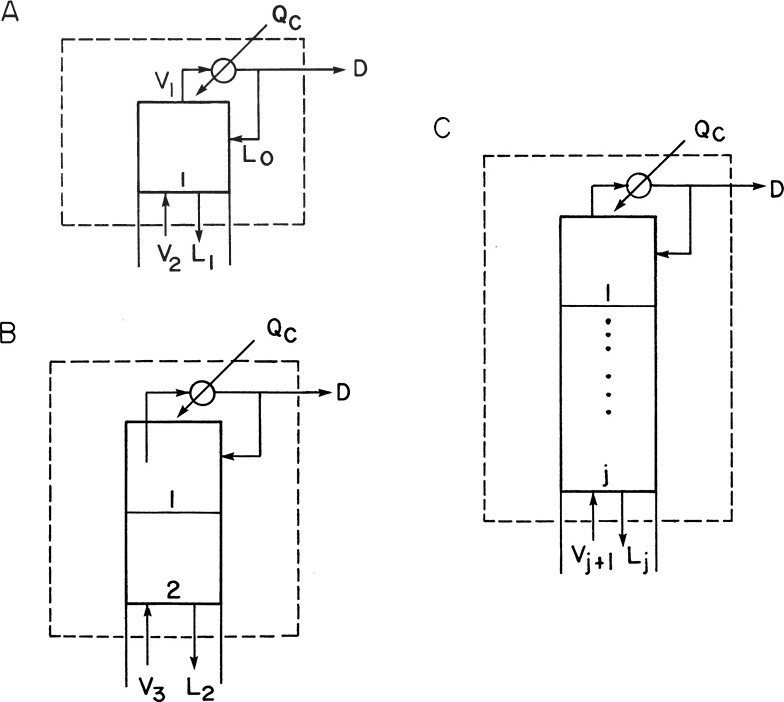

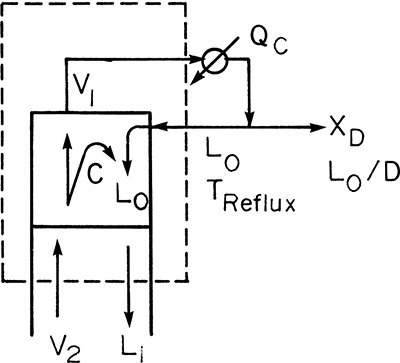

In the enriching section of the column it is convenient to use a balance envelope, as shown in Figure 4-1, that goes around the desired stage and around the condenser. The balance envelope for the first stage is shown in Figure 4-1A. The overall mass balance is

The more volatile component (MVC) mass balance is

For a well-insulated, adiabatic column (Qcolumn = 0), the energy balance is

Assuming that each stage is an equilibrium stage, liquid and vapor leaving each stage are in equilibrium. For a binary system, Gibbs phase rule is

Degrees of freedom = C – P + 2 = 2 – 2 + 2 = 2

Since pressure has been set, there is one remaining degree of freedom. Thus the intensive variables are all functions of a single variable. For the saturated liquid we can write

and for the saturated vapor,

The liquid and vapor mole fractions leaving a stage are also related:

Equations (4-4) for stage 1 represent the equilibrium relationship. Their exact form depends on the chemical system being separated. For example, we found that Eq. (2.B-2), a sixth-order polynomial, was a reasonable fit to the equilibrium data for Eq. (4-4c) for ethanol-water equilibrium. Equations (4-1, stage 1) to (4-4c, stage 1) are six equations with six unknowns: L1, V2, x1, y2, H2, and h1.

Since we have six equations and six unknowns, in theory, we can solve for the six unknowns. The exact methods for calculating the unknowns are the subject of the remainder of this chapter. For now we will just note that we can solve for the unknowns and then proceed to the second stage. For the second stage we will use the balance envelope shown in Figure 4-1B. The mass balances are now

while the energy balance is

The equilibrium relationships are

Again we have six equations with six unknowns. The unknowns are now L2, V3, x2, y3, H3, and h2.

We can now proceed to the third stage and utilize the same procedures. After that, we can go to the fourth stage and then the fifth stage and so forth. For a general stage j (j can be from 1 to f – 1, where f is the feed stage) in the enriching section, the balance envelope is shown in Figure 4-1C. For this stage the mass and energy balances are

and

while the equilibrium relationships are

When we reach stage j the values of yj, Qc, D, and hD will be known, and the unknown variables will be Lj, Vj+1, xj, yj+1, Hj+1, and hj. At the feed stage the mass and energy balances will change because of the addition of the feed stream.

Before continuing, note the symmetry of the mass and energy balances and the equilibrium relationships as we go from stage to stage. Equations (4-1) for stages 1, 2, and j all have the same structure and differ only in subscripts. Equations (4-1, stage 1) and (4-1, stage 2) can be obtained from the general Eq. (4-1, stage j) by replacing j with 1 or 2, respectively. The same observations can be made for the other equations. The unknown variables as we go from stage to stage are also similar and differ only in subscript.

In addition to this symmetry from stage to stage, there is symmetry between equations for the same stage. Thus Eqs. (4-1, stage j), (4-2, stage j), and (4-3, stage j) are all steady-state balances that state input = output. In all three equations the output (of overall mass, solute, or energy) is associated with streams Lj and D. The input is associated with stream Vj+1 and for energy with the cooling load, Qc.

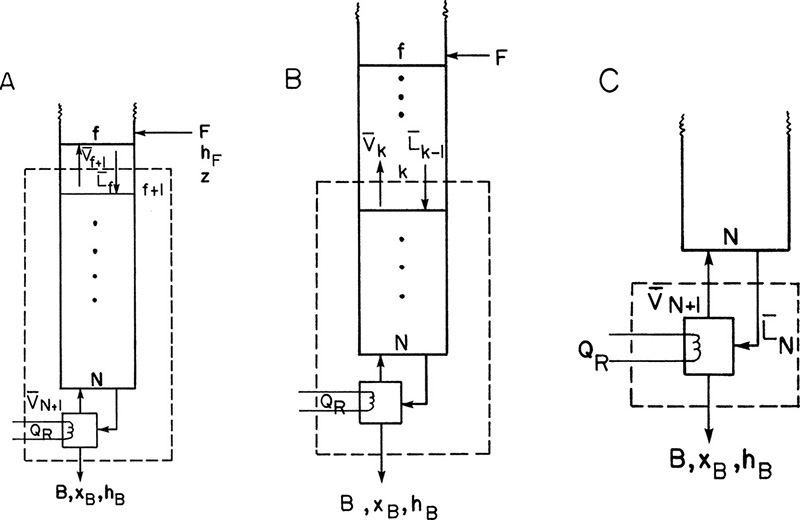

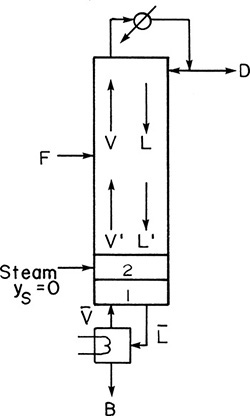

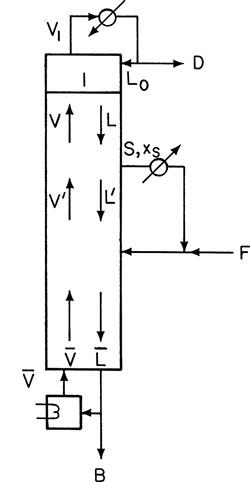

Below the feed stage the balance equations must change, but the equilibrium relationships in Eqs. (4-4a, b, and c) will be unchanged. The balance envelopes in the stripping section are shown in Figure 4-2 for a column with a partial reboiler. The bars over the flow rates signify that they are in the stripping section. It is traditional and simplest to write the stripping section balances around the bottom of the column using the balance envelope shown in Figure 4-2. Then these balances around stage f + 1 (immediately below the feed plate) are

FIGURE 4-2. Stripping section balance envelopes; (A) below feed stage (stage f + 1), (B) stage k, (C) partial reboiler

The equilibrium relationships are Eqs. (4-4) written for stage f + 1:

These six equations have six unknowns: ![]() ,

, ![]() , xf, yf+1, Hf+1, and hf. xB is specified in the problem statement; B and QR were calculated from the column balances; and yf (required for the last equation) was obtained from the solution of Eqs. (4-1, stage j) to (4-4c, stage j) with j = f – 1. At the feed stage we change from one set of balance envelopes to another.

, xf, yf+1, Hf+1, and hf. xB is specified in the problem statement; B and QR were calculated from the column balances; and yf (required for the last equation) was obtained from the solution of Eqs. (4-1, stage j) to (4-4c, stage j) with j = f – 1. At the feed stage we change from one set of balance envelopes to another.

Note that the same equations will be obtained if we write the balances above stage f + 1 and around the top of the distillation column (use a different balance envelope). This is easily illustrated with the overall mass balance, which becomes

Rearranging, we have

However, since the external column mass balance says F – D = B, the last equation becomes

which is Eq. (4-5, stage f + 1). Similar results are obtained for the other balance equations. Thus the balance envelope we use is arbitrary.

Once the six equations, Eqs. (4-4a) to (4-7), for stage f + 1 have been solved, we can proceed down the column to the next stage, f + 2. For a balance envelope around general stage k, as shown in Figure 4-2B, the equations are

The equilibrium expression will correspond to Eqs. (4-4, stage f + 1), with k – 1 replacing f as a subscript. Thus

A partial reboiler, as shown in Figure 4-2C, acts as an equilibrium contact. If we consider the reboiler as stage N + 1, the balances for the envelope shown in Figure 4-2C can be obtained by setting k = N + 1 and k – 1 = N in Eqs. (4-5, stage k), (4-6, stage k), and (4-7, stage k).

If xN+1 = xB, the N + 1 equilibrium contacts give us exactly the specified separation, and the problem is finished. If xN+1 < xB while xN > xB, the N + 1 equilibrium contacts give slightly more separation than is required.

Just as the balance equations in the enriching section are symmetric from stage to stage, they are also symmetric in the stripping section.

4.2 Binary Stage-by-Stage Solution Methods

The challenge for any stage-by-stage solution method is to solve the three balance equations and the three equilibrium relationships simultaneously in an efficient manner. This problem was first solved by Sorel (1893), and graphical solutions of Sorel’s method were developed independently by Ponchon (1921) and Savarit (1922). (Kockmann [2014] covers the history of distillation.) These methods all solve the complete mass and energy balance and equilibrium relationships stage by stage. Starting at the top of the column, as shown in Figure 4-1A, we can find the liquid composition, x1, in equilibrium with the leaving vapor composition, y1, from Eq. (4-4c, stage 1). The liquid enthalpy, h1, is found from Eqs. (4-4a, stage 1). The remaining four equations, Eqs. (4-1) to (4-3) and (4-4b), for stage 1 are coupled and must be solved simultaneously. The Ponchon-Savarit method does this graphically. The Sorel method uses a trial-and-error procedure on each stage.

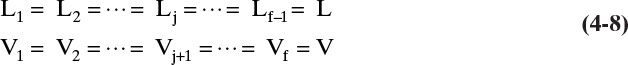

The trial-and-error calculations on every stage of the Sorel method are obviously slow and laborious. Lewis (1922) noted that in many cases the molar vapor and liquid flow rates in each section (a region between input and output ports) were constant. Thus in Figures 4-1 and 4-2

and

For each additional column section there will be another set of equations for constant flow rates. Note that in general ![]() and

and ![]() . Equations (4-8) and (4-9) are valid if every time a mole of vapor is condensed, a mole of liquid is vaporized. This occurs under the following conditions:

. Equations (4-8) and (4-9) are valid if every time a mole of vapor is condensed, a mole of liquid is vaporized. This occurs under the following conditions:

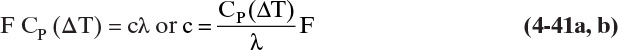

1. The heat of vaporization per mole λ is constant; that is, λ does not depend on concentration. This condition is the most important criterion.

2. The specific heat changes are small compared to latent heat changes.

3. The column is adiabatic.

Lewis called this set of conditions CMO. An alternative to conditions 1 and 2 is

4. The saturated liquid and vapor lines on an enthalpy-composition diagram (in molar units) are parallel.

For some systems, such as hydrocarbons, the latent heat of vaporization per kilogram is approximately constant. In such situations the mass flow rates are constant, and constant mass overflow should be used.

The Lewis method assumes before the calculation is done that CMO is valid. Thus Eqs. (4-8) and (4-9) are valid. With this assumption, the energy balance, Eqs. (4-3) and (4-7), will be automatically satisfied. Then only Eqs. (4-1), (4-2), and (4-4c) or Eqs. (4-5), (4-6), and (4-4c) need be solved. Equations (4-1, stage j) and (4-2, stage j) can be combined:

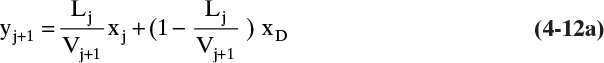

Solving for yj+1, we have

Since L and V are constant, this equation becomes

Equation (4-12b) is the operating equation in the enriching section. It relates the concentrations of two passing streams in the column and thus represents the mass balances in the enriching section. Equation (4-12b) is solved sequentially with the equilibrium expression for xj, Eq. (4-4c, stage j).

To start, we first use the external column balances to calculate D and B. Then

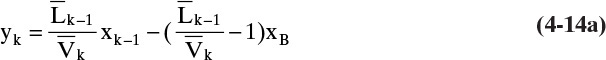

In the stripping section Eqs. (4-5, stage k) and (4-6, stage k) are combined to give

With CMO, ![]() and

and ![]() are constant, and the resulting stripping section operating equation is

are constant, and the resulting stripping section operating equation is

Once we know ![]() we can calculate by alternating between the operating Eq. (4-14b) and equilibrium Eq. (4-4c, stage k).

we can calculate by alternating between the operating Eq. (4-14b) and equilibrium Eq. (4-4c, stage k).

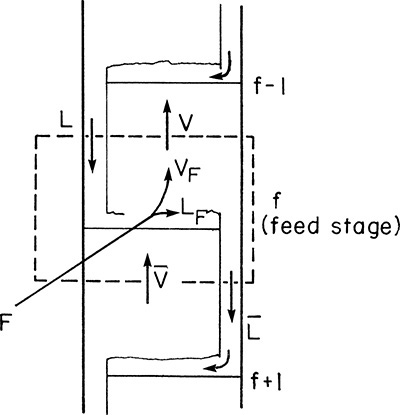

The phase and temperature of the feed affects the vapor and liquid flow rates in the column. For instance, if the feed is liquid, the liquid flow rate below the feed stage must be greater than liquid flow above the feed stage, ![]() , and if the feed is a vapor,

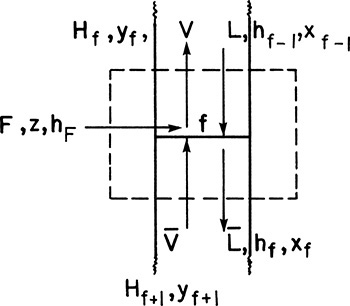

, and if the feed is a vapor, ![]() . These effects can be quantified by writing mass and energy balances around the feed stage. The feed stage is shown schematically in Figure 4-3. The overall mass balance and the energy balance for the balance envelope shown in Figure 4-3 are

. These effects can be quantified by writing mass and energy balances around the feed stage. The feed stage is shown schematically in Figure 4-3. The overall mass balance and the energy balance for the balance envelope shown in Figure 4-3 are

and

(Despite the use of “hF” as the symbol for the feed enthalpy, the feed can be a liquid or vapor or a two-phase mixture.) If we assume CMO, neither the vapor enthalpies nor the liquid enthalpies vary much from stage to stage. Thus Hf+1 ∼ Hf and hf–1 ∼ hf. Then Eq. (4-16) becomes

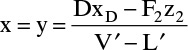

The mass balance Eq. (4-15) can be conveniently solved for ![]() :

:

which can be substituted into the energy balance to give us

or

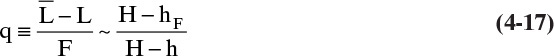

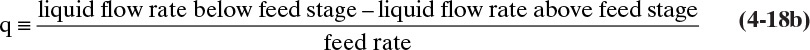

The “quality” q can be generalized to

The value of q can be approximated from

This result is analogous to the use of q in flash distillation. Since the liquid and vapor enthalpies can be estimated, we can calculate q from Eq. (4-17). Then

The quality q is the fraction of feed that is liquid. For example, if the feed is a saturated liquid, hF = h, q = 1, and ![]() . Once

. Once ![]() has been determined,

has been determined, ![]() is calculated from either Eq. (4-15) or Eq. (4-5, stage f + 1) or from

is calculated from either Eq. (4-15) or Eq. (4-5, stage f + 1) or from

This equation can be derived from Eqs. (4-15) and (4-19a).

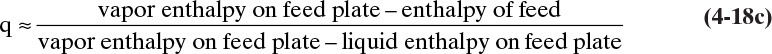

When the feed is a two-phase mixture, we can analyze the feed in exactly the same way as we analyzed flash distillation. If f is the fraction of feed that is vapor, then

In words this is

and we can estimate the fraction vapor from

If CMO is valid, the vapor and liquid flow rates in the column sections above and below the feed are related by

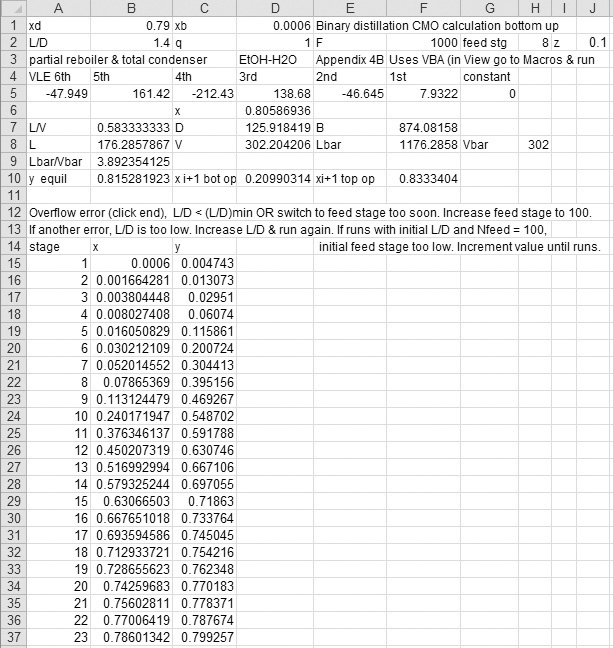

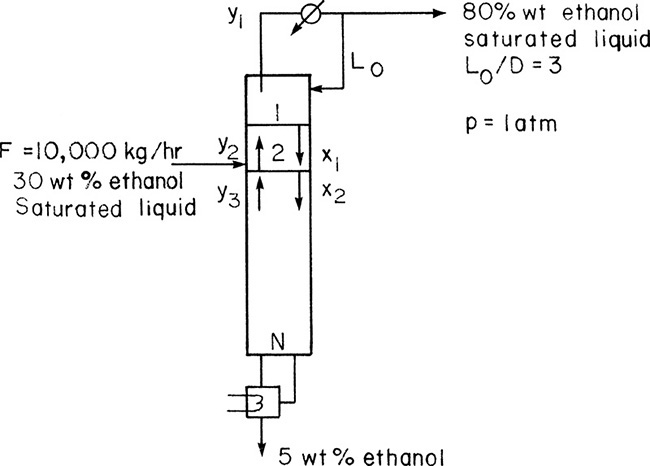

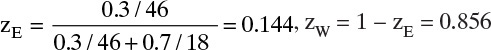

EXAMPLE 4-1. Stage-by-stage calculations by the Lewis method

A steady-state countercurrent, staged distillation column is separating ethanol from water. The feed is a 30.0 wt% ethanol, 70.0 wt% water mixture that is a saturated liquid at 1 atm pressure. Flow rate of feed is 10,000 kg/h. The column operates at a pressure of 1 atm. The reflux is returned as a saturated liquid. A reflux ratio of L/D = 3.0 is being used. Bottoms composition is xB = 0.05 (weight fraction ethanol), and distillate composition is xD = 0.80 (weight fraction ethanol). The system has a total condenser and a partial reboiler. The column is well insulated. Use the Lewis method to find the number of equilibrium contacts required if the feed is input on the second stage from the top.

Solution

A. Define. The column and known information are shown in the following figure. Find the number of equilibrium contacts required.

B. Explore. This problem is very similar to Example 3-1. The solutions for B and D obtained in that example are still correct: B = 6667 kg/h, and D = 3333 kg/h. Equilibrium data are available in weight fractions in Figure 2-4 and in mole fraction units in Figure 2-2 and Table 2-1. To use the Lewis method we must have CMO. We can check this by comparing the latent heat per mole of pure ethanol and pure water. (This checks the most important criterion for CMO. Since the column is well insulated, the third criterion, adiabatic, will be satisfied.) The latent heats are (Himmelblau, 1974)

λE = 9.22 kcal/mol, λW = 9.7171 kcal/mol

The difference of roughly 5% is reasonable particularly since we always use the ratio of L/V or ![]() . (Using the ratio causes some of the change in L and V to divide out.) Thus we will assume CMO. To have constant flow rates we must convert flows and compositions to molar units. MWW = 18 and MWE = 46.

. (Using the ratio causes some of the change in L and V to divide out.) Thus we will assume CMO. To have constant flow rates we must convert flows and compositions to molar units. MWW = 18 and MWE = 46.

C. Plan. After converting to molar units, do preliminary calculations to determine L/V and ![]() . Then start at the top, alternating between equilibrium [Figure 2-2 or Eq. (2.B-2)] and the top operating Eq. (4-12b). Since stage 2 is the feed stage, calculate y3 from the bottom operating Eq. (4-14).

. Then start at the top, alternating between equilibrium [Figure 2-2 or Eq. (2.B-2)] and the top operating Eq. (4-12b). Since stage 2 is the feed stage, calculate y3 from the bottom operating Eq. (4-14).

Preliminary Calculations: To convert to molar units choose a convenient basis, such as 1.0 kg of feed.

Average molecular weight of feed is

Feed rate = (10,000 kg/h)/(22.03 kg/kmol) = 453.9 kmol/h. Distillate mole fraction,

For distillate, the average molecular weight is

This is also the average for the reflux liquid and vapor stream V since they are all the same composition. Then D = (3333 kg/h)/35.08 = 95.23 kmol/h and L = (L/D)D = 3(95.23) = 285.7 kmol/h, and V = L + D = 380.9 kmol/h. Thus L/V = 285.7/380.9 = 0.75. Because of CMO, L/V is constant in the rectifying section.

Since the feed is a saturated liquid,

Since a saturated liquid feed does not affect the vapor, ![]() . Thus

. Thus ![]() . An internal check on consistency is L/V < 1 and

. An internal check on consistency is L/V < 1 and ![]() .

.

Stage-by-Stage Calculations: At the top of the column, y1 = xD = 0.61 (mole fraction). Liquid stream L1 of concentration x1 is in equilibrium with the vapor stream y1. From Figure 2-2, x1 = 0.4. (Note that y1 > x1, since ethanol is the more volatile component.) Vapor stream y2 is a passing stream relative to x1 and can be determined from the operating Eq. (4-12).

Stream x2 is in equilibrium with y2. From Figure 2-2 we obtain x2 = 0.11. Since stage 2 is the feed stage, use bottom operating Eq. (4-14) for y3.

Stream x3 is in equilibrium with y3. From Figure 2-2, this is x3 = 0.02. Since x3 = xB (in mole fraction), we are finished.

The third equilibrium contact is the partial reboiler. Thus the column has two equilibrium stages in addition to the partial reboiler.

E. Check. This is a small number of stages. However, not much separation is required, the external reflux ratio is large, and the separation of ethanol from water is easy in this concentration range. Thus the answer is reasonable. We can check the calculation of L/V with mass balances.

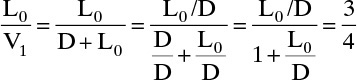

Since V1 = L0 + D,

Since L0, V1, and D are the same composition, L0/D and L0/V1 have the same values in mass and molar units. We can check the equilibrium calculation with Eq. (2.B-2). For example, for y1 = 0.61 we obtain x1 = 0.385.

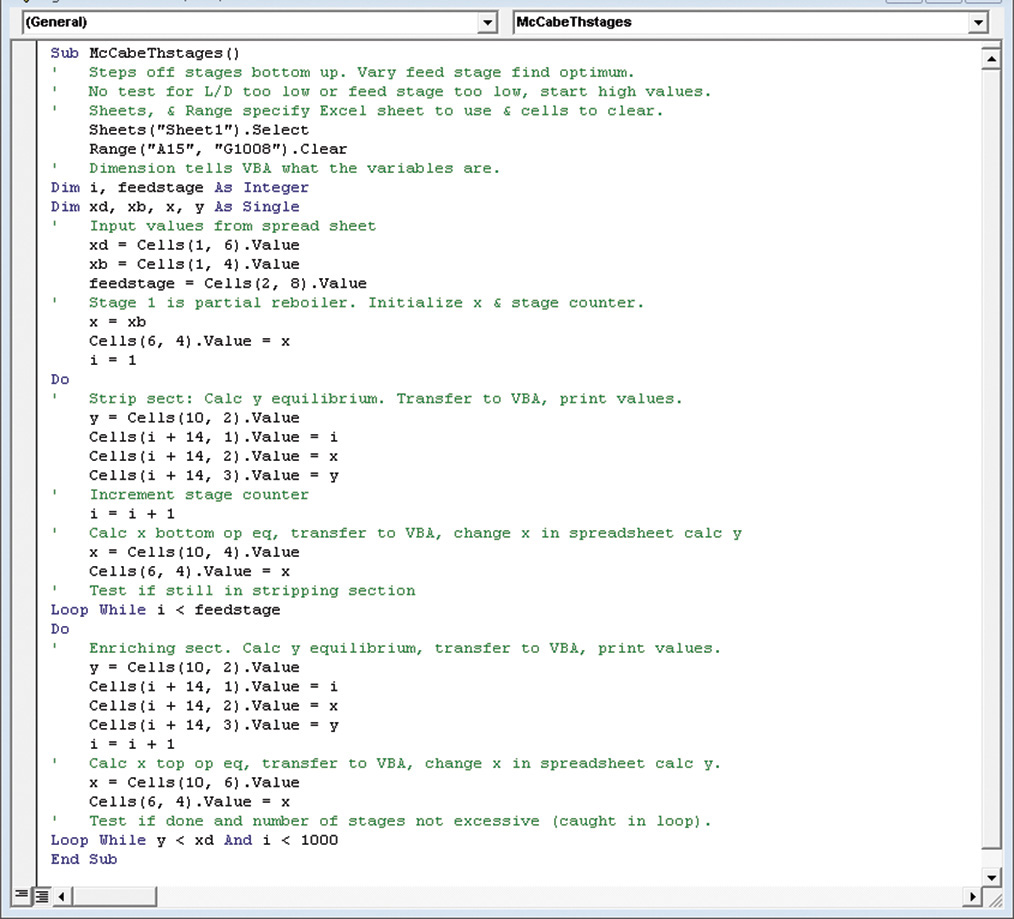

F. Generalizations. Always check that CMO is valid, and then convert all flows and compositions into molar units. The procedure for stepping off stages is easily programmed on a spreadsheet (see Appendix B of this chapter). We could also have started at the bottom and worked our way up the column stage by stage. Going up the column we calculate y values from equilibrium and x values from the operating equations.

Note that L/V < 1 and ![]() . This relationship makes sense, since we must have a net flow of material upward in the rectifying section to obtain a distillate product and a net flow downward in the stripping section to obtain a bottoms product. We must also have a net upward flow of ethanol in the rectifying section (Lxj < Vyj+1) and in the stripping section

. This relationship makes sense, since we must have a net flow of material upward in the rectifying section to obtain a distillate product and a net flow downward in the stripping section to obtain a bottoms product. We must also have a net upward flow of ethanol in the rectifying section (Lxj < Vyj+1) and in the stripping section ![]() . These conditions are satisfied by all pairs of passing streams.

. These conditions are satisfied by all pairs of passing streams.

The Lewis method is obviously much faster and more convenient than the Sorel method. It is also easier to program on a computer or in a spreadsheet. In addition, it is easier to understand the physical reasons why separation occurs instead of becoming lost in the algebraic details. However, remember that the Lewis method is based on the assumption of CMO. If CMO is not valid, then the answers will be incorrect.

If you find the Lewis method is confusing, continue to the next section. The graphical McCabe-Thiele procedure explained in Section 4.3 is easier for many students to understand. After completing the McCabe-Thiele procedure, return to this section and study the Lewis method again.

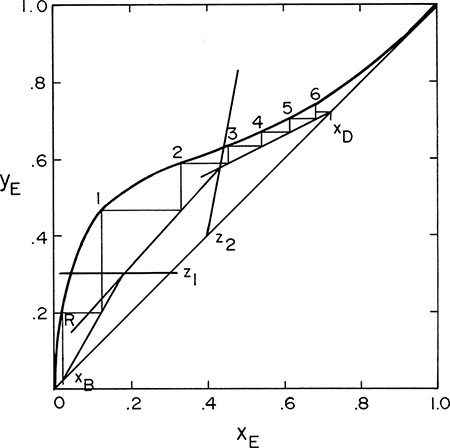

4.3 Introduction to the McCabe-Thiele Method

McCabe and Thiele (1925) developed a graphical solution method based on Lewis’ method and the observation that the operating Eqs. (4-12b) and (4-14) plot as straight lines (the operating lines) on a y-x diagram. On this graph the equilibrium relationship can be solved from the y-x equilibrium curve and the mass balances from the operating lines.

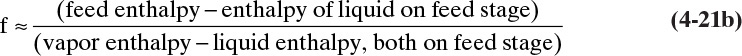

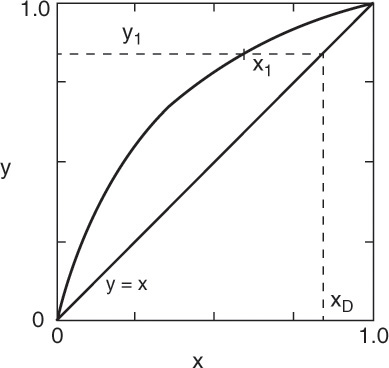

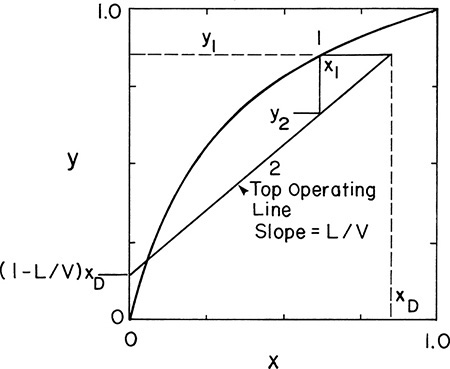

To illustrate, consider a typical design problem for a binary distillation column such as the one illustrated in Figure 3-8. Assume that equilibrium data are available at the operating pressure of the column. These data are plotted in Figure 4-4. At the top of the column is a total condenser. As noted in Chapter 3 in Eq. (3-10a), this condition means that y1 = xD = x0. The vapor leaving the first stage is in equilibrium with the liquid leaving the first stage. This liquid composition, x1, can be determined from the equilibrium curve at y = y1. This is illustrated in Figure 4-4.

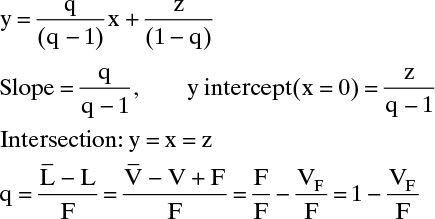

Liquid stream L1 of composition x1 passes vapor stream V2 of composition y2 inside the column (Figures 3-8 and 4-1A). When the mass balances are written around stage 1 and the top of the column (see balance envelope in Figure 4-1A), the result after assuming CMO and doing some algebraic manipulations is Eq. (4-12) with j = 1. This equation can be plotted as a straight line on the y-x diagram. Suppressing subscripts j + 1 and j, we write Eq. (4-12b) as

which is understood to apply to passing streams. Eq. (4-23) plots as a straight line (the top operating line) with a slope of L/V and a y intercept (x = 0) of (1 – L/V)xD. Once Eq. (4-23) has been plotted, y2 is easily found from the y value at x = x1. This is illustrated in Figure 4-5. Note that the top operating line goes through the point (y1, xD) since these coordinates satisfy Eq. (4-23).

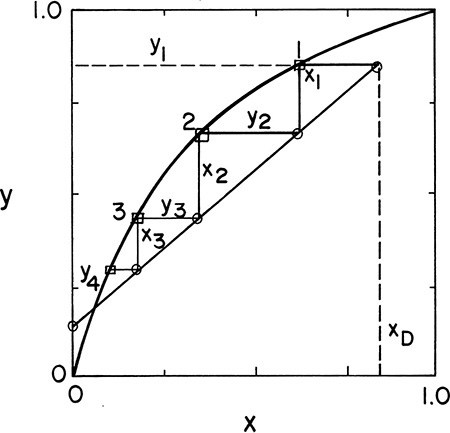

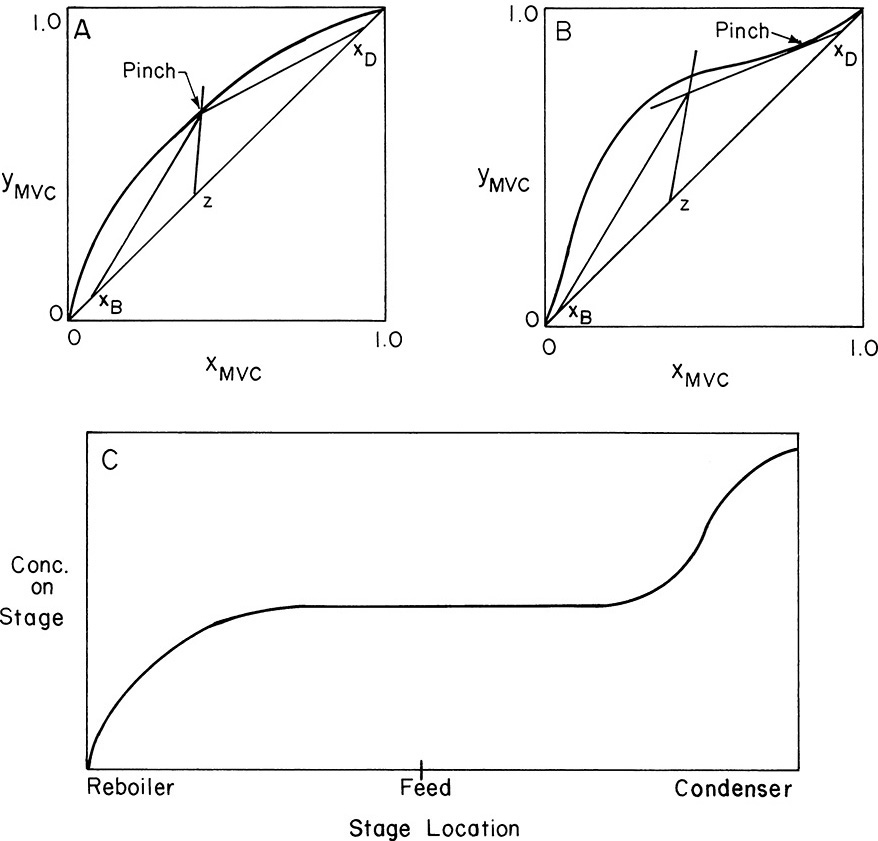

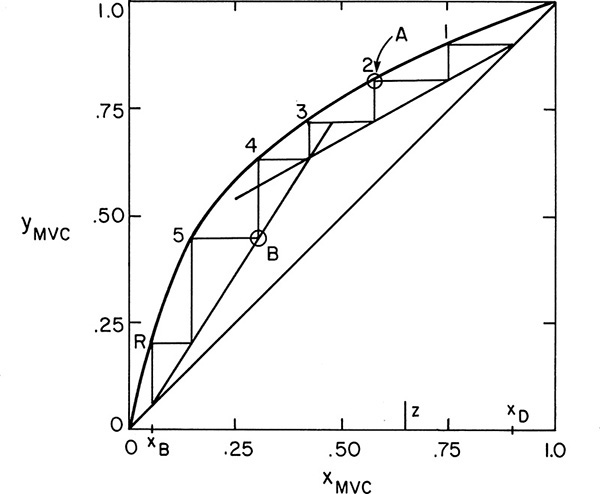

With y2 known we can proceed down the column. Since x2 and y2 are in equilibrium, we obtain x2 from the equilibrium curve. Then we obtain y3 from the operating line (mass balances), since x2 and y3 are the compositions of passing streams. This procedure of stepping off stages is shown in Figure 4-6. It can be continued as long as we are in the rectifying section. Note that this procedure produces a staircase on the y-x, or McCabe-Thiele, diagram. Instead of memorizing this procedure, you should follow the points on the diagram and compare them to the schematics of a distillation column (Figures 3-8 and 4-1). Note that the horizontal and vertical lines have no physical meaning. The points on the equilibrium curve (squares in Figure 4-6) represent liquid and vapor streams leaving an equilibrium stage. The points on the operating line (circles in Figure 4-6) represent the liquid and vapor streams passing each other in the column.

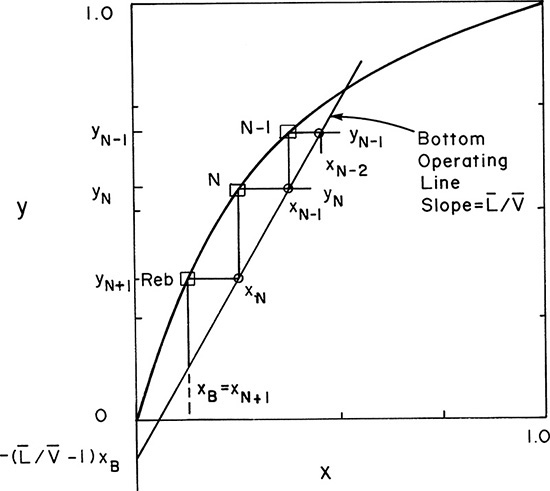

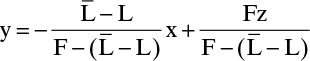

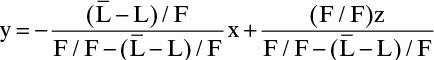

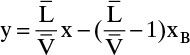

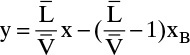

In the stripping section Eq. (4-23) is no longer valid since different mass balances and, hence, a different operating equation are required. The stripping section operating equation was given in Eq. (4-14b). When subscripts k and k – 1 are suppressed this equation becomes

Equation (4-24) plots as a straight line with slope ![]() and y intercept

and y intercept ![]() , as shown in Figure 4-7. This bottom operating line applies to passing streams in the stripping section. Liquid leaving the partial reboiler has a mole fraction of xB = xN+1. We know that the vapor leaving the partial reboiler (composition yN+1) is in equilibrium with xB, and we can find yN+1 from the equilibrium curve. Since liquid of composition xN is a passing stream to vapor of composition yN+1 (compare Figures 4-2 and 4-7), xN is found from the bottom operating line. This process of stepping off stages by alternating between the equilibrium curve and the bottom operating line continues as long as we are in the stripping section.

, as shown in Figure 4-7. This bottom operating line applies to passing streams in the stripping section. Liquid leaving the partial reboiler has a mole fraction of xB = xN+1. We know that the vapor leaving the partial reboiler (composition yN+1) is in equilibrium with xB, and we can find yN+1 from the equilibrium curve. Since liquid of composition xN is a passing stream to vapor of composition yN+1 (compare Figures 4-2 and 4-7), xN is found from the bottom operating line. This process of stepping off stages by alternating between the equilibrium curve and the bottom operating line continues as long as we are in the stripping section.

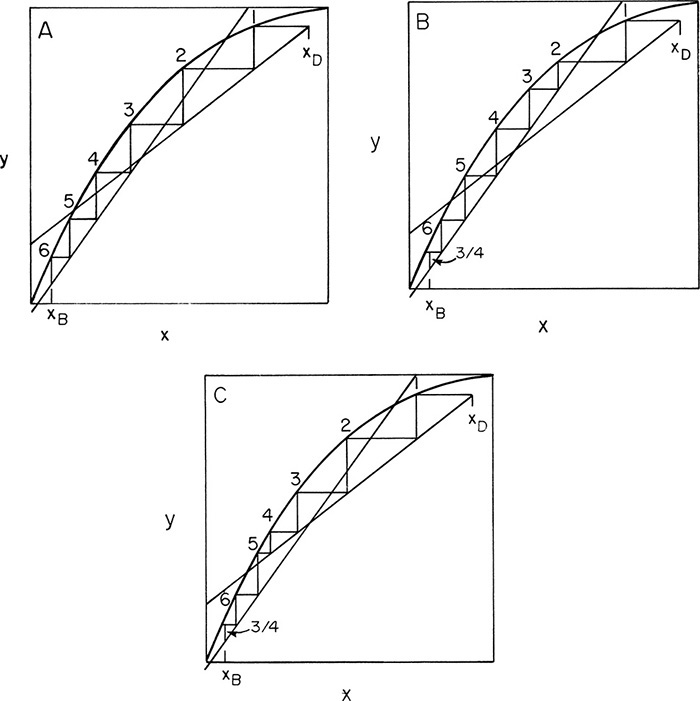

If we are stepping off stages down the column, at the feed stage f we switch from the top operating line to the bottom operating line (refer to Figure 4-3, a schematic of the feed stage). Above the feed stage we calculate yf from the top operating line. Since liquid and vapor leaving the feed stage are assumed to be in equilibrium, we can determine xf from the equilibrium curve at y = yf and then find yf+1 from the bottom operating line. This procedure is illustrated in Figure 4-8A, in which stage 3 is the feed stage. The separation shown in Figure 4-8A would require 5 equilibrium stages plus an equilibrium partial reboiler, or six equilibrium contacts, when stage 3 is used as the feed stage. In this problem, stage 3 is the optimum feed stage. That is, a separation will require the fewest total number of stages when stage 3 is the feed stage. Note in Figures 4-8B and 4-8C that if stage 2 or stage 5 is used, more total stages are required. For binary distillation the optimum feed plate is easy to determine; it is always the stage in which the step in the staircase includes the point of intersection of the two operating lines (compare Figure 4-8A to Figures 4-8B and 4-8C). A mathematical analysis of the optimum feed plate location suitable for computer calculation with the Lewis method is developed later.

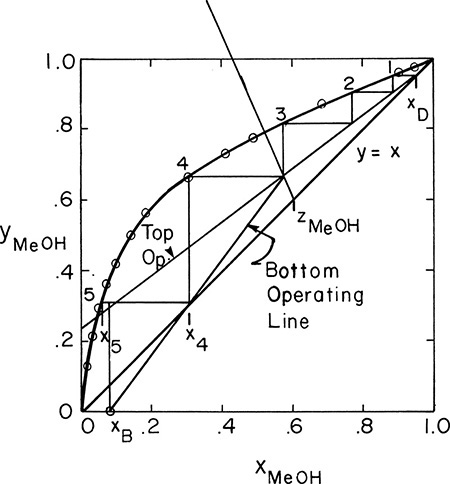

FIGURE 4-8. McCabe-Thiele diagram for entire column; (A) optimum feed stage (stage 3); (B) feed stage too high (stage 2); (C) feed stage too low (stage 5)

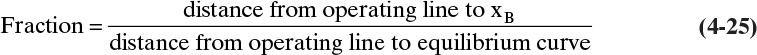

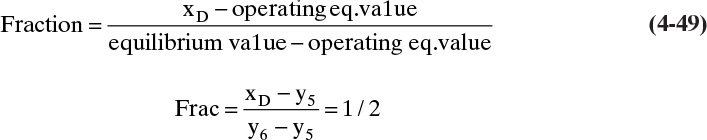

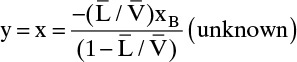

When stepping off stages from the top down, a fractional number of stages can be calculated as (see Figures 4-8B and 4-8C)

where the distances are measured horizontally on the diagram. The fraction has no physical meaning because we build either five or six stages; however, the fraction is somewhat useful when the stage efficiency is << 1.

Now that we know how to perform the stage-by-stage calculations on a McCabe-Thiele diagram, let us consider how to start with the design problem given in Figure 3-8 and Tables 3-1 and 3-2. The known variables are F, z, q, xD, xB, L0/D, p, and saturated liquid reflux, and we use the optimum feed location. Since the reflux is a saturated liquid, there will be no change in flow rates on stage 1 and L0 = L1 and V1 = V2. This allows us to calculate the internal reflux ratio, L/V, from the external reflux ratio, L0/D, which is specified.

With L/V and xD known, the top operating Eq. (4-23) is fully specified and can be plotted as a straight line.

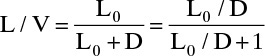

Since the boilup ratio, ![]() , is not specified, we cannot directly calculate

, is not specified, we cannot directly calculate ![]() , the slope of the bottom operating line. Instead, we need to utilize the condition of the feed to determine flow rates in the stripping section. The same procedure used with the Lewis method can be used here. The feed quality, q, is calculated from Eq. (4-17). Then

, the slope of the bottom operating line. Instead, we need to utilize the condition of the feed to determine flow rates in the stripping section. The same procedure used with the Lewis method can be used here. The feed quality, q, is calculated from Eq. (4-17). Then ![]() is given by Eq. (4-19a),

is given by Eq. (4-19a), ![]() , and

, and ![]() . We can calculate L as (L/D)D, where D and B are found from mass balances around the entire column. With

. We can calculate L as (L/D)D, where D and B are found from mass balances around the entire column. With ![]() and xB known, the bottom operating equation is fully specified, and the bottom operating line can be plotted.

and xB known, the bottom operating equation is fully specified, and the bottom operating line can be plotted.

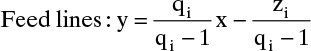

4.4 Feed Line

In any section of the column between feeds and/or product streams the mass balances are represented by an operating line that can be derived by drawing a mass balance envelope through an arbitrary stage in the section and around the top or bottom of the column. When material is added or withdrawn from the column the mass balances and the operating lines change. In the previous section the effect of a feed on the operating lines was determined from the feed quality and mass balances around the entire column. Here we will develop a graphical method for determining the effect of a feed on the operating lines.

Consider the simple, single-feed column with a total condenser and a partial reboiler shown in Figure 3-8. If CMO is valid the MVC mass balance in the rectifying section is

while the balance in the stripping section is

At the feed plate we switch from one mass balance to the other. We wish to find the point at which the top operating line—representing Eq. (4-27)—intersects the bottom operating line—representing Eq. (4-28). The intersection of these two lines means that

Equations (4-29) are valid only at the point of intersection or in the special case in which the lines are collinear (Section 4.10). Since the y’s and x’s are equal at the point of intersection, if we subtract Eq. (4-27) from Eq. (4-28), we obtain

From the overall mass balance around the entire column, Eq. (3-2), we know that the last term is –Fz. Then solving for y,

Eq. (4-30) is one form of the feed equation. Since L, ![]() , V,

, V, ![]() , F, and z are constant, it represents a straight line (the feed line) on a McCabe-Thiele diagram. Every possible intersection point of the two operating lines must occur on the feed line.

, F, and z are constant, it represents a straight line (the feed line) on a McCabe-Thiele diagram. Every possible intersection point of the two operating lines must occur on the feed line.

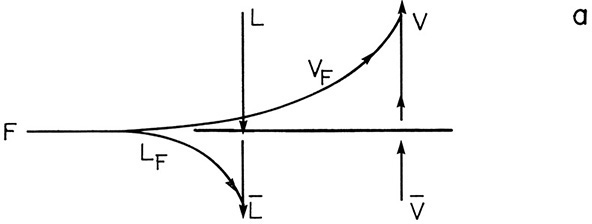

For the special case of a two-phase feed or one that flashes in the column to form vapor and liquid phases, we can relate Eq. (4-30) to flash distillation. In this case we have the situation shown in Figure 4-9. Part of the feed, VF, vaporizes, while the remainder is liquid, LF. Looking at the terms in Eq. (4-30), we note that ![]() is the change in liquid flow rates at the feed stage.

is the change in liquid flow rates at the feed stage.

The change in vapor flow rates is

Equation (4-30) then becomes

This is essentially the same as Eq. (2-11), the operating equation for flash distillation. Thus the feed line represents the flashing of the feed into the column. Equation (4-33) can also be written in terms of the fraction vaporized, f = VF/F, as [see Eqs. (2-12) and (2-13)]

In terms of the fraction remaining liquid, q = LF/F [see Eqs. (2-14) and (2-15)], Eq. (4-33) is

Eqs. (4-33) to (4-35) were derived for the special case in which the feed is a two-phase mixture, but they can be used for any type of feed. For example, if we want to derive Eq. (4-35) for the general case, we can start with Eq. (4-30). An overall mass balance around the feed stage (balance envelope shown in Figure 4-9) is

which can be rearranged to

Substituting this result into Eq. (4-30) gives

and dividing numerator and denominator of each term by the feed rate F, we get

which becomes Eq. (4-35) since ![]() . Derivation of Eq. (4-34) is similar.

. Derivation of Eq. (4-34) is similar.

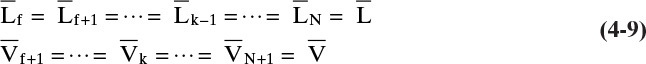

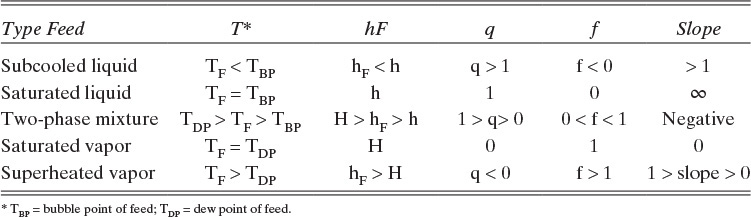

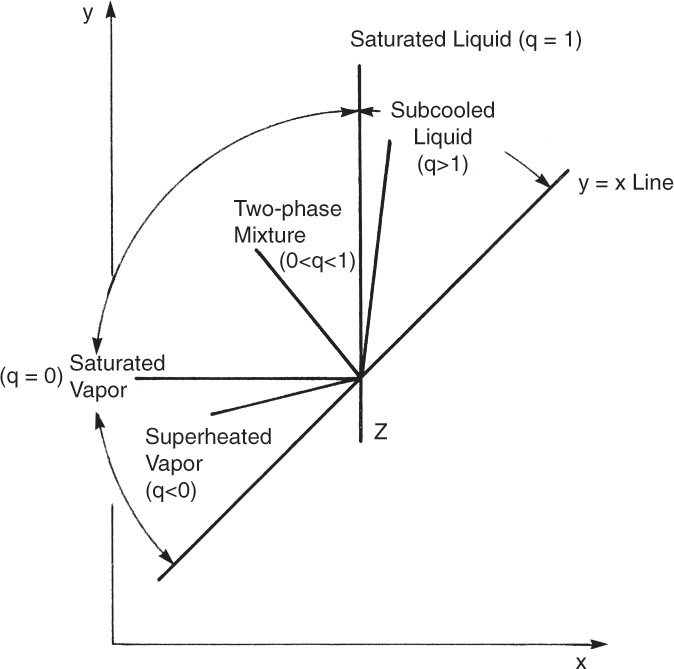

From Eq. (4-17) we can determine the value of q and hence the slope, q/(q – 1), of the feed line. For example, if the feed enters as a saturated liquid (i.e., at the liquid boiling temperature at the column pressure), then hF = h, and the numerator of Eq. (4-17) equals the denominator. Thus q = 1.0, and the slope of the feed line is q/(q – 1) = ∞. The feed line is vertical.

The various types of feeds and the slopes of the feed line are illustrated in Table 4-1 and Figure 4-10. Note that all the feed lines intersect at one point, which is at y = x. If we set y = x in Eq. (4-35), we find

is the point of intersection (try this derivation yourself). The feed line is easy to plot from the points y = x = z or y intercept (x = 0) = z/(1 – q) or x intercept (y = 0) = z/q, and the slope, which is q/(q – 1). (The process of plotting the feed line should remind you of binary flash distillation.)

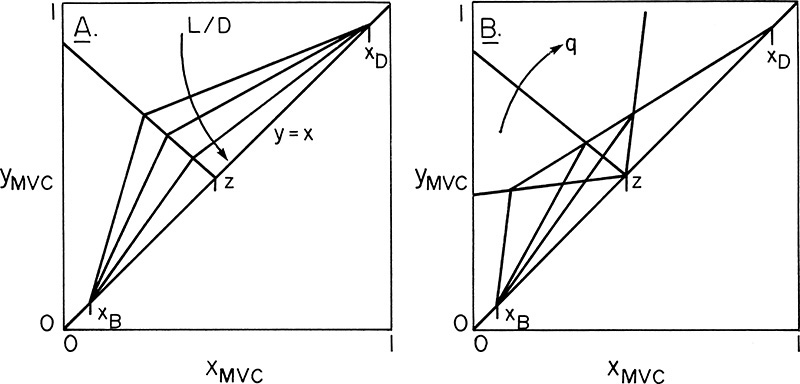

The feed line was derived from the intersection of the top and bottom operating lines. It thus represents all possible locations at which the two operating lines can intersect for a given feed (z, q). If we change the reflux ratio, we change the points of intersection, but they all lie on the feed line. This is illustrated in Figure 4-11A. If the reflux ratio is fixed (the top operating line is fixed) but q varies, the intersection point varies, as shown in Figure 4-11B. The slope of the bottom operating line, ![]() , depends on L0/D, xD, xB, and q.

, depends on L0/D, xD, xB, and q.

FIGURE 4-11. Operating line intersection; (A) changing reflux ratio with constant q; (B) changing q with fixed reflux ratio. Boilup ratio varies.

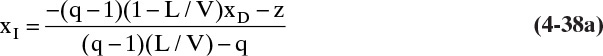

In Figure 4-8 we illustrate how to determine the optimum feed stage graphically. For computer applications an explicit test is easier to use. If the point of intersection of the two operating lines (yI, xI) is determined, then the optimum feed plate, f, is the one for which

and

This relationship is illustrated in Figure 4-12. For the simple column shown in Figure 3-8 the intersection point can be determined by straightforward but tedious algebraic manipulation as

The feed equations were developed for this simple column; however, Eqs. (4-30) and (4-33) through (4-35) are valid for any column configuration if we use the generalized definitions of q and f in Eqs (4-18a) and (4-21a).

EXAMPLE 4-2. Feed line calculations

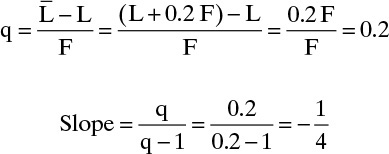

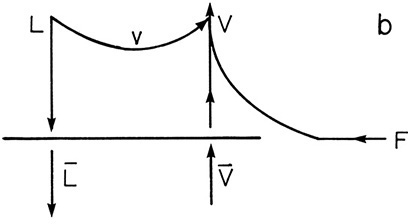

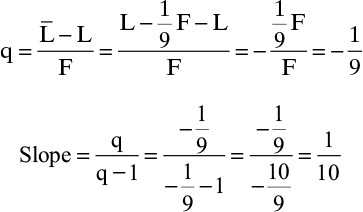

Calculate the feed line slope for the following cases.

a. A two-phase feed where 80% of the feed is vaporized under column conditions.

Solution

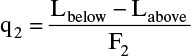

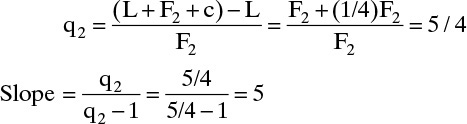

The slope is q/(q – 1), where q = (Lbelow feed – Labove feed)/F (other expressions could also be used). With a two-phase feed we have the situation shown in the figure.

![]() . Since 80% of the feed is vapor, 20% is liquid and LF = 0.2F. Then

. Since 80% of the feed is vapor, 20% is liquid and LF = 0.2F. Then

This agrees with Figure 4-10.

b. A superheated vapor feed where 1 mole of liquid vaporizes on the feed stage for each 9 moles of feed input.

Solution

This situation is shown in the following figure.

When the feed enters some liquid must be boiled to cool the feed. Thus

and the amount vaporized is v = (1/9) F. Thus

which agrees with Figure 4-10.

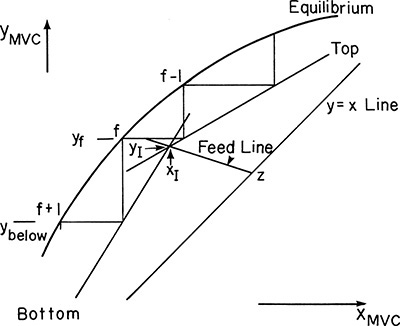

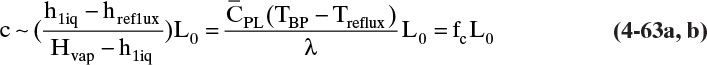

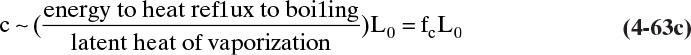

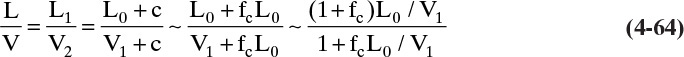

c. A liquid feed subcooled by 35°F. Average liquid heat capacity is 30 Btu/lbmol°F and λ = 15,000 Btu/lbmol.

Solution

Here some vapor must be condensed by the entering feed. Thus the situation can be depicted as shown.

and

where c is the amount condensed. Since the column is insulated, the source of energy to heat the feed to its boiling point is the condensing vapor.

Since ΔT = TBP – TF = 35°

This agrees with Figure 4-10. Despite the large amount of subcooling, the feed line is fairly close to vertical, and the results will be similar to a saturated liquid feed. If TF is given instead of ΔT, we need to estimate TBP. This estimation can be done with a temperature composition graph (Figure 2-3), an enthalpy-composition graph (Figure 2-4), or a bubble-point calculation (Section 5.3).

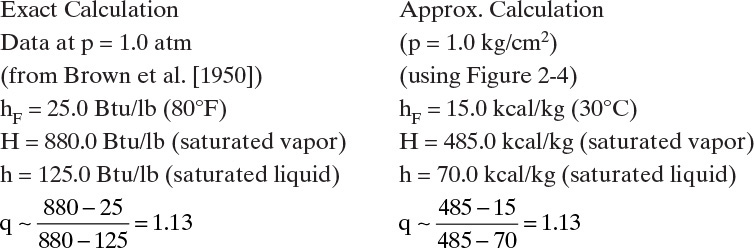

d. Feed is 40.0 mol% ethanol – 60.0 mol% water at 40°C. Pressure is 1.0 kg/cm2.

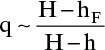

We can now use Eq. (4-17):

The enthalpy data are available in Figure 2-4. To use that figure we must convert mole fraction to weight fraction: 40 mol% is 63 wt%. Then from Figure 2-4, hF(0.63, 40°C) = 20 kcal/kg. The vapor (represented by H) and liquid (represented by h) will be in equilibrium at the feed stage, but the concentrations of the feed stage are unknown. Comparing the feed stage locations in Figures 4-8A, 4-8B, and 4-8C, we see that liquid and vapor concentrations on the feed stage can be very different and are usually not equal to the feed concentration z. However, when CMO is valid, liquid and vapor enthalpies per mole are constant. We can calculate all enthalpies at a weight fraction of 0.63 (mole fraction = 0.40), convert the enthalpies to kcal/kmol, and estimate q. From Figure 2-4, H (0.63, saturated vapor) = 395, h (0.63, saturated liquid) = 65 kcal/kg, and

Since all the molecular weights are at the same concentration, they divide out:

This agrees with Figure 4-10. Despite considerable subcooling this feed line is similar to a saturated liquid feed line. Note that feed rate was not needed to calculate q or the slope for any of these calculations.

4.5 Complete McCabe-Thiele Method

We are now ready to put all the pieces together and solve a design distillation problem by the McCabe-Thiele method. We will do this in the following example.

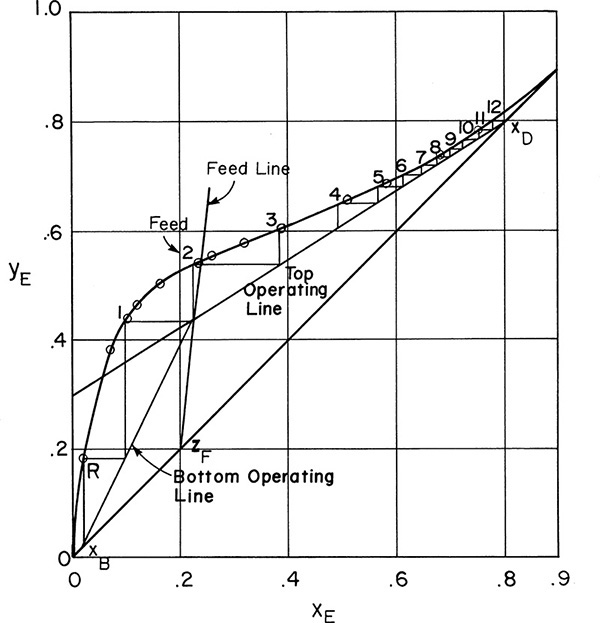

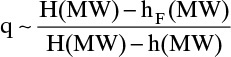

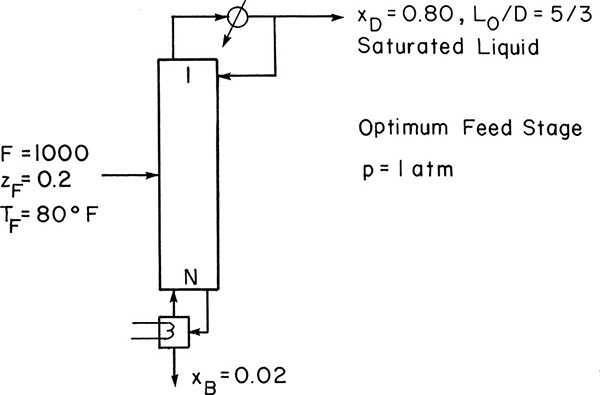

EXAMPLE 4-3. McCabe-Thiele method

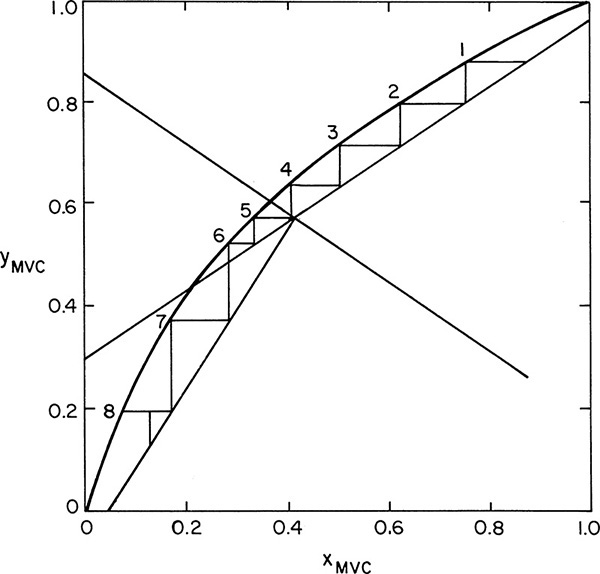

A distillation column with a total condenser and a partial reboiler is separating an ethanol-water mixture. Feed is 20.0 mol% ethanol, feed rate is 1000.0 kmol/h, and feed temperature is 80°F. Distillate is 80.0 mol% ethanol, and bottoms is 2.0 mol% ethanol. External reflux ratio is 5/3. Reflux is a saturated liquid, and CMO can be assumed. Pressure is 1.0 atm. Find optimum feed plate location as stages above the reboiler and total number of equilibrium stages.

A. Define. The column is sketched in the following figure.

Find the optimum feed plate location and the total number of equilibrium stages.

B. Explore. Equilibrium data at 1 atm are given in Figure 2-2. An enthalpy-composition diagram at 1 atm (Brown et al., 1950, or Foust et al., 1980, p. 36) is helpful to estimate q. However, a good estimate of q can be made from Figure 2-4 despite the pressure difference. In Example 4-1 we showed that CMO is valid. Thus we can apply the McCabe-Thiele method.

C. Plan. Determine q from Eq. (4-17) and the enthalpy-composition diagram at 1 atm. Plot the feed line. Calculate L/V. Plot the top operating line and plot the bottom operating line. Since we want the location of the feed stage above the reboiler, step off stages from the bottom up.

D. Do It. Feed Line: To find q, first convert feed concentration, 20.0 mol%, to wt% ethanol = 39.0 wt%. Two calculations in different units with different data are shown:

Thus small differences caused by pressure differences in the diagrams do not change the value of q. Note that molecular weight terms divide out as in Example 4-2d. Then

Feed line intersects y = x line at feed concentration z = 0.2 and is plotted in Figure 4-13.

FIGURE 4-13. Solution for Example 4-3

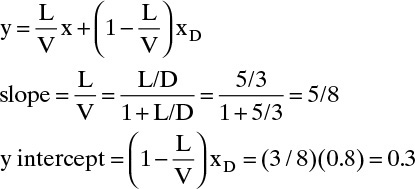

Top Operating Line:

Alternative solution: Intersection of top operating line and y = x (solve top operating line and y = x simultaneously) is at y = x = xD. The top operating line is plotted in Figure 4-13.

Bottom Operating Line:

We know that the bottom operating line intersects the top operating line at the feed line; this intersection is one point. We could calculate ![]() from mass balances or from Eq. (4-25), but it easier to find another point. The intersection of the bottom operating line and the y = x line is at y = x = xB (see Problem 4.C9). This intersection gives a second point.

from mass balances or from Eq. (4-25), but it easier to find another point. The intersection of the bottom operating line and the y = x line is at y = x = xB (see Problem 4.C9). This intersection gives a second point.

The feed line, top operating line, and bottom operating line are shown in Figure 4-13. We stepped off stages from the bottom up. The optimum feed stage is the second above the partial reboiler. Twelve equilibrium stages plus a partial reboiler are required.

E. Check. We have a built-in check on the top operating line since a slope and two points are calculated. The bottom operating line can be checked by calculating ![]() from mass balances and comparing it to the slope. The numbers are reasonable since L/V < 1,

from mass balances and comparing it to the slope. The numbers are reasonable since L/V < 1, ![]() , and q > 1 as expected. We have assumed CMO, which is not completely valid. An appropriate check on this assumption is to compare results with a calculation that does not assume CMO. Usually the most likely cause of significant error in a distillation calculation (and the hardest to check) is the equilibrium data. However, ethanol-water has been studied extensively, and the equilibrium data is accurate.

, and q > 1 as expected. We have assumed CMO, which is not completely valid. An appropriate check on this assumption is to compare results with a calculation that does not assume CMO. Usually the most likely cause of significant error in a distillation calculation (and the hardest to check) is the equilibrium data. However, ethanol-water has been studied extensively, and the equilibrium data is accurate.

F. Generalization. If constructed carefully, the McCabe-Thiele diagram is quite precise. Note that there is no need to plot parts of the diagram that are greater than xD or less than xB. Specified parts of the diagram can be expanded to increase the precision.

We did not use external balances in this example, while we did in Example 4-1,because in this example we used the feed line as an aid in finding the bottom operating line. The y = x intersection points are often useful, but when the column configuration is changed, their location may change.

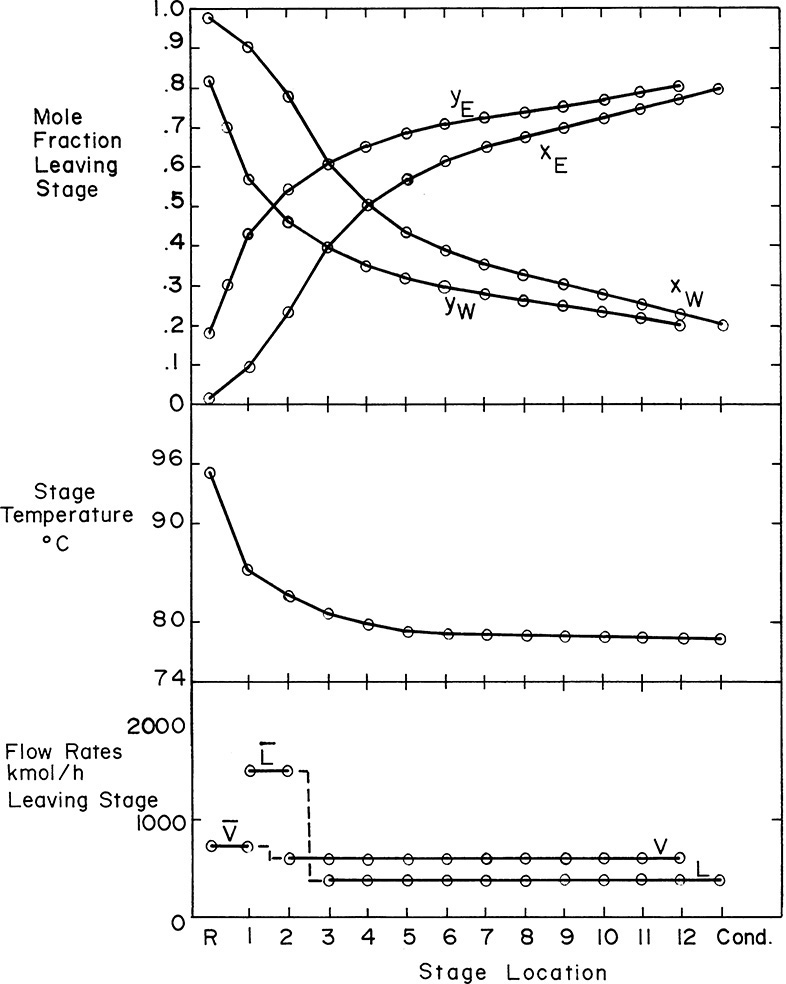

4.6 Profiles for Binary Distillation

Figure 4-13 essentially shows the complete solution of Example 4-3; however, it is useful to plot compositions, temperatures, and flow rates leaving each stage (these are known as profiles). From Figure 4-13 we can easily find the ethanol mole fractions in the liquid and vapor leaving each stage. Then xW = 1 – xE and yW = 1 – yE. The temperature of each stage can be found from equilibrium data (Figure 2-3) because the stages are equilibrium stages. Since we assumed CMO, the flow rates of liquid and vapor will be constant in the enriching and stripping sections, and we can determine the changes in the flow rates at the feed stage from the calculated value of q.

The profiles are shown in Figure 4-14. As expected, the water concentration in both liquid and vapor streams decreases monotonically as we go up the column, while the ethanol concentration increases. Since ethanol is more volatile, the temperature decreases monotonically as we go up the column. The profiles are not smooth curves because the stages are discrete. When the operating line and equilibrium curve almost touch in Figure 4-13, we have a pinch point. In the profiles pinch points show almost no change in composition and temperature from stage to stage (Figure 4-14). In this ethanol-water column the temperature decreases rapidly for the first few trays above the reboiler but is almost constant for the last eight stages. The location of a pinch point within the column depends on the system and the operating conditions.

FIGURE 4-14. Profiles for Example 4-3

Since we assumed CMO, the flow profiles are flat in each section of the column. As expected, ![]() and V > L (a convenient check). Since stage 2 is the feed stage, L2 is in the stripping section, and V2 is in the enriching section (draw a sketch of the feed stage if this distinction is not clear). Different quality feeds have different changes at the feed stage. Liquid and vapor flow rates can increase, decrease, or remain unchanged in passing from the stripping to the enriching section.

and V > L (a convenient check). Since stage 2 is the feed stage, L2 is in the stripping section, and V2 is in the enriching section (draw a sketch of the feed stage if this distinction is not clear). Different quality feeds have different changes at the feed stage. Liquid and vapor flow rates can increase, decrease, or remain unchanged in passing from the stripping to the enriching section.

Figure 4-13 illustrates the main advantage of McCabe-Thiele diagrams. They allow us to visualize the separation. Before the common use of digital computers, large (sometimes covering a wall) McCabe-Thiele diagrams were used to design distillation columns. McCabe-Thiele diagrams cannot compete with the speed and accuracy of process simulators (see this chapter’s Appendix A) or, for binary separations, with spreadsheets; however, McCabe-Thiele diagrams still provide superior visualization of the separation (Kister, 1995). Ideally, McCabe-Thiele diagrams are used in conjunction with process simulator results for both analysis and troubleshooting.

4.7 Open Steam Heating

We now have all the tools required to solve any binary distillation problem with the graphical McCabe-Thiele procedure. As a specific example, consider the separation of methanol from water in a staged distillation column.

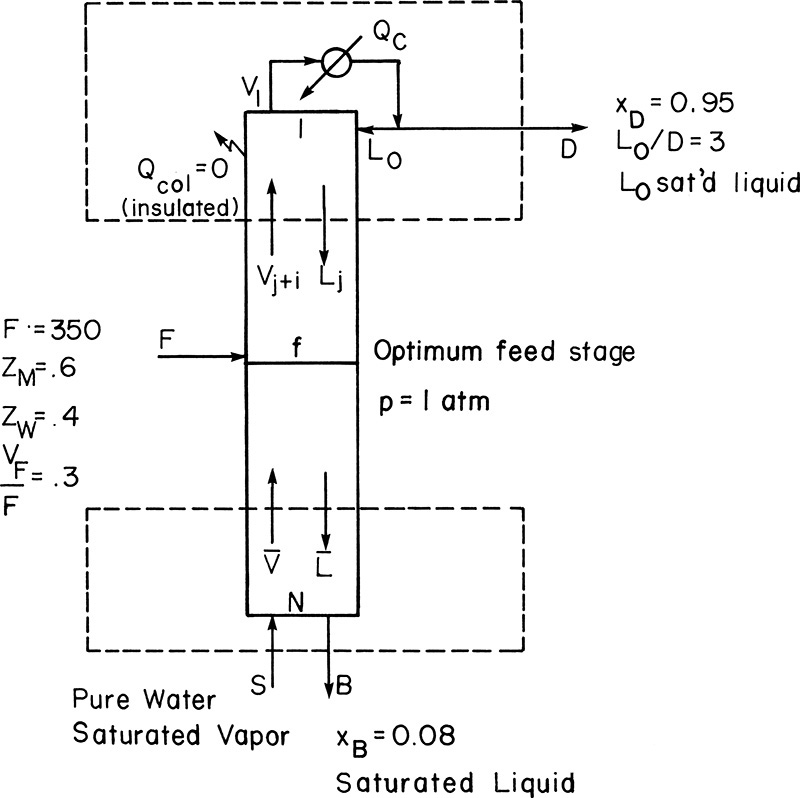

EXAMPLE 4-4. McCabe-Thiele analysis of open steam heating

A 60.0 mol% methanol and 40.0 mol% water feed is input as a two-phase mixture that flashes so that VF/F = 0.3. Feed flow rate is 350.0 kmol/h. The column is well insulated and has a total condenser. The reflux is returned to the column as a saturated liquid. An external reflux ratio of L0/D = 3.0 is used. We desire a distillate concentration of 95.0 mol% methanol and a bottoms concentration of 8.0 mol% methanol. Instead of using a reboiler, saturated steam at 1.0 atm is sparged directly into the bottom of the column to provide boilup (called direct or open steam). Column pressure is 1 atm. Calculate the number of equilibrium stages and the optimum feed plate location.

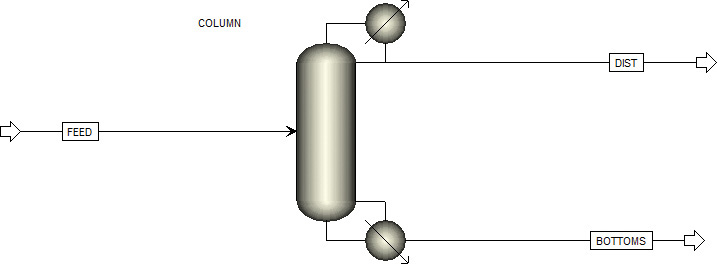

A. Define. It is helpful to draw a schematic diagram of the apparatus, particularly since a new type of distillation is involved, as shown in Figure 4-15. We wish to find the optimum feed plate location, NF, and the total number of equilibrium stages, N, required for this separation. We could also calculate Qc, D, B, and the steam rate S, but these are not asked for. We assume that the column is adiabatic since it is well insulated.

FIGURE 4-15. Distillation with direct steam heating, Example 4-4

B. Explore. The first thing we need is equilibrium data. Fortunately, these are readily available (see Table 2-7 in Problem 2.D1).

Second, we would like to assume CMO so that we can use the McCabe-Thiele analysis procedure. An easy way to check this assumption is to compare the latent heats of vaporization per mole (Himmelblau, 1974):

ΔHvap methanol (at boiling point) = 8.43 kcal/mol

ΔHvap water (at boiling point) = 9.72 kcal/mol

These values are not equal, and in fact water’s latent heat is 15.3% higher than methanol’s. Thus CMO is not strictly valid; however, we will solve this problem assuming CMO and check our results with a process simulator.

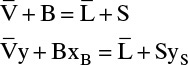

A look at Figure 4-15 shows that the configuration at the bottom of the column is different than when a reboiler is present. Thus we should expect that the bottom operating equations will be different from those derived previously.

C. Plan. We will use a McCabe-Thiele analysis. Plot the equilibrium data on a y-x graph.

Top Operating Line: Mass balances in the rectifying section (see Fig. 4-15) are

Vj+1 = Lj + D

yj+1Vj+1 = Lj xj +DxD

Assume CMO and solve for yj+1:

yj+1 = (L/V)xj + (1 – L/V)xD

Slope = L/V, y intercept (x = 0) = (1 – L/V) xD

Intersection y = x= xD

Since the reflux is returned as a saturated liquid,

Enough information is available to plot the top operating line.

Feed Line:

Once we substitute in values, we can plot the feed line.

Bottom Operating Line: The overall and methanol mass balances are

Solve for y:

Simplifications: Since the steam is pure water vapor, yS = 0.0 (contains no methanol). Since steam is saturated, S = V and B = L (constant molal overflow). Then

Note this is different from the operating equation for the bottom section when a reboiler is present. ![]() ,

, ![]() , and

, and

One known point is the intercept of the top operating line with the feed line. We still need a second point, and we can find it at the x intercept. When y is set to zero, x = xB (this is left as Problem 4.C1).

D. Do It. Equilibrium data are plotted on Figure 4-16.

FIGURE 4-16. Solution for Example 4-4

y = x = xD = 0.95

y intercept = (1 – L/V)xD = 0.2375

We can plot this straight line as shown in Figure 4-16.

Feed Line: Slope = q/(q – 1) = 0.7/(0.7 – 1) = –7/3.

Intersects at y = x = z = 0.6.

Bottom Operating Line: We can plot this line between two points, the intercept of top operating line and feed line and

x intercept (y = 0) = xB = 0.08

This is also shown in Figure 4-16.

Step off stages, starting at the top. x1 is in equilibrium with y1 at xD. Drawing a horizontal line to the equilibrium curve gives value x1. y2 and x1 are related by the operating line. At a constant value of y2 (horizontal line), go to the equilibrium curve to find x2. Continue this stage-by-stage procedure.

Optimum feed stage is determined as in Figure 4-8A. Optimum feed in Figure 4-16 is on stage 3 or 4 (since by accident x3 is at intersection point of feed and operating lines). Since the feed is a two-phase feed, we would introduce it above stage 4.

Number of stages: Five is more than enough. We can calculate a fractional number of stages.

In Figure 4-16

We need 4 + 0.9 = 4.9 equilibrium contacts.

E. Check. There are a series of internal consistency checks that can be made. Equilibrium should be a smooth curve. This will pick up incorrectly plotted points. L/V < 1 (otherwise no distillate product) and ![]() (otherwise no bottoms product). The feed line’s slope is in the correct direction for a two-phase feed. A final check on the assumption of CMO is advisable since the latent heats vary by 15%.

(otherwise no bottoms product). The feed line’s slope is in the correct direction for a two-phase feed. A final check on the assumption of CMO is advisable since the latent heats vary by 15%.

This problem was also run on the Aspen Plus process simulator (see Problem 4.G1 and this chapter’s Appendix A). Aspen Plus does not assume CMO and, with an appropriate vapor-liquid equilibrium (VLE) correlation (the nonrandom two-liquid [NRTL] model was used), should be more accurate than the McCabe-Thiele diagram, which assumes CMO. With five equilibrium stages and feed on stage 4 (the optimum location), xD = 0.9335 and xB = 0.08365, which does not meet the specifications. With six equilibrium stages and feed on stage 5 (the optimum), xD = 0.9646 and xB = 0.0768, which is slightly better than the specifications. The differences in the McCabe-Thiele and process simulation results are due to the error involved in assuming CMO and, to a lesser extent, differences in equilibrium. Note that the McCabe-Thiele diagram is useful since it visually shows the effect of using open steam heating.

F. Generalize. Note that the y = x line is not always useful. Do not memorize locations of points; learn to derive what is needed. The total condenser does not change compositions and is not counted as an equilibrium stage. The total condenser appears in Figure 4-16 as the single point y = x = xD. Think about why this is true. In general, all inputs to the column can change flow rates and hence slopes inside the column. The purpose of the feed line is to help determine this effect. The reflux stream and open steam are also inputs to the column. If they are not saturated streams the flow rates are calculated differently; this topic is discussed later.

Note that the open steam can be treated as a feed with ![]() . Thus,

. Thus, ![]() . The slope of this feed line is q/(q – 1) = 0, and it intersects the y = x line at y = x = z = 0, which means the feed line for saturated steam is the x-axis.

. The slope of this feed line is q/(q – 1) = 0, and it intersects the y = x line at y = x = z = 0, which means the feed line for saturated steam is the x-axis.

Ludwig (1997) states that one tray is used to replace the reboiler and one-third to one and possibly more trays to offset the water dilution; however, since reboilers are typically much more expensive than trays (see Chapter 11), this practice is economical. Open steam heating can be used even if water is not one of the original components.

Note to Students: When you read the description of developing the bottom operating equation and plotting the bottom operating line in Example 4-4, it probably appears easier than doing the development by yourself will prove to be. You need to practice deriving operating equations. Then practice simplifying the operating equation, realizing that “pure steam” means yS = 0 and that “saturated steam” means ![]() , and thus

, and thus ![]() are nontrivial steps. How did we know that the bottom operating line could be plotted using the point x = 0 (the y intercept)? We did not know this in advance, but tried it and it worked. You will become better at solving these problems as you work additional problems. To aid in this development, there are numerous problems at the end of this chapter.

are nontrivial steps. How did we know that the bottom operating line could be plotted using the point x = 0 (the y intercept)? We did not know this in advance, but tried it and it worked. You will become better at solving these problems as you work additional problems. To aid in this development, there are numerous problems at the end of this chapter.

4.8 General McCabe-Thiele Analysis Procedure

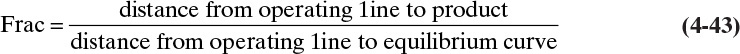

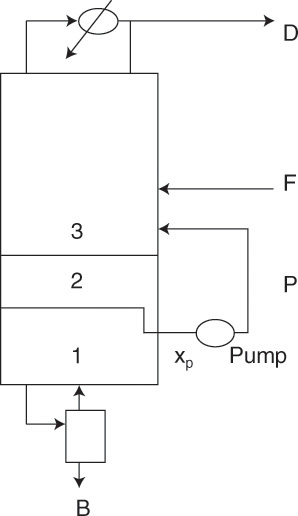

The open steam example illustrated one specific case. It is useful to generalize this analysis procedure. A section of the column is the segment of stages between two input or exit streams. Thus in Figure 4-15 there are two sections: top and bottom. Figure 4-17 illustrates a column with four sections. Each section’s operating equation can be derived independently. Thus the secret (if that’s what it is) is to treat each section as an independent sub problem connected to the other sub problems by the feed lines (which are also independent).

An algorithm for any problem is the following:

1. Draw a figure of the column, and label all known variables (e.g., as in Figure 4-15). Check to see if CMO is valid.

2. For each section:

a. Draw a mass balance envelope. We desire this envelope to cut the unknown liquid and vapor streams in the section and known streams (feeds, specified products or specified side-streams). The fewer streams involved, the simpler the mass balances will be. This step is important since it controls how easy the following steps will be.

b. Write the overall and MVC mass balances.

c. Derive the operating equation.

d. Simplify.

e. Calculate all known slopes, intercepts, and intersections.

3. Develop feed line equations. Calculate q values, slopes, and y = x intersections.

4. For operating and feed lines:

a. Plot as many of the operating lines and feed lines as you can.

b. If all operating lines cannot be plotted, step off stages if the stage location of any feed or side stream is specified.

c. If needed, do external mass and energy balances (see Example 4-5). Use the values of D and B in step 2.

5. When all operating lines have been plotted, step off stages and determine the optimum feed plate locations and the total number of stages. If desired, calculate a fractional number of stages.

Not all of these general steps are illustrated in the previous examples, but they are illustrated in the examples that follow.

This problem-solving algorithm should be used as a guide, not as a computer code to be followed exactly. The wide variety of possible configurations for distillation columns allows for plenty of problem-solving practice using the McCabe-Thiele method.

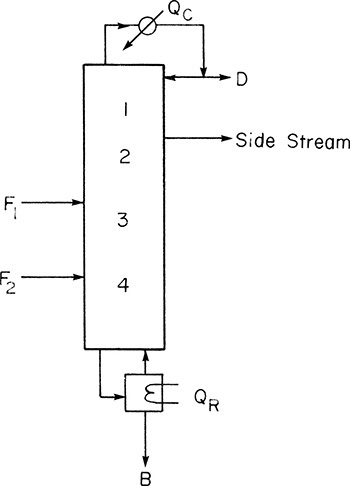

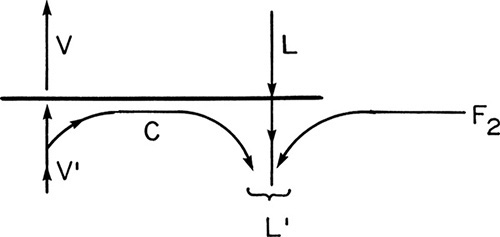

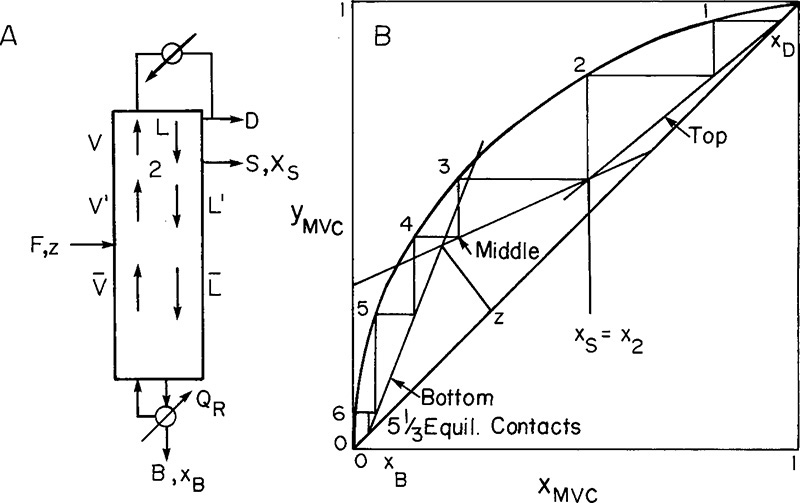

EXAMPLE 4-5. Distillation with two feeds

We wish to separate ethanol from water in a distillation column with a total condenser and a partial reboiler. We have 200.0 kmol/h of feed 1, which is 30.0 mol% ethanol and is saturated vapor. We also have 300.0 kmol/h of feed 2, which is 40.0 mol% ethanol. Feed 2 is a subcooled liquid. One mole of vapor must condense inside the column to heat up 4 moles of feed 2 to its boiling point. We desire a bottoms product that is 2.0 mol% ethanol and a distillate product that is 72.0 mol% ethanol. External reflux ratio is L0/D = 1.0. The reflux is a saturated liquid. Column pressure is 101.3 kPa, and the column is well insulated. The feeds are to be input at their optimum feed locations. Find the optimum feed locations (reported as stages above the reboiler) and the total number of equilibrium stages required.

Solution

A. Define. Again a sketch will be helpful (see Figure 4-18). Since the two feed streams are already partially separated, it makes sense to input them separately to maintain the separation that already exists. We have made an inherent assumption in Figure 4-18. That is, feed 2 of higher mole fraction ethanol enters the column higher up than feed 1. This assumption will be checked when the optimum feed plate locations are calculated, but it will affect the way we do the preliminary calculations. Since the feed plate locations were asked for as stages above the reboiler, the stages have been numbered from the bottom up.

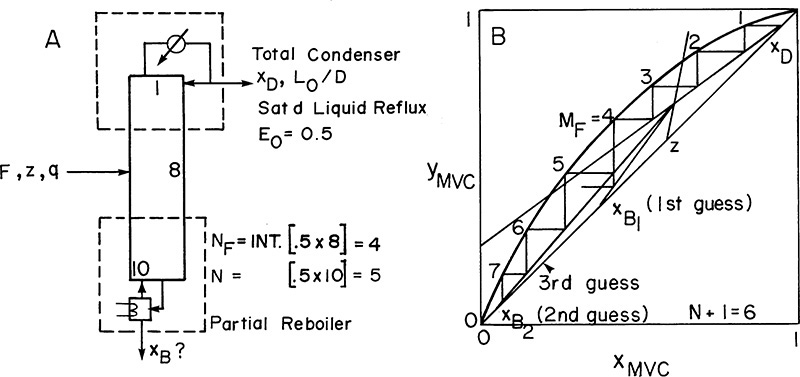

FIGURE 4-18. Two-feed distillation column for Example 4-5

B. Explore. Obviously equilibrium data are required, and they are available from Figure 2-2. We already checked (Example 4-1) that CMO is a reasonable assumption. A look at Figure 4-18 shows that the top section is the same as top sections used previously. The bottom section is also familiar. Thus the new part of this problem is the middle section. There will be two feed lines and three operating lines.

C. Plan. We will look at the two feed lines, top operating line, bottom operating line, and middle operating line. The simple numerical calculations will also be done here.

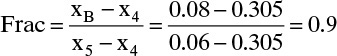

Feed 1: Saturated vapor, q1 = 0, slope = 0, y intercept = z1/(q1 – 1) = 0.3, intersection at y = x = z1 = 0.3.

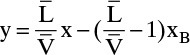

Feed 2:

The feed stage for feed 2 looks schematically as shown in the figure.

Then, Lbelow feed = L′ = L + F2 + c.

Amount condensed = c = (1/4) F2,

Intersection: y = x = z2 = 0.4

Top Operating Line: We start by deriving the top operating equation

This is the usual top operating line. With saturated liquid reflux the slope is

Intersection: y = x = xD = 0.72

Bottom Operating Line: Next, we derive the bottom operating equation

This is the usual bottom operating line, but slope = ![]() is unknown.

is unknown.

The intersection of the y = x line and the bottom operating line is at y = x = xB = 0.02. One other point is the intersection of the F1 feed line and the middle operating line, if we can find the middle operating line.

Middle Operating Line: To derive an operating equation for the middle section, we can write a mass balance around the top or the bottom of the column. The resulting equations will look different, but they are equivalent. We arbitrarily use the mass balance envelope around the top of the column, as shown in Figure 4-18. The overall and MVC mass balances are

F2 + V′ = L′ + D

F2z2 + V′ y = L′ x + DxD

Solve the second equation for y to develop the middle operating equation:

One known point is the intersection of the middle operating line, the F2 feed line and the top operating line. A second point is needed. We can try

However, this point is unknown.

The intersection of the middle operating line with the y = x line is found by setting y = x in Eq. (4-44) and solving

From the overall balance equation,

V′ – L′ = D – F2

Thus

This point is not known, but it can be calculated once D is known.

Slope = L′/V′ is unknown, but it can be calculated from balances at the feed-stage. From the definition of q2,

where L = (L/D)D. Once D is determined, L and then L′ can be calculated. Then the mass balance gives

V′ = L′ + D – F2

and the slope L′/V′ can be calculated.

The conclusion from these calculations is that we have to calculate D. To do this we need external mass balances:

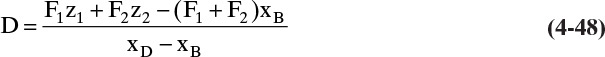

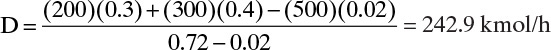

We can solve these two equations for the two unknowns, D and B. Substituting B = F1 + F2 – D into Eq. (4-47b) and solving for D:

This equation is essentially the solution for question 3.C3.

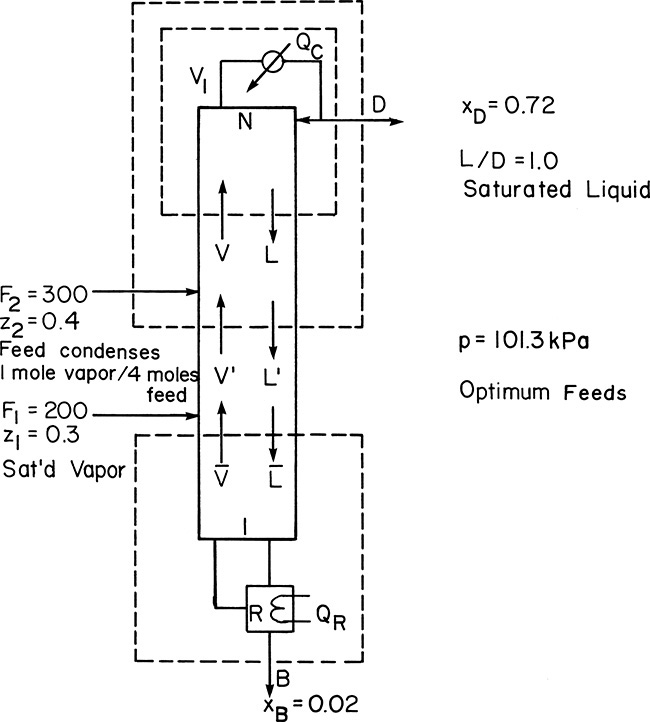

D. Do It. The two feed lines and the top operating line can immediately be plotted on a y-x diagram. This is shown in Figure 4-19. Before plotting the middle operating line we must find D from Eq. (4-48).

FIGURE 4-19. Solution for Example 4-5

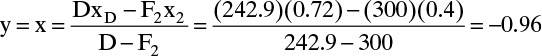

Now the middle operating line y = x intercept can be determined from Eq. (4-45b):

This intersection point could be used, but it is off the graph in Figure 4-19. Instead of using a larger sheet of paper, we will calculate the slope L′/V′.

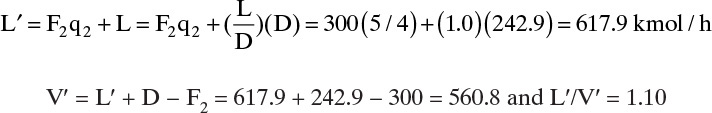

The middle operating line is plotted in Figure 4-19 from the intersection of feed line 2 and the top operating line, with a slope of 1.10. The bottom operating line then goes from y = x = xB to the intersection of the middle operating line and feed line 1 (see Figure 4-19).

Since the feed locations were desired as stages above the reboiler, we step off stages from the bottom up, starting with the partial reboiler as the first equilibrium contact. The optimum feed stage for feed 1 is the first stage, while the optimum feed stage for feed 2 is the second stage. Six stages + partial reboiler are more than sufficient. If desired, a fractional number of stages can be estimated:

We need 5½ stages and a partial reboiler.

E. Check. The internal consistency checks all make sense. Note that L′/V′ can be greater than or less than 1.0. Since the latent heats of vaporization per mole are close, CMO is probably a good assumption. Our initial assumption that feed 2 enters the column higher up than feed 1 is shown to be valid by the McCabe-Thiele diagram. We could also calculate ![]() and

and ![]() and check that the slope of the bottom operating line is correct.

and check that the slope of the bottom operating line is correct.

F. Generalize. The method of inserting the overall mass balance to simplify the intersection of the y = x line and middle operating line to derive Eq. (4-45) can be used in other cases. The method for calculating L′/V′ can also be generalized to other situations. That is, we can calculate D (or B), find flow rate in the section above (or below), and use feed conditions to find flow rates in the desired section. Since we stepped off stages from the bottom up, the fractional stage is calculated from the difference in y values (i.e., vertical distances) in Eq. (4-49). Although we obviously cannot build fractions of a stage, the calculation can be useful if the column efficiency is low (see Section 4.11). For example, if the overall efficiency is 20%, then 6 equilibrium contacts is 30 real stages, and 5½ equilibrium contacts is 28 real stages. Industrial systems typically use lower reflux ratios and have more stages. A relatively large reflux ratio is used in this example to keep the graph simple.

4.9 Other Distillation Column Situations

A variety of modifications of the basic columns are often used. In this section we briefly consider the unique aspects of several of these variations. CMO is assumed. Detailed examples are not given but are left to serve as homework problems.

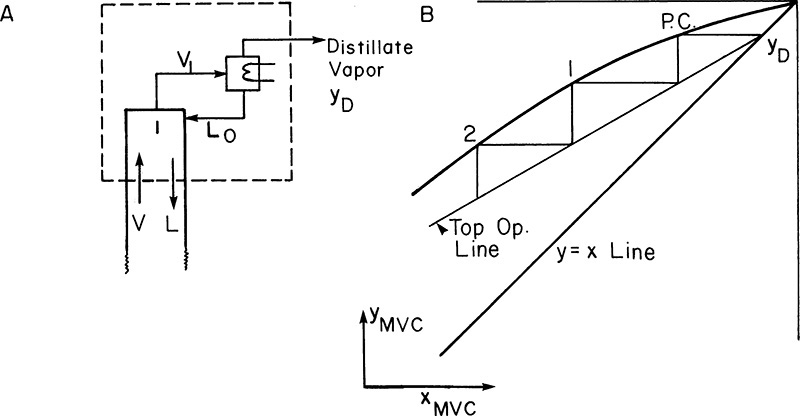

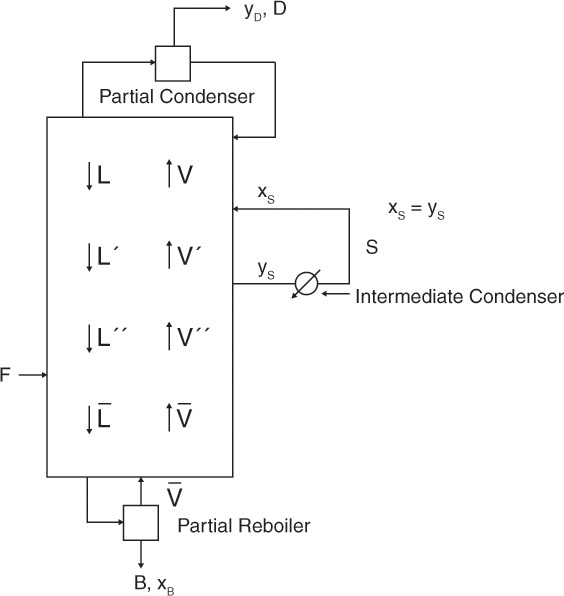

4.9.1 Partial Condensers

A partial condenser condenses only part of the overhead stream and returns this as reflux. This distillate product is removed as vapor, as shown in Figure 4-20. If a vapor distillate is desired, then a partial condenser is convenient. The partial condenser acts as one equilibrium contact.

If a mass balance is done on the MVC using the mass balance envelope shown in Figure 4-20, we obtain

Vy = Lx + DyD

Substituting in D = V – L and solving for y, we obtain the operating equation

This is essentially the same as the equation for a top operating line with a total condenser except that yD has replaced xD. The top operating line will intersect the y = x line at y = x = yD. The top operating line is shown in Figure 4-20. The major difference between this case and that in the figure for a total condenser is that the partial condenser serves as the first equilibrium contact.

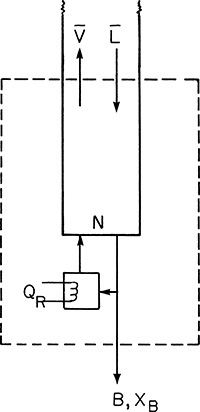

4.9.2 Total Reboilers

A total reboiler vaporizes the entire stream sent to it; thus the vapor composition is the same as the liquid composition. This scenario is illustrated in Figure 4-21. The mass balance and the bottom operating equation with a total reboiler are exactly the same as with a partial reboiler (Problem 4.C2). The only difference is that a partial reboiler is an equilibrium contact and is labeled as such on the McCabe-Thiele diagram. The total reboiler is not an equilibrium contact and appears on the McCabe-Thiele diagram as the single point y = x = xB.

Some types of partial reboilers may act as more or less than one equilibrium contact. In these cases, exact details of the reboiler construction are required.

4.9.3 Side Streams or Withdrawal Lines

If a product of intermediate composition is required, a vapor or liquid side stream may be withdrawn. This is commonly done in petroleum refineries and is illustrated in Figure 4-22A for a liquid side stream. Three additional variables, such as type of side draw (liquid or vapor), flow rate, SL or SV, and location or composition xS or yS, must be specified. The operating equation for the middle section can be derived from mass balances around the top or bottom of the column. For the situation shown in Figure 4-22A, the middle operating equation is

The y = x intercept is

This point can be plotted if SL, xS, D, and xD are known. Derivation of Eqs. (4-51) and (4-52) is left as Problem 4.C3.

A second point can be found where the side stream is withdrawn. A saturated liquid withdrawal is equivalent to a negative feed of concentration xS. Thus there must be a vertical feed line at x = xS. The top and middle operating lines must intersect at this feed line.

Side-stream calculations have one difference that sets them apart from feed calculations. The stage must hit exactly at the point of intersection of the two operating lines. This is illustrated in Figure 4-22B. Since the liquid side stream is withdrawn from tray 2, we must have xS = x2. If stage location is given, xS can be found by stepping off the required number of stages.

For a liquid withdrawal, vapor flow rates are unchanged, V = V′, and a balance on the liquid gives

Thus slope, L′/V′, of the middle operating line can be determined if L and V are known. L and V can be determined from L/D and D, where D can be found from external balances once xS is known.

For a vapor side stream, the feed line is horizontal at y = yS, which is equivalent to a negative horizontal feed line for a saturated vapor. A balance on vapor flow rates gives

and liquid flow rates are unchanged. Again L′/V′ can be calculated if L and V are known.

If a specified value of xS (or yS) is desired, the problem is trial and error. The top operating line is adjusted (change L/D) until a stage ends exactly at xS or yS.

Calculations for side streams below the feed can be developed using similar principles (Problem 4.C4).

4.9.4 Intermediate Reboilers and Intermediate Condensers

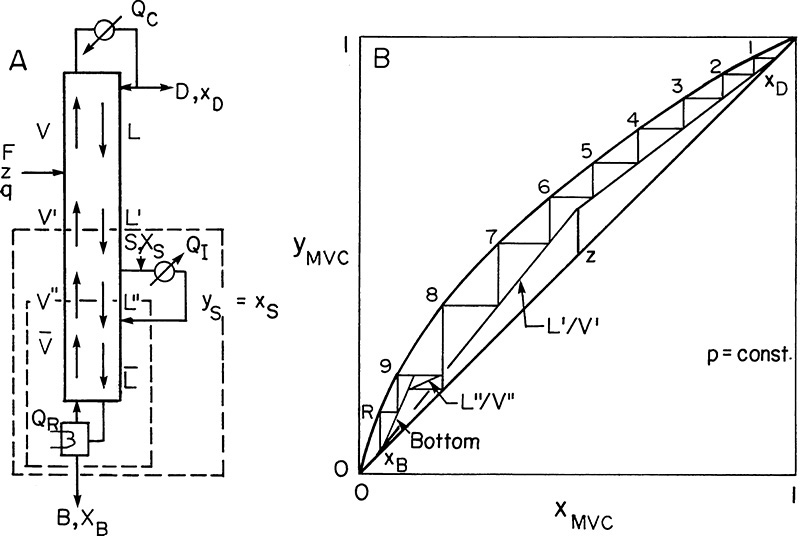

Another modification that is used occasionally is to have an intermediate reboiler or an intermediate condenser. The intermediate reboiler removes a liquid side stream from the column, vaporizes it, and reinjects the vapor into the column. An intermediate condenser removes a vapor side stream, condenses it, and reinjects it into the column. Figure 4-23A illustrates an intermediate reboiler.

An energy balance around the column will show that QR without an intermediate reboiler is equal to QR + QI with the intermediate reboiler (F, z, q, xD, xB, p, L/D constant). Thus the amount of energy required is unchanged; what changes is the temperature at which it is required. Since xS > xB, the temperature of the intermediate reboiler is lower than that of the reboiler, and a lower temperature and hence cheaper heat source often can be used. (Check this out with equilibrium data.)

Since the column shown in Figure 4-23A has four sections, there will be four operating lines. This is illustrated in the McCabe-Thiele diagram of Figure 4-23B. We would specify that the liquid be withdrawn at flow rate S at either a specified concentration xS or a given stage location. The saturated vapor is at concentration yS = xS. Thus there is a horizontal feed line at yS. If the optimum location for inputting the vapor is immediately below the stage where the liquid is withdrawn, the L″/V″ line will be present, but no stages will be stepped off on it, as shown in Figure 4-23B. (The optimum location for vapor feed may be several stages below the liquid withdrawal point.) Development of the two middle operating lines is left as Problem 4.C5. Use the mass balance envelopes shown in Figure 4-23A to solve that problem.

Intermediate condensers are useful since the coolant can be at a higher temperature (see Problem 4.C6). Intermediate reboilers and condensers are fairly common because they allow for more optimum use of energy resources, and they can help balance column diameters (see Section 10.4). During normal operation they should cause no problems; however, startup may be difficult (Sloley, 1996).

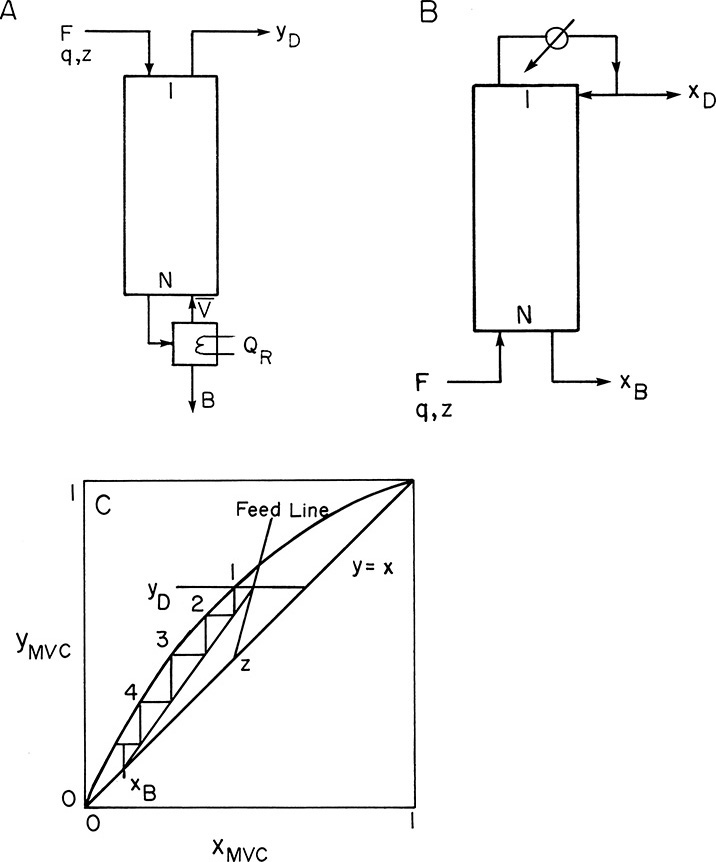

4.9.5 Stripping and Enriching Columns

Up to this point we have considered complete distillation columns with at least two sections. Columns with only a stripping section or only an enriching section are also commonly used. These are illustrated in Figures 4-24A and 4-24B. When only a stripping section is used, the feed must be a subcooled or saturated liquid. No reflux is used. A very pure bottoms product can be obtained, but the vapor distillate will not be pure. In the enriching or rectifying column, on the other hand, the feed is a superheated vapor or a saturated vapor, and the distillate can be very pure, but the bottoms will not be very pure. Striping columns and enriching columns are used when a pure distillate or a pure bottoms, respectively, is not needed.

FIGURE 4-24. Stripping and enriching columns; (A) stripping, (B) enriching, (C) McCabe-Thiele diagram for stripping column with subcooled feed

Analysis of stripping and enriching columns is similar. We will analyze the stripping column here and leave the analysis of the enriching column as a homework assignment (Problem 4.C8). The stripping column shown in Figure 4-24A can be thought of as a complete distillation column with zero liquid flow rate in the enriching section. Then the top operating line is y = yD. The bottom operating line can be derived as

which is the usual equation for a bottom operating equation with a partial reboiler. Top and bottom operating lines intersect at the feed line. If the specified variables are F, q, z, p, xB, and yD, the feed line can be plotted and then the bottom operating line can be obtained from its intersection at y = x = xB and its intersection with the feed line at yD. (Proof is left as Problem 4.C7.) If the boilup rate, ![]() , is specified, then yD will not be specified and can be solved for. The McCabe-Thiele diagram for a stripping column is shown in Figure 4-24C.

, is specified, then yD will not be specified and can be solved for. The McCabe-Thiele diagram for a stripping column is shown in Figure 4-24C.

Stripping and enriching columns have one less degree of freedom than complete columns. This is easy to see when CMO is valid. In stripping columns the liquid flow rate ![]() and the vapor flow rate

and the vapor flow rate ![]() . Thus, the boilup rate

. Thus, the boilup rate ![]() cannot be adjusted independently. In enriching columns the reflux ratio L/D = F/D cannot be adjusted independently.

cannot be adjusted independently. In enriching columns the reflux ratio L/D = F/D cannot be adjusted independently.

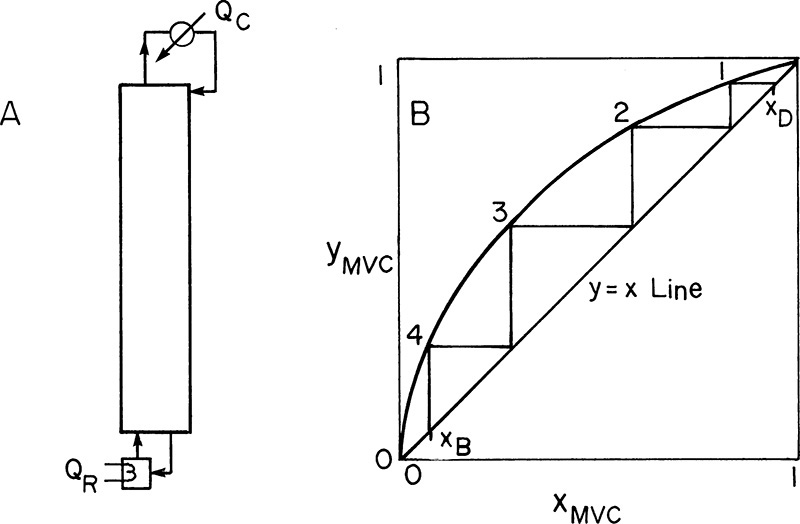

4.10 Limiting Operating Conditions

It is always useful to look at limiting conditions. For distillation, two limiting conditions are total reflux and minimum reflux. In total reflux (Figure 4-25A) all overhead vapor is returned to the column as reflux, and all underflow liquid is returned as boilup; thus, distillate and bottoms flow rates are zero. At steady state the feed rate must also be zero. Total reflux is used for starting up columns, for keeping a column operating when another part of the plant is shut down, and for testing column efficiency.

The analysis of total reflux is simple. Since all vapor is condensed and refluxed, L = V and L/V = 1.0. Also, ![]() and

and ![]() Thus both operating lines become the y = x line (Figure 4-25B). Total reflux represents the maximum separation that can be obtained with a given number of stages but zero throughput. Total reflux also gives the minimum number of stages required for a given separation. Although simple, total reflux can cause safety problems. Leakage near the top of the column can cause concentration of high boilers with a corresponding increase in temperature. This can result in polymerization, fires, or explosions (Kister, 1990). Thus the temperature at the top of the column should be monitored, and an alarm should sound if this temperature becomes too high.

Thus both operating lines become the y = x line (Figure 4-25B). Total reflux represents the maximum separation that can be obtained with a given number of stages but zero throughput. Total reflux also gives the minimum number of stages required for a given separation. Although simple, total reflux can cause safety problems. Leakage near the top of the column can cause concentration of high boilers with a corresponding increase in temperature. This can result in polymerization, fires, or explosions (Kister, 1990). Thus the temperature at the top of the column should be monitored, and an alarm should sound if this temperature becomes too high.

Minimum reflux, (L/D)min, is defined as the external reflux ratio at which the desired separation could just be obtained with an infinite number of stages. This is obviously not a real condition, but it is a useful hypothetical construct. To have an infinite number of stages, the operating and equilibrium lines must touch. In general, this can happen either at the feed or at a point tangent to the equilibrium curve. These two points are illustrated in Figures 4-26A and 4-26B. The point where the operating line touches the equilibrium curve is called the pinch point. At the pinch point the concentrations of liquid and vapor do not change from stage to stage. This pinch at the feed stage is illustrated in Figure 4-26C. If the reflux ratio is increased slightly, then the desired separation can be achieved with a finite number of stages.

FIGURE 4-26. Minimum reflux; (A) pinch at feed stage, (B) tangent pinch, (C) concentration profile for L/D ∼ (L/D)min

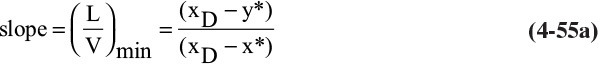

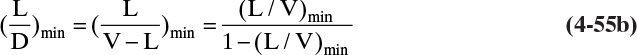

For binary systems the minimum reflux ratio is easily determined. The top operating line is drawn to a pinch point, as in Figures 4-26A and 4-26B. Then (L/V)min is equal to the slope of this top operating line (which cannot be used for an actual column, since an infinite number of stages are needed):

where (y*, x*) are the coordinates of the intersection of the feed line and the equilibrium curve. Once (L/V)min is known,

Note that the minimum reflux ratio depends on xD, z, and q and can depend on xB. The calculation of minimum reflux may be more complex when there are two feeds or a sidestream. This is explored in the homework problems.

The minimum reflux ratio is commonly used in specifying operating conditions. For example, we may specify the reflux ratio as L/D = 1.2(L/D)min. Minimum reflux uses the minimum amount of reflux liquid and hence the minimum amount of heat in the reboiler, but it uses the maximum (infinite) number of stages and a maximum (infinite) diameter for a given separation. Obviously the best operating conditions lies somewhere between minimum and total reflux. As a rule of thumb the optimum external reflux ratio for a column with enriching and stripping sections is between 1.05 and 1.25 times (L/D)min. (See Chapter 11 for more details.)

A maximum ![]() and hence a minimum boilup ratio

and hence a minimum boilup ratio ![]() can also be defined. The pinch points will look the same as in Figures 4-26A and 4-26B. Problem 4.C12 looks at this situation further.

can also be defined. The pinch points will look the same as in Figures 4-26A and 4-26B. Problem 4.C12 looks at this situation further.

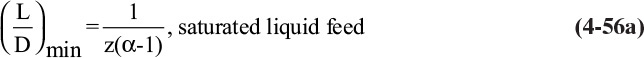

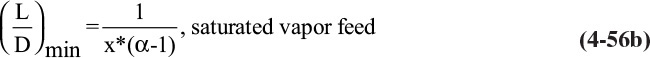

When the feed is a saturated liquid, x* = z and y* can be calculated from the relative volatility Eq. (2-22b) with x = z. The resulting equation for L/D can be simplified in the limit of perfect separation (xD → 1 and xB → 0) to

where α is the relative volatility calculated at x = z. For a saturated vapor feed the limiting case result is