8

Sustaining Momentum and Growing

“To improve is to change. To be perfect is to change often.”

—Winston Churchill

You have successfully launched your Lean Six Sigma initiative (from Chapter 6, “Launching the Initiative”), and you have been working on putting in place systems that are needed to effectively manage the deployment (from Chapter 7, “Managing the Effort”). Many Lean Six Sigma initiatives begin to hit a lull at this point as other priorities gradually erode the momentum. Now is the time to implement systems and processes that will help you sustain the energy. Sometimes the best defense is a good offense, and growth of the initiative can be a good offensive tactic that helps maintain momentum.

This chapter focuses on the defensive effort needed to sustain impetus and the offensive effort needed to expand the Lean Six Sigma initiative toward a true holistic improvement system. This sustaining and growing phase is defined as the time between completing the training and projects identified in the original deployment plan and transforming Lean Six Sigma from an initiative to the normal way you work, as Lean Six Sigma 2.0. This phase can last several years.

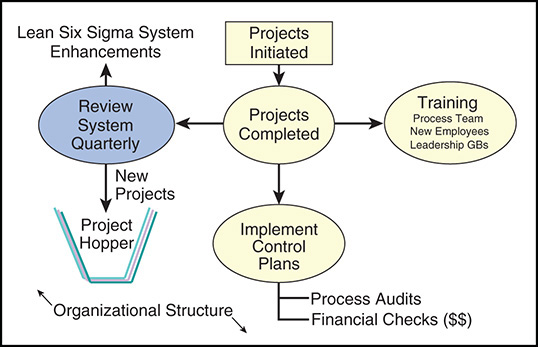

The momentum of Lean Six Sigma is maintained by holding the gains of completed projects and by sustaining the gains of the overall Lean Six Sigma system. Figure 8.1 schematically displays some of the methods discussed in this chapter. As you will see, and as should come as no surprise, the key is consistent implementation of periodic reviews, including audits. It is also important to implement a complete training system (instead of individual training courses), create a formal Lean Six Sigma organizational structure, and develop Leadership Green Belts. Note from Figure 8.1 that all the other elements are done within the context and direction of the Lean Six Sigma organizational structure. This makes up your defensive effort to maintain the momentum you already have.

At this stage, you also want to play offense and extend the deployment into new areas. You can accomplish this primarily by expanding the portfolio of improvement methodologies and also by expanding Lean Six Sigma to the whole organization. For example, expansion across the organization might include introducing customers and suppliers to Lean Six Sigma, and using Lean Six Sigma to increase revenue as well as reduce costs. Quality by design projects, using different methodologies than Lean or Six Sigma, can help drive new revenue. Lean Six Sigma can be applied to top-line growth, but quality by design methodologies are better suited for new product and service development. We first review the key elements of our defensive strategy and then discuss the offensive elements.

Figure 8.1 Sustaining the gains

Playing Defense: Sustaining Momentum

After a couple years, Lean Six Sigma could become old news and more recent issues or problems might divert managerial attention. All organizations deploying Lean Six Sigma have faced this phenomenon. Leadership’s response to it determines whether the deployment will succeed in the long term.

In Chapter 5, “How to Successfully Implement Lean Six Sigma 2.0,” we noted that implementing the remaining infrastructure elements is the key to successfully making this transition. Recall that these infrastructure elements were identified as part of the overall deployment plan developed in the phase of launching the initiative (Chapter 6). Some of these infrastructure elements were implemented during the phase of managing the effort (Chapter 7), such as the systems for selecting projects and Black Belts. You now close the loop and implement the remaining infrastructure elements identified in your deployment plan. These elements will enable you to sustain momentum without the same level of personal attention from senior leadership that you have had up to now.

Holding Project Gains

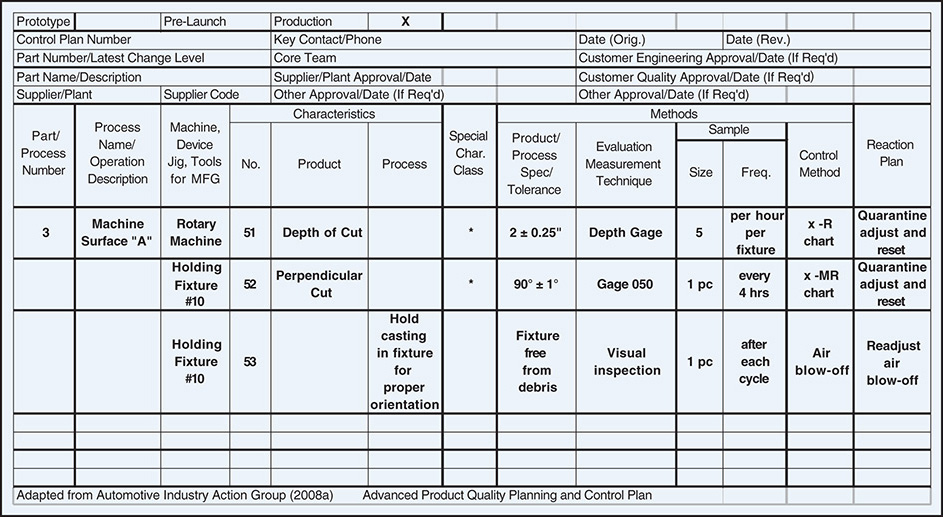

The improvements obtained from Six Sigma and Lean projects are held by implementing the project control plans, ensuring that all employees associated with the process are trained in the new way of operating the process, and performing periodic process and financial audits. A control plan (AIAG, 2008a) contains the information needed to monitor and control a process and to maintain improvements; it is finalized during the Control phase of a DMAIC project. This plan contains specific activities required to monitor and control the process, including answers to the questions of who, what, when, and how. The control plan also contains the reaction plan, which defines what should be done by whom and who should be informed when something goes wrong.

The control plan is effective when it contains all the information needed to ensure that the process is in a state of control, is in a form easily used by the operators (process workers), and is, in fact, used to operate the process. An evergreen document, it is continually updated to reflect the current methods and measurements used to monitor and control the process. Clarity, completeness, conciseness, and simplicity are key characteristics of effective control plans.

Figure 8.2 shows an example of a control plan adapted from the Automotive Industry Action Group (AIAG, 2008a). Control plans are process specific and have many different forms, as well a variety of information (such as process steps, FMEA findings, measurement system indices such as Gage R&R values, and process capability indices). The right control plan for your process is the one that contains the information needed to monitor and control your process and to maintain the gains of improvements projects.

Figure 8.2 Control plan example

Part of the control plan and project closure report is a schedule for the process and financial audits. The goal of the process audit is to see whether the process is being operated as directed by the control plan and standard operating procedures, as well as whether the process performance levels are being maintained. An effective way to integrate process audits into the normal work procedures is to make them part of the ISO 9000 audit. Recall that ISO 9000 is a common system used for quality and process management. Both control plans and ISO 9000 audits have provisions for changing the standard operating procedures as more effective means to operate the process are found. Incorporating these audits into ISO 9000 is an effective means of integrating breakthrough improvement with quality and process management as part of an increasingly holistic improvement system.

The financial audits determine whether the projected monetary gains are being realized. These audits, typically done by the financial organization, generally follow the financial performance of a project for 12 months after project closure. They help validate the results, build credibility for Lean Six Sigma, and identify opportunities for improvement. Recall that documentation of financial benefits is a key success factor for Lean Six Sigma. Maintaining the financial gains is equally important.

There also needs to be a concerted effort to ensure that all persons connected with the process, whether old hands or recently assigned, are trained in the new way of working. The adequacy of the training can also be checked as part of the ISO 9000 audit. (The overall training system is discussed later in this chapter.) Some organizations train all process operators as Lean Six Sigma Yellow Belts. Yellow Belt training is usually conducted by the Black Belt, typically lasts two days, and focuses on the Measure and Control phases of DMAIC. Although accountabilities vary considerably based on organizational philosophy and structure, in typical organizations, the operators’ (process workers’) main responsibilities are to take process data and to control the process.

Quarterly and Annual Reviews

Quarterly reviews conducted by the chief executive monitor the health and effectiveness of the overall Lean Six Sigma system. We noted in Chapter 5 that management reviews are the “secret sauce” that is needed to keep Lean Sigma deployments on track and sustain the gains. In large organizations, these reviews should also be held at the business and function levels. The goal is to check on the functioning of the overall Lean Six Sigma infrastructure, including all relevant systems and processes.

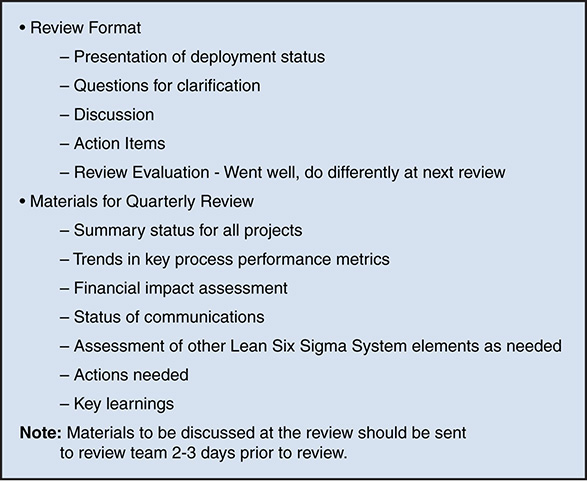

Table 8.1 is based on the elements of the deployment plan (see Chapter 6), but augmented with some specifics that have been developed since, such as review of selected projects and overall financial results. Table 8.2 shows a typical outline for such a quarterly meeting. The key Six Sigma processes to be reviewed are progress toward financial goals, training progress (particularly in the first two years), and the project selection process (including the project hopper). It is not imperative that all processes be checked in each quarterly review, but certainly all processes should be checked at least once per year.

Table 8.1 Augmented Deployment Plan

Table 8.2 Sample Quarterly Meeting Outline

A good strategy is to formally review the critical processes in each of the first three quarterly reviews. The fourth quarter or annual review should probe in more depth, reviewing all the processes and developing an annual plan and goals for the coming year. Obviously, the annual plan and goals should link tightly to the overall strategic plan and goals from the deployment plan.

The annual review is a good time to check the project hopper for sufficient projects to reach the financial goals set for the coming year and determine whether the project portfolio (mix of projects) is sufficient to satisfy the goals of the organization. Do you have the right mix of projects, as categorized by business unit, functional unit, cost reduction versus cost avoidance, strategic versus tactical, revenue enhancement versus cost reduction, and quality improvement?

Consider taking an organizational survey of Lean Six Sigma deployment every 18 to 24 months, to check on deployment progress and identify opportunities for improvement (Snee, 1995). This survey should measure the feelings and attitudes of all employees. Honest, unfiltered feedback from employees is difficult information for senior leadership to obtain but is very important. The results of the survey are useful input for the annual planning sessions. Organizations change slowly, and the 18- to 24-month frequency is usually sufficient to detect improvement needs and any trends that have occurred.

The Training System

To sustain Lean Six Sigma for the long term, organizations need an overall training system, not just a mass wave of training. Portions of this system will already exist by this phase, and Executive, Business Leader, Champion, Black Belt, Master Black Belt (MBB), and Green Belt training will be underway. It is now time to think holistically about the organization’s overall training needs relative to Lean Six Sigma and develop an expanding improvement methodology portfolio for years to come.

Key elements of a long-term training system follow:

![]() Six Sigma awareness training for new people

Six Sigma awareness training for new people

![]() Ongoing Champion, MBB, BB, and GB training

Ongoing Champion, MBB, BB, and GB training

![]() Champion, MBB, BB, and GB refresher training

Champion, MBB, BB, and GB refresher training

![]() Advanced Black Belt training

Advanced Black Belt training

![]() Initial MBB training

Initial MBB training

![]() Training in different languages

Training in different languages

![]() Curricula for operations, administration/transactional, and new product development processes

Curricula for operations, administration/transactional, and new product development processes

![]() Leadership Green Belt training

Leadership Green Belt training

![]() Training in newer elements of the improvement methodology portfolio

Training in newer elements of the improvement methodology portfolio

Advanced Black Belt training is typically needed because some skills specific to certain technical areas are not part of the general Black Belt training. Examples include mixture experimentation for the chemical, coatings, and foods industries; multidimensional tolerancing for the assembly industries; and advanced process control and process variance component studies for the process industries. Black Belts also might need additional or advanced skills that couldn’t be part of their original training because of time limitations. Some examples include advanced regression analysis and modeling techniques, complex multi-vari studies, and advanced design of experiments. Table 8.3 includes supplemental Black Belt materials and topics based on Hoerl (2001).

Table 8.3 Supplemental Black Belt Materials and Topics

Organizations are dynamic. People move in and out for various reasons. The training system must include processes for training new executives, Champions, Black Belts, MBBs, and Green Belts. Some training is job dependent; for example, engineers and financial personnel need different versions of training. In general, we recommend tailoring training to the degree feasible. Existing executives, Champions, Black Belts, MBBs, and Green Belts can also benefit from brief refresher courses, particularly when they stay in these roles for an extended period of time. New topics or techniques will likely be added to courses over time, and refreshers provide a convenient means for those previously trained to stay up-to-date. To sustain Lean Six Sigma momentum, training needs to be a sustained system, not simply a one-time event.

Multinational companies need to develop training materials and instructors to deliver Lean Six Sigma training in multiple languages. In our experience, you can often deliver Executive, Champion, MBB, and Black Belt training in English in most industrialized countries, but Green Belt training usually needs to be in the native language. Learning Lean Six Sigma is challenging enough without having to struggle with the nuances of a foreign language. Accurate translation of technical material is difficult, and for digital training systems, often unique challenges arise when translating into double-byte languages such as Chinese or Japanese (for which characters are stored as 2 bytes instead of 1 byte).

Expansion of the improvement methodology portfolio is a key aspect of growing the Lean Six Sigma initiative toward true holistic improvement, Lean Six Sigma 2.0. We discuss this in more detail later in this chapter. At this point, we just want to note that the training system will need to gradually expand to incorporate the additional improvement methodologies being added, such as Work-Out, Big Data analytics, or statistical engineering. This is required to address large, complex, unstructured problems.

A training system is much more extensive than a list of courses. A good system includes processes for developing and presenting new courses, keeping track of who has attended courses and passed exams, identifying people in need of specific training, translating materials, qualifying instructors, and providing managerial reports, all on an ongoing basis.

The organization must think carefully about how the training system will be managed over time. In most situations, a Lean Six Sigma provider manages the training system initially, but what happens when the contract expires? Taking over the responsibility for managing the training system from the Lean Six Sigma provider helps make improvement part of the culture—how things are done around here. Many organizations put MBBs in charge of managing the training system (perhaps through a Training Council) because training is a key role of MBBs.

Leadership Green Belt Training

It takes time for your entire management team to acquire the required Lean Six Sigma skills and experience. GE recognized this and decided to train all its professionals as Green Belts; the company also made Green Belt status a condition of promotion for professionals. Jack Welch said, “…with Six Sigma permeating much of what we do all day, it will be likewise unthinkable to hire into the Company, promote, or tolerate those who cannot, or will not, commit to this way of work” (GE Annual Report, 1997).

When management provides support in this manner, Lean Six Sigma becomes an effective leadership developmental tool. Leaders learn how to use Lean Six Sigma to improve an organization and its processes in all businesses, all functions, and all cultures. They see how formal approaches to improvement develop personnel, providing breadth of experience by allowing people to work on a variety of processes, empowering people to improve processes, teaching teamwork, and developing leaders. Leadership Green Belt training also results in all leaders hearing a common message that helps create alignment on the objectives and goals of improvement. Leaders with such perspective ensure that the gains of Lean Six Sigma are maintained.

Iomega reported, “Six Sigma is the best people development tool we have ever deployed” (English, 2001). Through its Six Sigma projects, Iomega (which provides storage products for digital items) developed a common language and a common approach for process design, improvement, and management. DuPont, Honeywell, and Bank of America have also provided Six Sigma training for their leadership.

We focus on Green Belt training as a leadership tool to ensure that all leaders have experienced Lean Six Sigma at the gut level. Green Belt training is needed at the beginning of implementation because, in most cases, none of the senior leaders will have held MBB or Black Belt positions. The need for Leadership Green Belt training will decrease over time as more leaders have Black Belt and MBB experience.

The goal of the Green Belt Leadership training is for the leaders to develop a deeper understanding of Lean Six Sigma and to learn how to use it to improve the organization. Lean Six Sigma training works best when it is project based, but finding appropriate projects for the leaders can be difficult. Training without a project is of less value; it can leave the impression that the leaders are just getting their tickets punched and are not serious about learning the methodology. A similar result can occur if the projects are not viewed as important, or if the leaders don’t do a good job and obtain poor results. So we have come full circle, finding that project selection is a potential Achilles’ heel of Leadership Green Belt training, just as it is for other types of Lean Six Sigma projects. We offer a few suggestions for finding appropriate projects next.

Focus on the work the leader actually does. This ensures that the project is meaningful, not merely duties added to an already overflowing plate. Recall from the discussion of nonmanufacturing applications that all work can be viewed as a process, but with general business processes, it is much harder to actually see the process. Experienced MBBs should be able to help the Leadership Green Belts see the underlying processes in managerial activities such as budgeting, evaluating performance, and allocating resources. Many senior executives feel that they spend too much time in unproductive meetings. All would appreciate improvements to the meeting process. Implementing and managing the systems and processes that are part of the Lean Six Sigma infrastructure would make excellent leadership DFSS projects.

A senior HR leader could implement a new reward and recognition system. An IT leader could design a new tracking and reporting system. Finance leaders could work on designing the financial auditing system for projects. Large projects such as these might need to be split up into several smaller projects, and additional team members will likely be needed to address details (such as writing computer code). Nevertheless, relevant, important project areas such as these tend to be much more fruitful than projects that are perceived as “moving the water cooler.” Table 8.4 gives other examples of topics for Leadership Green Belt projects.

Table 8.4 Sample Topics for Leadership Green Belt Projects

Our recommendation is that every Green Belt, including senior leadership, should do at least one formal project. We do not believe you can get a gut-level appreciation for Lean Six Sigma without actually doing it yourself. Through careful project selection and mentoring from experienced MBBs, Leadership Green Belts can successfully complete meaningful projects. Although extra mentoring from the MBB can be extremely helpful, the MBB must carefully avoid even the perception that he or she is doing the project for the Leadership Green Belt. People will be watching and will see that leaders are saying one thing, but doing something completely different.

Lean Six Sigma Organizational Structure

By now, you have realized that some Lean Six Sigma infrastructure is needed to sustain momentum. If properly designed and implemented, this infrastructure will be value added, with minimal bureaucracy. Note that we recommend a Lean infrastructure, one that is primarily automated and requires minimal human staffing.

For example, the project tracking and reporting system should be digital so that additional personnel are not required to process paper reports. Despite its Lean-ness, the infrastructure will require some human guidance to manage and improve it over time. Therefore, you will need a formal Lean Six Sigma organizational structure to clarify roles and responsibilities for managing the infrastructure. This organizational structure will likely have begun in the phase of managing the effort, but it needs to be expanded and invigorated now because of the extension of supporting systems and processes in this phase. Eventually, this will become the holistic improvement organization, the umbrella organization for all improvement work.

Organizational structure is particularly important now that the direct involvement of the Lean Six Sigma provider is winding down. In many Lean Six Sigma deployments, the provider handles much of the initial organizational effort. Transitioning to an internal organizational structure is an important step in becoming self-sufficient. It is particularly important that the training system be well managed and that it not miss a beat as the provider’s efforts wind down.

If the transition is not properly handled, a leadership vacuum will be created when the provider fades out of the picture. The best way to avoid this is to have a formal, functioning organizational structure, including an active Lean Six Sigma Council led by the overall Lean Six Sigma Leader, to manage the effort going forward. This implies more than just naming Champions, MBBs, Black Belts, and so on. You need a functioning team that works like a well-oiled machine to properly lead and coordinate all aspects of the Lean Six Sigma deployment.

By active, we mean that all members must participate regularly. It does little good to list the company’s top leaders as council members if they do not participate. As noted earlier, we can also set up Lean Six Sigma Councils within individual business units or functions. The leaders of the business unit and functional councils are usually members of the overall council, resulting in interlocking membership. This aids in communication and coordination across the organization.

For example, when Roger Hoerl was the Quality Leader (Six Sigma Leader) of the GE Corporate Audit Staff (CAS), he also was a participant in the GE Quality Leaders’ Council (overall Six Sigma Council). In addition, he led the CAS Quality Council that consisted of the following members:

![]() The CAS Vice President (head of CAS)

The CAS Vice President (head of CAS)

![]() Head of financial service business audits (GE Capital)

Head of financial service business audits (GE Capital)

![]() Head of industrial business audits

Head of industrial business audits

![]() CAS HR manager

CAS HR manager

![]() CAS IT leader

CAS IT leader

![]() An MBB

An MBB

This organizational structure worked well for a couple of reasons: (1) It ensured that the CAS Six Sigma effort was aligned with the overall direction of GE’s Six Sigma deployment, due to the interlocking membership; and (2) the participation of the key decision makers in the CAS council ensured alignment within CAS.

For example, when the council made policy decisions about certification criteria, training requirements, and so on, all the key leaders conveyed the same message. If the leaders had not participated in these decisions, there would have been potential for second-guessing, misalignment, or organizational conflict at the top. All members, including the vice president, made their active participation in this council a priority. The HR and IT representatives contributed significantly to training, reward and recognition, career development issues (HR), and tracking systems for projects, training, and certification (IT). Lean Six Sigma Councils typically include the Lean Six Sigma Leader, representative (not all) Champions, representative MBBs, and leaders of finance, HR, IT, and any other relevant functions.

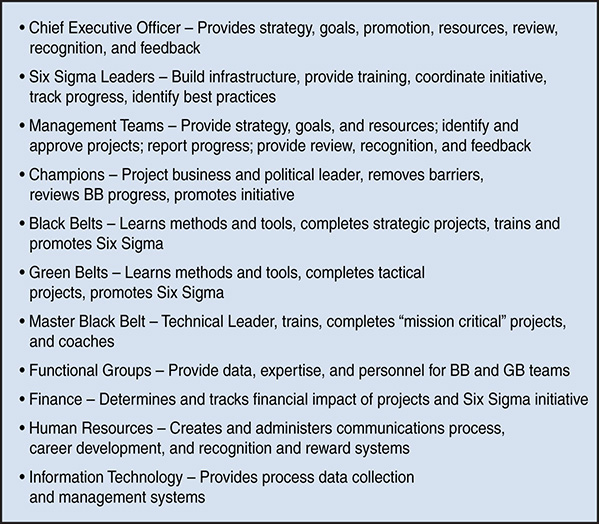

Six Sigma Leaders Must Work Together As a Team

It is important not only that an organizational structure be in place to lead and manage the Lean Six Sigma effort, but also that the key players work together as a team. A team functions well when each player does his or her job well and knows the roles and functions of all the other players on the team. Each person must focus on performing his or her role in such a way that the team wins. For example, it is important that the Black Belts understand the roles of the Champion and other Lean Six Sigma team members so they know where to go for help.

Similarly, it is critical that the functional group leaders know the role of the Black Belts so they can provide them with data, expertise, and resources. This attitude helps everyone learn their roles and functions effectively. The Lean Six Sigma Sweep sports analogy can help us deepen our understanding of this requirement.

The “Lean Six Sigma Sweep”

Columnist George Will tells us that “sports serve society by providing vivid examples of excellence.” This can be true with Lean Six Sigma. Sports provide vivid examples and analogies that help us understand why Lean Six Sigma is so effective—it provides a strategy, a methodology, and an infrastructure that enables all the leaders to work together as a team to improve the performance of the organization.

When you think of excellence and success in the sports world, many modern examples come to mind, such as the New England Patriots in football and the Golden State Warriors in basketball. However, we choose to look back to an “old school” football team from yesteryear, before the wide-open, passing-oriented game of today emerged. In the times of Vince Lombardi, football games were generally won in the “trenches,” through the running game. Lombardi was the coach of the Green Bay Packers team that won five National Football League titles and the first two Super Bowls in the 1960s. Many subsequent successful football coaches were students of Lombardi. How did he do it? His success came from careful thought, detailed planning, lots of practice and hard work, and a clear focus on the goal. These success factors also apply to Lean Six Sigma.

What was Lombardi’s methodology? The famous Packer Sweep was Lombardi’s signature play and a key component of his success. This was a running play in which the running back carried the ball to the outside behind two lineman (pulling guards). The popular “jet sweep” in today’s game is an adaption of the Packer Sweep. Lombardi practiced the sweep more than any other play, refining it until his players knew that they could run it anytime against any opponent. Anyone who has seen video of Green Bay playing during the Lombardi years will recall the sweep in which the guards Jerry Kramer (64) and Fuzzy Thurston (63) pulled out of the line and led the running back Jim Taylor (31) around the end while each of the other players completed his assignment.

Interestingly, Lombardi did not invent this play (he borrowed it from the Los Angeles Rams), but he certainly perfected it. He also developed many variations. On every play, each player knew his job and understood that if each person completed his assignment, the play would be successful. The play was so important to Lombardi’s offense that Coach John Madden recalls him devoting an entire one-day seminar to the subject (Madden, 1985). Lombardi discussed the play, its philosophy, its fundamentals, its objectives, each player’s role, and why the play couldn’t be stopped if each player executed well. Each variation of the sweep was discussed in the same detail.

Many similarities emerge between the Packer Sweep and Lean Six Sigma. First, Lean Six Sigma was not totally original. It built on the work of others and continues to be enhanced as we move toward holistic improvement. Lean Six Sigma works because it emphasizes focus, planning, constant practice (every project is a practice session), and dedicated leadership. The roles are well defined; if each person does his or her job, as defined by the process, the projects will succeed and Lean Six Sigma will achieve its goals.

Lean Six Sigma (ultimately, as holistic improvement via Version 2.0, as discussed in Chapter 2, “What Is Holistic Improvement?”) can be the signature business strategy and management process that separates an organization from its competition—providing focus, reducing costs, growing revenues, empowering and developing people, enhancing teamwork, and providing a common corporate language and methodology. In the process, Lean Six Sigma improves an organization’s performance, sweeping money to the bottom line, just as Lombardi’s Green Bay Sweep gained yards, put points on the scoreboard, won games, won conference titles, and won Super Bowls. We refer to this use of Lean Six Sigma as a signature business strategy as the Lean Six Sigma Sweep.

This analogy actually goes much deeper. There are 11 roles on the Lean Six Sigma Sweep team, just as there are 11 positions on a football team. These roles are detailed in Table 8.5 (also see Chapter 6) and are shown schematically with linkages in Figure 8.3. Although many analogies are possible, we resist the temptation to match the roles on the Lean Six Sigma team with those on a football team. The important point is that these roles must work together as a team just as the players on a football team must work together to be successful.

Table 8.5 Roles on the Lean Six Sigma Sweep Team

Figure 8.3 Lean Six Sigma Sweep team linkages

If the people in these roles perform their jobs as defined and understand the roles of the others on the team, just as Lombardi required of his players, the Lean Six Sigma Sweep will work. Organizational performance will improve, money will be swept to the bottom line, and the organization will be well down the road to success. In fact, when an organization moves out in front of its competition using Lean Six Sigma and continues to use it and expand it toward holistic improvement, the organization will most likely always be ahead of its competition. It is unlikely that the competition will ever catch up.

We again recall the AlliedSignal manager’s admonishment: “Six Sigma works if you follow the process. If it is not working, you are not following the process.”

Playing Offense: Growing the Effort

Although your efforts to hold project gains and the benefits of the overall Lean Six Sigma system help sustain momentum, this is basically a defensive strategy. You don’t want to lose the benefits you have worked so hard to obtain. As in many aspects of life, however, the best defense is a good offense.

While you work on holding gains, you also want to take proactive steps to grow and expand the deployment into new areas. This is your offensive strategy. Continuing to drive Lean Six Sigma into new areas will keep the initiative fresh and prevent it from losing steam.

Some key areas that can prove particularly fruitful are extending Lean Six Sigma to the entire organization, taking it to suppliers and customers, expanding your portfolio of improvement methodologies, and driving top-line growth to complement the bottom-line benefits already achieved.

Expanding Lean Six Sigma Throughout the Organization

Most Lean Six Sigma initiatives begin in manufacturing or operations because manufacturing typically has better measurement systems than other functions. These measurement systems enable you to get going on improvement projects faster. In addition, the money to be made is more obvious and easier to quantify than in other parts of the organization. Nothing shows that Lean Six Sigma works better than speed and results.

These two ingredients, speed and results, help you demonstrate success and allow the organization to see that “Lean Six Sigma will work here!” In the process, you gain experience in Lean Six Sigma, build confidence that you can deploy it successfully, and produce bottom-line results. Lean Six Sigma is shown to more than pay for itself.

But there is much more to be gained. Many believe that more than half of an organization’s improvement opportunity lies outside manufacturing or operations. This additional improvement is a huge opportunity the organization must capture. Organizations typically move Lean Six Sigma in one of two directions after manufacturing/operations: to administrative and transactional processes, or to new product development (R&D). Some organizations might want to improve both areas at the same time. Most, however, move first to the administrative and transactional processes, such as accounts receivable, transportation and shipping, human resources, finance, and other areas listed in Table 8.6.

Table 8.6 Administrative and Transactional Processes

Transactional and administrative areas have unique characteristics that are unlike those of manufacturing processes (Snee and Hoerl, 2005):

![]() The culture is usually less scientific, and people don’t think in terms of processes, measurements, and data.

The culture is usually less scientific, and people don’t think in terms of processes, measurements, and data.

![]() The work typically requires considerable human intervention, such as customer interaction, underwriting or approval decisions, and manual report generation. Human intervention is, of course, an additional source of variation and errors.

The work typically requires considerable human intervention, such as customer interaction, underwriting or approval decisions, and manual report generation. Human intervention is, of course, an additional source of variation and errors.

![]() Transactional and administrative processes are often invisible, complex, and not well defined or well documented. Such characteristics make opportunities for improvement difficult to identify and make projects difficult to define.

Transactional and administrative processes are often invisible, complex, and not well defined or well documented. Such characteristics make opportunities for improvement difficult to identify and make projects difficult to define.

![]() Measurements are often nonexistent or ill defined, resulting in the need to create measurement systems first and then begin to collect the data.

Measurements are often nonexistent or ill defined, resulting in the need to create measurement systems first and then begin to collect the data.

![]() The process output is often intangible and can be unique. For example, the actual output of a due diligence study is knowledge, possibly documented in the form of a report. Each due diligence study will be unique.

The process output is often intangible and can be unique. For example, the actual output of a due diligence study is knowledge, possibly documented in the form of a report. Each due diligence study will be unique.

![]() Similar activities are often done in varying ways. Three people in three different company locations are unlikely to do the same job in the same manner.

Similar activities are often done in varying ways. Three people in three different company locations are unlikely to do the same job in the same manner.

The most important of these unique attributes is the frequent lack of process measurements. In our experience, four key measures of the performance of nonmanufacturing processes come up repeatedly: accuracy, cycle time, cost, and customer satisfaction.

![]() Accuracy is measured by correct financial figures, completeness of information, and freedom from data errors.

Accuracy is measured by correct financial figures, completeness of information, and freedom from data errors.

![]() Cycle time is how long it takes to do something, such as pay an invoice.

Cycle time is how long it takes to do something, such as pay an invoice.

![]() By cost, we mean the internal cost of process steps, not the price charged for services. In many cases, cost is largely determined by the accuracy or cycle time of the process; the longer it takes and the more mistakes that have to be fixed, the higher the cost.

By cost, we mean the internal cost of process steps, not the price charged for services. In many cases, cost is largely determined by the accuracy or cycle time of the process; the longer it takes and the more mistakes that have to be fixed, the higher the cost.

![]() Customer satisfaction is the fourth common measurement. For a situation in which the key process outputs are intangible, such as customer service processes, customer satisfaction (often measured through surveys) will likely be the primary measure of success.

Customer satisfaction is the fourth common measurement. For a situation in which the key process outputs are intangible, such as customer service processes, customer satisfaction (often measured through surveys) will likely be the primary measure of success.

Fortunately, there are more similarities than differences between manufacturing and nonmanufacturing processes. One of the key similarities is that both types of processes have “hidden factories,” places where the defective product is sent to be reworked or scrapped (revised, corrected, or discarded in nonmanufacturing terms). In reality, every process has a hidden factory (see Figures 8.4 and 8.5). Nonmanufacturing examples include performing manual account reconciliation in accounting, revising budgets until management will “accept” them, and shipping product back to online retailers because a mistake was made in the order. Find the hidden factory, and you have found one good place to look for opportunities to improve the process.

Figure 8.4 Every process has a hidden factory: a nonmanufacturing view

Figure 8.5 Eyeglasses fitting process

Use of Lean Six Sigma in new product development (R&D) is commonly referred to as Design for Six Sigma (DFSS). This is another area in which you must expand the effort because the entitlement of a process is often determined in the Design phase. The goal is to improve the product development process so that the organization can get new and better products to market quicker and at less cost to both the consumer and the company.

The strategy is to build the Lean Six Sigma methods and tools into the company’s new product development process (usually a stage-gate process). Close interaction with marketing also greatly improves the development process and, therefore, the new products and services that are ultimately produced. The payoff on DFSS projects usually has a longer time frame because of the time required to get a new product to market. The training is still project focused (no project, no training) and is done at both the Black Belt/MBB and Green Belt levels. More will be said about DFSS when we discuss top-line growth later in this chapter.

Using Six Sigma to Improve Supplier Performance

You will quickly learn that the average level and variability of quality (not to mention the cost) of materials from suppliers have a big effect on the quality and cost of your products and services. It is not unusual for 40 to 60 percent of the final cost of a company’s product to derive from the costs of materials purchased from suppliers. You cannot overlook such a high cost or the effects of variation in materials on the performance of processes, so you might wonder how to get suppliers to use Lean Six Sigma to improve their performance, ultimately improving yours.

You will have more credibility going to suppliers with a recommendation to use Lean Six Sigma once you have used it in your organization and demonstrated that it works. For this reason, supplier Lean Six Sigma programs typically don’t start until after the first or second year of a deployment.

The first step in getting suppliers to use Lean Six Sigma is to determine how the quality and cost of supplier materials are affecting the performance of your organization. One way to accomplish this is to track supplier materials as they flow through your processes and determine the scrap, waste, downtime, and yield loss they cause. You will no doubt also see that a large portion of the loss comes from your company’s processes, thereby identifying additional opportunities for internal improvement.

We do not recommend focusing improvement efforts on “beating up” suppliers without a clear understanding of how their materials affect your process. This misguided step is popular because it requires no change or hard work on the part of your organization. A more effective method is to first focus Lean Six Sigma on what you can control and then, as you learn about root causes coming from materials, integrate suppliers into your improvement efforts.

This approach works in both manufacturing and nonmanufacturing environments. For example, a newspaper company initiated a Lean Six Sigma project to reduce errors in the paper. Such errors were generally found before publication, but finding and fixing them was an expensive form of rework. Data from the project ultimately revealed that the root causes of many errors were in the information obtained from external sources, such as wrong facts, wrong names, and wrong figures (Hoerl and Snee, 2012; see Chapter 10, “Final Thoughts for Leaders”). Armed with this information, the newspaper communicated to reporters and copy editors which information sources (suppliers) could be trusted and should be used. Other sources needed to initiate improvement efforts to be trusted and used in the future.

When you know the magnitude of the problems coming from suppliers, you can set an improvement goal for them to attain. A common goal is a 5 percent reduction per year in price, adjusted for inflation. The intent is for the price reduction to be based on supplier improvement projects that reduced the supplier’s own costs. In this way, both the supplier and the customer benefit financially. The price reduction goal could be mandatory, or suppliers that meet this price reduction goal could receive preferential treatment.

If these goals are based on actual data and can be achieved via a win–win approach, communicating such expectations is not simply “beating up” suppliers. When it makes business sense, companies also might find it appropriate to develop unique improvement goals for different organizations or processes within a given supplier.

Next, you have to determine which suppliers you are going to approach with encouragement to use the Lean Six Sigma approach. One way is to do a Pareto analysis of the key sources of costs, such as supplier-caused scrap, rework, and other losses. Focus on the materials and suppliers that are associated with the highest costs; the biggest problems usually represent the biggest opportunity. You might also want to approach key suppliers that you would like to form a long-term strategic relationship with.

Companies have introduced suppliers to Lean Six Sigma in a variety of ways. One way is to identify a few high-impact projects and form customer–supplier teams to complete the projects using Lean Six Sigma. If the supplier doesn’t have Black Belts available to work on the project, then the customer supplies the Lean Six Sigma expertise and any needed training. Tremendous progress is made when both the customer and the supplier have one or more Black Belts on the project team.

Another approach is for the company to make available supplier training programs that are partially funded by the customer and that make available both Champion and Black Belt training, at a minimum. An effective way to create such a program is to start with a few good projects and then use their success to expand the program. It is essential that the supplier’s management be involved in the program. An executive workshop is a good way to help build this involvement because it communicates what Lean Six Sigma is and the benefits the supplier organization can expect to receive.

Clearly, careful planning is needed to have a successful Lean Six Sigma supplier program. Any financial arrangements must be defined and agreed to up front so that the expectations of both parties are met. The goals and objectives have to be carefully thought out and clearly communicated.

Additionally, Lean Six Sigma must be positioned as a how instead of a what. In other words, your purpose is not to have the supplier use Lean Six Sigma. Instead, your purpose is for suppliers to make tangible improvements that positively affect you and your organization. Lean Six Sigma is just a means to help them accomplish this objective. If the supplier can obtain the desired results without Lean Six Sigma, this should be acceptable. Of course, desiring improvements without a method to achieve them is little more than daydreaming. Lean Six Sigma can be an effective methodology for achieving customer and supplier goals once those goals have been clearly defined and communicated.

Expanding the Improvement Portfolio

As we discussed in Chapters 1–3, holistic improvement integrates different methodologies under one overall improvement system. An organization needs diverse methods and tools at its disposal to be able to address the diverse nature of problems it will face. A key distinction of holistic improvement over approaches based on only one methodology is that it is method agnostic. That is, it starts by diagnosing the problem that needs to be solved and then selects the best improvement methodology for that particular problem. It does not force-fit a preselected methodology to a problem for which it is not well suited. This is a common shortcoming with virtually all other improvement approaches, including Six Sigma and Lean.

Furthermore, holistic improvement integrates the three main categories of improvement—quality by design, breakthrough improvement, and quality and process management systems—under one umbrella. Such integration makes the overall improvement effort more coordinated, integrated, and, ultimately, optimized. In most organizations, these three types of improvement reside in different organizational silos, resulting in a lack of coordination, isolated efforts (“islands of improvement”), and, in many cases, outright competition for resources and management’s attention.

Given these points, it might seem logical to implement a holistic improvement initiative from the beginning. This makes sense on paper, but in practice, it turns out to be too large an effort to launch at one time. As an analogy, strong middle school students don’t skip high school and go directly into college. A few students have done so successfully, but in general, it is a poor strategy and is not recommended. A much more pragmatic approach is to initially launch a Lean Six Sigma initiative and then gradually expand it to become holistic—to evolve toward Lean Six Sigma 2.0. This is the approach we have assumed in previous chapters.

Now that you have launched a Lean Six Sigma initiative, have transitioned to managing it through formal infrastructure (systems and organizational structure), and are now expanding the effort, you are in a good position to make significant progress toward holistic improvement. A key step in this direction is to expand the portfolio of improvement methodologies. So far, most projects will have utilized Lean and/or Six Sigma. Going forward, we would like a broader portfolio to allow the organization to attack problems that are not well suited for either Lean or Six Sigma, such as routine problem solving.

Three key questions must be answered:

1. How do we go about adding methodologies?

2. How do we modify the infrastructure developed in previous phases, given a broader portfolio of improvement methodologies?

3. How do we determine the most suitable methodology for a given project?

We address these three questions next.

Which Methodologies to Add?

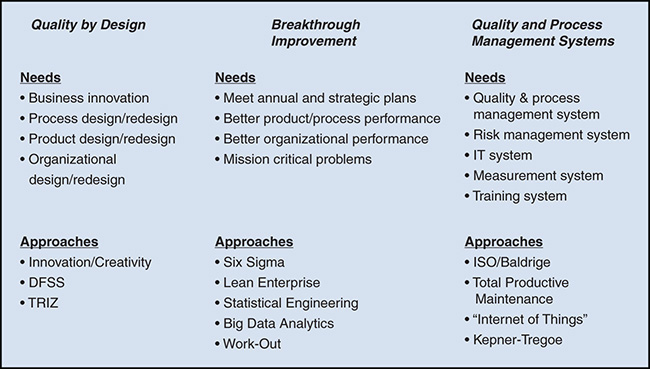

In thinking about which methodologies to add, it is good to revisit the concept of holistic improvement. We have reproduced Table 2.2 and labeled it here as Table 8.7. Note that we need to think about methodologies in each of the three categories listed: quality by design, breakthrough improvement, and quality and process management systems. As we discuss later in this chapter, DFSS is a logical next step because it brings quality by design into the mix and is a natural extension of Lean Six Sigma. No doubt Black Belts will have already identified design projects that require a somewhat different approach than DMAIC. We return to DFSS shortly.

Table 8.7 Holistic Improvement System Needs and Sample Approaches

Note that the methodologies listed in Table 8.7 are just a sample of recommended approaches that have proven effective within diverse organizations. Each organization should develop its own list, based on its particular needs, taking into account the methodologies and systems it already has in place. Consider Table 8.7 as a reference point or benchmark to begin building upon.

In the breakthrough improvement category, Work-Out is a logical methodology to add at this point. The organization will likely already have undergone improvement projects that did not require the rigor of Lean Six Sigma. The knowledge of the folks in the room might have been sufficient to solve the problem, producing bottom-line results more quickly. Furthermore, Work-Out does not use any sophisticated tools—just sound meeting management, including formal methods for idea generation and prioritization (Hoerl, 2008). Therefore, the additional training required to add Work-Out to the portfolio is relatively minor.

When the project does not require any tools, but can be considered a quick fix, we often refer to it as a “Nike project” (Just Do It!). Nike projects can still be important and impactful; they just don’t require the same degree of rigor and formal tools. Obviously, Nike projects are easy to add to the portfolio.

Your organization might or might not have a Big Data analytics group. If it does, now is a good time to begin informal networking to better coordinate these improvement efforts. Reorganizations are difficult and fraught with pitfalls, so we recommend leaving a formal reorganization for the fourth phase, the way we work. If no Big Data organization currently exists, it is a good idea to begin seeking individuals with the right skills (potentially, MBBs) who might begin such an effort. As previously noted, analyzing massive data sets provides a great opportunity for additional improvement beyond Lean Six Sigma.

Most organizations have a formal quality group active in ISO 9000, Malcolm Baldrige, or other quality management approaches, but routine problem solving still might need to be added to the improvement portfolio. As noted in Table 8.7, Is–Is Not analysis, often referred to by the authors names Kepner–Tregoe, is an effective methodology for addressing special cause problems. By special cause problems, we mean situations in which performance has deteriorated, but we don’t know why. Black Belts need to quickly identify the root cause of the problem so the organization can fix it and return performance to normal levels. Kepner–Tregoe does require training, but not as rigorous as Six Sigma or Lean.

In summary, the following improvement methodologies are potentially the most logical to add to the portfolio now:

![]() DFSS

DFSS

![]() Work-Out

Work-Out

![]() Nike projects

Nike projects

![]() Big Data analytics (exploratory)

Big Data analytics (exploratory)

![]() Kepner–Tregoe

Kepner–Tregoe

The other methodologies in Table 8.7, as well as others your organization identifies, can then be added gradually over time as you migrate toward holistic improvement. Recall that the improvement portfolio should be dynamic, evolving over time as new methods become available and potentially replace older methods that are no longer relevant. Managing the improvement portfolio is a critical responsibility of the Lean Six Sigma Council, often referred to as the Quality Council.

Implications for Infrastructure

Several elements of the existing infrastructure need to be modified to accommodate a broader improvement portfolio. For example, the training system now has more methodologies to consider. We recommend that the training system not try to train every employee, or even every Black Belt or MBB, in all methods in the portfolio. This training commitment would be monumental and very expensive. Instead, the training system needs to have the appropriate level of resources in each methodology to match the organization’s current needs. For example, we feel that everyone needs to be familiar with the basics of Six Sigma and the Lean principles. However, very few need to be competent in Big Data analytics.

Similarly, more R&D scientists and engineers will need training in DFSS relative to employees in manufacturing or finance. Even MBBs cannot be expected to specialize in all methodologies, although there will need to be a critical mass of MBBs who are well versed in each improvement methodology added to the portfolio. Such a critical mass might not exist at the time the methodology is added to the portfolio, so training will be required to develop it.

Recall that developing and managing a training system is much more challenging than conducting a mass wave of training. Mass waves of training rarely have lasting value (Snee and Hoerl, 2005). This is why we recommend chartering the Training Council at this point if it is not already in existence. Obviously, this council requires heavy involvement from HR, as well as a core group of MBBs who collectively understand the full set of methodologies and know who in the organization needs to be trained in each.

Another system that needs to be modified is the project selection and prioritization system. Until now, the main objectives were to identify and prioritize potential projects and put them in the project hopper. As noted in Chapter 6, some thought was needed regarding whether a Lean, Six Sigma, or perhaps hybrid approach was most logical so that an appropriate Black Belt could be assigned to lead the project. Now that we have a broader improvement portfolio, more thought needs to go into selecting the project methodology and the most appropriate Black Belt.

Going forward, once projects are identified, they also need to be mapped to the most appropriate methodology. For example, should this be a Six Sigma project or is it more suited to Kepner–Tregoe? The choice of methodology is important, so the project selection process must incorporate MBBs who collectively understand the full range of potential project types. You will notice that the MBB role becomes more critical as we migrate from Lean Six Sigma to holistic improvement.

After the project methodology has been chosen, a Black Belt with a strong background in the chosen methodology is needed. We certainly encourage cross-training to develop Black Belts with broad backgrounds, but as with MBBs, not every Black Belt will be competent in every improvement method. Recall that we strongly recommend selecting projects first and then assigning Black Belts, not vice versa.

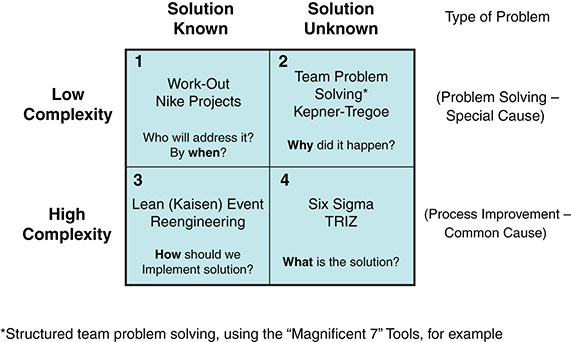

Selecting the Most Appropriate Methodology

Identifying the most appropriate improvement methodology can be challenging. Despite the fact that holistic improvement is a method-agnostic approach, people will no doubt still have their favorites. Therefore, it is often helpful to develop tools to guide the selection of methodology in an objective manner. Hoerl and Snee (2013) developed one such tool, which is shown in Figure 8.6 with minor updates. The two main questions that teams need to answer in using this approach are whether the solution is known or unknown (we discussed this previously) and whether the problem has relatively high or low complexity.

Figure 8.6 Selecting the most appropriate improvement methodology

The answers to these two questions identify the most appropriate cell in the matrix, which lists the logical questions that need to be answered in that cell and the potential methods to do so. High complexity is usually associated with quality by design or breakthrough improvement—achieving a new level of performance. Low complexity is usually associated with routine problem solving—fixing something that is broken. Note that reengineering is a more general term for DFSS projects. It was generally intended to represent the redesign of existing processes, often with the intent of automating something that was previously done manually.

Team problem solving is a generic term for any structured approach to solving problems. The so-called Magnificent 7 tools noted in Figure 8.6 are listed here:

![]() Cause-and-effect diagram

Cause-and-effect diagram

![]() Pareto chart

Pareto chart

![]() Check sheet

Check sheet

![]() Run chart

Run chart

![]() Histogram

Histogram

![]() Scatter diagram

Scatter diagram

![]() Stratification

Stratification

Figure 8.6 is intended to only highlight alternative improvement approaches; it is not intended to be comprehensive.

For solution-known, low-complexity problems (potentially Nike projects), we just need to know who is going to complete the project and by when. If the solution is not known, the root cause (the why) needs to be identified (potentially with Kepner–Tregoe) and then fixed. As noted previously, Lean tends to work best for solution-known problems that involve some degree of complexity—those that require breakthrough improvement. Because of the complexity, we still need to determine how to implement the known solution. This will rarely be trivial for Lean projects, including Kaizen events.

The “sweet spot” for Six Sigma is solution-unknown, high-complexity problems. In such cases, we need to perform significant data gathering and analysis to identify root causes and, subsequently, potential solutions to them. For even higher-complexity problems (for example, the large, complex, unstructured problems discussed in Chapter 1, “A New Improvement Paradigm Is Needed”), a statistical engineering approach might be more appropriate.

Of course, Figure 8.6 is just one example of a tool that might be used to help identify the most appropriate methodology for a given project. In Chapter 6, we discussed how to determine whether the issue is “within the boxes” or “between the boxes” of the flowchart when considering Six Sigma or Lean. This principle can also help in selecting the best methodology. Organizations should further develop their own tools to make this critical decision. More research is clearly needed in methodology selection for a given problem.

Growing the Top Line

A common question when implementing Lean Six Sigma is, “I can see how to use Lean Six Sigma to reduce costs, but how can I use Lean Six Sigma to increase revenues?” Expanding the improvement portfolio to incorporate more quality by design methodologies will certainly help, but it often goes unnoticed that Lean Six Sigma can also grow the top line. In general, revenues are increased by these actions:

![]() Obtaining new customers (find more)

Obtaining new customers (find more)

![]() Getting current customers to buy more (get more)

Getting current customers to buy more (get more)

![]() Regaining old customers who have left to do business with your competitors (keep more)

Regaining old customers who have left to do business with your competitors (keep more)

Fortunately, Lean Six Sigma can be applied in many ways that directly tie to one or more of these revenue-increasing areas. For example, consider the following specific approaches, with the principle revenue-increasing areas noted:

![]() Use DFSS to create new and better products (find, get, and keep more). DFSS is obviously a quality by design approach, but it is also a form of Six Sigma.

Use DFSS to create new and better products (find, get, and keep more). DFSS is obviously a quality by design approach, but it is also a form of Six Sigma.

![]() Increase capacity (productivity) when the product line is sold out (find and get more)

Increase capacity (productivity) when the product line is sold out (find and get more)

![]() Improve product quality and price (find, get, and keep more)

Improve product quality and price (find, get, and keep more)

![]() Improve the service processes that touch the customer, such as delivery, billing, and customer service (get and keep more)

Improve the service processes that touch the customer, such as delivery, billing, and customer service (get and keep more)

![]() Show customers how to benefit from Lean Six Sigma (get more).

Show customers how to benefit from Lean Six Sigma (get more).

![]() Institute “at the customer, for the customer” projects (get and keep more).

Institute “at the customer, for the customer” projects (get and keep more).

![]() Successfully complete strategic sales and marketing projects (find, get, and keep more).

Successfully complete strategic sales and marketing projects (find, get, and keep more).

Developing new and better products and services are obviously key to growing the top line. This is why integrating breakthrough improvement with quality by design is so important. These two types of quality improvement need to be well integrated to keep them from residing in separate silos. DFSS is the Six Sigma approach to accomplishing this objective. We have seen that DFSS is typically started about one year after initiating the DMAIC methodology for improving existing processes, and after gaining confidence that Lean Six Sigma will work in the company.

Conceptually, we can consider product design a process and apply Lean Six Sigma in a straightforward manner to improve it. In most cases, however, organizations want to apply Lean Six Sigma to the design of a specific new product or service. Although it applies equally well here, Lean Six Sigma requires a different roadmap that is more tailored to design. If a team applies the DMAIC roadmap to designing a new product, it will likely stumble in the Measure phase because there is no existing process on which to take measurements.

GE developed the DMADV roadmap, and many others have adopted it since then, to apply to design projects. As we explained in Chapter 3, “Key Methodologies in a Holistic Improvement System,” the Define stage is analogous to Define in DMAIC, although it is typically more complicated because we are designing a new product or service, not improving an existing process. In the DMADV Measure phase, we determine the CTQ characteristics and ensure that we have measurement capability, but we do not measure an existing process unless the new design is an enhancement of a current design.

The Analyze phase focuses on conceptual design, in which we use creative “out of the box” thinking to determine the most promising high-level design to satisfy CTQs. For product designs, we might develop prototypes. The details of this design are completed in the Design phase, where we make calculations to predict final design capability. If these calculations are not promising, the team must repeat the Analyze phase and the Design phase to improve the design capability. In the Verify phase, we pilot the new design under realistic conditions to obtain real data verifying the design capability.

For example, an organization that is designing a manufactured product would utilize a pilot run in a real manufacturing facility, using regular workers and raw materials for the Verify phase. This contrasts with a prototype made under ideal conditions that might be used to prove the design concept in the Analyze phase. Similarly, an organization that is designing a web-based insurance application and underwriting system would utilize people with computer skills similar to the targeted market to access the system during normal business hours using standard platforms. In many cases, we go through a mini-DMAIC cycle here to improve design flaws observed in the pilot. If major discrepancies in capability arise, organizations might need to loop back through the Analyze phase and Design phase again.

This approach to DFSS maintains the key technical elements of DMAIC:

![]() Disciplined approach

Disciplined approach

![]() Use of metrics throughout the process

Use of metrics throughout the process

![]() Use of analytical tools

Use of analytical tools

![]() Emphasis on variation

Emphasis on variation

![]() Data-based decision making

Data-based decision making

Lean Six Sigma can be used to improve the top line in ways besides DFSS. One way is to find situations in which a product is in a sold-out condition today or is forecast to be sold out in the near future. Here you can use Lean Six Sigma in a traditional manner (DMAIC) to increase capacity (productivity). Whereas Six Sigma is often thought of as primarily a quality improvement methodology, Lean tends to focus more on productively. Its integration provides a more balanced approach that applies equally well to improving quality or productivity. When we increase capacity closer to the theoretical maximum capacity (capacity entitlement), we have the opportunity to sell more to new or existing customers, resulting in top-line growth. When an organization has reached the theoretical maximum capacity, it will likely need quality by design approaches, such as DFSS or capital projects, to further increase output.

Often customers will buy more if the quality of the product improves or price is reduced. In these situations, companies can use Lean Six Sigma to improve quality and decrease internal costs. They can then pass on part of the cost savings to the customer if desired, thereby increasing volume without having to sacrifice margin. The company also might be able to obtain new customers because of the improved quality and decreased price. Better yet, some customers that the company previously lost because of poor quality or high price might return.

In many instances, the key problem is a service issue, such as customer response time (CRT), or the time between placing an order and receiving the product or service. Resolving service issues can require analyzing the entire process: order, manufacture, delivery, bill, and return. The root cause of the problem could lie in some or all of these steps.

A point often missed is that manufacturing is only one step in the process of serving the customer. We know of one instance in which the CRT for a piece of heavy equipment was 12 months. A look at the subprocess cycle times revealed that the physical manufacture took only three months, so reducing manufacturing time to just a few days still left 75 percent of the cycle time untouched. Clearly, sometimes moving outside of manufacturing is needed to obtain significant reductions in total cycle time.

Variation in CRT is as important as, if not more important than, the average level of CRT. For example, if a customer receives two orders, one 30 days early and one 30 days late, the average CRT is perfect, but neither order was on time! In some instances, early orders are worse than late ones because the customer is not prepared to handle the early delivery and might tell the shipper to return the order to the vendor. Noting this, GE focused on reducing variation as a way of creating greater customer satisfaction (see the “Message to the Shareholders” in the 1998 GE Annual Report).

The opportunity to increase revenues by improving quality or service requires input from the customer. Price reduction is universally appreciated! Organizations need to determine the key problems that, if fixed, would result in the customer buying more. Asking the customer, “What changes can I make in my products or services that would allow you to buy more from me?” is not without risk. It can lead the customer to expect that any improvements requested will be made. Of course, noncustomers or previous customers can also be asked the same question, to try to win their business as well.

Another way to use Six Sigma to grow the top line is to introduce customers to Lean Six Sigma and show how it can help them improve. The theory is that customers with a better bottom line will be happier customers with a closer working relationship and will then repay the company by buying more of its products and services.

Helping customers solve their problems as a method of developing better business relationships is not new; various companies have been doing this for many years. What is new is using Lean Six Sigma in working with customers in this way. GE developed such an approach by having its Black Belts work with customers to solve their problems. GE called the program Six Sigma at the Customer for the Customer.

Welch (2001) reported that, in 2000, GE helped 50 GE Aircraft Engine customers complete 1,500 projects that saved $230 million. Also in 2000, a total of 1,000 projects were completed for GE Medical Systems customers, returning $100 million to the customers’ bottom lines. Many of these projects were done primarily by GE Black Belts as at the customer, for the customer projects.

Lean Six Sigma can also be applied to strategic sales and marketing processes. DMAIC projects in these areas will primarily improve top-line growth, but they might have secondary benefits for cost savings as well. Such projects are generally initiated as part of the effort to spread Lean Six Sigma across the organization, as discussed earlier. Potential applications include these:

![]() Improving the impact of advertising (more bang for the buck)

Improving the impact of advertising (more bang for the buck)

![]() Improving marketing research studies, which drive DFSS projects

Improving marketing research studies, which drive DFSS projects

![]() Increasing sales force effectiveness

Increasing sales force effectiveness

With the exception of improving capacity, all the approaches discussed require close working relationships with customers. This aspect of Lean Six Sigma improvement differs somewhat from the improvements from cost reduction projects. Of course, all Lean Six Sigma projects have a link to customers in one way or another; some links are just stronger than others.

Summary and Looking Forward

Sustaining momentum and growing occurs between completing all the training and projects identified in the original deployment plan and completing deployment across the organization. Deployment is considered complete when you are ready to make the transition from Lean Six Sigma as an initiative to holistic improvement as the normal way you work—that is, to move to Lean Six Sigma 2.0.

This phase can last several years. It consists of both a defensive strategy (sustaining momentum) and an offensive strategy (growing the effort). Keys to the defensive strategy are taking proactive steps to hold the gains from completed projects and also hold the gains from the overall Six Sigma initiative.

Implementing the remaining infrastructure elements is the critical success factor in this defensive strategy. These elements include the following:

![]() Process and financial audits to verify the benefits

Process and financial audits to verify the benefits

![]() Lean Six Sigma system reviews

Lean Six Sigma system reviews

![]() A comprehensive training system (versus a mass training event)

A comprehensive training system (versus a mass training event)

![]() A formal Lean Six Sigma organizational structure

A formal Lean Six Sigma organizational structure

The offensive strategy consists of expanding the effort across the organization, involving strategic suppliers and customers, expanding the improvement portfolio, and using Lean Six Sigma to grow the top line. Utilizing a DFSS approach to new product and service design is a critical success factor because it influences each of these elements of the offensive strategy. By definition, it also helps bridge the quality by design work in the organization with the breakthrough improvement work. Using the philosophy that often the best defense is a good offense, organizations want to make sure they are aggressively deploying Lean Six Sigma in new areas to ensure that they maintain momentum and reach the entire organization and all its activities.

When Lean Six Sigma has become the modus operandi across the organization and is well integrated with both quality by design and also quality and process management efforts, the company will be well positioned to make the transition to “the way we work.” This transition will ensure that benefits are permanent and also that the organization achieves true holistic improvement, or Lean Six Sigma 2.0. Organizations that can accomplish this transition will no doubt be recognized as world-class leaders in improvement. We discuss how to make this difficult transition, including organizational changes, in the next chapter.

References

Automotive Industry Action Group. (2005) Statistical Process Control Reference Manual. 2nd ed.

Automotive Industry Action Group. (2008a) Advanced Product Quality Planning and Control Plan. 2nd ed.

Automotive Industry Action Group. (2008b) Potential Failure Mode and Effects Analysis Reference Manual. 4th ed.

Automotive Industry Action Group. (2010) Measurement System Analysis Reference Manual. 3rd ed.

Box, G. E. P., W. G. Hunter, and J. S. Hunter. (2005) Statistics for Experimenters. 2nd ed. Hoboken, NJ: John Wiley and Sons.

Box, G. E. P., G. M. Jenkins, G. Reinsel, and G. M. Ljung. (2015) Time Series Analysis: Forecasting and Control. 5th ed. Hoboken, NJ: John Wiley and Sons.

Cohen, L. (1995) Quality Function Deployment: How to Make QFD Work for You. Reading, MA: Addison-Wesley.

Cornell, J. A. (2011) A Primer on Experiments with Mixtures. Hoboken, NJ: John Wiley and Sons.

Draper, N. R., and H. Smith. (1998) Applied Regression Analysis. 3rd ed. New York: John Wiley and Sons.

English, Bill. (2001) “Implementing Six Sigma: The Iomega Story.” Presented at the Conference on Six Sigma in the Pharmaceutical Industry, Philadelphia, PA, November 27–28, 2001.

General Electric Company (1997). Annual Report, Fairfield, CT: General Electric Company.

General Electric Company (1998). Annual Report. Fairfield, CT: General Electric Company.

Hoerl, R. W. (2001) “Six Sigma Black Belts: What Do They Need to Know? (With Discussion).” Journal of Quality Technology 33, no. 4: 391–435.

Hoerl, R. W. (2008) “Work-Out.” In Encyclopedia of Statistics in Quality and Reliability, edited by F. Ruggeri, R. Kenett, and F. W. Faltin, 2103–2105. Chichester, UK: John Wiley and Sons.

Hoerl, R. W., and R. D. Snee. (2012) Statistical Thinking: Improving Business Performance. 2nd ed. Hoboken, NJ: John Wiley and Sons.

Hoerl, R. W., and R. D. Snee. (2013) “One Size Does Not Fit All: Identifying the Right Improvement Methodology.” Quality Progress (May): 48–50.

Madden, J. (1985) Hey, Wait a Minute! I Wrote a Book. New York: Random House.

Meeker, W. Q., and L. A. Escobar. (1998) Statistical Methods for Reliability Data. New York: John Wiley and Sons.

Montgomery, D. C. (2012a) The Design and Analysis of Experiments. 8th ed. Hoboken, NJ: John Wiley and Sons.

Montgomery, D. C. (2012b) Statistical Quality Control. 7th ed. Hoboken, NJ: John Wiley and Sons.

Montgomery, D. C., E. A. Peck, and G. Vining. (2012) Introduction to Linear Regression Analysis. 5th ed. Hoboken, NJ: John Wiley and Sons.

Myers, R. H., D. C. Montgomery, and C. M. Anderson-Cook. (2016) Response Surface Methodology, 4th ed. Hoboken, NJ: John Wiley and Sons.

Snee, R. D. (1995) “Listening to the Voice of the Employee.” Quality Progress (January): 91–95.

Snee, R. D., and R. W. Hoerl. (2005) Six Sigma Beyond the Factory Floor: Deployment Strategies for Financial Services, Health Care, and the Rest of the Real Economy. Upper Saddle River, NJ: Financial Times/ Prentice Hall.

Snee, R. D., and R. W. Hoerl. (2016) Strategies for Formulations Development: A Step-by-Step Guide Using JMP. Cary, NC: SAS Press.

Walpole, R. E., and R. H Myers. (2016) Probability and Statistics for Engineers and Scientists. 9th ed. Englewood Cliffs, NJ: Prentice Hall.

Welch, J. (2001) Jack, Straight from the Gut. New York: Warner Business Books.

Wheeler, D. J., and D. Chambers. (2010) Understanding Statistical Process Control. 3rd ed. Knoxville, TN: SPC Press.

Wheeler, D. J., and R. W. Lyday. (1989) Evaluating the Measurement Process. 2nd ed. Knoxville, TN: SPC Press.