Total Quality Management

An Overview

Abstract

Before the industrial revolution, quality management was part and parcel of an individual’s activities of designing, producing, and selling to the buyers. In the 19th and 20th centuries, as a principle of scientific management, the incentive schemes were introduced to boost production, which indirectly resulted in poor quality. The new concepts and practices in quality management, which had enabled the industries all over the world to transform the global economy are detailed in this book, while this chapter gives an introduction and illustrates the significance of this quality concept.

Keywords

Quality definitions; Quality quotes; Fitness for use; Total quality management; Scale of quality; Quality of design vs. quality of conformance; Five approaches to quality; PDCA cycle; Deming wheel; OPDCA; Baconian method; Empiricism; Kaizen; Manufacturing system; Quality trilogy; KISS principle; DFSS; SDLC; cGMPs; 2nd World Quality Day

Abbreviations

DMAIC define, measure, analyze, improve, and control

DMADV define, measure, analyze, design, verify

IDOV identify, design, optimize, and validate

DCCDI define, customer, concept, design, and implement

DMEDI define, measure, explore, develop, and implement

KISS Principle keep it simple statistically

DFSS design for six sigma

SDLC software development life cycle

cGMPs current good manufacturing practices

1.1 What Is Quality?

Quality indicates the capability of all components of an entity to satisfy the stated and implied needs, that a quality item will perform satisfactorily in service, and is suitable for its intended purpose. Quality is referred to as “fitness for use,” “fitness for purpose,” “customer satisfaction,” “conformance to the requirements,” or has a pragmatic interpretation as the non-inferiority or superiority of something. In any case, to achieve satisfactory quality, we must be concerned with all three stages of the product or service cycle which include:

● The product design and conformance

● The product support throughout its lifetime

Total quality management (TQM) consists of organization-wide efforts and an integrated system of principles, methods, and best practices to install and make a permanent climate in which an organization continuously improves its ability to deliver high-quality products and services to customers.

1.2 Quality Definitions

There have been several definitions of quality as given by various quality organizations, as well as quality gurus. Nevertheless, all these definitions focus on the efforts put in by organizations to fulfill customer requirements as stated above.

1. TQM is a management philosophy and company practices that aim to harness the human and material resources of an organization in the most effective way to achieve the objectives of the organization.

–British Standards Institution Standard BS 7850-1:1992

2. TQM is a philosophy for managing an organization in a way which enables it to meet stakeholder needs and expectations efficiently and effectively, without compromising ethical values.

–The Chartered Quality Institute

3. TQM is a term first used to describe a management approach to quality improvement. Since then, TQM has taken on many meanings. Simply put, it is a management approach to long-term success through customer satisfaction. TQM is based on all members of an organization participating in improving processes, products, services, and the culture in which they work.

–The American Society for Quality

4. TQM refers to management methods used to enhance quality and productivity in organizations, particularly businesses. TQM is a comprehensive system approach that works horizontally across an organization, involving all departments and employees and extending backward and forward to include both suppliers and clients/customers. It provides a framework for implementing effective quality and productivity initiatives that can increase the profitability and competitiveness of organizations.

www.inc.com/encyclopedia

5. Quality is the fitness for the purpose or use. (Fitness as defined by the customer.)

–Dr. J.M. Juran in 1988

6. Quality means getting everyone to do what he has agreed to do and do it right the first time. Quality is conformance to specifications.

–Philip Crosby

7. Quality is the degree to which a set of inherent characteristics fulfills requirements.

–ISO 9000

8. Quality is an effective system of integrating quality improvement efforts of various groups of the organization so as to provide products/services at a level which allow customer satisfaction.

–A.V. Feigenbaum

9. TQM is a way of managing to improve the effectiveness, flexibility, and competitiveness of a business.

–Prof. John Oakland

10. TQM is a management approach for an organization, centered on quality, based on the participation of all its members and aiming at long-term success through customer satisfaction, and benefits to all members of the organization and to society. One major aim is to reduce variation from every process so that greater consistency of effort is obtained.

–Royse, D., Thyer, B., Padgett D., and Logan T., 2006

11. TQM is the total approach in every aspect of management.

–Bill Creech

12. TQM is an evolving system of practices, tools, and training methods for managing companies to provide customer satisfaction in a rapidly changing world.

–Alan Graham and David Walden

13. Quality is synonym to characteristic, trait, goodness, or excellence.

–Roget’s Thesaurus

14. Quality in a product or service is not what the supplier puts in. It is what the customer gets out and is willing to pay for.

–Peter Drucker

15. Quality means products and services meet or exceed customers’ expectations.

16. Quality is conformance to requirements or specifications or standards.

–Crosby

17. Quality of a product includes a peculiar and essential character or feature. It may be noted here that the character applies to a peculiar and distinguishing quality of a thing or class, whereas the property implies a characteristic that belongs to a thing, essential nature and may be used to describe a type, carry a certain degree of excellence.

–Webster’s Collegiate Dictionary

18. Quality is the totality of features and characteristics of an entity, or a product or service that bear in its ability to satisfy stated or implied needs. The implied needs are usually very vague, indicated, or not indicated at all. Nonetheless they are expected by the customer sometimes more than the standard.

–ISO 8402-1994

19. Quality is the management philosophy and company practices that aim to harness the human and material resources of an organization in the most effective way to achieve its objectives. The objective of an organization may be customer satisfaction, growth, profit, and market position.

–BS 5750

20. TQM is the application of quantitative methods of human resources to improve the materials and services, supplies to an organization; all the processes within an organization and the degrees to which the needs of the customer are at present and in future.

–U.S. Department of Defense

21. TQM is both a philosophy and a set of guiding principles that represent the foundation of a continuously improving organization.

22. TQM is an approach for effective management of an enterprise through focus on its people and performance, safety, proper packaging, timely delivery, efficient technical service, and incorporating effective customer feedback.

23. TQM is a business philosophy founded on customer satisfaction.

24. Quality means productivity, competitive cost, timely delivery, and total customer satisfaction.

25. Product quality is decided by the customer needs, conforming to specifications, assured performance, safety, proper packaging, timely delivery, efficient technical service, and incorporating effective customer feedback.

26. TQM is an integrated organizational approach in delighting both external and internal customers by meeting their expectations on a continuous basis through everyone involved with the organization working on continuous improvement in all products, services, and procedures, along with proper problem-solving methodology.

1.3 Quotes on Quality

Apart from the above definitions, we can also cite some quotes from Mahatma Gandhi et al.

1. It is the quality of our work that pleases the God and not the quantity.

–Mahatma Gandhi

2. I have offended God and mankind because my work did not reach the quality it should have.

–Leonardo Da Vinci

3. 20th century was a century of manufacturing and 21st century is the century of Quality.

–J.M. Juran

4. Quality is everybody’s responsibility.

–Edward Deming

5. Quality is never an accident. It is always the result of intelligent effort.

–John Ruskin

6. When it is obvious that the goal cannot be reached, do not adjust the goal, adjust the action steps.

–Confucius

7. No matter how many goals you have achieved, you must set your eyes on a higher one.

–Jessica Savich

8. Problems are not stop signs, they are guidelines.

–Robert Schuller

9. Good management consists in showing average people how to do the work of superior people.

–John D Rockfeller

10. The new one is just an old thing that was forgotten.

–A Russian proverb

1.4 The Scale of Quality

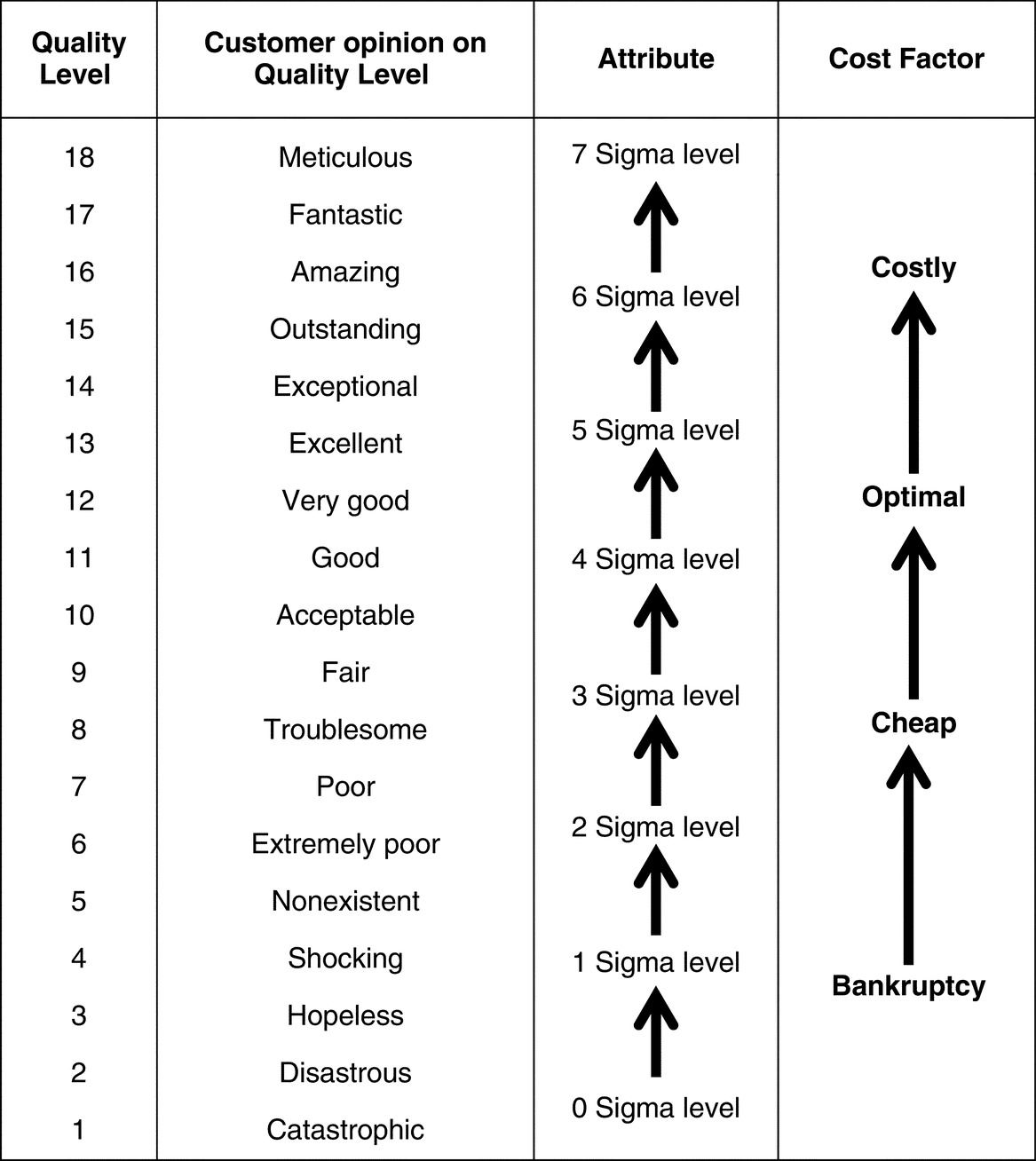

Few companies are able to spell out their quality levels to precise detail. The general terms of reference to the quality manager are to achieve the customer satisfaction economically, rather than costly over-perfection. Fig. 1.1 below illustrates the different scales of quality by attributes.

1.5 The Paradigm of TQM

In their definition of TQM, the International Organization for Standardization (ISO) has specified the three paradigms of TQM to be composed of:

Quality: With its usual definitions and all its complexities

Management: The system of managing with steps like Plan, Organize, Control, Lead, Staff, provisioning, etc.

We can elaborate ISO’s above definition indicating that the following are involved in TQM:

Total

● Production

● Marketing

● Purchase

● Maintenance

● Quality Control

● HR

● Chairman and Managing Director

● General Manager

● Supervisor

● Operator

● Corporate office

● Shareholders

● Suppliers

Quality

2. Customer driven

3. Functional requirement of the product

4. Product specifications

5. Process parameters

Management

1. Effective direction, monitoring, and control

2. Continuous improvement

3. Effective utilization of resourses

4. Executive commitment

5. Well-planned and effective decision-making

6. Employee empowerment

The TQM Company must think Quality, act Quality, and speak Quality to achieve Quality.

1.6 How can Effective TQM Change the Situation?

TQM means organized change management effort.

| From | To |

| Result-oriented | Process-oriented |

| Personalized | Process led |

| Product-oriented | Customer-centered |

| Owner-driven | Value-driven |

| Internally-focused | Stakeholder-focused |

| Making money | Reputation |

| Sustaining imitation/importation | Innovation/improvement |

| Tactic-oriented | Strategy-oriented |

| Expansion | Creation |

| Seniority-oriented | Competency-oriented |

| Motivation through fear and loyalty | Motivation through shared vision |

| “It’s their problem” attitude | Accountability to all problems |

| “We always did it this way” | “Let us improve to suit the customer” |

| Decisions-based on assumptions and subjective judgment | Decision-based on data and facts |

| All begin and end with management | All begin and end with the customer |

| Routine management | Breakthrough management |

| Crisis management and recovery | Doing it right the first time |

1.7 Quality of Design Versus Quality of Conformance

There are two major aspects of quality: Quality of design and quality of conformance. Quality of design as defined by the Business Dictionary, is “the level of effectiveness of the design process in determining a product’s operational requirements and their incorporation into design requirements.” This involves the variations of a product or service in grades or levels of quality, and includes the types of materials used in construction, tolerance in manufacturing, reliability, etc. Quality of conformance is also defined by the Business Dictionary as “the level of the effectiveness of the design and production functions in conforming to the product manufacturing requirements and process specifications while meeting process control limits, product tolerances and production targets.”

Quality of conformance signifies how well the product conforms to the specifications and tolerances required by the design and is influenced by the choices of manufacturing processes, training and supervision of the workforce, the type of quality-assurance system used, as well as the motivation of the workforce to achieve quality.

1.8 Changing Criteria of Quality

Changing Criteria of Quality

| Criterion | Concept on the Past | Today’s Concept |

| Definition of quality | Product quality | Customer requirement |

| Quality focus | Focus on product and services | Focus on all business tasks |

| Quality responsibility | With inspection/quality control department | With all employees |

| Organization | Quality is a function | Quality is a strategy |

| Result, or how you achieve the result? | Result is important | Process is important |

| Measurement | Quality is measured by product attributes | Quality is measured by the cost of quality |

| Quality champions | Quality champions were quality employers | Quality champions are top management teams |

| Human involvement | System is the main focus | Both systems and the human component are the main focus |

| Concept | Quality is considered a tool | Quality is process philosophy |

1.9 The Five Approaches to Quality

Harvard professor David Garvin, in his book, Managing Quality, summarized five principal approaches to define quality.

● Those who hold the transcendental view would say “I can’t define it, but I know it when I see it.”

● Advertisers are fond of promoting products in these terms.

● “Where shopping is a pleasure” (supermarket). “We love to fly and it shows” (airline). Television and print media are awash with such indefinable claims and therein lies the problem.

● Quality is difficult to define or to operationalize. It thus becomes elusive when using the approach as the basis for competitive advantage. Moreover, the functions of design, production, and service may find it difficult to use the definition as a basis for quality management.

2. Product-based

● Quality is viewed as a quantifiable or measurable characteristic or attribute. For example, durability or reliability can be measured and the engineer can design to that benchmark.

● Quality is determined objectively.

● Although this approach has many benefits, it has limitations as well. Where quality is based on individual taste or preference, the benchmark for measurement may be misleading.

3. User-based

● It is based on idea that quality is an individual matter and products that best satisfy their preferences are those with the highest quality. This is a rational approach, but leads to two problems.

● Consumer preference varies widely and it is difficult to aggregate these preferences into products with wide appeal. This leads to the choice between a niche strategy and a market aggregation approach, which tries to identify those product attributes that meet the needs of the largest number of consumers.

● Another problem concerns the answer to the question “Are quality and customer satisfaction the same?” The answer is probably not. One may admit that a Lincoln Continental has many quality attributes, but satisfaction may be better achieved with a Ford Escort.

4. Manufacturing-based

● Manufacturing-based definitions are concerned primarily with engineering and manufacturing practices and use the universal definition of “conformance to requirements.” Requirements or specifications are established by design and any deviation implies a reduction in quality. The concept applies to services as well as products. Excellence in quality is not necessarily in the eye of the beholder, but rather in the standards set by the organization.

● This approach has a serious weakness. The consumers’ perception of quality is equated with conformance and hence, is internally focused.

5. Value-based

● It is defined in term of costs and prices, as well as number of other attributes. Thus, the consumers’ purchase decision is based on quality at an acceptable price. This approach is reflected in the popular Consumer Reports magazine, which ranks products and services based on two criteria: quality and value.

● The highest quality is not usually the best value. That designation is assigned to the “best-buy” product or service.

1.10 PDCA Cycle

PDCA (plan-do-check-act) is a four-step management method developed by Edwards Deming and is widely used in business for the control and continuous improvement of processes and products. It is also called the PDCA circle, PDCA cycle, or PDCA wheel. Having been developed and emphasized by Deming, it is also named the “Deming Wheel.” Deming, however, referred to it as Shewart cycle, as a nod to his teacher, Walter Shewart. Subsequently, Deming replaced the word “Check” with “Study.” This PDCA cycle has come to be known as Deming Cycle. However, in most books on quality including this one, PDCA cycle is shown in Fig. 1.2, and continued to be referred to as the Deming Cycle.

The four components of this cycle are:

1. Plan: This step involves identifying and analyzing the problem. The objectives and processes are first established, keeping in mind the output expectations and quality requirements.

2. Do: This step involves implementing the plan, and executing the process to make the product. All data is collected and charted to be useful in the next step.

3. Check: This step involves measuring how effective the test solution was, and analyzing whether it could be improved in any way. Study the data results collected in the above step and compare against the expected results. The root causes for these differences are analyzed to ascertain if it is possible to improve the process to get better results. In Chapter 22 on Kaizen, this step is explained more in detail.

4. Act: In this step, the improved solutions are implemented by modifying the process or taking corrective actions on significant differences between actual and planned results by analyzing the differences to determine their root causes. Determine where to apply changes that will include improvement of the process or product. When a pass through these four steps does not result in the need to improve, the scope to which PDCA is applied may be refined to plan and improve with more detail in the next iteration of the cycle, or attention needs to be focused in a different stage of the process. Some authors use the term “adjust” instead of “Act,” signifying improvement.

5. Diversify: Jablonski, in his five-phase guideline for implementing TQM, adds a fifth step—Diversification. In this stage, managers utilize their TQM experiences and successes to bring groups outside the organization (suppliers, distributors, and other companies that have impacted the business's overall health) into the quality process. Diversification activities include training, rewarding, supporting, and partnering with groups that are embraced by the organization's TQM initiatives.

1.11 When to Use the PDCA Cycle

The PDCA Cycle is an effective problem-solving tool. It can be applied:

● For repeated PDCA cycles when Kaizen, the Continuous Improvement tool can to be applied for new areas for improvement.

● For exploring a range of possible new solutions to problems, trying them out, and improving them in a controlled way before selecting one for full implementation.

● For planning data collection and analysis, so as to verify and prioritize problems or root causes.

● For avoiding the large scale waste of resources.

● Daily routine management—for the individual and/or the team.

● Other fields where PDCA can be used are:

○ Continuous development

○ Vendor development

○ Human resources development

○ New product development

○ Process trials

1.12 Variations of PDCA Terminology

1. OPDCA—Another version of this PDCA cycle is OPDCA. The added “O” stands for observation, or as some versions say, “Grasp the current condition.”

2. DMAIC—as explained further in Chapter 24.

3. The Baconian method—Francis Bacon of the 16th century, in which his ideas for a universal reform of knowledge into scientific methodology and the improvement of mankind’s state using the Scientific method are emphasized.

4. Empiricism—John Locke of the 17th century which states that knowledge comes primarily from sensory experience.

5. As explained in Chapter 22 on Kaizen, several industrial engineering methods use approaches similar to PDCA. Examples are, methods improvement studies, whose seven basic steps are SREDDIM, value engineering, CREW, etc.

6. Manufacturing system—The manufacturing system, as explained in Chapter 6, emphasizes all the aspects PDCA, in all stages of manufacturing, as illustrated by Fig. 6.7.

1.13 Deming’s Fourteen Points to Improve Quality

After returning to the United States from Japan, Deming propounded the Deming Philosophy, with 14 principles which signified Total Quality Control. They are:

1. Create consistency to purpose towards improvement of product and service.

2. Adopt a new philosophy.

3. Cease dependence on mass inspection to achieve quality.

4. End the practice of awarding business on the basis of price tag.

5. Improve constantly and forever the system of production and service.

6. Institute modern methods of training and education on the job, including management.

7. Institute leadership.

8. Drive out fear.

9. Break down barriers between departments.

10. Eliminate slogans, extortions, and targets for the work force asking for Zero Defect and new levels of productivity.

11. Eliminate work standards that prescribe numerical quotas for both the work force and managers. In their place, use useful aids and supported supervision.

12. Remove barriers that impede hourly paid workers and managers from enjoying pride of workmanship.

13. Institute a vigorous program of education and retraining.

14. Structure top management to empower them to achieve the above 13 points.

1.14 Deming System of Profound Knowledge

Deming professed a system of profound knowledge that encompasses four interrelated dimensions.

1. Appreciation of a system: Understanding the overall processes involving all stake holders such as suppliers, producers, and customers (or recipients) of goods and services. For example, optimization of one subsystem or a part of the system is easier to achieve than optimization of the whole system. The former may give an impression of improvement, but in reality, it builds barriers that obstruct overall progress.

2. Knowledge of statistical theories that not only indicate the process variations in quality, but also the range and causes of variation. Deming believed that managers who lacked this understanding of the variation generally get confused between the random and significant variations, and he estimated that almost 98% of the quality losses are due to this confusion. Deming also illustrated the two kinds of mistakes that are normally committed by the above category of managers.

2.1 Mistake No.1: To react to any fault, complaint, mistake, breakdown accident, shortage etc., as if they come from significant causes, when in fact they come from random or general causes. For example, an engineer may treat an occasional dimensional variation seriously and get the tool holder adjusted.

2.2 Mistake No.2: To attribute to random causes if actually they come from significant causes. For example, the variations due to a loosely clamped tool holder may sometimes get dismissed as random causes.

3. Theory of knowledge: The concepts explaining knowledge and the limits of what can be known should be fully appreciated. A manager shall not only have profound knowledge on things but also should appreciate the theory behind such knowledge concerned with the nature and scope of knowledge, its presuppositions. We must know precisely what particular procedure to use in order to measure or judge something, and we need an unambiguous decision rule to tell us how to interpret and act on the result.

4. Knowledge of psychology: Concepts of human nature to understand people and the interactions between the leaders and the employees. Deming emphasized that people can be motivated more intrinsically than extrinsically.

1.15 Juran Quality Trilogy

Joseph Juran put forth his concept of the cross functional management for the quality function more popularly known as Juran’s Quality Trilogy and is as follows (adapted from the website forumqulaitygurus.com):

1. Quality Planning: This is the activity of developing the products and processes required to meet the customers’ needs. It involves the following steps:

● Identify the customers, those that would be impacted by the quality goals.

● Determine the customers’ need.

● Develop product features with reference to the customers’ needs.

● Develop a process.

● Prove process capability.

2. Quality Control: This activity sets up the control parameters as detailed below:

● Choose units of measurements.

● Establish measurement.

● Establish controls and transfer the plans to the operating forces.

● Establish standards of performance.

● Measure actual performance.

● Interpret the difference.

● Take action on the difference.

3. Quality Improvement: This activity emphasizes the raising of the performance to unprecedented levels and consists of the following steps:

● Prove the need for improvement.

● Establish the infrastructure needed to achieve annual quality improvements, including the training.

● Identify specific projects for improvement.

● Organize to guide projects.

● Organize for diagnosis—for discovery of causes.

● Diagnose to find the cause.

● Provide remedies.

● Prove that the remedies are effective under operating conditions.

● Provide for control to hold gains.

1.16 Conclusion

While the concept and practice of TQM evolved in the manufacturing industry, there is a marked shift of its emphasis into service and other industry categories, too, including health and social services as evidenced by the NIQR Awards, given even to the Dabbawalas of Mumbai. The real challenge today is to ensure that managers do not lose sight of the basic principles detailed in this book on which quality management and performance excellence are based.