Repurposing of batteries from electric vehicles

V.V. Viswanathan; M.C. Kintner-Meyer Pacific Northwest National Laboratory, Richland, WA, USA

Abstract

This chapter discusses the reuse of electric vehicle (EV) batteries at the end of their useful life in vehicles. EV batteries typically have 80% of their energy and power capacity at the end of vehicle life. Multiple grid applications are expected to come online in the next two decades. This would require development of storage technologies for each application, leading to delays in deployment of these technologies for the various applications. This chapter provides insight on the advantages of using the used EV batteries for a myriad of grid applications, thus providing an alternative while storage technologies tailored to each application are developed.

15.1 Introduction

Energy storage for stationary use is gaining traction both at the grid scale and at the distribution level. As renewable energy penetration increases, energy storage is needed to compensate for the volatility of renewables over various time scales. Other applications for energy storage include peak shaving, time-shifting, load leveling, VAR control, frequency regulation, spinning reserves, and other ancillary applications (Rastler, 2010). This requires energy storage that is tailored for various energy-to-power (E/P) ratios. Even though the need for energy storage for stationary applications is obvious, the regulations that determine the economic value of adding storage are at various stages of development. This has created a reluctance on the part of energy storage manufacturers to develop a suite of storage systems that can address the myriad applications associated with stationary applications. This creates a marketplace for the second use in stationary applications of electric vehicle (EV) batteries after their useful life in the vehicle.

Climate change is associated with greenhouse gases such as carbon dioxide and methane. Internal combustion engines operate at low efficiency and thus contribute significantly to climate change. Hybrid electric vehicles (HEVs) have gained in popularity because of their ability to provide acceleration and absorb braking power, thus allowing the engine to operate at its maximum efficiency, enabling fuel consumption as low as 0.02 gallons per mile. Plug-in hybrid electric vehicles (PHEVs) typically have a 1 h range and are charged by plugging them into a charging station. In a PHEV, the internal combustion engine operates at its high efficiency point and also provides additional range when the battery is fully discharged. EVs operate fully on battery power, with high associated capital costs. The high cost could be a barrier to market penetration of battery-powered vehicles. A business model that enables the second use of these batteries was developed (Narula et al., 2011).

During the PHEV Market Introduction Study Workshop held in December 2008 (Cleary et al., 2010), 75 policies were identified that would facilitate PHEV market penetration. The same study found that the following policies offered the greatest opportunity for increased PHEV penetration:

![]() Feedback program,

Feedback program,

![]() Annual operating cost allowance,

Annual operating cost allowance,

![]() Extension of existing plug-in vehicle tax credit,

Extension of existing plug-in vehicle tax credit,

![]() Federally backed battery warranty,

Federally backed battery warranty,

![]() Charging infrastructure financial incentives,

Charging infrastructure financial incentives,

![]() Government fuel efficiency regulations,

Government fuel efficiency regulations,

![]() Subsidies to lower initial vehicle price,

Subsidies to lower initial vehicle price,

![]() Federal gasoline tax increase.

Federal gasoline tax increase.

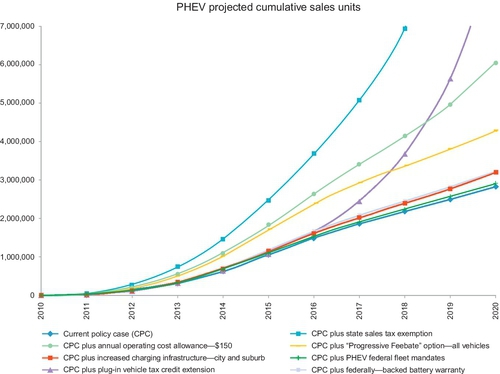

Figure 15.1 shows the results of the study in terms of projected PHEV sales for various incentive scenarios, as published in 2010 (Cleary et al., 2010). The first three incentives listed had the greatest impact on the market penetration of PHEVs. Some of the projections may be too optimistic, inasmuch as supply constraints were not considered, and the model behind some of the projections has been significantly updated (Lin, 2014).

EV batteries typically have 80% of their initial energy capacity at the end of life in the vehicle. According to a letter sent by Carla Bailo, senior vice president of research and development, Nissan Americas, to Nissan Leaf owners, “Nissan has projected that LEAF batteries will generally have 80% of their capacity under normal use after 5 years, and 70% after 10 years.”1 Assuming projected sales for EV batteries follow that of PHEV sales with the right incentives, millions of these batteries will come off the vehicles a few years from now. This, coupled with the anticipated need for storage to handle multiple grid applications, is expected to provide a good opportunity for used EV batteries.

This chapter is arranged as follows:

![]() Section 15.2 describes the problem that is being addressed by the second use of transportation batteries:

Section 15.2 describes the problem that is being addressed by the second use of transportation batteries:

– Immediate need for storage needed to support grid applications;

– Address yet-to-be-determined duty cycles for storage;

– High storage costs because of material constraints; second use fills the gap.

![]() Section 15.3 describes why second use of transportation batteries is beneficial to deployment of EVs and to the grid:

Section 15.3 describes why second use of transportation batteries is beneficial to deployment of EVs and to the grid:

– Well-defined drive cycle for transportation facilitate battery development;

– The wide range of E/P ratios for vehicle batteries suited for multiple grid applications;

– Second use of these batteries can determine feasibility in grid applications;

– Improved leasing terms due to residual value of storage at the end of useful life in vehicle.

![]() Section 15.4 lists the ongoing activity in this area:

Section 15.4 lists the ongoing activity in this area:

– GM Volt;

– Mitsubishi Leaf;

– BMW;

– Oak Ridge National Laboratory;

– Pacific Northwest National Laboratory;

– Berkeley Transportation Sustainability Research Center;

– National Renewable Energy Laboratory.

![]() Section 15.5 lists performance requirements for various duty cycles:

Section 15.5 lists performance requirements for various duty cycles:

– Energy Storage Standards activity;

– Frequency regulation duty cycles;

– Other duty cycles: peak Shaving, microgrid.

![]() Section 15.6 addresses reliability and warranty-related issues and mitigation approaches:

Section 15.6 addresses reliability and warranty-related issues and mitigation approaches:

– Design limitations and disadvantages of battery repurposing;

– Mitigation of aging-related issues;

– Barriers and proposed solutions;

– Safety-related issues being addressed by U.S. DOE-OE sponsored standards activity;

– Warranty issues related to battery management system (BMS) need to be worked out;

– Controls architecture for grid-related applications.

![]() Section 15.7. Trends:

Section 15.7. Trends:

– Increased photovoltaic (PV) penetration in Ontario, Hawaii, New York, and Long Island requires more storage;

– Alaska has high electricity costs. There is a need for storage for time-shifting;

– Batteries’ costs expected to decrease due to scale advantages. On the other hand, high demand could put pressure on material cost. Second-use batteries could control costs;

– Second use delays recycling and extracts value. Having identical batteries may allow use of standardized controls and facilitate plug and play;

– Standardization of batteries for EVs;

– Tesla opening up patents, leading to less barrier to entry. If there is too much supply and low material costs, the used batteries may have to be recycled.

![]() Section 15.8 provides sources for additional information.

Section 15.8 provides sources for additional information.

15.2 Problem being addressed

Deployment of battery energy storage systems in the transportation sector is ahead of the curve compared to the stationary space. Batteries, along with BMSs, have been deployed for HEVs, PHEVs, and EVs. HEVs were deployed in 1997 (Jong et al., 2009), whereas PHEVs and EVs have been deployed since 2010 (Cleary et al., 2010). Some of the batteries are approaching end of life within the vehicles and are ready to be taken off for recycling and disposal. Performance within a vehicle is nonnegotiable in terms of miles traveled per charge, resulting in the batteries retaining a significant portion of their life. For stationary applications, the remaining energy and power of the battery can still be used by grouping together a few of these batteries. This enables getting the most out of them, while ensuring that performance is not compromised in either the automotive or stationary applications.

In 2012, the global market for electric vehicles was 1.55 million vehicles, of which 94% were HEVs, with the PHEV and EV market shares 3.6% and 2.3%, respectively (Schreffler, 2013; Trigg and Telleen, 2013). These percentages were calculated from 2012 global sales figures for PHEVs and battery electric vehicles (BEVs), whereas global sales’ figures for HEVs were assumed to be the same as the number of Japanese HEVs sold. Analysts anticipate that in the future, most of the batteries used will be Li-ion based.

US cumulative EV sales have doubled to 270,000 in 1 year since October 2013 (EDTA, 2014), and yearly sales have increased 5.5 times to 95,100 vehicles in the 2011–2013 time frame (Shahan, 2014). The HEV has slowed from 350,530 vehicles in the first 8 months of 2013 to 327,418 vehicles over the same period in 2014. Nevertheless, that represents a lot of batteries that eventually may be available for the second use.

Transportation batteries typically have varying depth of discharge (DOD) depending on the application. HEV batteries operate in the ± 10% state of charge (SOC) range around the 50% SOC state, whereas PHEV batteries and EV batteries operate between 15% and 85% SOC. The criterion for HEV replacement typically is when the ability to provide power is compromised, whereas PHEV and EV batteries are replaced when the ability to provide the required power or energy is compromised.

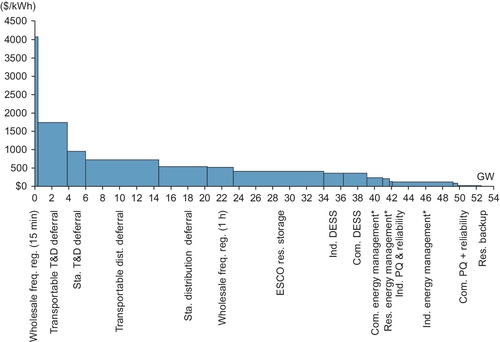

One roadblock to EV deployment is the high cost of battery systems, which is around $1000/kWh. Sandia National Laboratories (Eyer and Corey, 2010) and Electric Power Research Institute (EPRI) (Rastler, 2010) published a list of applications for stationary energy storage, which contained many commonalities. In a nutshell, the applications could be categorized as power or energy intensive. As shown in Figure 15.2, the price point at which storage is cost-effective for various applications is shown. Independent study by Pacific Northwest National Laboratory (PNNL) confirmed that storage is not cost-effective for energy-intensive applications, while in certain markets, storage is competitive for frequency regulation/balancing. At the same time, the various use cases for stationary energy storage are still under development (Viswanathan et al., 2012, 2014a,b; EPRI, 2014). Because getting a consensus on grid-related applications is expected to take some time, the batteries coming off the EVs at the end of life are expected to fill in nicely for the various grid applications.

At the recent Energy Storage North America meeting, several speakers (Baerman et al., 2014; Butler et al., 2014; Peterman et al., 2014; Rive and Detwiler, 2014) indicated the need for storage for firm and smooth PV systems that are distributed energy resources. In Hawaii, for example, the electricity cost is $0.40/kWh (Rive and Detwiler, 2014); hence, there is a tremendous push for PV. Per one of the conference speakers, energy storage at present is where PV was 10 years ago, whereas PV is where wind was 10 years ago (Rive and Detwiler, 2014). PV system costs have been coming down rapidly, from $5000/kW in 1998 to 1200/kW in 2011 (Feldman et al., 2012). Storage costs are expected to show a similar trend. Wind costs in the United States have dropped from $2000/kW to $1200/kW in the 1995–2005 time frame, followed by a slight increase in cost (Lantz et al., 2012). In the next 10 years, PV costs are expected either to stabilize or increase slightly due to demand, while over next 20 years, Energy Storage Systems (ESS) costs are expected to reach a minimum, followed by a demand-related increase. There is a window of 10 years within which the second-use batteries can be deployed to mitigate costs, followed by a prolonged period where battery costs are expected to increase due to higher demand, thus ensuring a market for the second-use EV batteries.

15.3 Advantages of battery repurposing

Grid-connected energy storage has a diverse set of applications, with a myriad of duty cycles. The benefits of various applications have yet to be fully determined, because regulatory policies are in a state of flux when it comes to assigning revenue streams to energy storage. This puts the energy storage developers in a bind, as there are no clear-cut directions for designing and sizing storage. On the other hand, the transportation sector has a much simpler and well-defined duty cycle, thus facilitating battery design and development. As these batteries near the end of their life, it makes sense to derate their available power and energy and use them for other applications.

Transportation batteries typically have E/P ratio of 0.5–3, where P is rated continuous power. Based on the battery design, peak power, defined as power for anywhere from 3 to 10 s, can range from 2 to 10 times rated power. In other words, sufficient versatility is built into these batteries to be seamlessly deployed into the stationary space once their life is completed in the vehicle. Although the regulatory issues, use cases, and other issues are being addressed by the relevant parties, it would be useful to use the steady stream of batteries coming off-line from vehicles to initially test the various duty cycles for stationary applications. This would further spur development of energy storage designed for stationary use, leveraging upon the experience gained from the used transportation batteries. On a cradle-to-grave basis, the reuse of the batteries allows prolonged use of the batteries, thus reducing the carbon footprint.

The global HEV market increased to 1.7 million vehicles in 2013 (Jong et al., 2009) from ~ 35,000 in 2001, for a compound annual growth rate (CAGR) of 38%. The CAGR for the 2009–2013 time frame is 7%, thus showing a clear slowdown. The PHEV-projected values correspond to 350,000 vehicles sold in the United States in 2020 (Jong et al., 2009) and 3 million sold worldwide (Navigant Research, 2013).

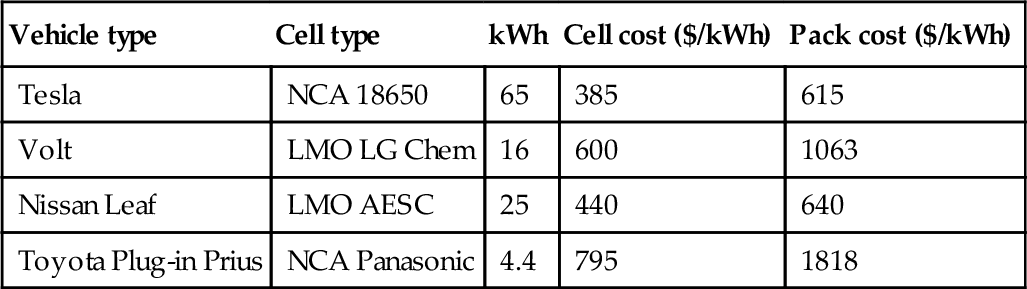

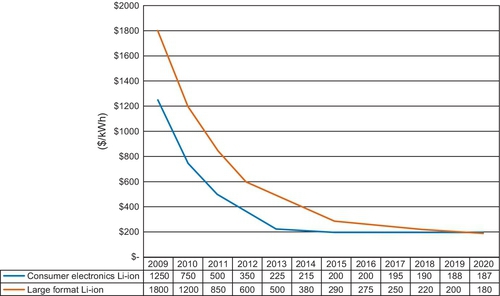

As previously discussed, the pathway to energy independence and mitigation of climate change involves electrification of the transportation sector. Although buses were the initial choice for electrification, electricity-powered automobiles are gaining ground. According to a Navigant Research study, the battery market for electric vehicles is expected to increase to $43 billion by 2022 from $2 billion in 2012 (Jaffe, 2014). Consumer battery costs have decreased to $250/kWh in 2013 from $1200/kWh in 2008, mainly due to improved manufacturing techniques. The lower costs have yet to be transferred to the larger EV market, mainly due to issues with respect to battery management, specifically thermal management. Figure 15.3 shows the projected drop in Li-ion cell costs for large format batteries, with comparison provided for consumer cells, whereas Table 15.1 shows the cell and battery cost in $/kWh for the Tesla, Volt, Nissan Leaf, and Toyota plug-in batteries. Although it is conceivable that prices could follow the drop experienced in the consumer space, some factors could keep costs high. The increased demand for raw materials could be the main factor: lithium deposits worldwide are limited in quantity. Currently, raw material for lithium batteries comes from lithium carbonate, which is plentiful. However, as the demand for lithium increases, the material will have to be obtained by mining, and mining costs are two to three times that of lithium carbonate retrieval. Therefore, the cost of Li-ion battery systems could remain high as demand increases. This allows used EV batteries to provide grid-related services while more cost-effective alternative technologies are developed. As long as the electric battery can be used beyond its useful life in the vehicle, the residual value of the EV is increased, thus improving leasing terms for the first-time buyer, facilitating EV deployment (Garthwaite, 2012).

15.4 Ongoing activities

Once the batteries reach their end of life in vehicles, they would still have about 80% of their initial energy capacity left. Hence, deployment of these batteries in stationary storage is a way of gaining the maximum use out of these batteries. Some of the activities in this area are described.

15.4.1 Oak Ridge National Laboratory

Oak Ridge National Laboratory (ORNL), Sentech, PNNL, and others conducted a study to look at the effects of incentives, regulations, and policies on the feasibility of the second use of EV batteries for stationary applications (Cleary et al., 2010). The ORNL study estimated the battery costs in 2020, along with the estimated availability of used batteries from HEVs, PHEVs, and EVs. Area regulation, transmission and distribution (T&D) upgrade deferral, and power quality were considered to be the most financially rewarding revenue streams for these used batteries. A financial analysis was done by taking into account the cost to refurbish the battery, transport it to the second-use venue, and operation and maintenance costs.

It was determined that energy-intensive applications such as arbitrage and capacity were not economically viable as stand-alone applications unless peak-to-valley price range was high and avoided T&D deferred costs were also high. The analysis was also done for a mix of applications after ensuring the duty cycles were not at odds with each other. For commercial customers, demand charges could be avoided by peak shaving, whereas residential customers could avoid time-of-use tariffs. Indirectly, benefits also accrue in terms of T&D deferral. A detailed analysis of refurbishment costs was carried out.

15.4.2 Pacific Northwest National Laboratory

Viswanathan and Kintner-Meyer performed an optimization study for the use of PHEV batteries for regulation services (up and down), which were assumed to be the highest value grid ancillary service (Viswanathan and Kintner-Meyer, 2011). A simplified model to estimate the battery state of health (SOH) was developed. For a battery life of 18 years, various combinations of battery use time in the vehicle were assumed. Assuming electricity consumption of 200 Wh/mile and an annual distance of 12,000 miles with 300 vehicle operating days, the optimization also varied the battery size to provide various depths of discharge. A total of up to three batteries was considered, and an optimum use profile was determined for various regulation rates in the $9–27/MW-h range. The depth of discharge in the vehicle was fixed by selecting the target SOH at the end of the first use. For the second use, the remaining years determined the number of cycles needed, which set the DOD for regulation. From the DOD, the energy per half cycle, and hence the power was calculated. Table 15.2 provides the highlight of optimum battery use for various values of regulation service rate, with the batteries taken out of the vehicle at low (65%), medium (75%), and high (85%) SOH. The net revenue is simply the difference between the net present revenue and the cost of the battery. The cost also included electricity charges during vehicle operation and regulation service use. Clearly, for low regulation rate, the batteries need to be used to the fullest, whereas for high rates, depending on the end SOH, the first and the second batteries are taken out of the vehicle in the 3-5-year time frame.

Table 15.2

Battery use profile for maximum revenue values for various end SOH and regulation rates

| End SOH | Regulation services rate ($/MW-h) | |||||||

| 0 | 9.2 | 27.5 | 57 | |||||

| Y1/Y2/Y3 | Total revenue | Y1/Y2/Y3 | Total revenue | Y1/Y2/Y3 | Total revenue | Y1/Y2/Y3 | Total revenue | |

| Low | 15/0/0 | −$11,000 | 10/5/0 | −$9800 | 6/3/6 | −$460 | 6/3/6 | $18,619 |

| Medium | 9/6/0 | −$16,000 | 8/7/0 | −$11,700 | 4/4/7 | −$400 | 3/3/9 | $22,500 |

| High | 3/12/0 | −$20,300 | 3/6/6 | −$14,350 | 4/4/7 | −$600 | 8/1/6 | $34,300 |

The United States Advanced Battery Consortium cost target for Li-ion batteries in 2020 is $150/kWh, whereas the Boston Consulting Group estimates a cost of $440/kWh. It was thereby assumed that the used batteries will sell at 50% of these values, or in the range of $75–220/kWh. Even if the resale value of Li-ion batteries is not high, the utilities could come out ahead by having at their disposal very low-cost energy storage options. General Motors (GM) and ABB have tested five used battery packs from Chevy Volts with air cooling after demonstrating the viability in the laboratory (Garthwaite, 2012). Duke Energy plans to use this battery to smooth and firm wind, along with other value streams. An additional option that researchers are investigating is using these batteries as community energy storage that is charged off peak or at night when there is excess wind generation to provide peak shaving by making the energy available for EV charging without upgrades to T&D.

In a National Assessment study, it was found that arbitrage as a stand-alone application was not cost-effective for storage (Kintner-Meyer et al., 2013). This is in line with the ORNL study described earlier.

15.4.3 University of California at Berkeley Transportation Sustainability Research Center

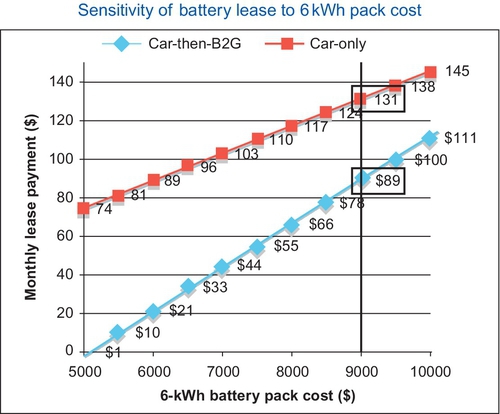

At the Second Life Workshop conducted on March 7, 2011, Haresh Kamath of EPRI gave a presentation on the potential for the second use of PHEV batteries (Kamath, 2011). Assuming a net worth for the battery and adding power conversion system (PCS) and balance of plant (BOP) costs, a scenario was possible wherein the cost of the used PHEV battery is higher than a new battery. The PCS and BOP costs were assigned the same for the used and new batteries. Even in this case, it makes sense to use these batteries because the end user simply procures the battery at a fraction of its residual value, thereby benefitting the utility customers. The key is that the net present value (NPV) of net revenues from various grid uses should be greater than the battery residual value at the end of its useful life in the PHEV. If it is not, the end user can simply sell the battery at its residual value. However, in our opinion, the residual value is simply tied to the revenue opportunities from grid services (or any other services) the battery can provide. The advantage of having a high residual value is that the monthly leasing costs are reduced as shown in Figure 15.4 (Williams, 2010). The residual value is a complex function of revenue opportunities and the anticipated new battery costs at the end of the useful life of the PHEV battery. In a recent communication, the author informed us that Figure 15.4 has been “superseded by subsequent work” (Williams, 2012; Williams and Lipman, 2011), which is expected to “show significant but more modest reductions in a different context.” In the subsequent work, the effect of various parameters such as unit power conditioning system cost, battery capital cost, power-to-energy ratio, balance of system cost, and amount of energy left at the end of useful life in the vehicle on battery lease payments was considered.

The University of California at Berkeley has a program at its TSRC to look at the viability of the second-use batteries for PHEVs (Lipman and Williams, 2011; Williams, 2010, 2011; Williams and Lipman, 2011). This is in collaboration with the National Renewable Energy Laboratory (NREL) on the NREL Secondary Use Project. The other project partners were the Center for Sustainable Energy (CSE) California, UC Davis, PIER, California Energy Commission, San Diego Gas & Electric, Sempra Energy, and AeroVironment.

Task 1 of this project was to identify the second-life applications. Task 2 was to acquire the following batteries from used PHEV battery packs:

![]() Lithium iron phosphate batteries from A123 Systems,

Lithium iron phosphate batteries from A123 Systems,

![]() Lithium manganese oxide batteries from EnerDel,

Lithium manganese oxide batteries from EnerDel,

![]() Lithium titanate batteries from Altairnano.

Lithium titanate batteries from Altairnano.

Task 3 was to identify the benefit opportunities after accounting for battery degradation and repurposing costs.

Table 15.3 shows the repurposing cost and additional costs for three different battery systems (Williams, 2011). Note that these numbers may have changed since this study. For example, the battery energy for each type has increased significantly.

Table 15.3

Repurposing and miscellaneous cost

| Component | Basis | PHV 6 kW/3 kWh ($/kWh) | Volt 16 kW/8 kWh ($/kWh) | Leaf 32 kW/16 kWh ($/kWh) |

| Battery (modules + BMS) | Repurposing cost | 744 | 1150 | 1780 |

| Power conditioning controls | $442/kW in 2002 with inflation adjustment | 3310 | 8830 | 17,300 |

| Accessories, facilities, shipping, catch-all | $117/kWh for load-leveling, arbitrage and transmission deferral facility at Chino | 442 | 1170 | 2290 |

| 10-Year O&M | NPV at $18/kW year for Chino facility | 828 | 2210 | 4330 |

| Installation, residential circuitry | EVSE-style installation costs | 800 | 200 | 4300 |

| Total cost | 6120 | 15,400 | 30,300 |

As seen from the repurposing and miscellaneous cost for the Leaf 32 kW/16 kWh battery cost, for an E/P ratio of 0.5, the cost is $2000/kWh or $1000/kW. The 10-year benefit for various grid applications is presented with permission (Williams, 2011, 2012; Williams and Lipman, 2011). Per this study, the results were not very sensitive to the state of health of the batteries at the end of their useful life in the vehicles.

Details of the battery repurposing were provided (Lipman and Williams, 2011). The capital equipment cost for testing 23 modules was estimated at $1.2 million. The various steps for repurposing were as follows:

![]() Collect used EV modules from dealerships and transport to refurbishing facility;

Collect used EV modules from dealerships and transport to refurbishing facility;

![]() Visual inspect modules for damage;

Visual inspect modules for damage;

![]() Determine manufacturer ratings and age from label or barcode;

Determine manufacturer ratings and age from label or barcode;

![]() Measure voltage and resistance to identify failed modules;

Measure voltage and resistance to identify failed modules;

![]() Load module onto test equipment;

Load module onto test equipment;

![]() Determine energy module capacity at C/3 rate at 100% DOD, four cycles;

Determine energy module capacity at C/3 rate at 100% DOD, four cycles;

![]() Determine power capacity at 50% SOC by discharging at two-thirds OCV for 30 s;

Determine power capacity at 50% SOC by discharging at two-thirds OCV for 30 s;

![]() Disconnect module from equipment;

Disconnect module from equipment;

![]() Sort modules by capacity, power, and age;

Sort modules by capacity, power, and age;

![]() Assemble into battery packs;

Assemble into battery packs;

![]() Ship to ESS assembler/integrator.

Ship to ESS assembler/integrator.

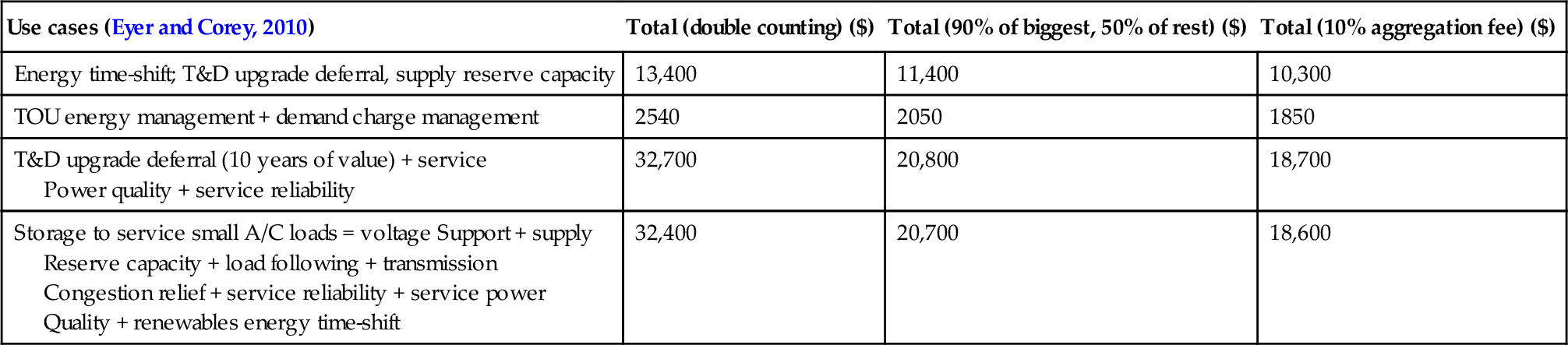

When the researchers used an appropriate mix of applications based on battery state of charge and benefits, they found several combinations of use cases whose benefits can potentially exceed the cost. It was proposed, for example, that it would take 44,000 Chevy Volt batteries to provide the regulation requirement of 732 MW/year (2006–2008 average CAISO (California Independent System Operator) up/down regulation requirement). There is sufficient regulation capacity to meet these requirements. Table 15.4 provides the potential for benefits combining various applications for a Volt battery (Williams and Lipman, 2011). Hence, for the Volt, the net benefit or residual value is $3200, which translates to a NPV at the time of purchase of $1510 using a 10% discount rate. This reduces the monthly lease payment by 20% from $122 to $95 per month. A similar reduction is obtained for the PHV and Leaf batteries.

Table 15.4

Potential revenue streams for multiple applications

| Use cases (Eyer and Corey, 2010) | Total (double counting) ($) | Total (90% of biggest, 50% of rest) ($) | Total (10% aggregation fee) ($) |

| Energy time-shift; T&D upgrade deferral, supply reserve capacity | 13,400 | 11,400 | 10,300 |

| TOU energy management + demand charge management | 2540 | 2050 | 1850 |

| T&D upgrade deferral (10 years of value) + service Power quality + service reliability | 32,700 | 20,800 | 18,700 |

| Storage to service small A/C loads = voltage Support + supply Reserve capacity + load following + transmission Congestion relief + service reliability + service power Quality + renewables energy time-shift | 32,400 | 20,700 | 18,600 |

Taking into account the battery capital cost and the benefits of using a combination of applications, it was estimated that the net benefit for the PHV, Volt, and Leaf batteries was $850, $3230, and $6450, respectively (Williams, 2012).

Note that PNNL recently completed a demonstration of a 120 kW, 500 kWh Li-ion battery storage system integrated with wind and solar PV and located at a substation to provide multiple services (Beaston et al., 2014). Automatic dispatch was done to maximize revenues from various use cases that included peak shaving, time-shifting, schedule management, avoiding wind curtailment, PV smoothing, and PV firming.

15.4.4 National Renewable Energy Laboratory

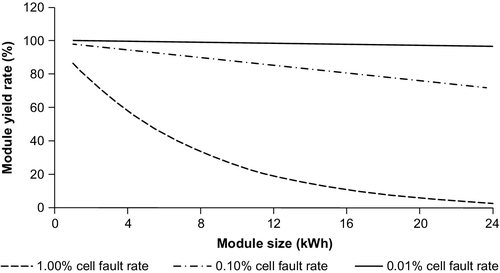

A techno-economic analysis was performed by the NREL team funded by the US Department of Energy’s (DOE’s) Vehicle Technologies Program (Neubauer et al., 2012). This work built on the detailed analysis done by the Sandia National Laboratory on the feasibility of using EV batteries in stationary applications (Cready et al., 2003). The resale price of the used battery was proportional to a “health factor,” the discount applied to reflect its usage, and the estimated cost of a new battery. The health factor was calculated by dividing the present value of the use battery’s energy throughput during its second life to that of a new battery for the same application. To estimate the repurposing cost, module yield was defined as cell fault rate raised to the number of cells in a module, with fault rates of 0.01%, 0.1%, and 1% assumed. The repurposing cost and purchase price were calculated assuming a selling price of $132/kWh for the various yields as shown in Figures 15.5 and 15.6 (Neubauer et al., 2012).

Clearly, the results are highly sensitive to the cell failure rate. At very low failure rate, there is no limit on module size, whereas at 1% failure rate, the module size is limited to 2 kWh to minimize repurchasing cost.

Because the resale price is proportional to the new battery price, assuming a steep fall in battery prices, a resale price of $38/kWh requires the used battery owner to pay the buyer $10–$40/kWh for it to be repurposed, for cell fault rate of 1%. Clearly, having a good SOH monitor during EV operation would help to identify modules with healthy cells. Taken to the next level, if entire battery packs are healthy, this would drop repurpose costs further. Based on this analysis, Table 15.5 shows the cost basis for the end user (Neubauer et al., 2012).

Table 15.5

Cost basis for the end user

| Item | Low | Estimate | High |

| Repurposed battery selling price ($/kWh) | 38 | 132 | 147 |

| Power conditioning, controls, interfaces ($/kW) | 100 | 319 | 319 |

| Accessories, facilities, shipping ($/kWh) | 117 | 117 | 482 |

| Installation and start-up ($/kWh) | 52 | 52 | 90 |

| Annual insurance, property tax (% of capital costs) | 1.0 | 1.5 | 2.0 |

| Installation for replacement batteries every 5 years ($/kWh) | 4 | 10 | 17 |

Assuming a 15-year second-use project lifetime, and purchase of second-use batteries during this period as needed, the payback period increased from 7 years to more than 15 years as the E/P ratio of the battery increased from 0.5 to 4.5. The services offered include power quality and reliability, and demand charges and time of use for the Southern California Edison rate structure.

15.4.5 Automobile manufacturers and collaborators

GM and ABB have tested five used battery packs from Chevy Volts with air cooling for community energy storage after demonstrating viability in the laboratory (Garthwaite, 2012; Hampton, 2013). The batteries were artificially degraded to 85–90% of their original energy capacity for this demonstration.

Based on the test results, GM signed a memorandum of understanding with ABB to scale up to power 50 homes, using the five-battery module as a repeating unit. Duke Energy plans to use this battery to smooth and firm wind, along with other value streams. An additional option being investigated is using these batteries for community energy storage. These second-use batteries can be charged at low peak times and then be used to charge electric vehicles, thereby reducing the need for expensive T&D equipment upgrade. GM is also considering using these batteries as a fast charging source in urban areas.

In January 2012, Nissan North America, ABB, 4R Energy, and Sumitomo Corporation announced their plans to build a grid-scale storage system prototype using Nissan Leaf batteries. Plans are to build a 50-kWh prototype to power 15 homes. Indy Power Systems used various lead–acid battery types to build a 50 kW, 15 kWh storage system for peak shaving for Melink Corporation, a HVAC equipment vendor (Hampton, 2013).

A collaboration, led by Electricore, with San Diego Gas & Electric (SDG&E), CSE, BMW, and Ricardo, is underway to standardize EV battery packs, which will greatly simplify their redeployment for stationary storage at the end of EV life (CSE, 2014).

Hart et al. (2014) modeled the use of the second-life batteries in a conventional and hybrid CERTS microgrid. It was found that the increase in impedance due to aging did not impact the performance of parallel connected batteries both in islanded and gird-connected mode.

Heymans et al. (2014) identified a significant opportunity for smaller storage systems for residential use for peak shaving. Decentralization using storage also serves to increase grid flexibility. It was determined that government incentives are needed for residential customers to take on installation and procurement costs.

Lih et al. (2012) used a simple approach to estimate the residual value at the end of the first-use life in the vehicle. The product of residual capacity and calendar life fractions was multiplied with a parameter that was set to 0.9 in the study. The cost to upgrade the battery was described by another equation, which includes an assumed improvement in performance for the upgraded battery and an upgrading cost, which was set at 20% of the residual value. It was not clear how the performance of the battery could be improved by upgrading, as the chemistry cannot be altered. To estimate the profit, the lease income in each stage was calculated. For the first stage, the difference between the new product price and the residual value was added to 15% of the residual value. For the second stage, the lease income was set to be the difference between the upgraded value and the scrap value. The total initial cost of the battery was subtracted from the total lease income to determine the profit over the life of the battery pack. For this case, the battery was in the vehicle for 3 years, followed by 12 years’ use in stationary application. A profit of 34% was obtained over the 15-year life of the battery. It is not clear why the cost for upgrading the battery pack was not considered in the total cost.

15.5 Performance requirements for various grid-storage applications

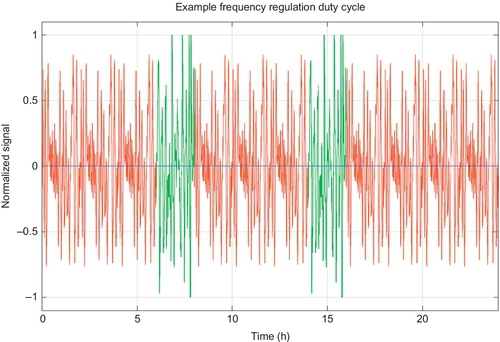

The various applications relevant to stationary energy storage are well summarized in several works. Each of these applications has its unique duty cycle to which the battery is subjected. PNNL, teaming with Sandia National Laboratory, is working on a DOE-OE funded project to develop prestandards for ESS for various bulk and distributed applications such as frequency regulation and peak shaving (Viswanathan et al., 2012, 2014a,b). Part of the scope was to develop representative duty cycles for various applications such as frequency regulation, peak shaving, regulation for renewables, and islanded microgrids. Figure 15.7 shows a representative duty cycle for frequency regulation based on the phase jitter modulation (PJM) signal sent every 4 s (Viswanathan et al., 2012, 2014a). As these duty cycles get developed for various applications, the matching of HEV, PHEV, EV batteries with various stationary storage use cases can be done. This work summarizes the opportunities for such repurposing of automotive batteries, along with the advantages and limitations.

In the short term, frequency regulation is one application that generates revenue. FERC order 755 was passed in October 2011 mandating pay-for-performance. Hence faster responding systems will be compensated more. Storage responds faster than traditional generators with less wear and tear. CAISO and PJM are the only two regional electricity markets in the United States to reward fast-responding systems for frequency regulation (Chu et al., 2012).

15.6 Issues and mitigation

Although the benefits of the second use are obvious, several hurdles need to be overcome before the business case for the second use of EV batteries is solidified.

15.6.1 Design limitations and disadvantages of battery repurposing

Battery systems do not fail at a linear rate from 100% to 0% state of health. When the batteries are taken off the vehicles, they have 80% of performance left in terms of power deliver and/or energy capacity. Typically, the energy capacity is around 80% of initial capacity at the rated continuous power when the batteries are considered to be at 0% SOH in terms of ability to perform in the vehicle. Because the battery management system recognizes this condition to be a fully discharged state, a separate BMS needs to be developed that resets the SOH appropriately. For example, the SOH for stationary can be defined so that when the battery reaches 60% of original energy capacity, its SOH is set to 0. Assuming a linear decline in SOH from 100% of initial energy capacity to 60% of energy capacity, the battery can be assumed to start at 50% SOH when it is taken off the vehicle. Life estimation is preferably done from calendar life and cycle life as a function of DOD. As an approximation, the SOH at the end of vehicle life can be reset to 100%, with the remaining energy capacity set as the initial capacity for stationary use. The number of cycles to end of life can be estimated by extrapolation of the cycle life curves obtained earlier. In parallel, vendors can determine cycle life to the end-of-life energy capacity for the second use. The remaining duration will be set as the calendar life for the second use. For situations when data are absent, an algorithm needs to be developed to estimate life remaining until the energy capacity drops to 60% of initial value. Identification of the onset of a steep fall in performance is needed to provide a headspace for the battery system to avoid unanticipated failure. A summary of this approach is described in the literature (Viswanathan and Kintner-Meyer, 2011).

It is also desired that when batteries are taken off the vehicle they are given a fresh BMS to estimate remaining life. In addition to SOC and SOH, safety issues related to aging need to be considered. Aged Li-ion batteries are prone to a greater rate of thermal runaway because of a variety of factors such as solid electrolyte interface layer breakdown, higher impedance, and delayed melting of separator relative to onset of exothermic reactions (Underwriters Laboratories). It is critical to understand the safety aspects of aged batteries to enable them to be used safely and effectively.

Deployment of used batteries becomes an issue when using them in applications that have a duty cycle significantly different from that of the vehicle. An example is an HEV battery used for time-shifting, or an EV battery used for frequency regulation. Although it is straightforward to avoid this situation for a single application, a combination of energy storage applications with multiple duty cycles can be more demanding in terms of battery system performance requirements. For example, if the storage is used to provide regulation, load following, and time-shifting, the superimposition of these duty cycles could result in a duty cycle that can be challenging for the used HEV and EV batteries. Use of PHEV batteries may provide the required balance needed for the multiple-use application. Depending on the application, an EV battery may be the preferred choice as it can provide the power of an HEV battery with about six times the energy.

15.6.2 Mitigation of issues related to aging

Several issues related to aging can adversely impact use of transportation batteries in the stationary energy storage space. Safety-related issues can be addressed by ensuring the battery is not abused significantly during operation. This could be achieved by having tight tolerance on operating temperature range, limiting the power in and out of the battery when battery impedance is high, and ensuring thermal runaway conditions are not approached. The latter can be ensured by characterizing batteries at various aged conditions. The characterization methods comprise accelerated rate calorimetry to determine onset of thermal runaway (Ottaway and Mores, 2001), determination of temperature increase at various multiples of rated power (Williford et al., 2009), and estimation of total heat generation from first principles (Viswanathan et al., 2010; Williford et al., 2009). Oversizing the storage system to provide a degree of flexibility would be another method to circumvent capacity loss related to aging. However, this is probably not a practical solution owing to higher capital costs. Another alternative is to have the storage output power decrease with aging during its second life, thus accounting for the decreasing performance with time. This scenario can be attractive when capital spending on T&D is spread out over a few years, thereby requiring less storage performance with each passing year.

The energy content for HEV batteries is ~ 2 kWh, PHEV batteries have ~ 8–16 kWh, and EV batteries have more than 16 kWh, with a pulse power requirement for all the batteries greater than 25 kW. The continuous rated power for PHEV and EV is about 15 kW for 1–3 h. Hence, it is possible to mix and match the various types of transportation batteries with the end application. For example, for a use case involving frequency regulation and time-shifting, it is conceivable that HEV batteries could be used for the former and PHEV/EV for the latter. The HEV batteries can also be used to supplement the power needs of an energy-intensive application such as time-shifting, by selectively providing/absorbing the additional power needed during conditions of excessive peak demand or supply.

Depending on the depth of discharge of these batteries, their cycle life would vary. For a 10- to 15-year life, the number of cycles needed is in the 3500–4500 range (Amjad et al., 2010). The cycle life depends on the depth of discharge for any chemistry. As shown in Figure 15.8, Li-ion batteries can undergo 4000 cycles at 50% DOD, whereas Ni–MH has a 70% DOD for the same number of cycles. This is simply an example, as cycle life at various DOD depends significantly on the specific Li-ion chemistry.

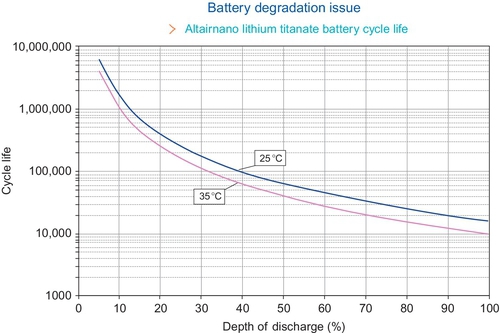

Li-ion batteries are expected to degrade when maintained at high SOC, high internal temperature, and when operated at a high depth of discharge. The following figure provides an example of effect of DOD and temperature on cycle life of an Altairnano battery (Lipman and Williams, 2011). Each Li-ion chemistry has its own cycle calendar life, energy, power, safety, and cost characteristics. There is no one size fits all. Hence, depending on the mix of applications being considered, different battery chemistries would be preferred candidates based on the desired property.

The BMS for the transportation batteries does Coulombic counting to estimate the SOC, with periodic checks on accuracy of these estimates. State of health determination is done by periodic capacity checks after a full charge, along with measurement of voltage efficiency at a fixed current charge/discharge at a fixed SOC (say 50%). An alternate means allow determination of internal resistance by measuring the voltage drop (or rise) at constant current discharge (or charge) for a few seconds. For HEV batteries, the voltage efficiency at 50% SOC and/or internal resistance at 50% SOC provides an indication of battery SOH. For PHEV and EV, along with this approach, the periodic capacity check provides an added criterion for battery SOH. As BMS systems get more sophisticated, the battery SOH can be more accurately estimated. This includes the effect of ambient temperature and calendar life on battery SOH, thereby taking into account the degradation of the battery during its life in the vehicle purely due to degradative effects of temperature and time.

The other issues are logistical in terms of how to track the various batteries seamlessly. According to Pablo Valenci of GM, the same system used to track and refurbish/resell auto parts such as water pumps and starters can be deployed for used batteries (Garthwaite, 2012).

15.6.3 Barriers and proposed solutions

Specifically, four barrier categories were identified, along with some proposed solutions during a one-day workshop at UCLA for the second use of EV batteries. Participants at the workshop included automakers, utilities, storage developers, business leaders, and public officials (Elkind et al., 2014).

Barrier Category 1: Economic uncertainty regarding residual value leading to lower purchase or lease costs:

![]() Uncertainty in the use cases for energy storage applications;

Uncertainty in the use cases for energy storage applications;

![]() Competition from cheap energy storage;

Competition from cheap energy storage;

![]() Expensive repurposing of battery pack;

Expensive repurposing of battery pack;

![]() All of the above pose risk to obtaining financing.

All of the above pose risk to obtaining financing.

The solutions proposed were as follows:

![]() Reduce uncertainty through demonstration projects;

Reduce uncertainty through demonstration projects;

![]() Improve the quality of such demonstration projects to achieve specific goals;

Improve the quality of such demonstration projects to achieve specific goals;

![]() Remove regulatory barriers to allow such pilot projects access to specific grid markets;

Remove regulatory barriers to allow such pilot projects access to specific grid markets;

![]() Offer federal and state tax rebates and financing for second-life demonstration projects;

Offer federal and state tax rebates and financing for second-life demonstration projects;

![]() Ease liability for faulty batteries.

Ease liability for faulty batteries.

Barrier Category 2: Difficult regulatory landscape

![]() Utility regulations very complex;

Utility regulations very complex;

![]() Transport of used batteries, classified as hazardous waste, have additional regulations;

Transport of used batteries, classified as hazardous waste, have additional regulations;

![]() Some incentives for storage make used assets ineligible;

Some incentives for storage make used assets ineligible;

![]() At the customer side, state and local permitting authorities may raise safety-related issues to prevent or slow down process.

At the customer side, state and local permitting authorities may raise safety-related issues to prevent or slow down process.

The solutions proposed were as follows:

![]() Develop “clear and consistent regulations” for the 2018–2028 time frame at the federal and state levels;

Develop “clear and consistent regulations” for the 2018–2028 time frame at the federal and state levels;

![]() State policy makers fund effort to identify critical regulatory needs that affect this use;

State policy makers fund effort to identify critical regulatory needs that affect this use;

![]() Federal and state programs should ensure used batteries are eligible for incentives;

Federal and state programs should ensure used batteries are eligible for incentives;

![]() Grid operators should modify rules to allow second-life battery participation.

Grid operators should modify rules to allow second-life battery participation.

Barrier Category 3: Uncertain liability picture for second-use batteries

![]() The automakers that own the battery may discourage its use in grid applications because of potential for damages from unknown duty cycles.

The automakers that own the battery may discourage its use in grid applications because of potential for damages from unknown duty cycles.

The solutions proposed were as follows:

![]() Liability shields that protect OEMs for reused, refurbished automotive parts such as engines and transmissions;

Liability shields that protect OEMs for reused, refurbished automotive parts such as engines and transmissions;

![]() Develop technical performance standards for second-life batteries. The model used by the PNNL/Sandia-led DOE-OE–sponsored performance protocol for energy storage systems can be followed here;

Develop technical performance standards for second-life batteries. The model used by the PNNL/Sandia-led DOE-OE–sponsored performance protocol for energy storage systems can be followed here;

![]() These standards can be used as a basis for liability protection;

These standards can be used as a basis for liability protection;

![]() Insurance companies can provide liability coverage for the second-life market.

Insurance companies can provide liability coverage for the second-life market.

Barrier Category 4: Difficulty in estimating battery life

![]() Lack of data on battery performance in the vehicle;

Lack of data on battery performance in the vehicle;

![]() Unknown duty cycles for second use.

Unknown duty cycles for second use.

The proposed solutions were as follows:

![]() Make the battery performance and SOH data in the vehicle available;

Make the battery performance and SOH data in the vehicle available;

![]() Make the data obtained by universities and national laboratories on the second-use application available

Make the data obtained by universities and national laboratories on the second-use application available

– Fund the collection and distribution of this data;

– Share utility infrastructure needs and database of energy data to allow creation of use cases for these batteries.

Nine barriers for widespread adoption of energy storage were identified by the California Public Utility Commission (Malashenko et al., 2012). Some were grid-related such as a well-defined interconnection procedure between the storage and the grid. Some related to the lack of operating experience and poor transparency of incentives for storage. Among the barriers identified, the ones that appear most critical are insufficient clarity of regulations, unclear use cases/applications duty cycle. To this we would add lack of a uniform standard to evaluate storage systems for grid applications. The potential to use storage for multiple applications creates additional complexity, as some of the applications may be at odds with the other in terms of compatibility. Energy storage procurement targets such as AB 2514 serve as a catalyst for higher storage demand.

15.6.4 Safety, warranty, and controls architecture

The US DOE Office of Electricity Delivery and Energy Reliability has created a Strategic Plan for Energy Storage Safety. As a part of this effort, PNNL has published two documents that provide an overview of issues affecting energy storage safety (Conover, 2014a) and an inventory of safety-related codes and standards related to energy storage systems (Conover, 2014b).

The SOH of the used battery determines to a large extent its residual value and ability to provide the required service during its second use. The uncertainty in terms of duty cycles for stationary applications is further expected to complicate the terms and conditions for warranties related to battery use and performance.

The controls’ architecture for an energy storage system is expected to be multilayered. A BMS resides on the DC side and an energy management system resides on the AC side, while a storage control system resides either on-site or in a remote location to interface with the grid. All of these control layers need to be compatible with each other, with a clear understanding of which layer has ultimate control and override capability.

15.7 Market forces and future trends

In 2012, the global market for EVs was 1.55 million vehicles, of which 94% were HEVs, with the PHEV and EV market shares 3.6% and 2.3%, respectively (Schreffler, 2013; Trigg and Telleen, 2013). These percentages were calculated from 2012 global sales’ figures for PHEVs and BEVs, whereas global sales’ figures for HEVs were assumed to be the same as the number of Japanese HEVs sold. It is anticipated that in the future, most of the batteries will be Li-ion based.

As discussed, the annual US EV sales, which include PHEVs and BEVs, were 95,000 in 2013 (Shahan, 2014). Assuming a 10% compounded annual growth, this translates to annual sales of 1.8 million electric vehicles by 2023. Assuming that HEV sales remain the same that is expected to add another 300,000 HEVs to the annual sales. With an expected life of 8 years in the vehicle, the number of batteries coming off-line is expected to grow at similar rates over the next 10 years. In a January 2010 report issued by ORNL, Sentech, PNNL/University of Michigan Transportation Research Institute, and the US DOE, it was projected that PHEV penetration by 2015 was expected to reach 1 million vehicles, with sales of 425,000 in 2015, corresponding to 2.5% of all new vehicle sales (Cleary et al., 2010).

There is the possibility of using these batteries in a demand response application, with the battery switching from charge to discharge during peak demand and from discharge to charge during peak supply. These batteries can also be used to provide regulation service, which again can have an impact on battery life. As regulatory and financial revenue streams are made clearer, more and more transportation batteries are expected to be used for such purposes, thus compromising their life in the vehicle. The flip side of this would be that these batteries would come off-line faster, while at the same time providing some valuable experience in terms of how these batteries actually perform under the various use cases.

It is expected that some of these batteries would be used in distributed configuration, with the entire battery being used as one system, with BMS in place. The remaining batteries will be placed in a central location, with their combined output used to stabilize the grid. The latter would be useful for bulk storage situations, where transmission congestion and regulation are addressed. This would necessitate the implementation of a central BMS that monitors each module that is part of the entire storage in the plant and directs power appropriately to each module.

The stationary energy storage space is still at its nascent stage, with the demand for the next 10 years significantly lagging the transportation sector. In the interim, with so much uncertainty over regulations that affect economic value for ESS, repurposing the transportation batteries for stationary storage is a viable option.

For vehicle batteries that are currently used to exchange power with the grid bidirectionally, the power electronics is already in place to charge and discharge the battery. In this instance, the entire battery with the PCS in place can be used in the stationary application. For cases where the battery does not power the grid, a separate inverter may be needed2 to send power to the grid.

HEV batteries can be used for power-intensive applications. In the case of distributed systems, the batteries from a vehicle can be used as is, with the BMS in place, and with the addition of an inverter if necessary. Or the battery can be used in conjunction with an off-the-shelf power conversion system for bidirectional power flow. PHEV batteries are appropriate for applications that require 30–60 min of charge or discharge, and applications for over an hour’s duration require an EV battery.

In addition to these applications, a mix of use cases is also possible. For example, the battery systems may be used for frequency regulation, renewables firming, and peak shaving, requiring durations in the seconds to hours range. For such applications, various configurations of batteries may be appropriate. For example, a parallel configuration of a PHEV or EV battery with an HEV battery could be used to sustain high power for short durations, with most of the energy supplied by the PHEV or EV battery. This could require sophisticated BMS to ensure the high energy does not charge the HEV battery if the SOC of the latter is above 50%. A simpler and probably more elegant solution is to use a battery with the energy required for the mix of applications, and bid into the power capacity market based on its ability to provide or accept power for the duration required. The power rating for time-shifting or arbitrage can be provided based on its ability to provide continuous power, while the rating for frequency regulation can be provided based on its ability to provide peak power for a few seconds. The specific power (kW/kg) or power density (kW/L) for high-energy batteries will be lower than for batteries designed for high-power applications. The energy-intensive batteries are expected to operate at a lower C rate, with peak power around 3–5C, where C is the energy content in kWh. However, due to their higher energy content, the absolute power is comparable to power batteries that provide peak power at ~ 15C rate. Considering peak power for regulation occurs very rarely, the high-energy battery can be gainfully used in a mix of applications ranging from energy to power.

15.8 Additional sources of information

The US DOE Vehicle Technology Office has some very interesting information on this topic, with several ongoing projects. The Society of Automotive Engineers publishes several articles related to EV batteries. The Journal of Power Sources, Energy & Environmental Science has several papers on batteries for transportation and stationary storage. In addition, the Energy Storage Associations in the United States, Germany, China, India, and Australia have extremely useful information on the grid-related applications for energy storage. The energy storage performance and safety-related standards effort led by PNNL-Sandia, EPRI, IEC, to name a few, are very important resources to consult for information on the metrics needed to assess storage technologies on an apples-to-apples basis.