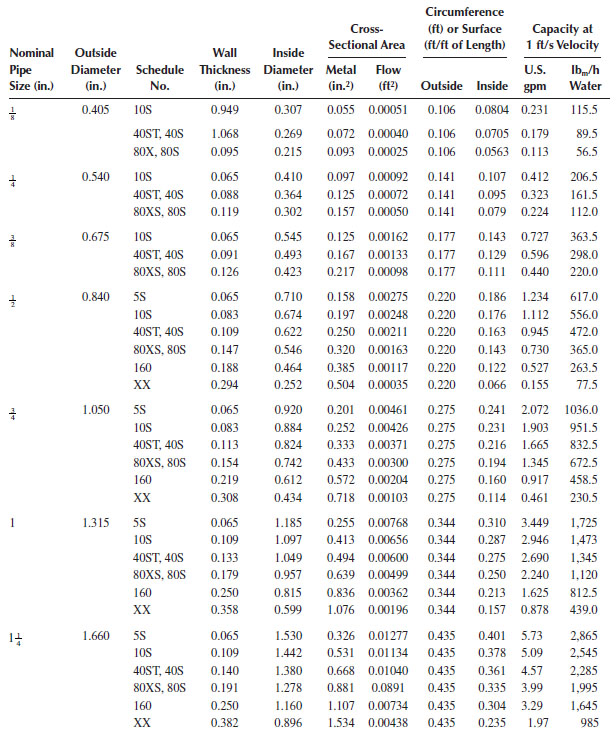

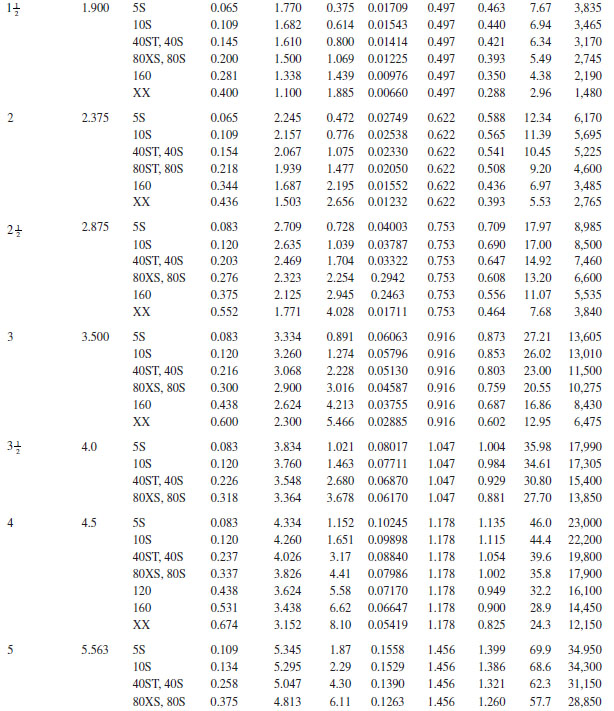

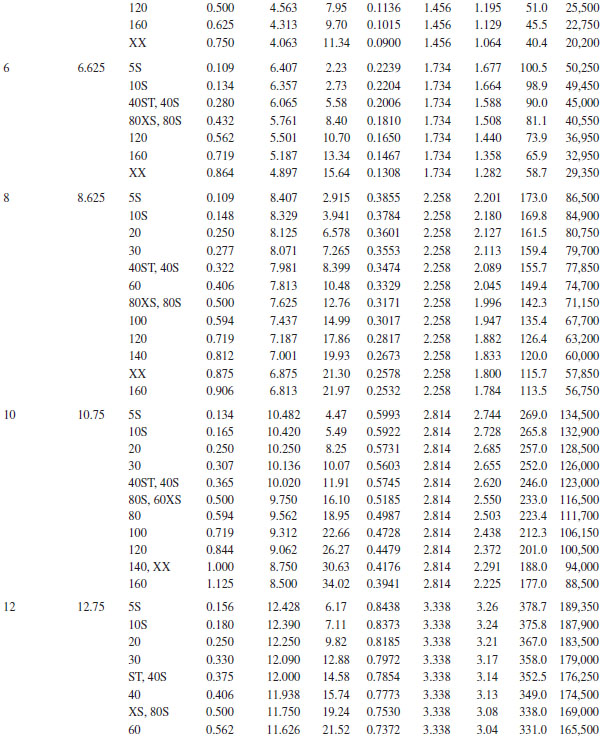

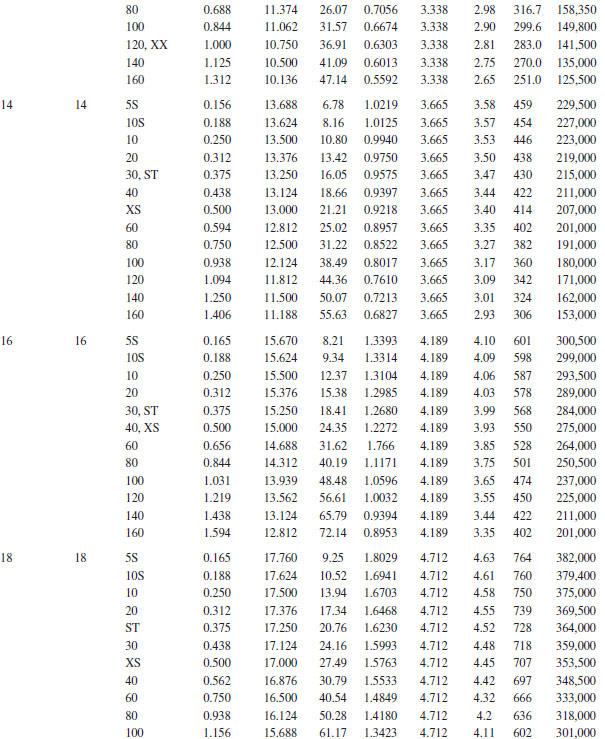

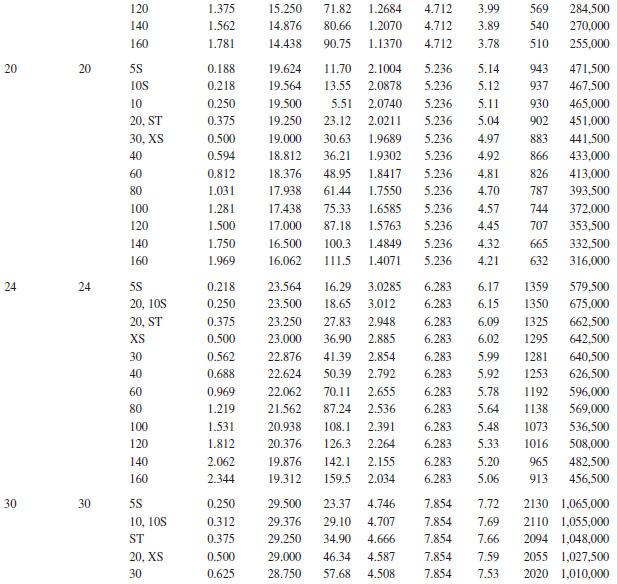

Appendix F: Standard Steel Pipe Dimensions and Capacities

Table F.1

Standard Steel Pipe Dimensions and Capacitiesa

a 5S, 10S, and 40S are extracted from stainless steel pipe, ANSI B36.19-1976, with permission from the publisher, the American Society of Mechanical Engineers, New York. ST, standard wall; XS, extra strong wall; XX, double extra strong wall. Schedules 10–160 are extracted from wrought-steel and wrought-iron pipe, ANSI B36.10-1975, with permission from the same publisher. Decimal thicknesses for respective pipe sizes represent their nominal or average wall dimensions. Mill tolerances as high as ±12.5% are permitted.

A plain-end pipe is produced by a square cut. The pipe is also shipped from the mills threaded, with a threaded coupling on one end, or with the ends beveled for welding or grooved or sized for patented couplings. Weights per foot for threaded and coupled pipe are slightly greater because of the weight of the coupling, but it is not available larger than 12 in. or lighter than Schedule 30 sizes 8 −12 in., or Schedule 40, 6 in. and smaller.

To convert inches to millimeters, multiply by 25.4; to convert square inches to square millimeters, multiply by 645; to convert feet to meters, multiply by 0.3048; to convert square feet to square meters, multiply by 0.0929; to convert pounds per foot to kilograms per meter, multiply by 1.49; to convert gallons to cubic meters, multiply by 3.7854 × 10−3; and to convert pounds to kilograms, multiply by 0.4536.