Chapter 15

Level Indication

The Need for Level Indication

As noted in earlier chapters, moving-magnet (MM) cartridges do not have a wide range of output levels—about 7 dB covers almost all on the market—and so in general no gain adjustment is required or provided. There is therefore no need for an indication that the gain is wrongly set. On the other hand, the moving-coil (MC) cartridges available have a range of output levels that extends over more than 30 dB, and so gain adjustment is very much needed if a phono amplifier is to be able to cope with all of them. This makes some form of level indicator which allows that gain to be correctly set very desirable, because the alternative is to take cartridge sensitivities and estimated recorded velocities and start calculating. This could get very tedious if you change cartridges often.

This chapter therefore examines the various options for level indication, from a single LED indicating a single level, through the Log-Law Level LED which gives much more information but still uses a single LED to a complete bargraph meter. It is some decades since flashing lights were automatically regarded as enhancing the musical experience, and so once the gain has been correctly set for a given cartridge, it is nice to be able to switch the metering off, for example by means of a small slide-switch on the rear panel.

The brightness of the display is also an issue. A bargraph that can be easily read in a sunlit room is going to be over-bright in semi-darkness. It is of course possible to have manual control of display brightness, but few people are going to want to turn it up and down on a daily basis. A practical solution, and one which makes a nice feature on high-end equipment, is to have automatic brightness control using a light sensor such as a phototransistor. A simple way to do this is given at the end of the chapter.

Signal-Present Indication

Some amplifiers are fitted with a “signal-present” indicator that illuminates to give reassurance that a channel is receiving a signal and doing something with it. The level at which it triggers must be well above the noise floor but also well below the peak indication or clipping levels. Signal-present indicators are usually provided for each channel and are commonly set up to illuminate when the channel output level exceeds a threshold something like 20 or 30 dB below the nominal signal level, though there is a wide variation in this.

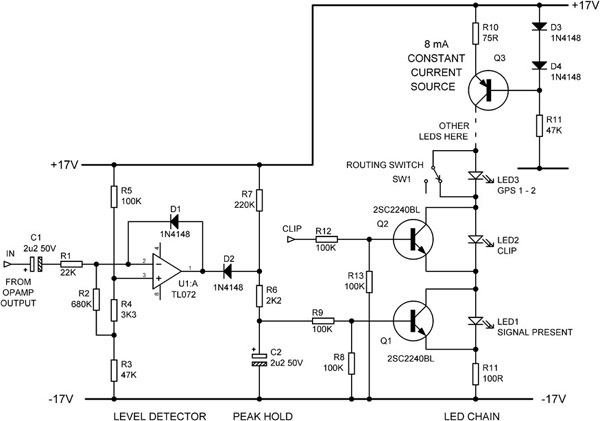

A simple signal-present detector is shown in Figure 15.1, based on an opamp rather than a comparator. The threshold is −32 dBu, which, combined with the −2 dBu nominal level which it was designed for, gives an indication at 30 dB below nominal. Since an opamp is used which is internally compensated for unity-gain stability, there is no need to add hysteresis to prevent oscillation when the signal lingers around the triggering point. U1 is configured as an inverting stage, with the inverting input biased slightly negative of the noninverting input by R4 in the bias chain R3, R4, R5. The opamp output is therefore high with no signal but is clamped by negative feedback through D1 to prevent excessive voltage excursions at the output, which might crosstalk into other circuitry; C2 is kept charged via R6 and R7, so Q1 is turned on and LED1 is off. When an input signal exceeds the threshold the opamp output goes low and C2 is rapidly discharged through R6 and D2. R6 limits the discharge current to a safe value; the overload protection of the opamp would probably do this by itself, but I have always been a bit of a belt-and-braces man in this sort of case. When C2 is discharged, Q1 turns off and LED1 illuminates as the 8 mA of LED chain current flows through it. When the input signal falls below the threshold, the opamp output goes high again, and C2 charges slowly through R7, giving a peak-hold action. This is a unipolar detector; only one polarity of signal activates it.

The LED chain current is provided by a wholly conventional constant-current source Q3, which allows any number of LEDs to be turned on and off without affecting the brightness of other LEDs. In this case the clip-detect LED is shown just above the signal-present LED; since it is only illuminated when the signal-present LED is already on, the drive requirements for Q2 are simple, and it can be driven from exactly the same sort of capacitor-hold circuitry. The other LEDs in the chain (here assumed to be routing switch indicators) simply “float” above the LEDs controlled by transistors. The LED chain is connected between the two supply rails, so there is no possibility of current being injected into the ground. This gives a span of 34 V, allowing a large number of LEDs to be driven economically from the same current. The exact number depends on their colour, which affects their voltage drop. It is of course necessary to allow enough voltage for the constant-current source to operate correctly, plus a suitable safety margin.

I have used this circuit many times, and it can be regarded as well-proven.

A vital design consideration for signal-present indicators is that since they are likely to be active most of the time, the operation of the circuitry must not introduce distortion into the signal being monitored; this could easily occur by electrostatic coupling or imperfect grounding if there is a comparator switching on and off at signal frequency. Avoid this.

Peak Indication

A peak indicator is driven by fast-attack, slow-decay circuitry so that even brief peak excursions give a positive display. It is important that the circuitry should be bipolar, i.e. it will react to both positive and negative peaks. The peak values of a waveform can show asymmetry up to 8 dB or more, being greatest for unaccompanied voice or a single instrument. This level of uncertainty in peak detection is not a good thing, so only the simplest implementations use unipolar peak detection. Composite waveforms, produced by mixing several voices or instruments together, do not usually show significant asymmetries in peak level.

Figure 15.2 shows a simple unipolar Peak LED driving circuit. This only responds to positive peaks, but it does have the advantage of using but two transistors and is very simple and cheap to implement. When a sufficient signal level is applied to C1, Q1 is turned on via the divider R1, R2; this turns off Q2, which is normally held on by R4, and Q2 then ceases to shunt current away from peak LED D1. C2 acts as a Miller integrator to stretch the peak-hold time; when Q1 turns off again, R4 must charge C2 before Q2 can turn on again. Note that this circuit is integrated into an LED chain, with R5 setting the current through it; a mode indicator LED can be illuminated by removing the short placed across it by SW1. R5 is of high enough value, because it is connected between the two supply rails, for there to be no significant variation in the brightness of one LED when the other turns off. If for some reason this was a critical issue, R5 could be replaced by a floating constant-current source. Other LEDs switched in the same way, or nonswitched for a power indicator, can be included in the LED chain.

This peak-detect circuit has a nonlinear input impedance and must only be driven from a low-impedance point, preferably direct from the output of an opamp. The peak LED illuminates at an input of 6.6 Vpeak, which corresponds to 4.7 Vrms (for a sine wave) and +16 dBu. For typical opamp circuitry running off the usual supply rails this corresponds to having only 3 or 4 dB of headroom left. The detect threshold can be altered by changing the values of the divider R1, R2.

The Log-Law Level LED (LLLL)

The Log-Law Level LED or LLLL was evolved for the Elektor preamplifier project of 2012 to aid in the adjustment of a phono input with several different gain options. It is, to the best of my knowledge, a new idea. Usually a single LED level indicator is driven by an opamp or a comparator, and typically goes from fully off to fully on with less than a 2 dB change in input level when fed with music (not steady sinewaves). It therefore only gives effectively one bit of information.

It would be useful to get a bit more enlightenment from a single LED. More gradual operation could be adopted, but anything that involves judging the brightness of an LED is going to be of doubtful use, especially in varying ambient lighting conditions. The LLLL, on the other hand, uses a comparator to drive the indicating LED hard on or hard off. It incorporates a simple log-converter so that that the level range from LED always-off to always-on is much increased, to about 10 dB, the on-off ratio indicating where the level lies in that range. In some applications, such as the Elektor preamplifier, it may be appropriate to set it up so that the level is correct when the LED is on about 50% of the time. This gives a much better indication.

The circuitry of the LLLL is shown in Figure 15.3. The U1:A stage is a precision rectifier circuit that in conjunction with R3 provides a full-wave rectified signal to U1:B; this is another precision rectifier circuit that establishes the peak level of the signal on C1. This is buffered by U2:A and applied to the approximately log-law network around U2:B. As the signal level increases, first D6 conducts, reducing the gain of the stage, and then at a higher voltage set by R9, R10, D7 conducts and reduces the gain further. If sufficient signal is present to exceed the threshold set by R11, R12, the output of open-collector comparator U3:A goes low and U3:B output goes high, removing the short across LED1 and allowing it to be powered by the 6 mA current-source Q1. As with other circuitry in this chapter, the LED current is run from rail to rail, avoiding the ground. Many other LEDs can be inserted in the constant-current LED chain. The LLLL has been built in significant numbers, and I have never heard of any problems with it.

If a stereo version of the LLLL is required, which will indicate the greater of the two input signals, the output of comparator U3:A is wire-OR’ed with the output of U3:C, which has the same function in the other channel; the circuitry up to this point is duplicated. A more elegant way to make a stereo version would be to combine the outputs of two peak rectifiers to charge C1. This would save a handy number of components, but I have not yet actually tried it out.

I have spent some time testing the operation of this scheme, using various musical genres controlled by a high-quality slide fader. I believe it is a significant advance in signalling level when there is only one LED available, but in the words of Mandy Rice-Davies, “Well, he would say that, wouldn’t he”.[1] More opinions on the value of the LLLL would be most welcome; I haven’t had a negative one yet.

Distributed Peak Detection

When an audio signal path consists of a series of circuit blocks, each of which may give either gain or attenuation, it is something of a challenge to make sure that excessive levels do not occur anywhere along the chain. Simply monitoring the level at the end of the chain is no use because a circuit block that gives gain, leading to clipping, may be followed by one that attenuates the clipped signal back to a lower level that does not trip a final peak-detect circuit. The only way to be absolutely sure that no clipping is happening anywhere along the path is to implement bipolar peak detection at the output of every opamp stage. This is however normally regarded as a bit excessive, and the usual practice in high-end equipment is to just monitor the output of each circuit block, even though each such block (for example an elliptical rumble filter) may actually contain several opamps. It could be argued that a well-designed circuit block should not clip anywhere except at its output, no matter what the control setting, but this is not always possible to arrange.

A multipoint or distributed peak detection circuit that I have made extensive use of is shown in Figure 15.4. It can detect when either a positive or negative threshold is exceeded at any number of points desired; to add another stage to its responsibilities you need only add another pair of diodes, so it is very economical. However, if one peak detector monitors too many points in the signal path, it can be hard to determine which of them is causing the problem.

The operation is as follows. Because R5 is greater than R1, normally the noninverting input of the opamp is held below the inverting input and the opamp output is low. If any of the inputs to the peak system exceed the positive threshold set at the junction of R4, R3, one of D1, D3, D5 conducts and pulls up the noninverting input, causing the output to go high. Similarly, if any of the inputs to the peak system exceed the negative threshold set at the junction of R2, R6, one of D2, D4, D6 conducts and pulls down the inverting input, once more causing the opamp output to go high. When this occurs C1 is rapidly charged via D7. The output-current limiting of the opamp discriminates against very narrow noise pulses. When C1 charges, Q1 turns on and illuminates D8 with a current set by the value of R7. R8 ensures that the LED stays off when U4 output is low, as it does not get close enough to the negative supply rail for Q1 to be completely turned off.

Each input to this circuit has a nonlinear input impedance, and so for this system to work without introducing distortion into the signal path, it is essential that the diodes D1–D6 are driven directly from the output of an opamp or an equivalently low impedance. Do not try to drive them through a coupling capacitor, as asymmetrical conduction of the diodes can create unwanted DC-shifts on the capacitor.

The peak-detect opamp U4 must be a FET-input type to avoid errors due to bias currents flowing in the relatively high-value resistors R1–R6, and a cheap TL072 works very nicely here; in fact the resistor values could probably be raised significantly without any problems.

As with other nonlinear circuits in this book, everything operates between the two supply rails, so unwanted currents cannot find their way into the ground system.

Combined LED Indicators

In the professional audio industry, there has for many years been a tendency towards very crowded channel front panels, driven by a need to keep the overall size of equipment within reasonable limits. One apparently ingenious way to gain a few more square millimetres of panel space is to combine the signal-present and peak indicators into one by using a bi-colour LED. Green shows signal present, and red indicates peak. One might even consider using orange (both LED colours on) for an intermediate level, giving three possible indications.

Unfortunately, such indicators are hard to read, even if with normal colour vision, because a light coming on is much more obvious than a light that is already on changing colour. If you have red-green colour-blindness, the most common kind (6% of males, 0.4% of females), they are useless. Space is unlikely to be in desperately short supply on the front of a phono amplifier, and combining indicators like this is really not a good idea.

LED Bargraph Metering

Bargraph meters are commonly made up of an array of LEDs. An LED bargraph meter can be made effectively with an active-rectifier circuit and a resistive divider chain that sets up the trip voltage of an array of comparators; this allows complete freedom in setting the trip level for each LED. A typical circuit which indicates from 0 dB to −14 dB in 2 dB steps with a selectable peak or average-reading characteristic is shown in Figure 15.5 and illustrates some important points in bargraph design.

U3 is a half-wave precision rectifier of a familiar type, where negative feedback servos out the forward drop of D11 and D10 prevents opamp clipping when D11 is reverse-biased. The rectified signal appears at the cathode of D11 and is smoothed by R7 and C1 to give an average, sort-of-VU response. D12 gives a separate rectified output and drives the peak-storage network R10, C9, which has a fast attack and a slow decay through R21. Either average or peak outputs are selected by SW1 and applied to the non-inverting inputs of an array of comparators. The LM2901 quad voltage comparator is very handy in this application; it has low input offsets and the essential open-collector outputs.

The inverting comparator inputs are connected to a resistor divider chain that sets the trip level for each LED. With no signal input, the comparator outputs are all low, and their open-collector outputs shunt the LED chain current from Q1 to −15V, so all LEDs are off. As the input signal rises in level, the first comparator U2:D switches its output off, and LED D8 illuminates. With more signal, U2:C also switches off and D7 comes on, and so on, until U1:A switches off and D1 illuminates. The important points about the LED chain are that the highest level LED is at the bottom of the chain, as it comes on last, and that the LED current flows from one supply rail down to the other and is not passed into a ground. This prevents noise from getting into the audio path. The LED chain is driven with a constant-current source to keep LED brightness constant despite varying numbers of them being in circuit; this uses much less current than giving each LED its own resistor to the supply rail and is universally used in mixing console metering. Make sure you have enough voltage headroom in the LED chain, not forgetting that yellow and green LEDs have a larger forward drop than red ones. The circuit shown has plenty of spare voltage for its LED chain, and so it is possible to put other indicator LEDs in the same constant-current path; for example D9 can be switched on and off completely independently of the bargraph LEDs and can be used to indicate Channel- on status or whatever. An important point is that in use the voltage at the top of the LED chain is continually changing in 2-volt steps, and this part of the circuit must be kept away from the audio path to prevent horrible crunching noises from crosstalking into it.

This meter can of course be modified to have a different number of steps, and there is no need for the steps to be the same size. It is as accurate in its indications as the use of E24 values in the resistor divider chain allows.

If a lot of LED steps are required, there are some handy ICs which contain multiple open-collector comparators connected to an in-built divider chain. The National LM3914 has 10 comparators and a divider chain with equal steps, so they can be daisy-chained to make big displays, but some law-bending is required if you want a logarithmic output. The National LM3915 also has 10 comparators, but a logarithmic divider chain covering a 30 dB range in 3 dB steps.

A More Efficient LED Bargraph

The bargraph meter shown in Figure 15.5 draws 6 mA from the two supply rails at all times, even if all the level LEDs are off for long periods, which is often the case for equipment owned by people who think that a warm-up period of a couple of months is reasonable (I am not one of them). This can be actually desirable in a simple system where the meter current is taken from the ±15V or ±17V rails used to power the audio circuitry and step changes in current taken by the meter could get into the ground system via decoupling capacitors and suchlike, causing highly unwelcome crunching noises.

More sophisticated phono amplifiers are likely to have a separate meter supply that is provided to prevent this problem, and this allows more freedom in the design of the meter circuitry. In the example here the meter supply available is assumed to be a single rail of +24V, which is the highest voltage that can conveniently be generated with standard IC regulators. It is further assumed that we wish to make a classy meter with 20 LEDs. An immediate problem is that you cannot power 20 LEDs of assorted colours in one chain running from +24V as there just is not enough voltage available; two LED chains are required, and the power consumption of the meter, even when completely dormant, becomes twice as great. I therefore devised a more efficient system, which not only saves a considerable amount of power but also actually economises on components.

The meter circuit is shown in Figure 15.6, and I must admit it is not one of those circuit diagrams where the modus operandi exactly leaps from the page. However, stick with me.

There are two LED chains, each powered by its own constant-current source Q1, Q2. The relevant current source is only turned when it is needed. With no signal input, all LEDs are off; the outputs of comparators U10 and U20 are high (open-collector output off) and both Q1 and Q2 are off. The outputs of all other comparators are low. When a steadily increasing signal arrives, U20 is the first comparator to switch, and LED D20 turns on. With increasing signal, the output of U19 goes high, and the next LED, D19, turns on. This continues, in exactly the same way as the conventional bargraph circuit described earlier, until all the LEDs in the chain D11–D20 are illuminated. As the signal increases further, comparator U10 switches and turns on the second current source Q2, illuminating D10; the rest of the LEDs in the second chain are then turned on in sequence as before. This arrangement saves a considerable amount of power, as no supply current at all is drawn when the meter is inactive, and only half the maximum is drawn so long as the indication is below −2 dB.

There are 10 comparators for each LED chain, 20 in all, so a long potential divider with 21 resistors would be required to provide the reference voltage for each comparator if it was done in the conventional way, as shown in Figure 15.5. However, looking at all those comparator inputs tied together, it struck me there might be a better way to generate all the reference voltages required, and there is.

The new method, which I call a “matrix divider” system, uses only 10 resistors. This is more significant than it might at first appear, because the LEDs are on the edge of the PCB, the comparators are in compact quad packages, and so the divider resistors actually take up quite a large proportion of the PCB area. Reducing their number by half made fitting the meter into a pre-existing and rather cramped meter bridge design possible without recourse to surface-mount techniques. There are now two potential dividers. Divider A is driven by the output of the rectifier circuit, while Divider B produces a series of fixed voltages with respect to the +8.0V subrail. As the input signal increases, the output of the meter rectifier goes straight to comparators U16–U20, which take their reference voltages from Divider B and turn on in sequence as described earlier. Comparators U11–U15 are fed with the same reference voltages from Divider B, but their signal from the meter rectifier is attenuated by Divider A, coming from the tap between R3 and R5, and so these comparators require more input signal to turn on. This process is repeated for the third bank of comparators U6–U10, whose input signal is further attenuated, and finally for the fourth bank of comparators U1–U5, whose input is still further attenuated. The result is that all the comparators switch in the correct order.

Since in this application there was only a single supply rail, a bias generator is required to generate an intermediate subrail to bias the opamps. This subrail is set at +8.0V rather than V/2 to allow enough headroom for the rectifier circuit, which produces only positive outputs; it is generated by R18, R19 and C3 and buffered by opamp section U3:B. The +24V supply is protected by a 10 Ω fusible resistor R22, so if a short circuit occurs the resistor will fail to open without flame. A small but vital point is that the supply for Divider B is taken from outside this fusing resistor; if it was not, the divider voltages would vary with the number of LED chains powered, upsetting meter accuracy.

The LM2901 quad voltage comparator is used again here, as it has low input offset voltages and the requisite open-collector outputs. Transistors Q1, Q2 can be any TO-92 devices with reasonable beta; their maximum power dissipation, which occurs with only one LED on in the chain, is a modest 128 mW. This meter system has been used by me in commercial products with great success, and its only downside is that it is a bit harder to understand than conventional meter circuitry.

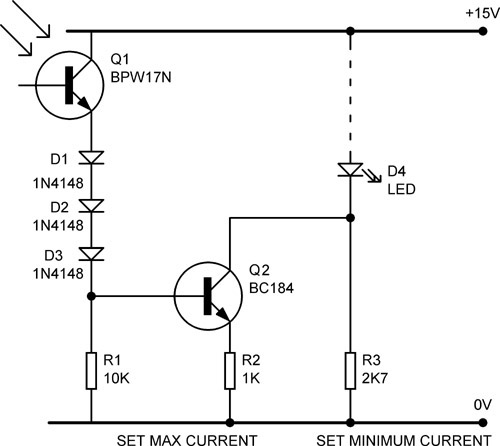

Automatic Brightness Control

Level meters or other indicators have to be bright to be visible in daylight. This often means that they are excessively bright and distracting in a semi-darkened listening room. While manual brightness control is a possibility, it is clumsy, and a better way is automatic brightness control with a photo-sensor mounted on the front panel. Figure 15.7 shows a simple circuit that I have used several times. In darkness the phototransistor Q1 does not conduct and the LED current is set at its minimum by R3. When light hits the front panel Q1 conducts and turns on Q2, increasing the current through the LED chain to a maximum set by R2. D1–D3 modify the control law to give smooth operation. Take care that light from the LEDs cannot reach the phototransistor, or you may get optical oscillation.

Reference

1. https://en.wikipedia.org/wiki/Mandy_Rice-Davies Accessed Nov 2016.