Chapter 1. Introduction to Fatigue and Tribology of Plastics and Elastomers

1.1. Introduction to Fatigue

There are two recently published books on the properties of engineering plastics in this series. The Effect of Temperature and Other Factors on Plastics1 discusses the general mechanical properties of plastics. The mechanical properties as a function of temperature, humidity, and other factors are presented in graphs or tables. That work includes hundreds of graphs of stress versus strain, modulus versus temperature, impact strength versus temperature, etc. Time was not a factor in that book. The Effect of Creep and Other Time Related Factors on Plastics2 discusses the long-term behavior of plastics when exposed to constant stresses or strains for long periods of time. This book adds another two layers of plastics performance criteria, fatigue, and tribology.

This book provides graphical multipoint data and tabular data on fatigue and tribological properties of plastics and elastomers. This first chapter deals with the types of stress and an introduction to fatigue. Tribology is discussed in Chapter 2. The chemistry of plastics follows in Chapter 3. The remaining chapters contain the data.

The idea of fatigue is very simple. If an object is subjected to a stress or deformation, and it is repeated, the object becomes weaker. This weakening of plastic material is called fatigue and occurs when the material is subject to alternating stresses over a long period of time.

1.2. Types of Stress

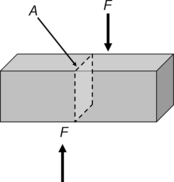

As noted in Section 1.1, fatigue occurs as a result of rapidly changing stress or strain. Stress and strain can be applied in a number of ways. Normal stress (σ) is the ratio of the applied force (F) over the cross-sectional area (A) as shown in Equation 1.1 and Figure 1.1.

(1.1)

1.2.1. Tensile and Compressive Stress

When the applied force is directed away from the part, as shown in Figure 1.1, it is a tensile force inducing a tensile stress. This is also called a normal stress as it is applied perpendicularly. When the force is applied toward the part, it is a compressive force inducing a compressive stress.

1.2.2. Shear Stress

A shear stress (τ) is defined as a stress which is applied parallel or tangential to a face of a material as shown in Figure 1.2. The shear force is applied parallel to the cross-sectional area “A”.

Shear stress is also expressed as force per unit area as in Equation 1.2.

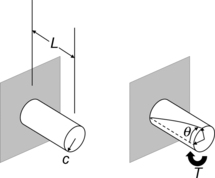

1.2.3. Torsional Stress

Torsional stress (τ) occurs when a part such as a rod for a shaft is twisted as in Figure 1.3. This is also a shear stress, but the stress is variable and depends how far the point of interest is from the center of the shaft. The equation describing torsional stress is shown in Equation 1.3.

(1.3)

In this equation, T is the torque and c is the distance from the center of the shaft or rod. K is a torsional constant that is dependent on the geometry of the shaft, rod, or beam. The torque (T) is further defined by Equation 1.4, in which θ is the angle of twist, G is the modulus of rigidity (material dependent), and L is the length.

(1.4)

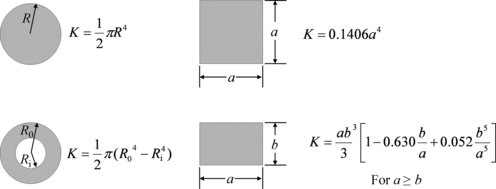

The torsional constant (K) is dependent upon geometry and the formulas for several geometries are shown in Figure 1.4. Additional formulas for torsional constant are published. 3

1.2.4. Flexural or Bending Stress

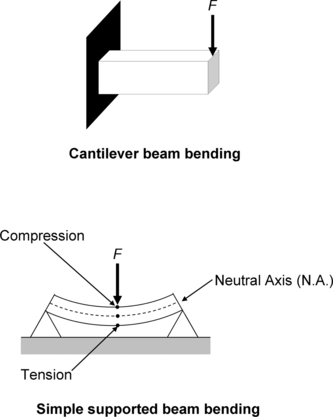

Bending stress or flexural stress commonly occurs in two instances, shown in Figure 1.5. One is called a simply supported structural beam bending and the other is called cantilever bending. For the simply supported structural beam, the upper surface of the bending beam is in compression and the bottom surface is in tension. The neutral axis (NA) is a region of zero stress. The bending stress (σ) is defined by Equation 1.5. M is the bending moment, which is calculated by multiplying a force by the distance between that point of interest and the force. c is the distance from the neutral axis (N.A. in Figure 1.5) and I is the moment of inertia. The cantilevered beam configuration is also shown in Figure 1.5 and has a similar formula. The formulas for M, c, and I can be complex, depending on the exact configuration and beam shape, but many are published. 3

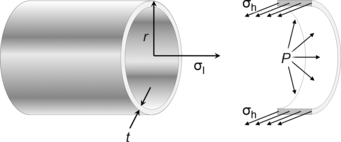

1.2.5. Hoop Stress

Hoop stress (σh) is mechanical stress defined for rotationally symmetric objects such as pipe or tubing. The real-world view of hoop stress is the tension applied to the iron bands, or hoops, of a wooden barrel. It is the result of forces acting circumferentially. Figure 1.6 shows stresses caused by pressure (P) inside a cylindrical vessel. The hoop stress is indicated in the right-hand side of Figure 1.6 that shows a segment of the pipe.

The classic equation for hoop stress created by an internal pressure on a thin wall cylindrical pressure vessel is given in Equation 1.6.

(1.6)

The SI unit for P is the Pascal (Pa), while t and r are in meters (m).

If the pipe is closed on the ends, any force applied to them by internal pressure will induce an axial or longitudinal stress (σl) on the same pipe wall. The longitudinal stress under the same conditions of Figure 1.6 is given in Equation 1.7.

(1.7)

There could also be a radial stress especially when the pipe walls are thick, but thin walled sections often have negligibly small radial stress (σr). The stress in radial direction at a point in the tube or cylinder wall is shown in Equation 1.8.

(1.8)

Often the stresses in the pipe are combined into a measure called equivalent stress. This is determined using the Von Mises equivalent stress formula which is shown in Equation 1.9.

(1.9)

Failure by fracture in cylindrical vessels is dominated by the hoop stress in the absence of other external loads as it is the largest principal stress. Failure by yielding is affected by an equivalent stress that includes hoop stress and longitudinal stress. The equivalent stress can also include tangential shear stress and radial stress when present.

1.3. Fatigue Testing

There are many machines that have been designed to put a periodic stress or strain on a test coupon or specimen. While the details of these machines vary, they really fall into similar designs. This section will first present several basic fatigue test machine designs. Machines can be designed to put a cycling stress or a strain on the test coupon. The strain is a fixed displacement (% or mm/mm) and the stress is a pressure (MPa).

1.3.1. Tensile Eccentric Fatigue Machine

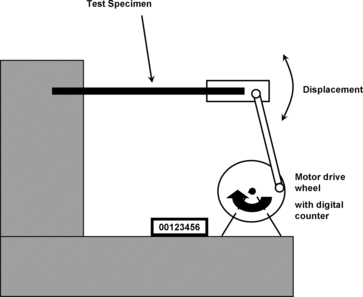

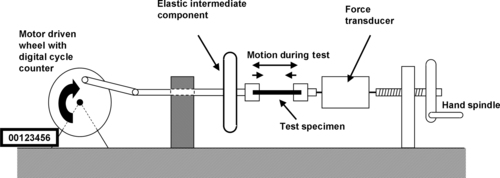

Many of the machines apply the stress or strain based on a circular drive mechanism and so they are called eccentric machines. One such machine for tensile and compressive testing is shown in Figure 1.7. This machine may compress and extend a test specimen repeatedly (Figure 1.8).

|

| Figure 1.7 |

|

| Figure 1.8 (photo courtesy of Fatigue Dynamics, Inc.) |

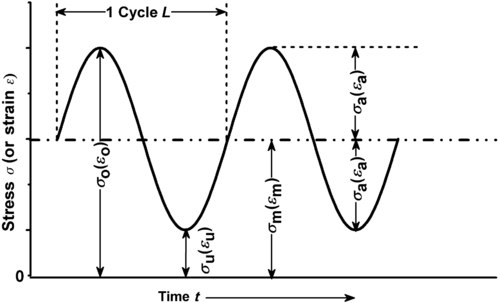

The stress and strain in eccentric machines vary in a sinusoidal manner as depicted in Figure 1.9. This shows the change in stress or strain versus time. There are several descriptive parameters noted on this figure that are useful in specifying or describing the test conditions.

|

| Figure 1.9 |

The terms and symbols are:

L = Cycle, one full oscillation of the loading (stress or strain), almost always assumed to be constant

f = Cycle frequency; number of cycles per unit time in Hz (1/s)

N = Number of cycles

σo = maximum stress, highest absolute stress value

σu = minimum stress, lowest absolute stress value

σm = mean stress = 0.5 (σo + σu)

εo = maximum strain (displacement), highest absolute strain value

εu = minimum strain (displacement), lowest absolute strain value

εm = mean strain (displacement) = 0.5 (εo + εu)

εa = strain (displacement) amplitude = ±0.5 (εo − εu)

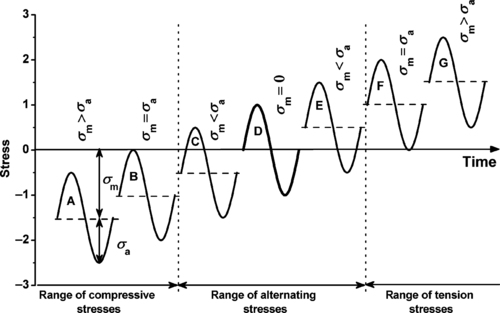

The mean stress, σm, or the mean strain, εm, is not always zero. A range of values is possible as shown in Figure 1.10. Curves A, D, and F are most common testing conditions. The simplest is the reversed stress cycle, Curve D. This is a sine wave where the maximum stress and minimum stress magnitudes are equal except that they differ by a negative sign. A real-world example of this type of stress cycle would be in an axle, in which every half turn the stress on a point would be reversed. The most common types of cycle found in engineering applications are the other curves where the maximum and minimum stresses are asymmetric, not equal and opposite. This type of stress cycle is called repeated stress cycle.

|

| Figure 1.10 |

The stroke set on the rotating wheel on the eccentric unit controls the strain/stress amplitude for the oscillation test. The mean stress is set using the hand spindle shown in Figure 1.7 and Figure 1.8. The cycle frequency is controlled by the rotational speed of the wheel. The frequency is often kept relatively low to minimize sample heating during the test. The mean and minimum stress can be set by adjusting the fixed clamping device. The stress amplitude may decrease during the test, which is caused by relaxation and heating. Correcting stress amplitude for this decrease required increasing the eccentric stroke when the machine is turned off. To avoid any interruption to the test, an elastic intermediate component is incorporated in the test setup as shown in the figure, which considerably reduces the stress reduction, since its spring travel is greater than that of the plastic. This allows the machine to operate with quasiconstant stress values.

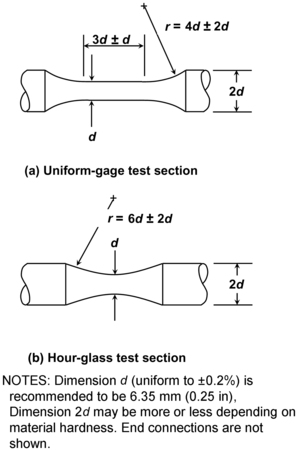

1.3.1.1. Fatigue Coupons

The test specimens are usually molded bars or rods that are further machined to specific shapes and configurations. ASTM International, originally known as the American Society for Testing and Materials (ASTM), is one organization that defines standard tests; its standards are the well-known ASTM standards. ASTM E606 describes fatigue specimens as shown in Figure 1.11 and Figure 1.12. Figure 1.11 shows specimens that are made from molded sheet or bars. The test area is primarily in the center of these pieces. Specimen (a) in Figure 1.11 has a rectangular cross section while specimen (b) is circular.

Specimens made from molded rods are shown in Figure 1.12. The rods in this figure do not show the clapping options, of which there are many, to secure the specimen to the test machine.

1.3.1.2. Fatigue Testing Method

Usually a minimum of six identical testing specimens are made for testing. A specimen is tested first at the highest stress or strain amplitude. It is tested until it fails (breaks). The stress/strain amplitude is recorded along with the cycles it took to fail. Because of the variability in the test, measurements are usually replicated a second or third time at the same stress/strain amplitude. Next the stress/strain is reduced and the test is run till failure, which of course takes longer. The reduction in stress or strain continues until failure does not occur in 106–107 cycles.

A specimen may fail to break even with at the highest stress or strain. In cases such as these, it is necessary to specify the number of cycles up to a particular level of material damage (e.g., 20% stress reduction if strain is controlled, or 20% increase in strain if stress is controlled) instead of the number of cycles to failure.

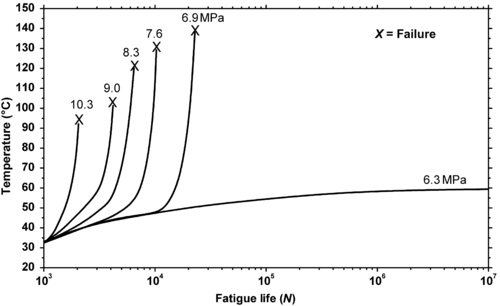

The temperature of the specimen is monitored while testing as the specimen may heat up during the test. This process is referred to as hysteretic heating. Temperature is measured at the surface either by thermocouples that are attached to the surface or by noncontact infrared thermometers. Figure 1.13 and Table 1.1 show examples of heating in polytetrafluoroethylene (PTFE) during fatigue testing.

|

| Figure 1.13 |

| Stress (MPa) | N (Cycles) | Temperature (°C) |

|---|---|---|

| 10.3 | 2 × 103 | 100 |

| 9.0 | 4 × 103 | 115 |

| 8.3 | 6.1 × 103 | 125 |

| 7.6 | 9.5 × 103 | 130 |

| 6.9 | 1.9 × 104 | 141 |

| 6.3 | 1 × 107 | 60 |

The data shown in Figure 1.13 and Table 1.1 do show the effect of temperature rise, and that it is most significant as the material being tested approaches failure.

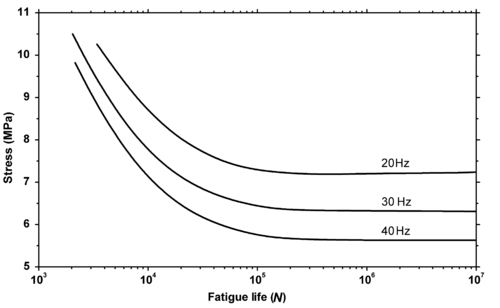

Frequency also affects fatigue testing because it also contributes to hysteretic temperature rise. An example of this is shown in Figure 1.14. The significance of this curve is explained in a later section.

Most fatigue tests are conducted at room temperature with a cycle frequency, f, of 7Hz, but the cycle frequency may be adjusted to minimize temperature rise and reduce testing time. Fatigue tests in all three loading ranges (compressive, alternating, and tension) can be conducted on the eccentric testing machines. These machines impart a constant strain. The measured imparted stress amplitude may become smaller with an increasing number of cycles if the specimen relaxes and heats up.

The plotting and analysis of the data are discussed in a later section of this chapter.

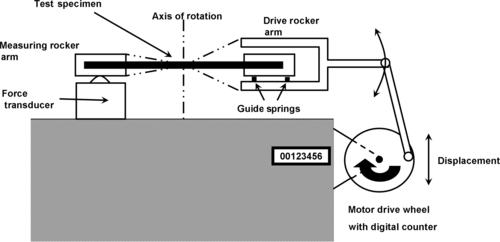

1.3.2. Flexural Eccentric Fatigue Machine

An eccentric machine for flexural fatigue testing is shown in Figure 1.15 and Figure 1.16. The stroke on this type of flexural unit imposes a constant bending radius on the specimen during the fatigue test at the axis of rotation in the figure. The guide springs under the right-hand clamping unit permit the specimen to move in the longitudinal direction which reduces the additional tensile forces that would otherwise develop during bending.

1.3.3. Cantilevered Beam Eccentric Flexural Fatigue Machine

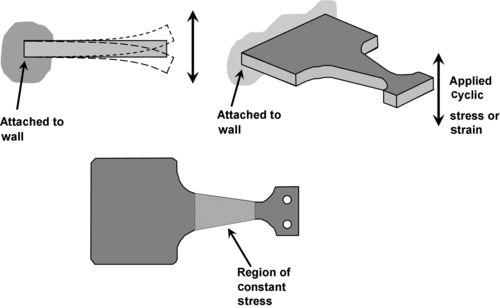

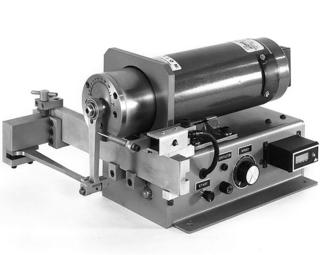

The cantilevered beam flexural fatigue machine is similar to the machine shown in Figure 1.17 except that the test specimen is fixed and immovable at one end. ASTM D671 describes this test. Test specimen is supported as a cantilevered beam and is subjected to an alternating force at one end as shown in Figure 1.18. The alternating applied stress and the cycles to failure are recorded. The “odd” triangular shape of the test specimen is designed to produce a constant stress along the length of the test section of the specimen. The machine that is used to perform this test is shown in Figure 1.18 and Figure 1.19.

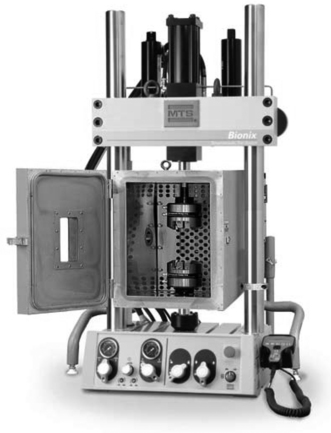

1.3.4. Servohydraulic, Electrohydraulic, or Pulsator Fatigue Testing Machines

Servohydraulic, electrohydraulic, or pulsator fatigue testing machines do not use an eccentric wheel to apply cyclic stress and strain. These machines use a computer-controlled hydraulic drive or pulsator to apply the varying stress or strain to the test specimen. This is particularly important because some real-world cycle modes have stress level, and frequency varies randomly. Wave forms do not need to be limited to sine waves either. A real-world example of this situation would be the simulation of the function of automobile shocks, where the frequency magnitude of imperfections in the road will produce varying minimum and maximum stresses. Figure 1.20 shows a picture of a servohydraulic machine. These machines may apply compressive, tensile, or flexural loads. The pulsator in Figure 1.20 is located at the top. The machines are usually run in a force- or stress-controlled manner. This particular example includes an environmental chamber which can be used to control the temperature, humidity, and atmosphere that the fatigue test will take place in.

|

| Figure 1.20 (photo courtesy of MTS Systems Corporation © 2009) |

This machine can be run in a pulsating bending or flexing mode by utilizing a testing stage such as that shown in Figure 1.21. The specimen is supported by roller bearings and is subjected to three-point bending. The bearings minimize the generated tensile stresses.

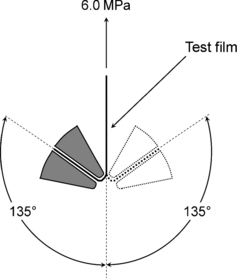

1.3.5. MIT Flex Life Machine

The MIT Flex Test is used to measure the ability of plastic films to withstand fatigue from flexing. This test method is described in ASTM Standard D-2176-69, which is the standard method for testing the endurance of paper with the MIT test apparatus. A diagram of the flex held in the MIT flex tester is shown in Figure 1.22. One end of the plastic test film is clamped in a holder that rotates through 270° very rapidly. The other end is pulled with a constant stress. Even though the ASTM standard describes a paper test, it can be applied to any thin film plastic. It is often used in the evaluation of wire plastic insulation. This test may also help provide insight into the effect of tensioning on life. Flex testing is occasionally performed after exposing the plastics to heat and/or chemicals in order to simulate in use exposure conditions. The flex life is the number of cycles before the film breaks.

1.3.6. Fatigue and Fracture Standards

There are many testing or standard agencies that have standards concerning fatigue and fracture. Some of them include:

• ASTM—ASTM International, originally known as the American Society for Testing and Materials

• ISO—ISO (International Organization for Standardization)

• DIN—Deutsches Institut für Normung.-German Institute for Standardization

• ANSI—American National Standards Institute

• JIS—Japanese Industrial Standards

• SAE—Society of Automotive Engineers

1.4. Understanding Fatigue Testing Data

This section develops an understanding of what happens to a specimen during fatigue testing and describes various ways of reporting fatigue testing results.

1.4.1. Monotonic Stress–Strain Behavior

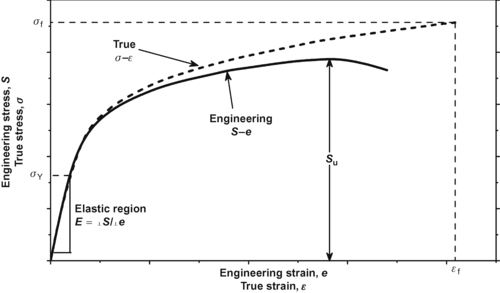

Monotonic stress–strain curves such as the one shown in Figure 1.23 are very common. They are used to obtain design parameters for limiting stresses on structures and components subjected to static loading. They are frequently measured at a series of temperatures or strain rates as shown in an earlier book of this series. 1

The engineering stress–strain curve shown in the figure is obtained by means of a tension test, in which a specimen is subjected to a continually increasing, monotonic load. The elongation of the specimen is measured, and engineering stress and strain values are derived as described below.

The measured engineering stress is the average stress in the specimen, and is given by:

(1.10)

(1.11)

Keeping in mind that when the specimen is stretched, the cross-sectional area changes, the true stress–strain curve, shown in black, is calculated using the instantaneous length and cross-sectional area, instead of average values. The true stress, σ, is calculated from Equation 1.12 and is always larger than the engineering stress.

(1.12)

The true strain is also calculated by Equation 1.13.

(1.13)

The stress–strain curve ends (at the ultimate tensile strength Su), when the specimen fails, either by breaking or yielding. If it fails by yielding the specimen necks, it thins nonuniformly as shown in Figure 1.24.

Until failure occurs, true stress and strain are related to engineering stress and strain by (1.14) and (1.15).

(1.14)

(1.15)

Also shown in Figure 1.18 is the true fracture strength which is the true stress at final fracture, and is calculated by Equation 1.16.

(1.16)

The true fracture strain is the true strain at final fracture, and is calculated by:

(1.17)

Figure 1.23 has a region labeled the elastic region. This region of the stress–strain curve is linear. In this region, ideally, if the stress is removed, the strain returns back to zero. The deformation is completely reversible. The modulus of elasticity or Young’s modulus is defined by the slope of the stress–strain curve in the elastic region. The end point of the linear elastic region is called the yield point or elastic limit. The stress at the yield point is called the yield stress, σY. The rest of the stress–strain curve beyond the elastic region is called the plastic region. The total true strain is calculated from the equations above. The true stress–strain curve shown in Figure 1.23 can be approximately modeled by Equation 1.18:

(1.18)

Considered in the next section is what happens when this measurement is reversed cyclically.

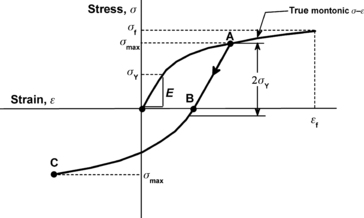

1.4.2. Cyclic Stress–Strain Behavior

When the stress–strain measurement shown in Figure 1.23 is reversed at a point after the yield stress, σY, but before failure, εf, the stress–strain relationship will initially follow a line with a slope equivalent to the elastic modulus E. This is illustrated by segment A–B in Figure 1.25. If the process were stopped at point B, the length of the specimen does not fully recover to its initial value. However, in this particular example, the specimen is then subjected to a compressive load to σmax to point C in Figure 1.25.

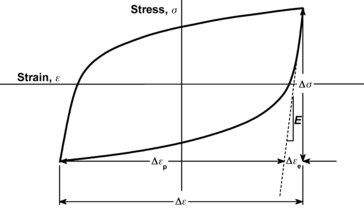

If the loading process shown in Figure 1.25 is reversed again from −σmax to +σmax, then a hysteresis loop will result such as that shown in Figure 1.26. The hysteresis loop defines a single fatigue cycle in the strain-life method. After a number of cycles, the hysteresis loop stabilizes. The stability occurs normally in less than 10% of the total life. The hysteresis loop is often characterized by its stress range, Δσ, and strain range, Δε. The strain range may be split into an elastic part, Δεe and a plastic part, Δεp.

When subjected to strain-controlled cyclic loading, the stress–strain response of a material can change depending upon the number of applied cycles. In plastics, the maximum stress generally decreases with the increase in the number of cycles. The test is typically run to failure of the specimen or some maximum number of cycles, often 1 × 107 cycles.

The test is often run at a series of different strain ranges (or strain amplitudes) on new specimens. Each strain range tested will have a corresponding stress range that is measured. This data can be plotted as shown in Figure 1.27 and is called a cyclic stress–strain curve.

The cyclic stress–strain curve is different from the initial behavior that is measured in a traditional tensile test. A power function, Equation 1.19, may be fitted to this curve to obtain three material properties.

(1.19)

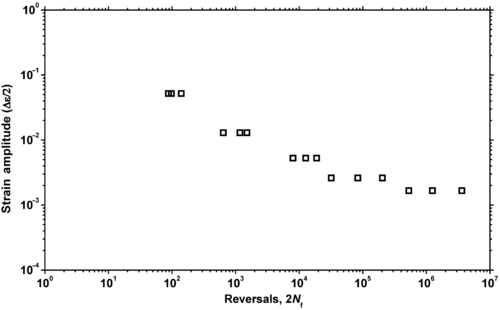

1.4.3. Strain-Life Behavior

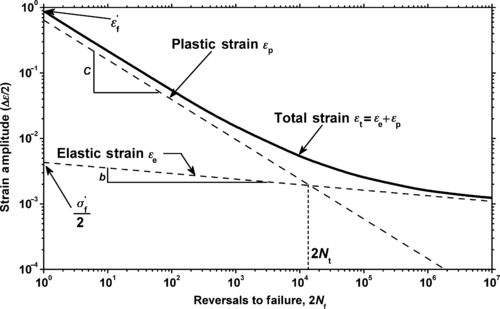

The cyclic stress–strain measurement can be run until the specimen fails or a maximum number of cycles have been made. These measurements are done with machines that control the strain. The strain range is controlled and the corresponding stress range and fatigue life are measured. When a series of these cyclic stress–strain measurements (to failure) are done at different strain levels, the data may be plotted as shown in Figure 1.28. The data are usually plotted on a log–log plot, with reversals (note: 2 reversals = 1 cycle) or cycles to failure on the X-axis and strain amplitude on the Y-axis. As can be deduced from this plot, the data are usually run in duplicate or triplicate at each set strain amplitude.

Separate researchers had noticed that the lower cycle data points could be fit by a straight line and the higher cycle points could be fit by separate straight lines as shown in Figure 1.29.4.5. and 6.

The equation developed for the high-cycle straight line on the log–log strain life plot corresponds to elastic material behavior of the material. The equation developed, shown in Equation 1.20, defines two material parameters. 7

(1.20)

The equation developed for the low-cycle straight line on the log–log strain life plot corresponds to plastic material behavior of the material. The equation developed, shown in Equation 1.21, defines two material parameters.4. and 5.

(1.21)

The complete strain-life curve, εt, is the sum of the elastic and plastic components, Equation 1.22.

(1.22)

All of these are summarized in Figure 1.29.

One additional parameter shown on this graph is the transition life, 2Nt. This represents the life at which the elastic and plastic strain ranges are equivalent and can be expressed by Equation 1.23. The transition life provides an accepted demarcation between low-cycle and high-cycle fatigue regimes.

(1.23)

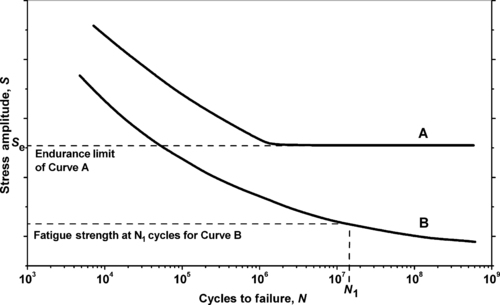

1.4.4. Stress-Life Behavior

The most common published fatigue data chart is the stress-life curve which is commonly called an S–N curve or a Wöhler8 curve. This is a graph of the magnitude of a cyclical stress (S), linear or log scale, against the cycles to failure (N) on a log scale. The cyclic measurement is made under constant oscillatory load amplitude. It is generally applied in high-cycle regimes, where the strain-life behavior is used in low-cycle regimes. Figure 1.31 shows two generic S–N curves. Curve A in this figure shows a fatigue limit. If the material is loaded below the fatigue limit, it will not fail, regardless of the number of fatigue cycles it experiences. Many materials do not behave in this manner and their S–N curve will look more like Curve B in Figure 1.31. Fatigue strength is noted on this curve and is defined as the stress amplitude at which failure occurs for a given number of cycles. Inversely, fatigue life is the number of cycles required for a material to fail at a given stress amplitude.

For those fatigue tested specimens that survive the test through the maximum specified cycle limit without failure, the fatigue damage may still be estimated. The short-term properties may be measured on these specimens (e.g. tensile strength and elongation at break). The ratio of the short-term properties of new (untested) specimens to those of the tested specimens constitutes a measure of the damage suffered in the fatigue test.

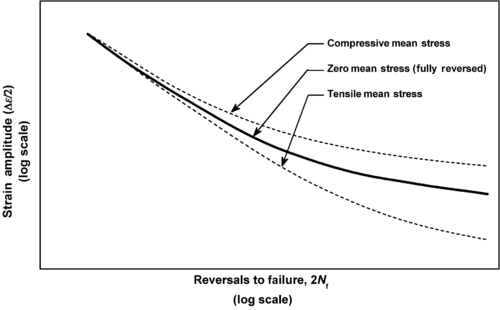

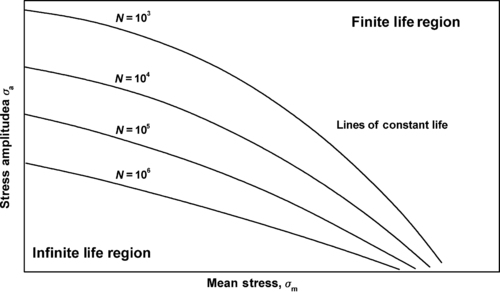

Most S–N curves are run at zero mean stress. When the fatigue tests are run at a nonzero mean stress, a different plot called a Haigh diagram is often made. The Haigh diagram, as shown in Figure 1.32, plots the mean stress on the X-axis versus the stress amplitude on the Y-axis. A family of curves is typical with lines drawn at a given life. The region under the lowest curve is called the infinite life region. The finite life region is the region above the curves.

1.5. The Fatigue Process

Failure by fatigue always involves cracking.9. and 10. The process may be simplified into three steps:

1. Crack initiation or nucleation

2. Crack growth or propagation

3. Final fracture

1.5.1. Crack Initiation

The initial crack occurs in this stage. The crack may be caused by:

1. cyclic loading

2. surface scratches induced during handling or tooling of the material

3. a defect introduced during manufacture, such as during casting or molding

4. mechanical impact

5. thermal shock, thermal expansion, or contraction

6. chemical attack (such as pitting or corrosion)

1.5.2. Crack Growth or Propagation

Once a crack has started, it continues to grow as a result of continuous applied stresses present under the influence of cyclic loading. If the crack grow to a critical length, then fracture of the component will occur. The rate of the crack growth before it reaches the critical length directly influences fatigue life. Fortunately a mathematical model known as Paris' Law11 provides a way to predict the crack growth rate.

The stress intensity factor, K, is used in fracture mechanics to accurately predict the stress intensity near the tip of a crack in an item caused by a load applied someplace on that item or by residual stresses. The magnitude of K depends on sample geometry, the size and location of the crack, and the magnitude and the distribution of loads on the material. Equation 1.24 shows the calculation of the stress intensity factor.

(1.24)

Stress intensity factors have been tabulated for thousands of part and crack geometries. 12

Paris proposed that the stress intensity factor range, ΔK, characterizes subcritical crack growth under fatigue loading, because he found that plots of crack growth rate versus stress intensity factor range gave straight lines on log–log scales. The stress intensity factor range is defined by Equation 1.25.

(1.25)

The equation of that line is shown in Equation 1.26, where C and m are constants for a given material. Equation 1.26 can be rearranged to remove the logs, giving Equation 1.27.

(1.26)

(1.27)

Integrating this equation from zero to the number of cycles which caused fast fracture, or from initial and final crack size gives Equation 1.28, which became known as the Paris Law.

(1.28)

It was later realized that the Paris Law applied to growth rates in a particular range as shown in Figure 1.33. This figure, a fatigue crack growth rate curve, plots the fatigue crack growth rate against the stress intensity factor range. The lower crack growth rate region is called the threshold regime. The higher growth rate regime occurs where values of maximum stress intensity in the fatigue cycle and failure approach rapidly. A more detailed information is available in the literature. 13

1.5.3. Failure

As the crack grows, there is less material available to withstand the applied stress or strain. Failure occurs when the material that has not been affected by the crack cannot withstand the applied stress. This stage happens very quickly. Failure in materials is often classified as ductile or brittle. Brittle failure occurs in some metals, which experience little or no plastic deformation prior to fracture. Ductile failure shows observable plastic deformation prior to fracture. At times materials behave in a transitional manner—partially ductile/brittle.

Fatigue failure is often classified into two types: high-cycle fatigue and low-cycle fatigue. High-cycle failure is generally classified as failure above 104 cycles. In high-cycle fatigue situations, material performance is commonly characterized by the S–N curve described in the previous section.

Where the stress is high enough for plastic deformation to occur leading to failure in less than 104 cycles, low-cycle fatigue is usually characterized by the Coffin–Manson relation14. and 15. given in Equation 1.29.

(1.29)

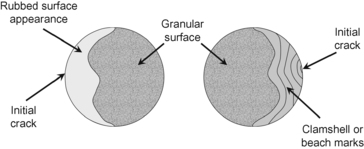

Examination of the fracture site of material failed by fatigue often shows two distinct regions. One region is smooth or burnished as a result of the rubbing of the bottom and top of the crack during the cyclic action of the stress or strain. The second region appears granular due to the rapid failure of the material. These may be seen in Figure 1.34. The rough, granular surface indicates brittle failure, while the smooth surface represents crack propagation.

Often features of a fatigue fracture are visible, such as beach marks or clamshell marks and striations. Beach marks or clamshell marks may be seen in fatigue failures of materials that are not in continuous use. They may be used for a period of time, allowed to rest and then used again. Striations are thought to be steps in crack propagation. Thousands of striations may be found within each beach mark.

1.6. Factors that Affect Fatigue Life

The following factors are known to affect fatigue life:

• Cyclic stress state—Stress amplitude, mean stress, biaxiality, in-phase or out-of-phase shear stress, and load sequence.

• Geometry—Notches and variation in cross section throughout a part lead to stress concentrations where fatigue cracks can begin.

• Surface quality—Surface roughness can cause microscopic stress concentrations that lower the fatigue strength.

• Material type—Behavior during cyclic loading, varies widely for different materials and is the basis for the data portion of this book.

• Residual stresses—Molding, cutting, machining, and other manufacturing processes involving heat or deformation can produce high levels of tensile residual stress, which decreases the fatigue strength.

• Size and distribution of internal defects—Defects such as gas porosity shrinkage voids can significantly reduce fatigue strength.

• Direction of loading—For nonisotropic materials such as fiber reinforced plastics, fatigue strength depends on the direction of the principal stress.

• Environment—Environmental conditions can cause erosion, oxidation, degradation, and environmental or solvent stress cracking which all affect fatigue life.

• Temperature—Higher temperatures generally decrease fatigue strength.

1.7. Design Against Fatigue

Design against fatigue failure requires thorough education and experience in structural engineering, mechanical engineering, and materials science. 16 This subject is beyond the objectives of this book. To dependably design against fatigue failure, one needs a thorough engineering education and years of experience in engineering and materials science. There are three principal approaches to life assurance for mechanical parts:

1. Design to keep stress below threshold of the material’s fatigue limit (sometimes called the infinite lifetime concept). This depends on having enough fatigue data which this book aims to provide.

2. Design for a fixed life and plan to replace the part with a new one much like car manufacturers do with their maintenance schedules. This is sometimes called “a so-called lifed part,” finite lifetime concept, 17 or “safe-life” design practice.

3. Plan to inspect the part periodically for cracks and replace the part once an observed crack exceeds a critical length. This approach usually requires an accurate prediction of the rate of fatigue crack growth. This sometimes is referred to as damage tolerant design18 or “retirement-for-cause.”

There are other strategies to deal with the factors that accelerate fatigue listed in Section 1.6. Perhaps most important, apart from the material of manufacture, is paying particular attention to the manufacturing process. The aim is to minimize internal and surface defects that concentrate stresses. One can also engineer temperature control and environmental exposure.

1.8. Summary

This chapter has provided a general summary of fatigue concepts, measurement techniques or methods, data presentation, and theory. It was meant to be introductory only and additional details should be obtained from the literature cited in this chapter.19.20. and 21.Chapter 4, Chapter 5, Chapter 6, Chapter 7, Chapter 8, Chapter 9, Chapter 10, Chapter 11 and Chapter 12 contain hundreds of plots of fatigue-related data on hundreds of different plastics.

References

1. McKeen, LW, The effect of temperature and other factors on plastics, plastics design library. (2008) William Andrew Publishing, Norwich, NY.

2. McKeen, LW, The effect of creep and other time related factors on plastics, plastics design library. (2009) William Andrew Publishing, Norwich, NY.

3. Pilkey, WD, Formulas for stress, strain, and structural matrices. 2nd ed. (2005) John Wiley & Sons, Hobaken, NJ; pp. 63–76. Online version available at: http://www.knovel.com/knovel2/Toc.jsp?BookID=1429&VerticalID=0.

4.

5. Coffin Jr., LF, A study of the effects of cyclic thermal stresses on a ductile metal, Trans ASME 76 (1954) 931–950.

6.

7. Riddell, MN; Koo, GP; O’Toole, JL, Polym Eng Sci 6 (1966) 363.

8. Day, L, Biographical dictionary of the history of technology. (1995) Routledge, London; p. 765.

9. Hertzberg, RW; Manson, J, Fatigue of engineering plastics. (1980) Academic Press, New York, NY.

10. Moalli, J., Plastics failure—analysis and prevention. (2001) William Andrew Publishing/Plastics Design Library, Norwich, NY; Online version available at: http://knovel.com/web/portal/browse/display?_EXT_KNOVEL_DISPLAY_bookid=382&VerticalID=0.

11. Paris, P; Erdogan, F, A critical analysis of crack propagation laws, J Basic Eng. Trans Am Soc Mech Eng (1963) 528–534; December.

12. Murakami, Y, Stress intensity factors handbook. (2003) Elsevier Science Ltd, Oxford, UK.

13. Suresh, S, Fatigue of materials. 2nd ed. (1998) Cambridge University Press, Cambridge, England.

14. Coffin Jr., LF, Trans ASME 76 (1954) 931–950.

15.

16. Schijve, J, Fatigue of structures and materials. 2nd ed. (2009) Springer, Netherlands; pp. 559–586.

17. Ashby, MF; Bréchet, Y, Materials selection for a finite life time, Adv Eng Mater 4 (6) (2002) 35–341.

18.

19.

20. Harris, B, Fatigue in composites. (2003) CRC Press, Boca Raton, FL.

21. Lee, Y-L; et al., Fatigue testing and analysis: theory and practice. (2005) Elsevier Butterworth-Heinemann.

..................Content has been hidden....................

You can't read the all page of ebook, please click here login for view all page.