Chapter 1: Diagrams for Understanding Chemical Processes

WHAT YOU WILL LEARN

Different types of chemical process diagrams

How these diagrams represent process views at different scales

One consistent method for drawing process flow diagrams

The information to be included in a process flow diagram

The purpose of operator training simulators and recent advances in 3-D representation of different chemical processes

The chemical process industry (CPI) is involved in the production of a wide variety of products that improve the quality of our lives and generate income for companies and their stockholders. In general, chemical processes are complex, and chemical engineers in industry encounter a variety of chemical process flow diagrams. These processes often involve substances of high chemical reactivity, high toxicity, and high corrosivity operating at high pressures and temperatures. These characteristics can lead to a variety of potentially serious consequences, including explosions, environmental damage, and threats to people’s health. It is essential that errors or omissions resulting from missed communication between persons and/or groups involved in the design and operation do not occur when dealing with chemical processes. Visual information is the clearest way to present material and is least likely to be misinterpreted. For these reasons, it is essential that chemical engineers be able to formulate appropriate process diagrams and be skilled in analyzing and interpreting diagrams prepared by others.

The most effective way of communicating information about a process is through the use of flow diagrams.

This chapter presents and discusses the more common flow diagrams encountered in the chemical process industry. These diagrams evolve from the time a process is conceived in the laboratory through design, construction, and the many years of plant operation. The most important of these diagrams are described and discussed in this chapter.

The following narrative is taken from Kauffman [1] and describes a representative case history related to the development of a new chemical process. It shows how teams of engineers work together to provide a plant design and introduces the types of diagrams that will be explored in this chapter.

The research and development group at ABC Chemicals Company worked out a way to produce alpha-beta souptol (ABS). Process engineers assigned to work with the development group have pieced together a continuous process for making ABS in commercial quantities and have tested key parts of it. This work involved hundreds of block flow diagrams, some more complex than others. Based on information derived from these block flow diagrams, a decision was made to proceed with this process.

A process engineering team from ABC’s central office carries out the detailed process calculations, material and energy balances, equipment sizing, etc. Working with their drafting department, they produced a series of PFDs (Process Flow Diagrams) for the process. As problems arise and are solved, the team may revise and redraw the PFDs. Often the work requires several rounds of drawing, checking, and revising.

Specialists in distillation, process control, kinetics, and heat transfer are brought in to help the process team in key areas. Some are company employees and others are consultants.

Since ABC is only a moderate-sized company, it does not have sufficient staff to prepare the 120 P&IDs (Piping and Instrumentation Diagrams) needed for the new ABS plant. ABC hires a well-known engineering and construction firm (E&C Company), DEFCo, to do this work for them. The company assigns two of the ABC process teams to work at DEFCo to coordinate the job. DEFCo’s process engineers, specialists, and drafting department prepare the P&IDs. They do much of the detailed engineering (pipe sizes, valve specifications, etc.) as well as developing the necessary computer aided design (CAD) and process drawings. The job may take two to six months. Every drawing is reviewed by DEFCo’s project team and by ABC’s team. If there are disagreements, the engineers and specialists from the companies must resolve them.

Finally, all the PFDs and the P&IDs are completed and approved. ABC can now go ahead with the construction. They may extend their contract with DEFCo to include this phase, or they may go out for construction bids from a number of other companies.

This narrative describes a typical sequence of events taking a project from its initial stages through plant construction. If DEFCo had carried out the construction, ABC could go ahead and take over the plant or DEFCo could be contracted to carry out the start-up and to commission the plant. Once satisfactory performance specifications have been met, ABC would take over the operation of the plant and commercial production would begin.

From conception of the process to the time the plant starts up, two or more years will have elapsed and millions of dollars will have been spent with no revenue from the plant. The plant must operate successfully for many years to produce sufficient income to pay for all plant operations and to repay the costs associated with designing and building the plant. During this operating period, many unforeseen changes are likely to take place. The quality of the raw materials used by the plant may change, product specifications may be raised, production rates may need to be increased, the equipment performance will decrease because of wear, the development of new and better catalysts will occur, the costs of utilities will change, new environmental regulations may be introduced, or improved equipment may appear on the market.

As a result of these unplanned changes, plant operations must be modified. Although the operating information on the original process diagrams remains informative, the actual performance taken from the operating plant will be different. The current operating conditions will appear on updated versions of the various process diagrams, which will act as a primary basis for understanding the changes taking place in the plant. These process diagrams are essential to an engineer who has been asked to diagnose operating problems, solve problems in operations, debottleneck systems for increased capacity, and predict the effects of making changes in operating conditions. All these activities are essential in order to maintain profitable plant operation.

In this chapter, the focus is on three diagrams that are important to chemical engineers: block flow, process flow, and piping and instrumentation diagrams. Of these three diagrams, the most useful to chemical engineers is the PFD. The understanding of the PFD represents a central goal of this textbook.

1.1 Block Flow Diagram (BFD)

Block flow diagrams are introduced early in the chemical engineering curriculum. For example, in the first course in material and energy balances, often an initial step is to convert a word problem into a simple block diagram. This diagram consists of a series of blocks representing different equipment or unit operations that are connected by input and output streams. Important information such as operating temperatures, pressures, conversions, and yield are included on the diagram along with flowrates and some chemical compositions. However, the diagram does not include any details of equipment within any of the blocks.

The block flow diagram can take one of two forms. First, a block flow diagram may be drawn for a single process. Alternatively, a block flow diagram may be drawn for a complete chemical complex involving many different chemical processes. These two types of diagrams are differentiated by calling the first a block flow process diagram and the second a block flow plant diagram.

1.1.1 Block Flow Process Diagram

An example of a block flow process diagram is shown in Figure 1.1, and the illustrated process is described below.

Toluene and hydrogen are converted in a reactor to produce benzene and methane. The reaction does not go to completion, and excess toluene is required. The noncondensable gases are separated and discharged. The benzene product and the unreacted toluene are then separated by distillation. The toluene is then recycled back to the reactor and the benzene removed in the product stream.

This block flow diagram gives a clear overview of the production of benzene, unobstructed by the many details related to the process. Each block in the diagram represents a process function and may, in reality, consist of several pieces of equipment. The general format and conventions used in preparing block flow process diagrams are presented in Table 1.1.

Table 1.1 Conventions and Format Recommended for Laying Out a Block Flow Process Diagram

|

Although much information is missing from Figure 1.1, it is clear that such a diagram is very useful for “developing a feel” for the process. Block flow process diagrams often form the starting point for developing a PFD. They are also very helpful in conceptualizing new processes and explaining the main features of the process without getting bogged down in the details.

1.1.2 Block Flow Plant Diagram

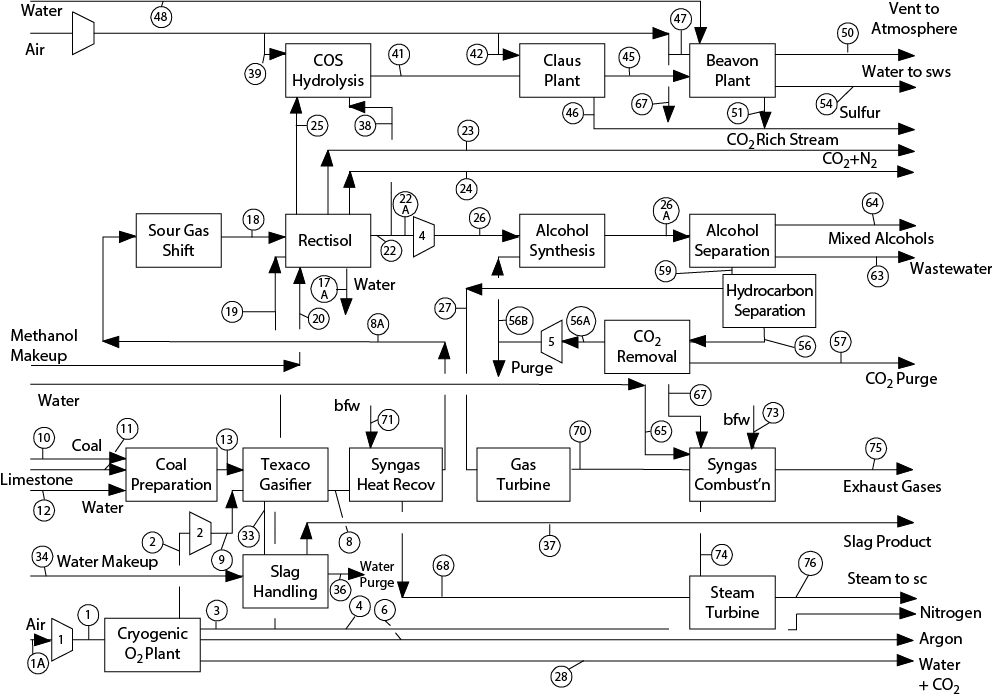

An example of a block flow plant diagram for a complete chemical complex is illustrated in Figure 1.2. This block flow plant diagram is for a coal to higher alcohol fuels plant. Clearly, this is a complicated process in which there are a number of alcohol fuel products produced from a feedstock of coal. Each block in this diagram represents a complete chemical process (compressors and turbines are also shown as trapezoids), and a block flow process diagram could be drawn for each block in Figure 1.2. The advantage of a diagram such as Figure 1.2 is that it allows a complete picture to be obtained of what this plant does and how all the different processes interact. On the other hand, in order to keep the diagram relatively uncluttered, only limited information is available about each process unit. The conventions for drawing block flow plant diagrams are similar to Table 1.1.

Both types of block flow diagrams are useful for explaining the overall operation of chemical plants. For example, consider that you have just joined a large chemical manufacturing company that produces a wide range of chemical products from the site to which you have been assigned. You would most likely be given a block flow plant diagram to orient you to the products and important areas of operation. Once assigned to one of these areas, you would again likely be provided with a block flow process diagram describing the operations in your particular area.

In addition to the orientation function described earlier, block flow diagrams are used to sketch out and screen potential process alternatives. Thus, they are used to convey information necessary to make early comparisons and eliminate competing alternatives without having to make detailed and costly comparisons.

1.2 Process Flow Diagram (PFD)

The process flow diagram (PFD) represents a quantum step up from the BFD in terms of the amount of information that it contains. The PFD contains the bulk of the chemical engineering data necessary for the design of a chemical process. For all of the diagrams discussed in this chapter, there are no universally accepted standards. The PFD from one company will probably contain slightly different information from the PFD for the same process from another company. Having made this point, it is fair to say that most PFDs convey very similar information. A typical commercial PFD will contain the following information:

All the major pieces of equipment in the process will be represented on the diagram along with a description of the equipment. Each piece of equipment will have a unique equipment number and a descriptive name.

All process flow streams will be shown and identified by a number. A description of the process conditions and chemical composition of each stream will be included. These data will be either displayed directly on the PFD or included in an accompanying flow summary table.

All utility streams supplied to major equipment that provide a process function will be shown.

Basic control loops, illustrating the control strategy used to operate the process during normal operations, will be shown.

It is clear that the PFD is a more complex diagram than a BFD requiring a substantial effort to prepare. It is essential that it should remain uncluttered and be easy to follow, to avoid errors in presentation and interpretation. Often PFDs are drawn on large sheets of paper (for example, size D: 24 in × 36 in), and several connected sheets may be required for a complex process. Because of the page size limitations associated with this text, complete PFDs cannot be presented here. Consequently, certain liberties have been taken in the presentation of the PFDs in this text. Specifically, certain information will be presented in accompanying tables, and only the essential process information will be included on the PFD. The resulting PFDs will retain clarity of presentation, but the reader must refer to the flow summary and equipment summary tables in order to extract all the required information about the process.

Before the various aspects of the PFD are discussed, it should be noted that the PFD and the process that is described in this chapter will be used throughout the book. The process is the hydrodealkylation of toluene to produce benzene. This is a well-studied and well-understood commercial process still used today. The PFD presented in this chapter for this process is technically feasible but is in no way optimized. In fact, many improvements to the process technology and economic performance can be made. Many of these improvements will become evident when the appropriate material is presented. This allows the techniques provided throughout this text to be applied both to identify technical and economic problems in the process and to make the necessary process improvements. Therefore, throughout the text, weak spots in the design, potential improvements, and a path toward an optimized process flow diagram will be identified.

The basic information provided by a PFD can be categorized into one of the following:

Process topology

Stream information

Equipment information

Each aspect of the PFD will be considered separately. After each of the three topics has been addressed, all the information will be gathered and presented in the form of a PFD for the benzene process.

1.2.1 Process Topology

Figure 1.3 is a skeleton process flow diagram for the production of benzene (see also the block flow process diagram in Figure 1.1). This skeleton diagram illustrates the location of the major pieces of equipment and the connections that the process streams make between equipment. The location of and interaction between equipment and process streams are referred to as the process topology.

Figure 1.3 Skeleton Process Flow Diagram (PFD) for the Production of Benzene via the Hydrodealkylation of Toluene

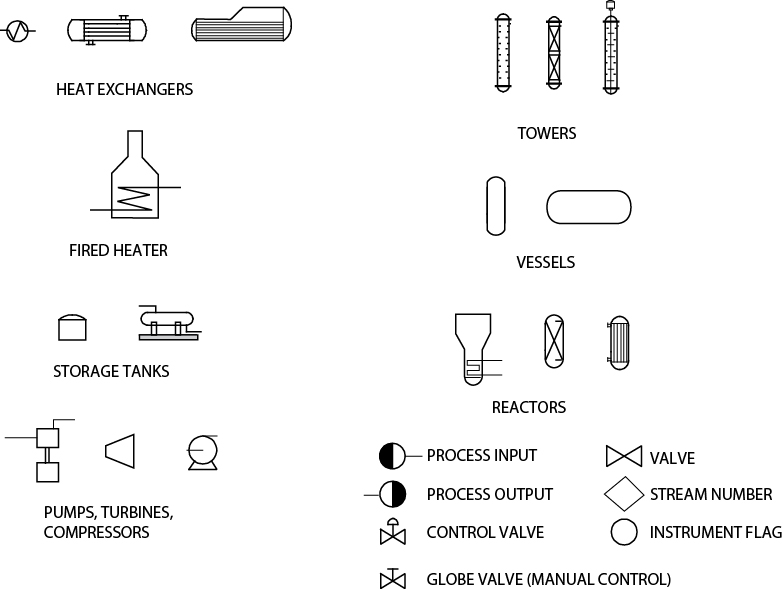

Equipment is represented symbolically by “icons” that identify specific unit operations. Although the American Society of Mechanical Engineers (ASME) [2] publishes a set of symbols to use in preparing flowsheets, it is common for companies to use in-house symbols. A comprehensive set of symbols is also given by Austin [3]. Whatever set of symbols is used, there is seldom a problem in identifying the operation represented by each icon. Figure 1.4 contains a list of the symbols used in process diagrams presented in this text. This list covers more than 90% of those needed in fluid (gas or liquid) processes.

Figure 1.3 shows that each major piece of process equipment is identified by a number on the diagram. A list of the equipment numbers along with a brief descriptive name for the equipment is printed along the top of the diagram. The location of these equipment numbers and names roughly corresponds to the horizontal location of the corresponding piece of equipment. The convention for formatting and identifying the process equipment is given in Table 1.2. This table provides the information necessary for the identification of the process equipment icons shown in a PFD. As an example of how to use this information, consider the unit operation P-101A/B and what each number or letter means.

P-101A/B identifies the equipment as a pump.

P-101A/B indicates that the pump is located in area 100 of the plant.

P-101A/B indicates that this specific pump is number 01 in unit 100.

P-101A/B indicates that a backup pump is installed. Thus, there are two identical pumps, P-101A and P-101B. One pump will be operating while the other is idle.

Table 1.2 Conventions Used for Identifying Process Equipment

General Format XX-YZZ A/B |

XX are the identification letters for the equipment classification C – Compressor or Turbine E – Heat Exchanger H – Fired Heater P – Pump R – Reactor T – Tower TK – Storage Tank V – Vessel Y designates an area within the plant ZZ is the number designation for each item in an equipment class A/B identifies parallel units or backup units not shown on a PFD Additional description of equipment is given on top of PFD |

The 100 area designation will be used for the benzene process throughout this text. Other processes presented in the text will carry other area designations. Along the top of the PFD, each piece of process equipment is assigned a descriptive name. From Figure 1.3 it can be seen that Pump P-101 is called the “toluene feed pump.” This name will be commonly used in discussions about the process and is synonymous with P-101.

During the life of the plant, many modifications will be made to the process; often it will be necessary to replace or eliminate process equipment. When a piece of equipment wears out and is replaced by a new unit that provides essentially the same process function as the old unit, then it is not uncommon for the new piece of equipment to inherit the old equipment’s name and number (often an additional letter suffix will be used, e.g., H-101 might become H-101A). On the other hand, if a significant process modification takes place, then it is usual to use new equipment numbers and names. The key point here is that when an engineer looks for information about a piece of equipment there should be no ambiguity. For example, if they find data on a piece of equipment named E-103 then there should be no confusion to what heat exchanger this documentation refers. If the original E-103 had been replaced with a different exchanger also designated E-103 then clearly a lot of confusion, wasted time, and potential safety issues could result by using the data for the old exchanger to modify and/or evaluate the new exchanger. Example 1.1, taken from Figure 1.3, illustrates this concept.

Operators report frequent problems with E-102, which are to be investigated. The PFD for the plant’s 100 area is reviewed, and E-102 is identified as the “Reactor Effluent Cooler.” The process stream entering the cooler is a mixture of condensable and noncondensable gases at 654°C that are partially condensed to form a two-phase mixture. The coolant is water at 30°C. These conditions characterize a complex heat transfer problem. In addition, operators have noticed that the pressure drop across E-102 fluctuates wildly at certain times, making control of the process difficult. Because of the frequent problems with this exchanger, it is recommended that E-102 be replaced by two separate heat exchangers. The first exchanger cools the effluent gas and generates steam needed in the plant. The second exchanger uses cooling water to reach the desired exit temperature of 38°C. These exchangers are to be designated as E-107 (reactor effluent boiler) and E-108 (reactor effluent condenser).

In reviewing Example 1.1, the E-102 designation is retired and not reassigned to the new equipment. There can be no mistake that E-107 and E-108 are new units in this process and that E-102 no longer exists.

1.2.2 Stream Information

Referring back to Figure 1.3, it can be seen that each of the process streams is identified by a number in a diamond box located on the stream. The direction of the stream is identified by one or more arrowheads. The process stream numbers are used to identify streams on the PFD, and the type of information that is typically given for each stream is discussed in the next section.

Also identified in Figure 1.3 are utility streams. Utilities are needed services that are available at the plant. Chemical plants are provided with a range of central utilities that include electricity, compressed air, cooling water, refrigerated water, steam, condensate return, inert gas for blanketing, chemical sewer, wastewater treatment, and flares. A list of the common services is given in Table 1.3, which also provides a guide for the identification of process streams.

Table 1.3 Conventions for Identifying Process and Utility Streams

Process Streams |

|

All conventions shown in Table 1.1 apply. Diamond symbol located in flow lines. Numerical identification (unique for that stream) inserted in diamond. Flow direction shown by arrows on flow lines. |

|

Utility Streams |

|

lps |

Low-Pressure Steam: 3–5 barg (sat)* |

mps |

Medium-Pressure Steam: 10–15 barg (sat)* |

hps |

High-Pressure Steam: 40–50 barg (sat)* |

htm |

Heat Transfer Media (Organic): to 400°C |

cw |

Cooling Water: From Cooling Tower 30°C Returned at Less than 45°C† |

wr |

River Water: From River 25°C Returned at Less than 35°C |

rw |

Refrigerated Water: In at 5°C Returned at Less than 15°C |

rb |

Refrigerated Brine: In at −45°C Returned at Less than 0°C |

cs |

Chemical Wastewater with High COD |

ss |

Sanitary Wastewater with High BOD, etc. |

el |

Electric Heat (Specify 220, 440, 660V Service) |

bfw |

Boiler Feed Water |

ng |

Natural Gas |

fg |

Fuel Gas |

fo |

Fuel Oil |

fw |

Fire Water |

*These pressures are set during the preliminary design stages and typical values vary within the ranges shown. †Above 45°C, significant scaling occurs and the usual return temperature is 40°C. |

|

Each utility is identified by the initials provided in Table 1.3. As an example, locate E-102 in Figure 1.3. The notation, cw, associated with the nonprocess stream flowing into E-102 indicates that cooling water is used as a coolant.

Electricity used to power motors and generators is an additional utility that is not identified directly on the PFD or in Table 1.3 but is treated separately. Most of the utilities shown are related to equipment that adds or removes heat within the process in order to control temperatures. This is common for most chemical processes.

From the PFD in Figure 1.3, the identification of the process streams is clear. For small diagrams containing only a few operations, the characteristics of the streams such as temperatures, pressures, compositions, and flowrates can be shown directly on the figure, adjacent to the stream. This is not practical for a more complex diagram. In this case, only the stream number is provided on the diagram. This indexes the stream to information on a flow summary or stream table, which is often provided below the process flow diagram. In this text the flow summary table is provided as a separate attachment to the PFD.

The stream information that is normally given in a flow summary table is given in Table 1.4. It is divided into two groups—required information and optional information—that may be important to specific processes. The flow summary table, for Figure 1.3, is given in Table 1.5 and contains all the required information listed in Table 1.4.

Table 1.4 Information Provided in a Flow Summary

Required Information |

Stream Number Temperature (°C) Pressure (bar) Vapor Fraction Total Mass Flowrate (kg/h) Total Mole Flowrate (kmol/h) Individual Component Flowrates (kmol/h) |

Optional Information |

Component Mole Fractions Component Mass Fractions Individual Component Flowrates (kg/h) Volumetric Flowrates (m3/h) Significant Physical Properties Density Viscosity Other Thermodynamic Data Heat Capacity Stream Enthalpy K-values Stream Name |

Table 1.5 Flow Summary Table for the Benzene Process Shown in Figure 1.3 (and Figure 1.5)

Stream Number |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

13 |

14 |

15 |

16 |

17 |

18 |

19 |

Temperature (°C) |

25 |

59 |

25 |

225 |

41 |

600 |

41 |

38 |

654 |

90 |

147 |

112 |

112 |

112 |

38 |

38 |

38 |

38 |

112 |

Pressure (bar) |

1.90 |

25.8 |

25.5 |

25.2 |

25.5 |

25.0 |

25.5 |

23.9 |

24.0 |

2.6 |

2.8 |

3.3 |

2.5 |

3.3 |

2.3 |

2.5 |

2.8 |

2.9 |

2.5 |

Vapor Fraction |

0.0 |

0.0 |

1.00 |

1.0 |

1.0 |

1.0 |

1.0 |

1.0 |

1.0 |

0.0 |

0.0 |

0.0 |

1.0 |

0.0 |

0.0 |

1.0 |

1.0 |

0.0 |

1.0 |

Mass Flow (tonne/h) |

10.0 |

13.3 |

0.82 |

20.5 |

6.41 |

20.5 |

0.36 |

9.2 |

20.9 |

11.6 |

3.27 |

14.5 |

22.7 |

22.7 |

8.21 |

2.61 |

0.07 |

11.5 |

0.01 |

Mole Flow (kmol/h) |

108.7 |

144.2 |

301.0 |

1204.4 |

758.8 |

1204.4 |

42.6 |

1100.8 |

1247.0 |

142.2 |

35.7 |

185.2 |

291.6 |

290.7 |

105.6 |

304.2 |

4.06 |

142.2 |

0.90 |

Component Flowrates (kmol/h) |

|

|

|

|

|

|

|

|

|

||||||||||

Hydrogen |

0.0 |

0.0 |

286.0 |

735.4 |

449.4 |

735.4 |

25.2 |

651.9 |

652.6 |

0.02 |

0.0 |

0.0 |

0.02 |

0.0 |

0.0 |

178.0 |

0.67 |

0.02 |

0.02 |

Methane |

0.0 |

0.0 |

15.0 |

317.3 |

302.2 |

317.3 |

16.95 |

438.3 |

442.3 |

0.88 |

0.0 |

0.0 |

0.88 |

0.0 |

0.0 |

123.05 |

3.10 |

0.88 |

0.88 |

Benzene |

0.0 |

1.0 |

0.0 |

7.6 |

6.6 |

7.6 |

0.37 |

9.55 |

116.0 |

106.3 |

1.1 |

184.3 |

289.46 |

289.46 |

105.2 |

2.85 |

0.26 |

106.3 |

0.0 |

Toluene |

108.7 |

143.2 |

0.0 |

144.0 |

0.7 |

144.0 |

0.04 |

1.05 |

36.0 |

35.0 |

34.6 |

0.88 |

1.22 |

1.22 |

0.4 |

0.31 |

0.03 |

35.0 |

0.0 |

With information from the PFD (Figure 1.3) and the flow summary table (Table 1.5), problems regarding material balances and other problems are easily analyzed. Examples 1.2 and 1.3 are provided to offer experience in working with information from the PFD.

Check the overall material balance for the benzene process shown in Figure 1.3.

Solution

From the figure, identify the input streams as Stream 1 (toluene feed) and Stream 3 (hydrogen feed) and the output streams as Stream 15 (product benzene) and Stream 16 (fuel gas). From the flow summary table, these flows are listed as (units are in (103 kg)/h):

Input: |

|

Output: |

||

Stream 3 Stream 1 Total |

0.82 10.00 10.82 × 103 kg/h |

|

Stream 15 Stream 16 Total |

8.21 2.61 10.82 × 103 kg/h |

This confirms that the overall material balance is achieved.

Determine the conversion per pass of toluene to benzene in R-101 in Figure 1.3.

Solution

Conversion is defined as

X = (benzene produced in reactor)/(total toluene fed to reactor)

From the PFD, the input streams to R-101 are shown as Stream 6 (reactor feed) and Stream 7 (recycle gas quench), and the output stream is Stream 9 (reactor effluent stream). From the information in Table 1.5 (units are kmol/h):

Toluene fed to reactor = 144 (Stream 6) + 0.04 (Stream 7) = 144.04 kmol/h

Benzene produced in reactor = 116 (Stream 9) – 7.6 (Stream 6) – 0.37 (Stream 7) = 108.03 kmol/h

X = 108.03/144.04 = 0.75

Alternatively, the following can be written:

Moles of benzene produced in reactor = Toluene in – Toluene out = 144.04 – 36.00 = 108.04 kmol/h

X = 108.04/144.04 = 0.75

1.2.3 Equipment Information

The final element of the PFD is the equipment summary. This summary provides the information necessary to estimate the purchase costs of equipment and furnish the basis for the detailed design of equipment. Table 1.6 provides the information needed for the equipment summary for most of the equipment encountered in fluid processes.

Table 1.6 Equipment Descriptions for PFD and P&IDs

Equipment Type |

Description of Equipment |

Towers |

Size (height and diameter), Pressure, Temperature Number and Type of Trays Height and Type of Packing Materials of Construction |

Heat Exchangers |

Type: Gas-Gas, Gas-Liquid, Liquid-Liquid, Condenser, Vaporizer Process: Duty, Area, Temperature, and Pressure for Both Streams Number of Shell and Tube Passes Materials of Construction: Tubes and Shell |

Tanks and Vessels |

Height, Diameter, Orientation, Pressure, Temperature, Materials of Construction |

Pumps |

Flow, Discharge Pressure, Temperature, ΔP, Driver Type, Shaft Power, Materials of Construction |

Compressors |

Actual Inlet Flowrate, Temperature, Pressure Inlet and Outlet, Driver Type, Shaft Power, Materials of Construction |

Heaters (Fired) |

Type, Tube Pressure, Tube Temperature, Duty, Fuel, Material of Construction |

Other |

Provide Critical Information |

The information presented in Table 1.6 is used in preparing the equipment summary portion of the PFD for the benzene process. The equipment summary for the benzene process is presented in Table 1.7, and details of how to estimate and choose various equipment parameters are discussed in Chapter 11.

Table 1.7 Equipment Summary for Toluene Hydrodealkylation PFD

Heat Exchangers |

E-101 |

E-102 |

E-103 |

E-104 |

E-105 |

E-106 |

||

Type |

Fl.H. |

Fl.H. |

MDP |

Fl.H. |

MDP |

Fl.H. |

||

Area (m2) |

36 |

763 |

11 |

35 |

12 |

80 |

||

Duty (MJ/h) |

15,190 |

46,660 |

1055 |

8335 |

1085 |

9045 |

||

Shell |

||||||||

Temp. (°C) |

225 |

654 |

160 |

112 |

112 |

185 |

||

Pres. (bar) |

26 |

24 |

6 |

3 |

3 |

11 |

||

Phase |

Vap. |

Par. Cond. |

Cond. |

Cond. |

l |

Cond. |

||

MOC |

316SS |

316SS |

CS |

CS |

CS |

CS |

||

Tube |

||||||||

Temp. (°C) |

258 |

40 |

90 |

40 |

40 |

147 |

||

Pres. (bar) |

42 |

3 |

3 |

3 |

3 |

3 |

||

Phase |

Cond. |

l |

l |

l |

l |

Vap. |

||

MOC |

316SS |

316SS |

CS |

CS |

CS |

CS |

||

Vessels/Tower/Reactors |

V-101 |

V-102 |

V-103 |

V-104 |

T-101 |

R-101 |

||

Temperature (°C) |

55 |

38 |

38 |

112 |

147 |

660 |

||

Pressure (bar) |

2.0 |

24 |

3.0 |

2.5 |

3.0 |

25 |

||

Orientation |

Horizontal |

Vertical |

Vertical |

Horizontal |

Vertical |

Vertical |

||

MOC |

CS |

CS |

CS |

CS |

CS |

316SS |

||

Size |

||||||||

Height/Length (m) |

5.9 |

3.5 |

3.5 |

3.9 |

29 |

14.2 |

||

Diameter (m) |

1.9 |

1.1 |

1.1 |

1.3 |

1.5 |

2.3 |

||

Internals |

|

s.p. |

s.p. |

|

42 sieve trays 316SS |

Catalyst packed bed-10m |

||

Pumps/Compressors |

P-101 (A/B) |

P-102 (A/B) |

C-101 (A/B) |

Heater |

|

H-101 |

||

Flow (kg/h) |

13,000 |

22,700 |

6770 |

Type |

|

Fired |

||

Fluid Density (kg/m3) |

870 |

880 |

8.02 |

MOC |

|

316SS |

||

Power (shaft) (kW) |

14.2 |

3.2 |

49.1 |

Duty (MJ/h) |

|

27,040 |

||

Type/Drive |

Recip./Electric |

Centrf./Electric |

Centrf./Electric |

Radiant Area (m2) |

106.8 |

|||

Efficiency (Fluid Power/Shaft Power) |

0.75 |

0.50 |

0.75 |

Convective Area (m2) |

320.2 |

|||

Pumps/Compressors |

P-101 (A/B) |

P-102 (A/B) |

C-101 (A/B) |

Heater |

|

H-101 |

||

MOC |

CS |

CS |

CS |

Tube P (bar) |

|

26.0 |

||

Temp. (in) (°C) |

55 |

112 |

38 |

|

|

|

||

Pres. (in) (bar) |

1.2 |

2.2 |

23.9 |

|

|

|

||

Pres. (out) (bar) |

27.0 |

4.4 |

25.5 |

|

|

|

||

Key: |

|

|

|

|

|

|||

MOC 316SS CS Vap Cond Recipr. Centrf. |

Materials of construction Stainless steel type 316 Carbon steel Stream being vaporized Stream being condensed Reciprocating Centrifugal |

Par F.H. Fl.H. Rbl s.p. l MDP |

Partial Fixed head Floating head Reboiler Splash plate Liquid Multiple double pipe |

|||||

1.2.4 Combining Topology, Stream Data, and Control Strategy to Give a PFD

Up to this point, the amount of process information displayed on the PFD has been kept to a minimum. A more representative example of a PFD for the benzene process is shown in Figure 1.5. This diagram includes all of the elements found in Figure 1.3, some of the information found in Table 1.5, plus additional information on the major control loops used in the process.

Figure 1.5 Benzene Process Flow Diagram (PFD) for the Production of Benzene via the Hydrodealkylation of Toluene

Stream information may be added to the diagram by attaching “information flags.” The shape of the flags indicates the specific information provided on the flag. Figure 1.6 illustrates all the flags used in this text. These information flags play a dual role. They provide information needed in the plant design leading to plant construction and in the analysis of operating problems during the life of the plant. Flags are mounted on a staff connected to the appropriate process stream. More than one flag may be mounted on a staff. Example 1.4 illustrates the different information displayed on the PFD.

Locate Stream 1 in Figure 1.5 and note that immediately following the stream identification diamond a staff is affixed. This staff carries three flags containing the following stream data:

Temperature of 25°C

Pressure of 1.9 bar

Mass flowrate of 10.0 × 103 kg/h

The units for each process variable are indicated in the key provided at the left-hand side of Figure 1.5.

With the addition of the process control loops and the information flags, the PFD starts to become cluttered. Therefore, in order to preserve clarity, it is necessary to limit what data are presented with these information flags. Fortunately, flags on a PFD are easy to add, remove, and change, and even temporary flags may be provided from time to time.

The information provided on the flags is also included in the flow summary table. However, often it is far more convenient when analyzing the PFD to have certain data directly on the diagram.

Not all process information is of equal importance. General guidelines for what data should be included in information flags on the PFD are difficult to define. However, at a minimum, information critical to the safety and operation of the plant should be given. This includes temperatures and pressures associated with the reactor, flowrates of feed and product streams, and stream pressures and temperatures that are substantially higher than the rest of the process. Additional needs are process specific. Examples 1.5–1.7 illustrate where and why information should be included directly on a PFD.

Acrylic acid is temperature sensitive and polymerizes at 90°C when present in high concentration. It is separated by distillation and leaves from the bottom of the tower. In this case, a temperature and pressure flag would be provided for the stream leaving the reboiler.

In the benzene process, Figure 1.5, the feed to the reactor is substantially hotter than to the rest of the equipment and is crucial to the operation of the process. In addition, the reaction is exothermic, and the reactor effluent temperature must be carefully monitored. For this reason Stream 6 (entering) and Stream 9 (leaving) have temperature flags.

The pressures of the streams to and from R-101 in the benzene process are also important. The difference in pressure between the two streams gives the pressure drop across the reactor. This, in turn, gives an indication of any maldistribution of gas through the catalyst beds. For this reason, pressure flags are also included on Streams 6 and 9 in Figure 1.5.

Of secondary importance is the fact that flags are useful in reducing the size of the flow summary table. For pumps, compressors, and heat exchangers, the mass flows are the same for the input and output streams, and complete entries in the stream table are not necessary. If the input (or output) stream is included in the stream table, and a flag is added to provide the temperature (in the case of a heat exchanger) or the pressure (in the case of a pump) for the exit stream, then there is no need to present this stream in the flow summary table. Example 1.8 illustrates this point.

Follow Stream 13 leaving the top of the benzene column in the benzene PFD given in Figure 1.5 and in Table 1.5. This stream passes through the benzene condenser, E-104, into the reflux drum, V-104. The majority of this stream then flows into the reflux pump, P-102, and leaves as Stream 14, while the remaining noncondensables leave the reflux drum in Stream 19. The mass flowrate and component flowrates of all these streams are given in Table 1.5. The stream leaving E-104 is not included in the stream table. Instead, a flag giving the temperature (112°C) is provided on the diagram (indicating condensation without subcooling). An additional flag, showing the pressure following the pump, is also shown. In this case the entry for Stream 14 could be omitted from the stream table, because it is simply the sum of Streams 12 and 15, and no information would be lost.

More information could be included in Figure 1.5 had space for the diagram not been limited by text format. It is most important that the PFD remain uncluttered and easy to follow in order to avoid errors and misunderstandings. Adding additional material to Figure 1.5 risks sacrificing clarity.

The flow table presented in Table 1.5, the equipment summary presented in Table 1.7, and Figure 1.5 taken together constitute all the information contained on a commercially produced PFD.

The PFD is the first comprehensive diagram drawn for any new plant or process. It provides all of the information needed to understand the chemical process. In addition, sufficient information is given on the equipment, energy, and material balances to establish process control protocol and to prepare cost estimates to determine the economic viability of the process.

Many additional drawings are needed to build the plant. However, all the process information required can be taken from this PFD. As described in the narrative at the beginning of this chapter, the development of the PFD is most often carried out by the operating company. Subsequent activities in the design of the plant are often contracted out.

The value of the PFD does not end with the construction of the plant. It remains the document that best describes the process, and it is used in the training of operators and new engineers. It is consulted regularly to diagnose operating problems that arise and to predict the effects of changes on the process. Finally as changes are made to the process the PFD is updated to reflect the current operating conditions and process performance.

1.3 Piping and Instrumentation Diagram (P&ID)

The piping and instrumentation diagram (P&ID), also known as the mechanical flow diagram (MFD), provides information needed by engineers to begin planning for the construction of the plant. The P&ID includes every mechanical aspect of the plant except the information given in Table 1.8. The general conventions used in drawing P&IDs are given in Table 1.9.

Table 1.8 Exclusions from Piping and Instrumentation Diagram

|

Table 1.9 Conventions in Constructing Piping and Instrumentation Diagrams

For Equipment—Show Every Piece Including |

Spare Units Parallel Units Summary Details of Each Unit |

For Piping—Include All Lines Including Drains and Sample Connections, and Specify |

Size (Use Standard Sizes) Schedule (Thickness) Materials of Construction Insulation (Thickness and Type) |

For Instruments—Identify |

Indicators Recorders Controllers Show Instrument Lines |

For Utilities—Identify |

Entrance Utilities Exit Utilities Exit to Waste Treatment Facilities |

Each PFD will require many P&IDs to display all the necessary data. Figure 1.7 is a representative P&ID for the distillation section of the benzene process shown in Figure 1.5. The P&ID presented in Figure 1.7 provides information on the piping, and this is included as part of the diagram. As an alternative, each pipe can be numbered, and the specifics of every pipe/line can be provided in a separate table accompanying this diagram. When possible, the physical size of the larger-sized equipment is reflected by the size of the symbol in the diagram.

Figure 1.7 Piping and Instrumentation Diagram for Benzene Distillation (adapted from Kauffman, D., Flow Sheets and Diagrams, AIChE Modular Instruction, Series G: Design of Equipment, series editor J. Beckman, AIChE, New York, 1986, vol. 1, Chapter G.1.5, AIChE copyright © 1986 AIChE, all rights reserved)

Utility connections are identified by a numbered box in the P&ID. The number within the box identifies the specific utility. The key identifying the utility connections is shown in a table on the P&ID.

All process information that can be measured in the plant is shown on the P&ID by circular flags. This includes the information to be recorded and used in process control loops. The circular flags on the diagram indicate where the information is obtained in the process and identify the measurements taken and how the information is used. Table 1.10 summarizes the conventions used to identify information related to instrumentation and control. Example 1.9 illustrates the interpretation of instrumentation and control symbols.

Table 1.10 Conventions Used for Identifying Instrumentation on P&IDs (ISA standard ISA-S5-1, [4])

Location of Instrumentation |

||||

|

Instrument Located in Plant |

|||

|

Instrument Located on Front of Panel in Control Room |

|||

|

Instrument Located on Back of Panel in Control Room |

|||

Meanings of Identification Letters |

||||

|

|

First Letter (X) |

Second or Third Letter (Y) |

|

|

A |

Analysis |

Alarm |

|

|

B |

Burner Flame |

|

|

|

C |

Conductivity |

Control |

|

|

D |

Density or Specific Gravity |

|

|

|

E |

Voltage |

Element |

|

|

F |

Flowrate |

|

|

|

H |

Hand (Manually Initiated) |

High |

|

|

I |

Current |

Indicate |

|

|

J |

Power |

|

|

|

K |

Time or Time Schedule |

Control Station |

|

|

L |

Level |

Light or Low |

|

|

M |

Moisture or Humidity |

Middle or Intermediate |

|

|

O |

Orifice |

||

|

P |

Pressure or Vacuum |

Point |

|

|

Q |

Quantity or Event |

|

|

|

R |

Radioactivity or Ratio |

Record or print |

|

|

S |

Speed or Frequency |

Switch |

|

|

T |

Temperature |

Transmit |

|

|

V |

Viscosity |

Valve, Damper, or Louver |

|

|

W |

Weight |

Well |

|

|

Y |

Relay or Compute |

||

|

Z |

Position |

Drive |

|

|

Identification of Instrument Connections |

|||

____________ |

Capillary |

|||

|

Pneumatic |

|||

|

Electrical |

|||

Consider the benzene product line leaving the right-hand side of the P&ID in Figure 1.7. The flowrate of this stream is controlled by a control valve that receives a signal from a level measuring element placed on V-104. The sequence of instrumentation is as follows:

A level sensing element (LE) is located on the reflux drum V-104. A level transmitter (LT) also located on V-104 sends an electrical signal (designated by a dashed line) to a level indicator and controller (LIC). This LIC is located in the control room on the control panel or console (as indicated by the horizontal line under LIC) and can be observed by the operators. From the LIC, an electrical signal is sent to an instrument (LY) that computes the correct valve position and in turn sends a pneumatic signal (designated by a solid line with cross hatching) to activate the control valve (LCV). In order to warn operators of potential problems, two alarms are placed in the control room. These are a high-level alarm (LAH) and a low-level alarm (LAL), and they receive the same signal from the level transmitter as does the controller.

This control loop is also indicated on the PFD of Figure 1.5. However, the details of all the instrumentation are condensed into a single symbol (LIC), which adequately describes the essential process control function being performed. The control action that takes place is not described explicitly in either drawing. However, it is a simple matter to infer that if there is an increase in the level of liquid in V-104, the control valve will open slightly and the flow of benzene product will increase, tending to lower the level in V-104. For a decrease in the level of liquid, the valve will close slightly.

The details of the other control loops in Figures 1.5 and 1.7 are left to problems at the end of this chapter. It is worth mentioning that in virtually all cases of process control in chemical processes, the final control element is a valve. Thus, all control logic is based on the effect that a change in a given flowrate has on a given variable. The key to understanding the control logic is to identify which flowrate is being manipulated to control a given variable. Once this has been done, it is a relatively simple matter to see in which direction the valve should change in order to make the desired change in the control variable. The response time of the system and type of control action used—for example, proportional, integral, or differential—are left to the instrument engineers and are given in a typical process control course but are not covered in this text.

The final control element in nearly all chemical process control loops is a valve.

The generation of the final P&ID is one of the last stages of the design process and this diagram serves as a guide for those who will be responsible for the final design and construction. Based on this diagram,

Mechanical engineers and civil engineers will design and install the various pieces of process equipment.

Instrument engineers will specify, install, and check control systems.

Piping engineers will develop plant layout, piping isometrics, and elevation drawings.

Project engineers will develop plant and construction schedules.

Before final acceptance, the P&IDs serve as a checklist in the construction phase against which each item in the plant is checked.

The P&ID is also used to train operators. Once the plant is built and is operational, there are limits to what operators can do. About all that can be done to correct or alter performance of the plant is to open, close, or change the position of a valve. Part of the training would pose situations and require the operators to be able to describe what specific valve should be changed, how it should be changed, and what to observe in order to monitor the effects of the change. Plant simulators (similar to flight simulators) are often used in operator training. These programs are sophisticated, real-time process simulators that show a trainee operator how quickly changes in controlled variables propagate through the process. It is also possible for such programs to display scenarios of process upsets so that operators can receive training in recognizing and correcting such situations. These types of programs are very useful and cost-effective in initial operator training. However, the use of P&IDs is still very important in this regard.

The P&ID is particularly important for the development of start-up procedures when the plant is not under the influence of the installed process control systems. An example of a start-up procedure is given in Example 1.10.

Consider the start-up of the distillation column shown in Figure 1.7. What sequence would be followed?

Solution

The procedure is beyond the scope of this text, but it would be developed from a series of questions such as

What valve should be opened first?

What should be done when the temperature of...reaches...?

To what value should the controller be set?

When can the system be put on automatic control?

These last three sections have followed the development of a process from a simple BFD through the PFD and finally to the P&ID. Each step showed additional information. This can be seen by following the progress of the distillation unit as it moves through the three diagrams described.

Block Flow Diagram (BFD) (see Figure 1.1): The column was shown as a part of one of the three process blocks.

Process Flow Diagram (PFD) (see Figure 1.5): The column was shown as the following set of individual equipment: a tower, condenser, reflux drum, reboiler, reflux pumps, and associated process controls.

Piping and Instrumentation Diagram (P&ID) (see Figure 1.7): The column was shown as a comprehensive diagram that includes additional details such as pipe sizes, utility streams, sample taps, numerous indicators, and so on. It is the only unit operation on the diagram.

The value of these diagrams does not end with the start-up of the plant. The design values on the diagram are changed to represent the actual values determined under normal operating conditions. These conditions form a “base case” and are used to compare operations throughout the life of the plant.

1.4 Additional Diagrams

During the planning and construction phases of a new project, many additional diagrams are needed. Although these diagrams do not possess additional process information, they are essential to the successful completion of the project. Computers are being used more and more to do the tedious work associated with all of these drawing details. The creative work occurs through the development of the concepts provided in the BFD and the process development required to produce the PFD. The computer can help with the drawings but cannot create a new process. Computers are valuable in many aspects of the design process where the size of equipment to do a specific task is to be determined. Computers are also used when considering performance problems that deal with the operation of existing equipment. However, steady-state simulations are limited when dealing with diagnostic problems that are required throughout the life of the plant and operational experience is important in diagnosing problems within the process.

The diagrams presented here are in both American Engineering and SI units. The most noticeable exception is in the sizing of piping, where pipes are specified in inches and pipe schedule. This remains the way they are produced and purchased in the United States. A process engineer today must be comfortable with SI, conventional metric, and American (formerly British, who now use SI exclusively) Engineering units.

These additional diagrams are discussed briefly below.

A utility flowsheet may be provided that shows all the headers for utility inputs and outputs available along with the connections needed to the process. It provides information on the flows and characteristics of the utilities used by the plant. In particular, it is common to perform utility balances (steam balance, cooling water balance, etc.) in order to check the total utilities required and to ensure that the design of the facilities to produce the utilities are sized correctly.

Vessel sketches, logic ladder diagrams, wiring diagrams, site plans, structural support diagrams, and many other drawings are routinely used but add little to our understanding of the basic chemical processes that take place.

Additional drawings are necessary to locate all of the equipment in the plant. Plot plans and elevation diagrams are provided that locate the placement and elevation of all of the major pieces of equipment such as towers, vessels, pumps, heat exchangers, and so on. When constructing these drawings, it is necessary to consider and provide for access for repairing equipment, removing tube bundles from heat exchangers, replacement of units, and so on. What remains to be shown is the addition of the structural support and piping.

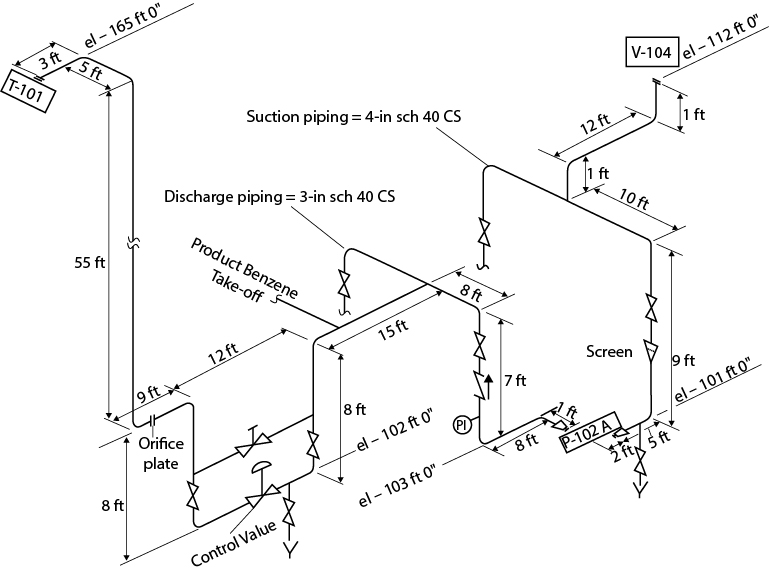

Piping isometrics are drawn for every piece of pipe required in the plant. These drawings are 3-D sketches of the pipe run, indicating the elevations and orientation of each section of pipe. An example of a piping isometric for the liquid return line from V-104 to T-101 is illustrated in Figure 1.8. Note that the drawing has all the information needed to estimate the frictional losses in the pipe at a given flowrate (see Chapter 19). In addition, there is enough information for a piping engineer/technician to construct and route the pipe through the plant. In the past, it was also common to build a scale model (prior to 1980) for comprehensive plants so the process could be viewed in three dimensions and modified to remove any potential problems. Over the past thirty or more years, scale models have been replaced by three-dimensional computer aided design (CAD) programs that are capable of representing the plant as-built in three dimensions. They provide an opportunity to view the local equipment topology from any angle at any location inside the plant. One can actually “walk through” the plant and preview what will be seen when the plant is built. The ability to “view” the plant before construction is made even more realistic with the development and implementation of virtual reality software. With this relatively new tool, it is possible for an avatar operated by an engineer to not only to walk through the plant but also to “touch” the equipment, turn valves, “climb” to the top of distillation columns, and so on. In the next section, the information needed to complete a preliminary plant layout design is reviewed, and the logic used to locate the process units in the plant and how the elevations of different equipment are determined are briefly explained.

Figure 1.8 Piping Isometric for the Liquid Line from the Overhead Reflux Drum (V-104) to the Distillation Tower (T-101)

1.5 Three-Dimensional Representation of a Process

As mentioned earlier, the major products of design work, both chemical and mechanical, are recorded on two-dimensional diagrams (PFD, P&ID, etc.). However, when it comes to the construction of the plant, there are many issues that require a three-dimensional representation of the process. For example, the location of shell-and-tube exchangers must allow for tube bundle removal for cleaning and repair. Locations of pumps must allow for access for maintenance and replacement. For compressors, this access may also require that a crane be able to remove and replace a damaged drive. Control valves must be located at elevations that allow operator access. Sample ports and instrumentation must also be located conveniently. For anyone who has toured a moderate-to-large chemical facility, the complexity of the piping and equipment layout is immediately apparent. Even for experienced engineers, the review of equipment and piping topology is far easier to accomplish in 3-D than 2-D. Due to the rapid increase in computer power and advanced software, such representations are now done routinely using the computer. In order to “build” an electronic representation of the plant in 3-D, all the information in the previously mentioned diagrams must be accessed and synthesized. This in itself is a daunting task, and a complete accounting of this process is well beyond the scope of this text. However, in order to give the reader a flavor of what can now be accomplished using such software, a brief review of the principles of plant layout design will be given. A more detailed account involving a virtual plant tour of the dimethyl ether (DME) plant (Appendix B.1) can be found on the website.

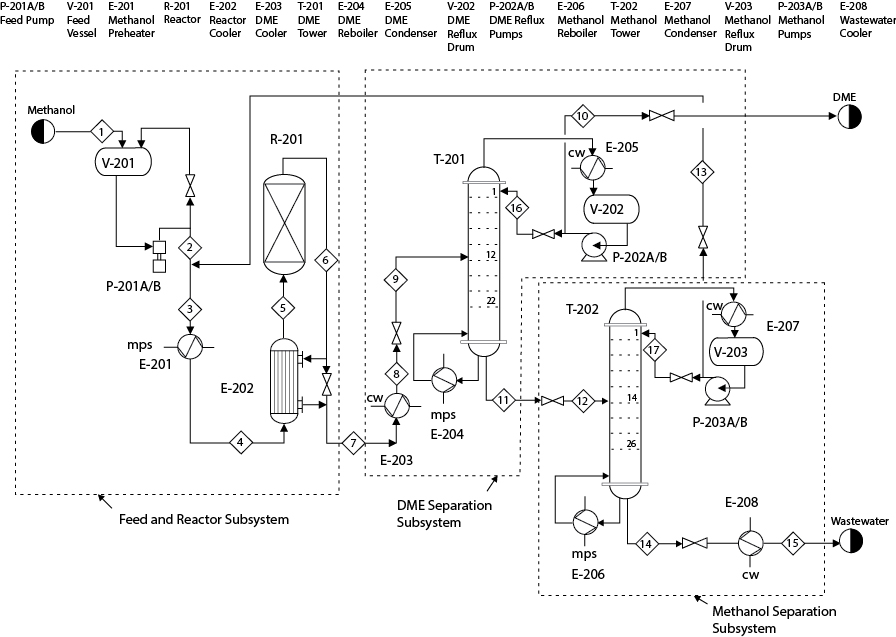

For a complete, detailed analysis of the plant layout, all equipment sizes, piping sizes, PFDs, P&IDs, and all other information should be known. However, for this description, a preliminary plant layout based on information given in the PFD for the DME process (Figure B.1.1) in Appendix B is considered. Using this figure and the accompanying stream tables and equipment summary table (Tables B.1.1 and B.1.3), the following steps are followed:

The PFD is divided into logical subsystems. For the DME process, there are three logical subsections, namely, the feed and reactor section, the DME purification section, and the methanol separation and recycle section. These sections are shown as dotted lines on Figure 1.9.

For each subsystem, a preliminary plot plan is created. The topology of the plot plan depends on many factors, the most important of which are discussed below.

In general, the layout of the plot plan can take one of two basic configurations: the grade-level, horizontal, in-line arrangement and the structure-mounted vertical arrangement [5]. The grade-level, horizontal, in-line arrangement will be used for the DME facility. In this arrangement, the process equipment units are aligned on either side of a pipe rack that runs through the middle of the process unit. The purpose of the pipe rack is to carry piping for utilities, product, and feed to and from the process unit. Equipment is located on either side of the pipe rack, which allows for easy access. In addition, vertical mounting of equipment is usually limited to a single level. This arrangement generally requires a larger “footprint” and, hence, more land than does the structure-mounted vertical arrangement. The general arrangement for these layout types is shown in Figure 1.10.

Figure 1.10 Different Types of Plant Layout: (a) Grade-Mounted, Horizontal, In-line Arrangement, and (b) Structure-Mounted Vertical Arrangement

(Source: Process Plant Layout and Piping Design, by E. Bausbacher and R. Hunt, © 1994, reprinted by permission of Pearson Education, Inc., Upper Saddle River, NJ)

The minimum spacing between equipment should be set early on in the design. These distances are set for safety purposes and should be set with both local and national codes in mind. A comprehensive list of the recommended minimum distances between process equipment is given by Bausbacher and Hunt [5]. The values for some basic process equipment are listed in Table 1.11.

Table 1.11 Recommended Minimum Spacing (in Feet) between Process Equipment for Refinery, Chemical, and Petrochemical Plants

Pumps

Compressors

Reactors

Towers and Vessels

Exchangers

Pumps

M

25

M

M

M

Compressors

M

30

M

M

Reactors

M

15

M

Towers

M

M

Exchangers

M

M = minimum for maintenance access

Source: Process Plant Layout and Piping Design, by E. Bausbacher and R. Hunt, © 1994, reprinted by permission of Pearson Education, Inc., Upper Saddle River, NJ

The sizing of process equipment should be completed and the approximate location on the plot plan determined. Referring to Table B.1.3 for equipment specifications gives some idea of key equipment sizes. For example, the data given for the reflux drums V-202 and V-203, reactor R-201, and towers T-201 and T-202 are sufficient to sketch these units on the plot plan. However, pump sizes must be obtained from vendors or previous jobs, and additional calculations for heat exchangers must be done to estimate their required footprint on the plot plan. Calculations to illustrate the estimation of equipment footprints are given in Example 1.11.

Estimate the footprint for E-202 in the DME process.

From Table B.1.3 the following information can be found:

Floating-Head Shell-and-Tube design

Area = 171 m2

Hot Side—Temperatures: in at 364°C and out at 281°C

Cold Side—Temperatures: in at 154°C and out at 250°C

Choose a two-shell pass and four-tube pass exchanger

Area per shell = 171/2 = 85.5 m2

Using 12 ft, 1-in OD tubes, 293 tubes per shell are needed

Assuming the tubes are laid out on a ¼-in square pitch, a 27-in ID shell is required, see Table 20.6.

Assume that the front and rear heads (where the tube fluid turns at the end of the exchanger) are 30-in in diameter and require 2 ft of length each (including flanges), and that the two shells are stacked on top of each other. The footprint of the exchanger is given in Figure E1.11.

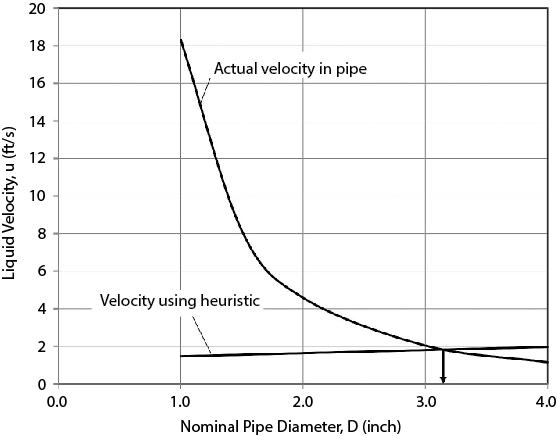

Estimates of major process pipe sizes are made. In order to estimate these pipe sizes, it is necessary to use some heuristics. A heuristic is a simple algorithm or hint that allows an approximate answer to be calculated. The preliminary design of a piece of equipment might well use many such heuristics, and some of these might conflict with each other. Like any simplifying procedure, the result from a heuristic must be reviewed carefully. For preliminary purposes, the heuristics from Chapter 11 can be used to estimate approximate pipe sizes. Example 1.12 illustrates the heuristic for calculating pipe size.

Consider the suction line to P-202 A/B; what should the pipe diameter be?

Solution

From Table 11.8, 1(b) for liquid pump suction, the recommended liquid velocity and pipe diameter are related by u = (1.3 + D (in)/6) ft/s.

From Table B.1.1, the mass flowrate of the stream entering P-202,

= Stream 16 + Stream 10 = 2170 + 5970 = 8140 kg/h and the density is found to be 800 kg/m3.

The volumetric flowrate is 8140/800 = 10.2 m3/h = 0.00283 m3/s = 0.0998 ft3/s.

The procedure is to calculate the velocity in the suction line and compare it to the heuristic. Using this approach, Table E1.12 is constructed:

Table E1.12 Actual Velocities and Velocities from Heuristic for the Suction Line to P-202 A/B

Nominal Pipe Diameter (inch)

Velocity (ft/s) = Vol Flow/Flow Area

Velocity (ft/s) from u = (1.3 + D/6)

1.0

18.30

1.47

1.5

8.13

1.55

2.0

4.58

1.63

3.0

2.03

1.80

4.0

1.14

1.97

The data in Table E1.12 are plotted in Figure E1.12 and show that the pipe diameter satisfying both the heuristic and the continuity equation lies between 3 and 4 inches. Taking a conservative estimate, a 4-in suction line is chosen for P-202.

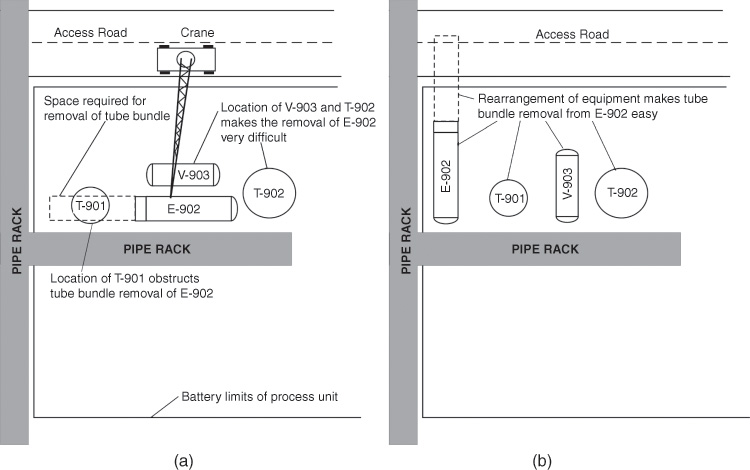

Placement of equipment within the plot plan. Equipment placement must be made considering the required access for maintenance of the equipment and also the initial installation. Although this step may seem elementary, there are many cases [5] where the incorrect placement of equipment subsequently led to considerable cost overruns and major problems both during the construction of the plant and during maintenance operations. Consider the example shown in Figure 1.11(a), where a vessel, two towers, and a heat exchanger are shown in the plot plan. Clearly, T-901 blocks the access to the exchanger’s tube bundle, which often requires removal to change leaking tubes or to remove scale on the outside of the tubes. With this arrangement, the exchanger would have to be lifted up vertically and placed somewhere where there was enough clearance so that the tube bundle could be removed. However, vessel, V-903, and tower T-902 are located such that crane access is severely limited and a very tall (and expensive) crane would be required. The relocation of these same pieces of equipment, as shown in Figure 1.11(b), alleviates both these problems. There are too many considerations of this type to cover in detail in this text, and the reader is referred to Bausbacher and Hunt [5] for more in-depth coverage of these types of problems. Considering the DME facility, a possible arrangement for the feed and reactor subsection is shown in Figure 1.12.

The elevation of all major equipment is established. In general, equipment located at grade (ground) level is easier to access and maintain and is cheaper to install. However, there are circumstances that dictate that equipment be elevated in order to provide acceptable operation. For example, the bottoms product of a distillation column is a liquid at its bubble point. If this liquid is fed to a pump, then, as the pressure drops in the suction line due to friction, the liquid boils and causes the pumps to cavitate. To alleviate this problem, it is necessary to elevate the bottom of the column relative to the pump inlet, in order to increase the Net Positive Suction Head Available (for more detail about NPSHA see Chapter 19). This can be done by digging a pit below grade for the pump or by elevating the tower. Pump pits have a tendency to accumulate denser-than-air gases, and maintenance of equipment in such pits is dangerous due to the possibility of suffocation and poisoning (if the gas is toxic). For this reason, towers are generally elevated between 3 and 5 m (10 and 15 ft) above ground level by using a “skirt.” This is illustrated in Figure 1.13. Another reason for elevating a distillation column is also illustrated in Figure 1.13. Often a thermosiphon reboiler is used. These reboilers use the difference in density between the liquid fed to the reboiler and the two-phase mixture (saturated liquid-vapor) that leaves the reboiler to “drive” the circulation of bottoms liquid through the reboiler. In order to obtain an acceptable driving force for this circulation, the static head of the liquid must be substantial, and a 3–5 m height differential between the liquid level in the column and the liquid inlet to the reboiler is typically sufficient. Examples showing when equipment elevation is required are given in Table 1.12.

Table 1.12 Reasons for Elevating Equipment

Equipment to Be Elevated

Reason for Elevation

Columns or vessels

When the NPSH available (NPSHA) is too low to avoid cavitation in the discharge pump, equipment must be elevated.

Columns

To provide driving head for thermosiphon reboilers.

Any equipment containing suspended solids or slurries

To provide gravity flow of liquids containing solids that avoids the use of problematic slurry pumps.

Contact barometric condensers

This equipment is used to produce vacuum by expanding high-pressure steam through an ejector. The condensables in the vapor are removed by direct contact with a cold-water spray. The tail pipe of such a condenser is sealed with a 34-foot leg of water.

Critical fire-water tank (or cooling water holding tank)

In some instances, flow of water is absolutely critical, for example, in firefighting or critical cooling operations. The main water supply tank for these operations may be elevated to provide enough water pressure to eliminate the need for feed pumps.

Major process and utility piping are sketched in. The final step in this preliminary plant layout is to sketch in where the major process (and utility) pipes (lines) go. Again, there are no set rules to do this. However, the most direct route between equipment that avoids clashes with other equipment and piping is usually desirable. It should be noted that utility lines originate and usually terminate in headers located on the pipe rack. When process piping must be run from one side of the process to another, it may be convenient to run the pipe on the pipe rack. All control valves, sampling ports, and major instrumentation must be located conveniently for the operators. This usually means that they should be located close to grade or on a steel access platform. This is also true for equipment isolation valves.

1.6 The 3-D Plant Model

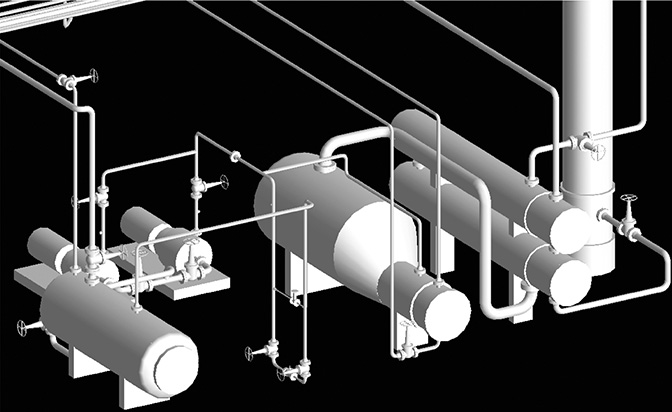

The best way to see how all the above elements fit together is to view the Virtual Plant Tour AVI file on the website for this book. The quality and level of detail that 3-D software is capable of giving depend on the system used and the level of detailed engineering that is used to produce the model. Figures 1.14–1.16 were generated for the DME facility using the PDMS software package from Cadcentre, Inc. (These figures and the Virtual_Plant_Tour.AVI file are presented here with permission of Cadcentre, Inc.) In Figure 1.14, an isometric view of the DME facility is shown. All major process equipment, major process and utility piping, and basic steel structures are shown. The pipe rack is shown running through the center of the process, and steel platforms are shown where support of elevated process equipment is required. The distillation sections are shown to the rear of the figure on the far side of the pipe rack. The reactor and feed section is shown on the near side of the pipe rack. The elevation of the process equipment is better illustrated in Figure 1.15, where the piping and structural steel have been removed. The only elevated equipment apparent from this figure are the overhead condensers and reflux drums for the distillation columns. The overhead condensers are located vertically above their respective reflux drums to allow for the gravity flow of condensate from the exchangers to the drums. Figure 1.16 shows the arrangement of process equipment and piping for the feed and reactor sections. The layout of equipment corresponds to that shown in Figure 1.12. It should be noted that the control valve on the discharge of the methanol feed pumps is located close to grade level for easy access.

Figure 1.14 Isometric View of Preliminary 3-D Plant Layout Model for DME Process (Reproduced by Permission of Cadcentre, an Aveva Group Company, from their Vantage/PDMS Software)

Figure 1.15 3-D Representation of Preliminary Equipment Layout for the DME Process (Reproduced by Permission of Cadcentre, an Aveva Group Company, from their Vantage/PDMS Software)

Figure 1.16 3-D Representation of the Reactor and Feed Sections of the DME Process Model (Reproduced by Permission of Cadcentre, an Aveva Group Company, from their Vantage/PDMS Software)

1.7 Operator and 3-D Immersive Training Simulators

1.7.1 Operator Training Simulators (OTS)

Up to this point in the chapter, the different elements and diagrams used in the specification and description of a process have been covered. The means by which the material balances, energy balances, and design calculations for the various unit operations, required to specify all the design conditions, have been carried out has not been covered. Indeed, the simulation of chemical processes using programs such as CHEMCAD, Aspen Plus, PRO/II, HYSIS, and others is not addressed until much later, in Chapter 13. Nevertheless, it should be clear that extensive simulation of the process will be required to determine and to specify all of the conditions needed in the design. Typically, these simulations are carried out under steady-state conditions and represent a single design operating point, although simulations for several different operating points might also be made. The steady-state simulation of the process is clearly very important from the standpoint of defining the design conditions and specifying the equipment parameters, such as vessel sizes, heat-exchanger areas and duties, pipe sizes, and so on. However, once the plant has been built, started up, and commissioned, it is rare that the process will operate at that design condition for any given period of time. Moreover, how the process can be started up or run at, for example, 65% or 110% of design capacity is not evident from the original design. Nevertheless, the plant will be run at off-design conditions throughout its life. In order to help operators and engineers understand how to start up and shut down the process, deal with emergencies, or operate at off-design conditions, an operator training simulator (OTS) may be built.

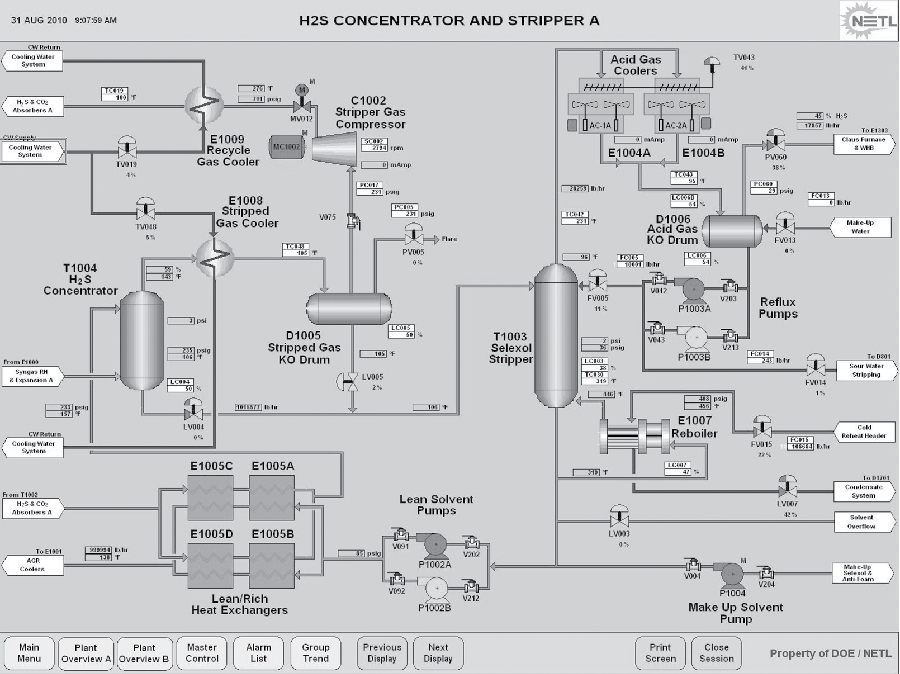

The foundation of an OTS is a dynamic simulation (model) of the process to which a human machine interface (HMI) is connected. The HMI, in its simplest form, is a pictorial representation of the process that communicates with the dynamic model, and through it, process variables are displayed. The HMI also displays all the controls for the process; an operator can control the process by changing these controls. An example of an HMI is shown in Figure 1.17. This particular example shows a portion of an acid-gas recovery (AGR) unit for an OTS developed by the Department of Energy to simulate an IGCC (Integrated Gasification Combined Cycle) coal-fed power plant. Process variables calculated by the dynamic model are displayed in boxes throughout the HMI. Operators can monitor the change in these variables with time just as they would in a control room situation. The only difference is that the process is simulated rather than actually operating. In general terms, the OTS functions for an operator just as a flight simulator does for a pilot or astronaut. Therefore, operators and engineers can gain operational experience and understanding about a process or plant through the OTS but with the added benefit that any mistakes or errors can be identified and corrected during training sessions without exposing personnel to any risks that might occur if training were to be done on the actual plant.

Figure 1.17 Example of an HMI Interface for an OTS (Reproduced by Permission of the DOE’s National Energy Technical Laboratory and Invensys Systems Inc., Property and Copyright of Invensys plc, UK)

The starting point for developing an OTS is the steady-state simulation, the equipment information, and instrumentation and control data. In general, the P&IDs are used as the starting point for the generation of the HMIs since they contain all the necessary information for the controls and instrumentation. The dynamic model is developed so that the steady-state design condition will be simulated when all the inputs (feeds) are at their design values. Details of how dynamic simulators are used in process design are included in Chapter 17. Needless to say, the development of a fully functioning dynamic model for a process that accurately reflects all the controls and valves in the process is a substantial task that takes a team of engineers many months to accomplish.

1.7.2 3-D Immersive Training Simulators (ITS)

In Section 1.6, the concept of a 3-D plant model was introduced. Such models are “constructed” with specialized software using precise design data on the size, location and elevation (x-, y-, and z-coordinates), and orientation of each piece of equipment. In addition, the piping arrangement and location of valves, nozzles, instruments, sample ports, drains, and so forth are all specified. Such a representation allows the engineer and operator to evaluate the accessibility of critical process components and to obtain a feel for how the plant will look (and operate) when constructed. The engineer may access this information through either a 2-D viewer or a 3-D virtual environment (for example, using 3-D goggles). However, no matter how the information is viewed, the resulting images are essentially static and are generally of low to medium fidelity. Therefore, when viewing a 3-D plant model, it will always be clear to the viewer that it is just a model, and that the representation of the 3-D object is crude.

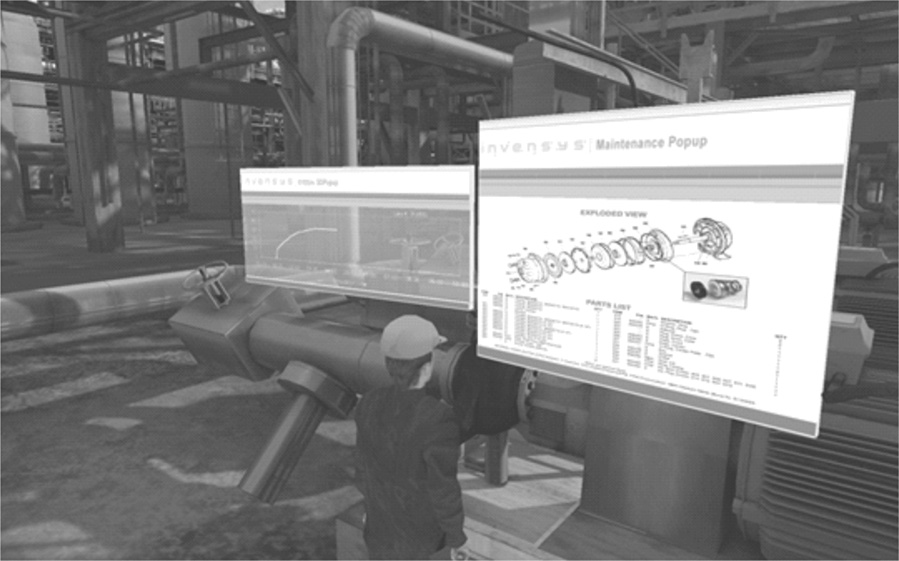

The visual enhancement of 3-D models using sophisticated imaging software and overlaying photorealistic images on top of a skeleton of the 3-D representation are now not only possible but commonplace for higher-end video games. Computer-generated graphics are now so advanced that, as any movie fan will attest, it is often difficult to determine what is “real” and what is animated. This technology is now being applied to develop 3-D immersive training simulators (ITS) for chemical plants. As can be seen from Figure 1.18, the quality and realism captured by computer-generated graphics are excellent. Furthermore, the use of avatars to represent plant operators makes it possible for a user to navigate through, interact with, and be truly immersed in the virtual plant.

Figure 1.18 An Example of a Computer-Generated Image of a Horizontal Drum (Reproduced by Permission of the DOE’s National Energy Technical Laboratory and Invensys Systems Inc., Property and Copyright of Invensys plc, UK)

1.7.3 Linking the ITS with an OTS