Chapter 13: Synthesis of a Process Using a Simulator and Simulator Troubleshooting

WHAT YOU WILL LEARN

Process simulators are used in the design of chemical processes.

All process simulators contain the same basic algorithms and require the same information, but they all have different user interfaces.

The correct choice of thermodynamics package is crucial for accurate simulations of chemical processes.

Simulation of highly nonideal vapor-liquid equilibrium is supported by all process simulators.

Using solid components requires careful evaluation and implementation.

The advancement in computer-aided process simulation over the past generation has been nothing short of spectacular. Until the late 1970s, it was rare for a graduating chemical engineer to have any experience in using a chemical process simulator. Most material and energy balances were still done by hand by teams of engineers. The rigorous simulation of multistaged separation equipment and complicated reactors was generally unheard of, and the design of such equipment was achieved by a combination of simplified analyses, shortcut methods, and years of experience. In the present day, however, companies now expect their junior engineers to be conversant with a wide variety of computer programs, especially a process simulator.

To some extent, the knowledge base required to simulate a chemical process successfully will depend on the simulator used. Currently there are several process simulators on the market, for example, CHEMCAD, Aspen Plus, Aspen HYSYS, PRO/II, and SuperPro Designer. Many of these companies advertise their product in the trade magazines—for example, Chemical Engineering, Chemical Engineering Progress, Hydrocarbon Processing, or The Chemical Engineer—and on the Internet. A process simulator typically handles batch, semibatch, and continuous processes; although, the extent of integration of the batch and continuous processes in a single process flow diagram (PFD) varies among the various popular simulators. The availability of such powerful software is a great asset to the experienced process engineer, but such sophisticated tools can be potentially dangerous in the hands of the neophyte engineer. The bottom line in doing any process simulation is that you, the engineer, are still responsible for analyzing the results from the computer. The purpose of this chapter is not to act as a primer for one or all of these products. Rather, the general approach to setting up processes is emphasized, and the aim is to highlight some of the more common problems that process simulator users encounter and to offer solutions to these problems. Some typical errors made by novice simulator users are discussed. In addition, two sections have been included at the end of this chapter on electrolyte systems and solids modeling. Electrolyte systems play a key role in many processes. These systems can be modeled in current process simulators reasonably accurately without significant effort. Many process simulators now also have the capability to model solids. This helps to integrate the unit operations involving solids with the rest of the plant without major simplifications.

13.1 The Structure of a Process Simulator

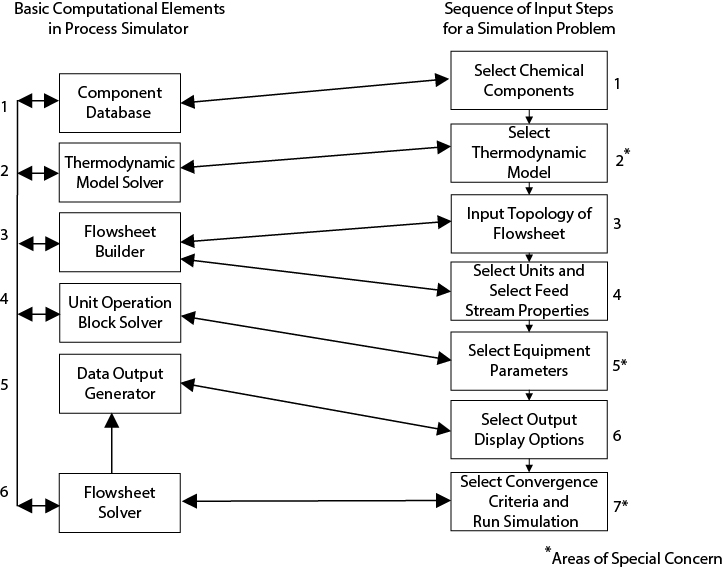

The six main features of all process simulators are illustrated in the left-hand column of Figure 13.1. These elements are as follows:

Figure 13.1 Relationship between Basic Computational Elements and Required Input to Solve a Process Simulation Problem

Component Database: This contains the parameters required to calculate the physical properties from the thermodynamic models.

Thermodynamic Model Solver: A variety of options for vapor-liquid (VLE) and liquid-liquid (LLE) equilibrium, enthalpy calculations, and other thermodynamic property estimations are available.

Flowsheet Builder: This part of the simulator keeps track of the flow of streams and equipment in the process being simulated. This information is input and displayed graphically.

Unit Operation Block Solver: Computational blocks or modules are available that allow energy and material balances and some design calculations to be performed for a wide variety of process equipment.

Data Output Generator: This part of the program serves to customize the results of the simulation in terms of an output report. Often, graphical displays of tower profiles, heating curves, and a variety of other useful process data can be produced.

Flowsheet Solver: This portion of the simulator controls the sequence of the calculations and the overall convergence of the simulation.

There are several other elements commonly found in process simulators that are not shown in Figure 13.1. For example, there are file control options, the option to use different engineering units, possibly some additional features associated with regressing data for thermodynamic models, and so on. The availability of these other options is dependent on the simulator used and will not be discussed further.

Also shown on the right-hand side of the diagram in Figure 13.1 are the seven general steps to setting up a process simulation problem. The general sequence of events that a user should follow in order to set up a problem on a simulator is as follows:

Select all of the chemical components that are required in the process from the component database.

Select the thermodynamic models required for the simulation. These may be different for different pieces of equipment. For example, to simulate a liquid-liquid extractor correctly, it is necessary to use a thermodynamic model that can predict liquid-phase activity coefficients and the existence of two liquid phases. However, for a pump in the same process, a less sophisticated model could be used.

Select the topology of the flowsheet to be simulated by specifying the input and output streams for each piece of equipment.

Select the properties (temperature, pressure, flowrate, vapor fraction, and composition) of the feed streams to the process.

Select the equipment specifications (parameters) for each piece of equipment in the process.

Select the way in which the results are to be displayed.

Select the convergence method and run the simulation.

Step 3 is achieved by constructing the flowsheet using equipment icons and connecting the icons with process streams. Sometimes, it is convenient to carry out this step first.

The interaction between the elements and steps and the general flow of information is shown by the lines on the diagram. Of the seven input steps given above, Steps 2, 5, and 7 are the cause of most problems associated with running process simulations. These areas will be covered in more detail in the following sections. However, before these topics are covered, it is worth looking at the basic solution algorithms used in process simulators.

There are basically three types of solution algorithms for process simulators [1]: sequential modular, equation solving (simultaneous nonmodular), and simultaneous modular.

In the sequential modular approach, the equations describing the performance of equipment units are grouped together and solved in modules—that is, the process is solved equipment piece by equipment piece. In the equation solving, or simultaneous nonmodular, technique, all the relationships for the process are written out together and then the resulting matrix of nonlinear simultaneous equations is solved to yield the solution. This technique is very efficient in terms of computation time but requires a lot of time to set up and is unwieldy. The final technique is the simultaneous modular approach, which combines the modularizing of the equations relating to specific equipment with the efficient solution algorithms for the simultaneous equation solving technique.

Of these three types, the sequential modular algorithm is by far the most widely used. In the sequential modular method, each piece of equipment is solved in sequence, starting with the first, followed by the second, and so on. It is assumed that all the input information required to solve each piece of equipment has been provided (see Section 13.2.5). Therefore, the output from a given piece of equipment, along with specific information on the equipment, becomes the input to the next piece of equipment in the process. Clearly, for a process without recycle streams, this method requires only one flowsheet iteration to produce a converged solution. The term flowsheet iteration means that each piece of equipment is solved only once. However, there may be many iterations for any one given piece of equipment, and batch units require time-series calculations to match the required scheduling of operations for the given unit. This concept is illustrated in Figure 13.2.

Figure 13.2 Solution Sequence Using Sequential Modular Simulator for a Process Containing No Recycles

The solution sequence for flowsheets containing recycle streams is more complicated, as shown in Figure 13.3. Figure 13.3(a) shows that the first equipment in the recycle loop (C) has an unknown feed stream (r). Thus, before Equipment C can be solved, some estimate of Stream r must be made. This leads to the concept of tear streams. A tear stream, as the name suggests, is a stream that is torn or broken. If the flowsheet in Figure 13.3(b) is considered, with the recycle stream torn, it can be seen, provided information is supplied about Stream r2, the input to Equipment C, that the flowsheet can be solved all the way around to Stream r1 using the sequential modular algorithm. Then Streams r1 and r2 are compared. If they agree within some specified tolerance, then there is a converged solution. If they do not agree, then Stream r2 is modified and the process simulation is repeated until convergence is obtained. The splitting or tearing of recycle streams allows the sequential modular technique to handle recycles. The convergence criterion and the method by which Stream r2 is modified can be varied, and multivariable successive substitution, Wegstein, and Newton-Raphson techniques [2, 3] are all commonly used for the recycle loop convergence. Usually, the simulator will identify the recycle loops and automatically pick streams to tear and a method of convergence. The tearing of streams and method of convergence can also be controlled by the user, but this is not recommended for the novice. Note that the implementation of heat integration (Chapter 15) may introduce (many) recycle streams.

Figure 13.3 The Use of Tear Streams to Solve Problems with Recycles Using the Sequential Modular Algorithm

13.2 Information Required to Complete a Process Simulation: Input Data

Referring back to Figure 13.1, each input block is considered separately. The input data for the blocks without asterisks (1, 3, 4, and 6) are quite straightforward and require little explanation. The remaining blocks (2, 5, and 7) are often the source of problems, and these are treated in more detail.

13.2.1 Selection of Chemical Components

Usually, the first step in setting up a simulation of a chemical process is to select which chemical components are going to be used. The simulator will have a databank of many components (more than a thousand chemical compounds are commonly included in these databanks). It is important to remember that all components—inerts, reactants, products, by-products, utilities, and waste chemicals—should be identified. If the chemicals that are needed are not available in the databank, then there are usually several ways that components (user-added components) can be added to the simulation. How to input data for user-added components is simulator specific, and the simulator user manual should be consulted.

13.2.2 Selection of Physical Property Models

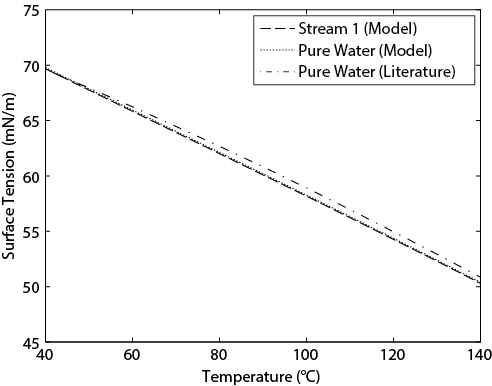

Selecting the best physical property model is an extremely important part of any simulation. If the wrong property package or model is used, the simulated results will not be accurate and cannot be trusted. The choice of models is often overlooked by the novice, causing many simulation problems down the road. Simulators use both pure component and mixture properties. These range from molecular weight to activity-coefficient models. Transport properties (viscosity, thermal conductivity, diffusivity), thermodynamic properties (enthalpy, fugacity, K-factors, critical constants), and other properties (density, molecular weight, surface tension) are all important.

The physical property options are labeled as “thermo,” “method,” “property package,” or “databank” in common process simulators. There are pure-component and mixture sections, as well as a databank. For temperature-dependent properties, different functional forms are used (from extended Antoine equation to polynomial to hyperbolic trigonometric functions). The equation appears on the physical property screen or in the help utility.

For pure-component properties, the simulator has information in its databank for thousands of compounds. Some simulators offer a choice between DIPPR and proprietary databanks. These are largely the same, but the proprietary databank may contain additional components, petroleum cuts, electrolytes, and so on. DIPPR is the Design Institute for Physical Property Research (a part of AIChE), and sharing of process data across different simulators (e.g., Aspen Plus, CHEMCAD, Aspen HYSYS, PRO/II, SuperPro Designer) can be enhanced by using that databank. (Note that some proprietary databanks may not be supplied in the academic versions of these simulators.) All simulators also have built-in procedures to estimate pure-component properties from group-contribution and other techniques. The details of these techniques are covered in standard chemical engineering thermodynamics texts [4–6] and are not described here. However, the user must be aware of any such estimations made by the simulator. Any estimation, by definition, increases the uncertainty in the results of the simulation. The entry in the databank for each component should indicate estimations. For example, many long-chain hydrocarbons have no experimental critical point because they decompose at relatively low temperatures. However, because critical temperatures and pressures are needed for most thermodynamic models, they must be estimated. Although these estimations allow the use of equation-of-state and some other models, one must never assume that these are experimental data.

Heat capacities, densities, and critical constants are the most important pure-component data for simulation. The transport and other properties are used in equipment sizing calculations. The techniques used in the simulators are no more accurate than those covered in transport, thermodynamics, unit operations, and separations courses—they are just easier to apply.

Even though simple mass and energy balances cannot be done by the simulator without the above-mentioned, pure-component properties, often the most influential decision in a simulation is the choice of a model to predict phase equilibria. Several of the popular simulators have expert systems to help the user select the appropriate model for the system. The expert system determines the range (usually with additional user input) of operating temperatures and pressures covered by the simulation and, with data on the components to be used, makes an informed guess of the thermodynamic models that will be best for the process being simulated. The word expert should not be taken too seriously! The expert-system choice is only a first guess. Additionally, the model chosen may not be best for a given piece of equipment. A moderately complex simulation may use at least two different thermodynamic packages for different parts of the flowsheet.

Due to the importance of thermodynamic model selection and the many problems that the wrong selection leads to, a separate section (Section 13.4) is dedicated to this subject. An example of how the wrong thermodynamic package can cause serious errors is given in Example 13.1.

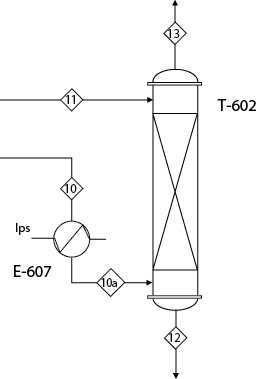

Consider the HCl absorber (T-602) in the separation section of the allyl chloride process, Figure C.3 in Appendix C. This equipment is shown in Figure E13.1. The function of the absorber is to contact countercurrently Stream 10a, containing mainly propylene and hydrogen chloride, with water, Stream 11. The HCl is highly soluble in water and is almost completely absorbed to form 32 wt% hydrochloric acid, Stream 12. The gas leaving the top of the absorber, Stream 13, is almost pure propylene, which is cleaned and then recycled.

Solution

Table E13.1 shows the results for the two outlet streams from the absorber—Streams 12 and 13—for two simulations, each using a different thermodynamic model for the vapor-liquid equilibrium calculations. The second and third columns in the table show the results using the SRK (Soave [7], Redlich and Kwong [8]) model, which is the preferred model for many common organic components. The fourth and fifth columns show the results using a model that is specially designed to deal with ionic type compounds (HCl) that dissolve in water and then dissociate. The difference in results is remarkable. The HCl-water system is highly nonideal, and, even though the absorption of an acid gas into aqueous solutions is quite common, the SRK model is not capable of correctly modeling the phase behavior of this system. With the SRK model, virtually all the HCl leaves the absorber as a gas. Clearly, if the simulation were done using only the SRK model, the results would be drastically in error. This result is especially disturbing because SRK is the default thermodynamics package in many simulators.

Table E13.1 Results of Simulation of HCl Absorption Using Two Different Physical Property Models

Using SRK Model |

Using PPAQ* Model |

|||

Phase Component Flows (kmol/h) |

Stream 12 Liquid |

Stream 13 Vapor |

Stream 12 Liquid |

Stream 13 Vapor |

Propylene |

0.05 |

57.48 |

— |

57.53 |

Allyl chloride |

0.01 |

— |

0.01 |

— |

Hydrogen chloride |

0.91 |

18.78 |

19.11 |

0.58 |

Water |

81.37 |

0.63 |

81.88 |

0.12 |

Total |

82.34 |

76.89 |

101.00 |

58.23 |

* This is a model used in the CHEMCAD simulator especially for HCl-water and similar systems. |

||||

More details of model selection are given in Section 13.4.

The importance of thermodynamic model selection and its impact on the validity of the results of a simulation are discussed at length by Horwitz and Nocera [9], who warn

“You absolutely must have confidence in the thermodynamics that you have chosen to represent your chemicals and unit operations. This is your responsibility, not that of the software simulation package. If you relinquish your responsibility to the simulation package, be prepared for dire consequences.”

13.2.3 Selection and Input of Flowsheet Topology

The most reliable way to input the topology of the process flow diagram is to make a sketch on paper and have this in front of you when you construct the flowsheet on the simulator. Contrary to the rules given in Chapter 1 on the construction of PFDs, every time a stream splits or several streams combine, a simulator equipment module (splitter or mixer) must be included. These “phantom” units were introduced in Chapter 5 and are useful in tracing streams in a PFD as well as being required for the simulator. They are required in the simulator so it “knows” to do the necessary material and energy balances on mixers and splitters; however, they should not appear on a PFD. Certain conventions in the numbering of equipment and streams are used by the simulator to keep track of the topology and connectivity of the streams. When using the graphical interface, the streams and equipment are usually numbered sequentially in the order they are added. These can be altered by the user if required. Care must be taken when connecting batch and continuous unit operations, because it is often assumed that “continuous” units approach steady state instantaneously.

13.2.4 Selection of Feed Stream Properties

As discussed in Section 13.1, the sequential modular approach to simulation requires that all feed streams be specified (composition, flowrate, vapor fraction, temperature, and pressure). In addition, estimates of recycle streams should also be made. Although feed properties are usually well defined, some confusion may exist regarding the number and type of variables that must be specified to define the feed stream completely. In general, feed streams will contain n components and consist of one or two phases. For such feeds, a total of n + 2 specifications completely defines the stream. This is a consequence of the phase rule. Providing the flowrate (kmol/h, kg/s, etc.) of each component in the feed stream takes care of n of these specifications. The remaining two specifications should also be independent. For example, if the stream is one phase, then giving the temperature and pressure of the stream completely defines the feed. Temperature and pressure also completely define a multicomponent stream having two phases. However, if the feed is a single component and contains two phases, then temperature and pressure are not independent. In this case, the vapor fraction and either the temperature or the pressure must be specified. Vapor fraction can also be used to specify a two-phase multicomponent system, but if used, only temperature or pressure can be used to specify the feed completely. To avoid confusion, it is recommended that vapor fraction (vf) be specified only for saturated vapor (vf = 1), saturated liquid (vf = 0), and two-phase, single-component (0 < vf < 1) streams. All other streams should be specified using the temperature and pressure.

Use the vapor fraction (vf) to define feed streams only for saturated vapor (vf = 1), saturated liquid (vf = 0), and two-phase, single-component (0 < vf < 1) streams.

By giving the temperature, pressure, and vapor fraction for a feed, the stream is overspecified and errors will result.

13.2.5 Selection of Equipment Parameters

It is worth pointing out that process simulators, with a few exceptions, are structured to solve process material and energy balances, reaction kinetics, reaction equilibrium relationships, phase-equilibrium relationships, and equipment performance relationships for equipment in which sufficient process design variables and batch operations scheduling have been specified. For example, consider the design of a liquid-liquid extractor to remove 98% of a component in a feed stream using a given solvent. In general, a process simulator will not be able to solve this design problem directly; that is, it cannot determine the number of equilibrium stages required for this separation. However, if the problem is made into a simulation problem, then it can be solved by a trial-and-error technique. Thus, by specifying the number of stages in the extractor, case studies in which the number of stages are varied can be performed, and this information can be used to determine the correct number of stages required to obtain the desired recovery of 98%. In other cases, such as a plug flow reactor module, the simulator can solve the design problem directly—that is, calculate the amount of catalyst required to carry out the desired reaction. Therefore, before starting a process simulation, it is important to know what equipment parameters must be specified in order for the process to be simulated.

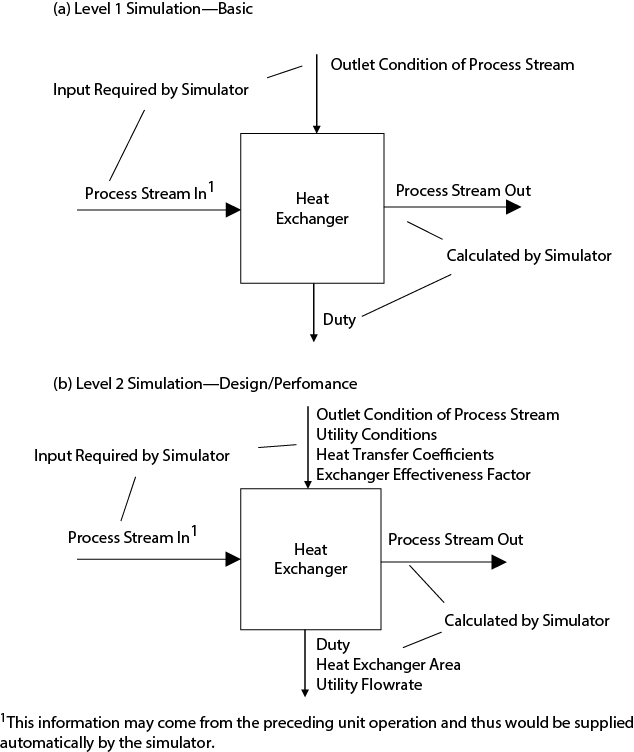

There are essentially two levels at which a process simulation can be carried out. The first level, Level 1, is one in which the minimum data are supplied in order for the material and energy balances to be obtained. The second level, Level 2, is one in which the simulator is used to do as many of the design calculations as possible. The second level requires more input data than the first. An example of the differences between the two levels is illustrated in Figure 13.4, which shows a heat exchanger in which a process stream is being cooled using cooling water. At the first level, Figure 13.4(a), the only information that is specified is the desired outlet condition of the process stream—for example, pressure and temperature or vapor fraction—if the stream is to leave the exchanger as a two-phase mixture. However, this is enough information for the simulator to calculate the duty of the exchanger and the properties of the process stream leaving the equipment. At the second level, Figure 13.4(b), additional data are provided: the inlet and desired outlet temperature for the utility stream, the fact that the utility stream is water, the overall heat transfer coefficient, and the heat-exchanger configuration or log-mean-temperature-correction factor, F. Using this information, the simulator calculates the heat-exchanger duty, the required cooling water flowrate, and the required heat transfer area.

When attempting to do a simulation on a process for the first time, it is recommended that the minimum data required be provided for a Level 1 simulation. When a satisfactory, converged solution is obtained, more data can be provided to obtain desired design parameters, that is, a Level 2 solution.

When first simulating a process, input only the data required to perform the material and energy balances for the process.

The structure of the process simulator will determine the exact requirements for the input data, and such information will be available in the user manual for the software or on help screens. However, for Level 1 simulations, a brief list of typical information is presented below that may help a novice user prepare the input data for a process simulation.

Pumps, Compressors, and Power Recovery Turbines (Expanders). For pumps, the desired pressure of the fluid leaving the pump or the desired pressure increase of the fluid as it flows through the pump and the efficiency are all that is required.

For compressors and turbines, the desired pressure of the fluid leaving the device or the desired pressure increase of the fluid as it flows through the equipment is required. In addition, the efficiency and the mode of compression or expansion—adiabatic, isothermal, or polytropic—are required.

Heat Exchangers. For exchangers with a single process stream exchanging energy with a utility stream, all that is required is the condition of the exit process stream. This can be the exit pressure (or pressure drop) and temperature (single-phase exit condition) or the exit pressure and vapor fraction (two-phase exit condition).

For exchangers with two or more process streams exchanging energy (as might be the case when heat integration is being considered), the exit conditions (pressure and temperature or vapor fraction) for both streams are required. However, the system should not be overspecified. Of the two flowrates and four temperatures (two input, two output), one should not be specified, and the simulator will calculate the unknown variable from the energy balance. The user must be aware of the possibility of temperature crosses in heat-exchange equipment. The simulator may or may not warn the user that a temperature cross has occurred but will continue to simulate the rest of the process. The results from such a simulation will not be valid, and the temperature cross must be remedied before a correct solution can be obtained. Therefore, it is recommended that the user check the temperature profiles for all heat exchangers after the simulation.

Fired Heaters (Furnaces). The same requirements for heat exchangers with a single process fluid apply to fired heaters.

Mixers and Splitters. Mixers and splitters used in process simulators are usually no more than simple tees in pipes. Unless special units must be provided—for example, when the fluids to be mixed are very viscous and in-line mixers might be used—the capital investment of these units can be assumed to be zero.

Mixers represent points where two or more process streams come together. The only required information is an outlet pressure or pressure drop at the mixing point. Usually, the pressure drop associated with the mixing of streams is small, and the pressure drop can be assumed to be equal to zero with little error. If feed streams enter the mixer at different pressures, the simulator assignes the outlet stream pressure to be at the lowest pressure of the mixing streams. This assumption causes little error in the material and energy balance. However, since the pressures of mixing streams will be equal, if a system is actually designed with streams mixing at different pressures, the pressures will equalize by adjusting the flowrates, and the process will not operate as designed. It is recommended that valves be added to the simulation so that mixing streams are at the same pressure.

Splitters represent points at which a process stream splits into two or more streams with different flowrates but identical compositions. The required information is the outlet pressure or pressure drop across the device and the relative flows of the output streams. Usually, there is little pressure drop across a splitter, and all streams leaving the unit are at the same pressure as the single feed stream. In a batch operation, the splitter can be assigned on and off times to divert the inlet flow to various other units on a schedule.

Valves. Either the outlet pressure or pressure drop is required.

Reactors. The way in which reactors are specified depends on a combination of the input information required and the reactor category. Generally there are four categories of reactor: stoichiometric reactor, kinetic (plug flow or CSTR) reactor, equilibrium reactor, and batch reactor. All these reactor configurations require input concerning the thermal mode of operation: adiabatic, isothermal, amount of heat removed or added. Additional information is also required. Each reactor type is considered separately below.

Stoichiometric Reactor: This is the simplest reactor type that can be simulated. The required input data are the number and stoichiometry of the reactions, the temperature and pressure, and the conversion of the limiting reactant. Reactor configuration (plug flow, CSTR) is not required because no estimate of reactor volume is made. Only basic material and energy balances are performed.

Kinetic (Plug Flow and CSTR) Reactor: This reactor type is used to simulate reactions for which kinetics expressions are known. The number and stoichiometry of the reactions are required input data. Kinetics constants (Arrhenius rate constants and Langmuir-Hinshelwood constants, if used) and the form of the rate equation (simple first-order, second-order, Langmuir-Hinshelwood kinetics, etc.) are also required. Reactor configuration (plug flow, CSTR) is required. Options may be available to simulate cooling or heating of reactants in shell-and-tube reactor configurations in order to generate temperature profiles in the reactor. If the reactor volume (or shell-and-tube configuration details) is provided, the simulator determines the outlet conditions. Some simulators allow the fractional conversion of a reactant to be specified and calculate the necessary volume.

Equilibrium Reactor: As the name implies, this reactor type is used to simulate reactions that obtain or approach equilibrium conversion. The number and stoichiometry of the reactions and the fractional approach to equilibrium are the required input data. In addition, equilibrium constants as a function of temperature may be required for each reaction or may be calculated directly from information in the database. In this mode, the user has control over which reactions should be considered in the analysis.

Minimum Gibbs Free Energy Reactor: This is another common form of the equilibrium reactor. In the Gibbs reactor, the outlet stream composition is calculated by a free energy minimization technique. Usually data are available from the simulator’s databank to do these calculations. The only input data required are the list of components that one anticipates in the output from the reactor. In this mode the equilibrium conversion that would occur for an infinite residence time is calculated.

Batch Reactor: This reactor type is similar to the kinetic reactor (and requires the same kinetics input), except that it is batch. The volume of the reactor is specified. The feeds, product compositions, and reactor temperature (or heat duty) are scheduled (i.e., they are specified as time series).

As a general rule, the least complicated reactor module that will allow the heat and material balance to be established should be used. The reactor module can always be substituted later with a more sophisticated one that allows the desired design calculations to be performed. It should also be noted that a common error made in setting up a reactor module is the use of the wrong component as the limiting reactant when a desired conversion is specified. This is especially true when several simultaneous reactions occur, and the limiting component may not be obvious solely from the amounts of components in the feed.

Flash Units. In simulators, the term flash refers to the module that performs a single-stage vapor-liquid equilibrium calculation. Material, energy, and phase-equilibrium equations are solved for a variety of input parameter specifications. In order to specify completely the condition of the two output streams (liquid and vapor), two parameters must be input. Many combinations are possible—for example, temperature and pressure, temperature and heat load, or pressure and mole ratio of vapor to liquid in exit streams. Often, the flash module is a combination of two pieces of physical equipment, that is, a a heat exchanger followed by a phase separator. These should appear as separate equipment on the PFD. Note that a flash unit can also be specified for batch operation, in which case the unit can serve as a surge or storage vessel.

Distillation Columns. Usually, both rigorous methods (stage-by-stage calculations) and shortcut methods (like Fenske, Underwood, and Gilliland relationships using key components) are available. In preliminary simulations, it is advisable to use shortcut methods. The advantage of the shortcut methods is that they allow a design calculation (which estimates the number of theoretical plates required for the separation) to be performed. For preliminary design calculations, this is a very useful option and can be used as a starting point for using the more rigorous algorithms, which require that the number of theoretical stages be specified. It should be noted that, in both methods, the calculations for the duties of the reboiler and condenser are carried out in the column modules and are presented in the output for the column. Detailed design of these heat exchangers (area calculations) often cannot be carried out during the column simulation.

Shortcut Module: The required input for the design mode consists of identification of the key components to be separated, specification of the fractional recoveries of each key component in the overhead product, the column pressure and pressure drop, and the ratio of actual to minimum reflux ratio to be used in the column. The simulator will estimate the number of theoretical stages required, the exit stream conditions (bottom and overhead products), optimum feed location, and the reboiler and condenser duties.

If the shortcut method is used in the rating (or performance) mode, the number of equilibrium stages must also be specified, but the R/Rmin is calculated.

Rigorous Module: The number of theoretical stages must be specified, along with the condenser and reboiler type (total or partial), column pressure and pressure drop, feed tray locations, and side product locations (if side stream products are desired). Even though total condensers and total reboilers are not equilibrium stages, they are included in the stage count in a rigorous distillation module, so the simulator can do the required calculations for them. That is why the type of condenser and reboiler must be specified, so the simulator “knows” whether to do an equilibrium calculation or whether to take saturated vapor to saturated liquid (or vice versa). In addition, the total number of specifications given must be equal to the number of products (top, bottom, and side streams) produced. These product specifications are often a source of problems, and this is illustrated in Example 13.2.

Several rigorous modules may be available in a given simulator. Differences between the modules are the different solution algorithms used and the size and complexity of the problems that can be handled. Stage-to-stage calculations can be handled for several hundred stages in most simulators. In addition, these modules can be used to simulate accurately other equilibrium-staged devices, for example, absorbers and strippers.

Batch Distillation: This module is similar to the rigorous module, except that feeds and product draws are on a schedule (not continuous). Therefore, the start and stop times of the feeds and products must be specified, and a time series of tray concentrations and temperatures is generated by the simulator.

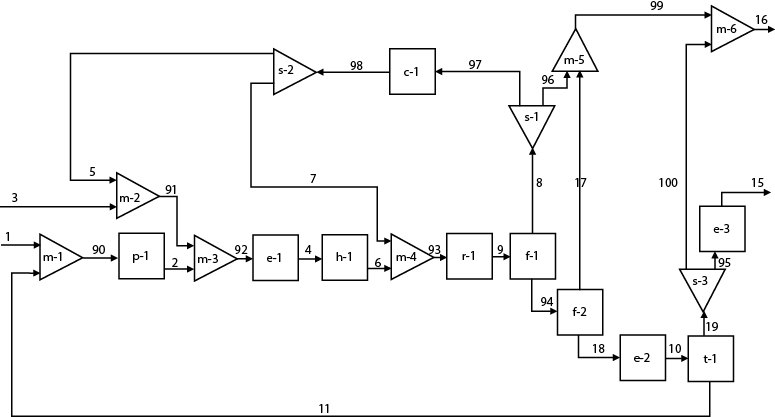

Consider the benzene recovery column in the toluene hydrodealkylation process shown in Figure 1.5. This column is redrawn in Figure E13.2. The purpose of the column is to separate the benzene product from unreacted toluene, which is recycled to the front end of the process. The desired purity of the benzene product is 99.6 mol%. The feed and the top and bottoms product streams are presented in Table E13.2, which is taken from Table 1.5.

Figure E13.2 Benzene Column in Toluene Hydrodealkylation Process (from Figure 1.5)

Table E13.2 Stream Table for Figure E13.2

Component |

Stream 10 |

Stream 15 |

Stream 19 |

Stream 11 |

Hydrogen |

0.02 |

— |

0.02 |

— |

Methane |

0.88 |

— |

0.88 |

— |

Benzene |

106.3 |

105.2 |

— |

1.1 |

Toluene |

35.0 |

0.4 |

— |

34.6 |

Solution

There are many ways to specify the parameters needed by the rigorous column algorithm used to simulate this tower.

Two examples are given:

The key components for the main separation are identified as benzene and toluene. The composition of the top product is specified to be 99.6 mol% benzene, and the recovery (not the mole fraction) of toluene in the bottoms product is 0.98.

The top composition is specified to be 99.6 mol% benzene, and the recovery of benzene in the bottoms product is 0.01.

The first specification violates the material balance, whereas the second specification does not. Looking at the first specification, if 98% of the toluene in the feed is recovered in the bottoms product, then 2% or 0.7 kmol/h must leave with the top product. Even if the recovery of benzene in the top product were 100%, this would yield a top composition of 106.3 kmol/h benzene and 0.7 kmol/h toluene. This corresponds to a mole fraction of 0.993. Therefore, the desired mole fraction of 0.996 can never be reached. Thus, by specifying the recovery of toluene in the bottoms product, the specification for the benzene purity is automatically violated.

The second specification shows that both specifications can be achieved without violating the material balance. The top product contains 99% of the feed benzene (105.2 kmol/h) and 0.4 kmol/h toluene, which gives a top composition of 99.6 mol% benzene. The bottoms product contains 1.0% of the feed benzene (1.1 kmol/h) and 34.6 kmol/h of toluene.

When giving the top and bottom specifications for a distillation column, make sure that the specifications do not violate the material balance.

If problems continue to exist, one way to ensure that the simulation will run is to specify the top reflux rate and the boil-up rate (reboiler duty). Although this strategy will not guarantee the desired purities, it will allow a base case to be established. With subsequent manipulation of the reflux and boil-up rates, the desired purities can be obtained. Another strategy that may be useful when a high purity is needed is to start with a lower purity and then increase the purity specification in steps to the desired purity. This only works if the simulation is not “reset” after each run, that is, the previous result is used as the starting point each time.

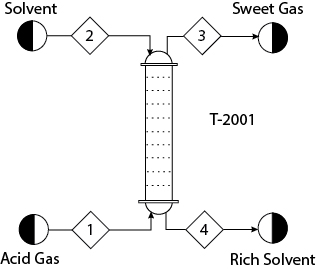

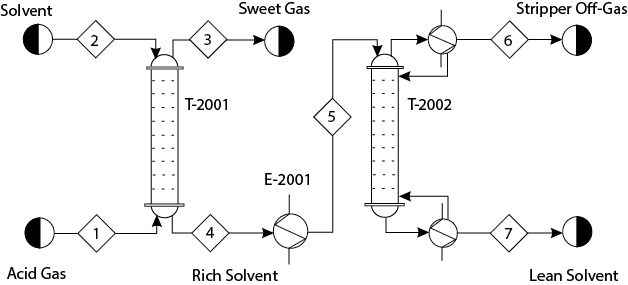

Absorbers and Strippers. Usually these units are simulated using the rigorous distillation module given above. The input streams and the number of equilibrium stages are specified, and the outlet streams are obtained. The main difference in simulating this type of equipment is that condensers and reboilers are not normally used. In addition, there are two feeds to the unit: one feed enters at the top and the other at the bottom. It may also be necessary to toggle a setting to indicate that an absorber/stripper is being simulated.

Liquid-Liquid Extractors. A rigorous tray-by-tray module is used to simulate this multistaged equipment. The input streams and the number of equilibrium stages are specified, and the outlet streams are obtained. It is imperative that the thermodynamic model for this unit be capable of predicting the presence of two liquid phases, each with appropriate liquid-phase activity coefficients. This module is usually different from the module that simulates vapor-liquid systems, like distillation, absorption, and stripping.

13.2.6 Selection of Output Display Options

Several options will be available to display the results of a simulation. Often, a report file can be generated and customized to include a wide variety of stream and equipment information. In addition, a simulation flowsheet (not a PFD); T-Q diagrams for heat exchangers; vapor and liquid flows; temperature and composition profiles (tray-by-tray) for multistaged equipment; temperature and composition profiles along a tubular reactor; scheduling charts for batch operations; environmental parameters for exit streams; and a wide variety of phase diagrams for streams can be generated. The user manual should be consulted for the specific options available for the simulator you use.

13.2.7 Selection of Convergence Criteria and Running a Simulation

For equipment requiring iterative solutions, there will be user-selectable convergence and tolerance criteria in the equipment module. There will also be convergence criteria for the whole flowsheet simulation, which can be adjusted by the user.

The two most important criteria are number of iterations and tolerance. These criteria will often have default values set in the simulator. These default values should be used in initial simulations. If problems arise, these values should be adjusted, but it may also be necessary to choose a different convergence method.

If the simulation has not converged, the results do not represent a valid solution and should not be used.

When convergence is not achieved, three common causes are as follows:

The problem has been ill posed. This normally means that an equipment specification has been given incorrectly. For example, see the first specification in Example 13.2 for the rigorous column module.

The tolerance for the solution has been set too tightly, and convergence cannot be obtained to the desired accuracy no matter how many solution iterations are performed.

The number of iterations is not sufficient for convergence. This occurs most often when the flowsheet has many recycle streams. Rerunning the flowsheet simulation with the results from the preceding run may give a converged solution. If convergence is still not obtained, then one way to address this problem is to remove as many recycle streams as possible. The simulation is then run, and the recycle streams are added back, one by one, using the results from the preceding simulation as the starting point for the new one. This method is discussed in more detail in Section 13.3.

Of the three reasons, the first one is by far the most common.

The most common reason for the failure of a simulation to converge is the use of incorrect or impossible equipment specifications.

13.2.8 Common Errors in Using Simulators

As mentioned previously, simulators perform some calculations that are not physically correct, and some unit operations in simulators do not correspond to acutal equipment. Two examples were previously mentioned. One is that mixing streams will be at the same pressure, not the lower of the pressures of the mixing streams, which is what simulators assume. It is the user’s responsibility to add valves to the higher-pressure streams so that mixing streams are at the same pressure. Another example is the “flash” tank that operates at a different temperature from the feed stream without a heat exchanger. In reality, the “flash” operation is a partial vaporization or partial condensation, which requires a heat exchanger. The correct equipment configuration is a heat exchanger followed by a tank to disengage the vapor and liquid phases. The tank can be modeled in a simulator as a flash operating at the same conditions as the feed stream, which is the exit stream from the heat exchanger. It is also important to make use of the information available within a simulator, for example, temperature and composition profiles in tubular reactors and T-xy diagrams for heat exchangers.

Table 13.1 summarizes some common errors made by students when using process simulators.

Table 13.1 Commonly Observed Simulation Errors

Physical Situation |

Error Observed |

Correct Method |

Incorrect use of flash unit simulation |

Including flash unit with heat load, so temperature changes “magically” |

Simulate as heat exchanger followed by flash unit operating at inlet conditions |

Mixing points |

Mixing streams at different pressures, outlet stream at lowest pressure (simulator default) |

Add valves to input streams to mixer as appropriate to ensure mixing streams at same pressure |

Zoned analysis required |

For phase change operations, only one zone used with one heat transfer coefficient |

Simulate each zone as separate heat exchanger with separate heat transfer coefficient, but PFD shows one heat exchanger (some simulators allow zoned analysis in heat exchange unit if each zone’s heat transfer coefficient is provided) |

LMTD correction factor required but ignored |

Standard configuration in industry is 1-2 exchanger |

Check approach temperatures to see if more shell passes are needed, often occurs if heat integration used |

Inappropriate reactor size |

Desired product rate approaches constant value or starts to decrease |

Examine reactor profiles to determine if reactor is oversized or if selectivity is decreasing |

Real vs. actual trays |

Column design and cost calculated for number of equilibrium trays |

Include tray efficiency in simulation or add trays when performing cost calculation |

Column pressure drop |

Column assumed to be at constant pressure or pressure drop chosen does not correspond to reality |

Include pressure drop and make sure pressure drop per tray roughly corresponds to weir height, and that weir height is not too small or not more than 50% of tray spacing; or assume weir height (typically 4-6 in and less than half of tray spacing) and include pressure drop in simulation |

13.3 Handling Recycle Streams

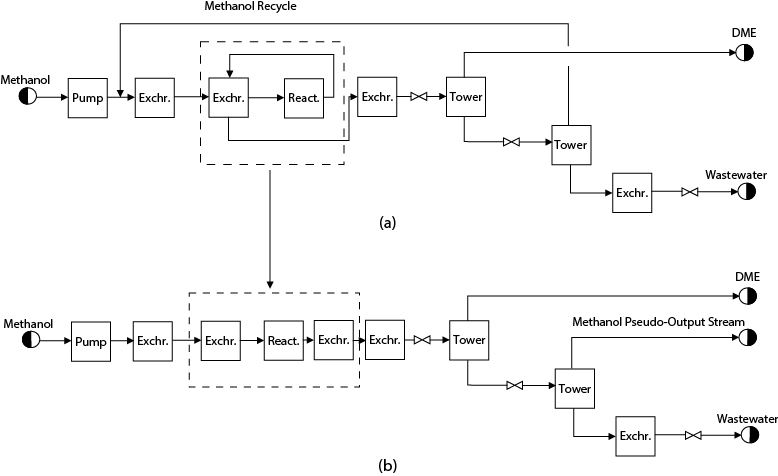

Recycle streams are very important and common in process flowsheets. Computationally, they can be difficult to handle and are often the cause for unconverged flowsheet simulations. There are ways in which the problems caused by recycle streams can be minimized. When a flowsheet is simulated for the first time, it is wise to consider carefully any simplifications that may help the convergence of the simulation. Consider the simulation of the DME flowsheet illustrated in Figure B.1.1, Appendix B. This flowsheet is shown schematically in Figure 13.5(a). The DME process is simple, no by-products are formed, the separations are relatively easy, and the methanol can be purified easily prior to being recycled to the front end of the process. In attempting to simulate this process for the first time, it is evident that two recycle streams are present. The first is the unreacted methanol that is recycled to the front of the process, upstream of the reactor. The second recycle loop is due to the heat integration scheme used to preheat the reactor feed using the reactor effluent stream. The best way to simulate this flowsheet is to eliminate the recycle streams as shown in Figure 13.5(b). In this figure, two separate heat exchangers have been substituted for the heat integration scheme. These exchangers allow the streams to achieve the same changes in temperature while eliminating the interaction between the two streams. The methanol recycle is eliminated in Figure 13.5(b) by producing a methanol pseudo-output stream. The simulation of the flowsheet given in Figure 13.5(b) is straightforward; it contains no recycle streams and will converge in a single flowsheet iteration. Troubleshooting of the simulation, if input errors are present, is very easy because the flowsheet converges very quickly. Once a converged solution has been obtained, the recycle streams can be added back. For example, the methanol recycle stream would be introduced back into the simulation. The composition of this stream is known from the preceding simulation, and this will be a very good estimate for the recycle stream composition. The simulation is then run with the preceding simulation as the starting point. Once the simulation has been run successfully with the methanol recycle stream, the heat integration around the reactor can be added back and the simulation run again. Although this method may seem unwieldy, it does provide a reliable method for obtaining a converged simulation.

Figure 13.5 Block Flow Diagram for DME Process Showing (a) Recycle Structure and (b) Elimination of Recycles

For the DME flowsheet in Figure 13.5, the unreacted methanol that was recycled was almost pure feed material. This means that the estimate of the recycle stream composition, obtained from the once-through simulation using Figure 13.5(b), was very good. When the recycle stream contains significant amounts of by-products, as is the case with the hydrogen recycle stream in Figure 1.5 (Streams 5 and 7), the estimate of the composition using a once-through simulation will be significantly different from the actual recycle stream composition. For such cases, when purification of the recycle stream does not occur, it is best to keep this recycle stream in the flowsheet and eliminate all other recycle streams for the first simulation. Once a converged solution is reached, the other recycle streams can be added back one at a time.

Often, a series of case studies will need to be run using a base-case simulation as a starting point. This is especially true when performing a parametric optimization on the process (see Chapter 14). When performing such case studies, it is wise to make small changes in input parameters in order to obtain a converged simulation. For example, assume that a converged simulation for a reactor module at 350°C has been obtained, and a case study needs to be run at 400°C. When the equipment temperature in the reactor module is changed and the simulation is rerun, it may be found that the simulation does not converge. If this is the case, then, for example, start with the base-case run, change the reactor temperature by 25°C, and see whether it converges. If it does, then the input can be changed by another 25°C to give the desired conditions, and so on. The use of small increments or steps when simulating changes in flowsheets often produces a converged simulation when a single large change in input will not.

Often when simulating a process, it is the flowrate of products (not feeds) that is known—for example, production of 60,000 tonne/y of chemical X, with a purity of 99.9 wt%. If a converged solution has been found in which all the product specifications have been met except that the flowrate of primary product is not at the desired value, it is a simple matter to multiply all the feeds to the process by a factor to obtain the desired flowrate of the product; that is, the solution is scaled up or down by a constant factor and the simulation rerun to get the correct equipment specifications.

For more advanced simulation applications, such as optimizing or simulating existing plants, it may be necessary or useful to use controller modules (also called design specifications, depending on the simulator) in the simulation to obtain a desired result. For example, in a recycle loop, it might be required that the ratio of two components entering a reactor be set at some fixed value. A controller module could be used to adjust the purge flowrate from the recycle stream to obtain this ratio. A controller module can also be used to specify the feed necessary for the product flowrate to be at a specific value. The use of controller modules introduces additional recycle loops. The way in which specifications for controllers are given can cause additional convergence problems, and this topic is covered in detail by Schad [10].

13.4 Choosing Thermodynamic Models

The results of any process simulation are never better than the input data, especially the thermodynamic data.

Everything from the energy balance to the volumetric flowrates to the separation in the equilibrium-stage units depends on accurate thermodynamic data.

If reaction kinetics information is missing, the simulator cannot calculate the conversion from a given reactor volume. Because such a calculation is not possible, only equilibrium reactor modules and those with specified conversions can be used.

Only a few, readily available data are required to estimate the parameters in simple thermodynamic models. If the critical temperature and critical pressure are known for each pure component, the parameters for simple, cubic equations of state can be estimated. Even if these critical properties are unknown, they in turn can be estimated from one vapor pressure and one liquid density. Group-contribution models require even less information: merely the chemical structure of the molecule. However, these estimations can never be as accurate as experimental data. In thermodynamics, as elsewhere, you get only what you pay for—or less!

Using the default thermodynamics packages in a process simulator will often lead to an erroneous solution.

Compounding this problem is the development and implementation of expert systems to help choose the thermodynamic model. These methods are a good starting point but verification through comparison with real data is always necessary.

A safe choice of thermodynamic model requires knowledge of the system, the calculation options of the simulator, and the margin of error. In this section, guidance on choosing and using a thermodynamic model is given. In an academic setting, the choice of thermodynamic model affects the answers but not the ability of the student to learn how to use a process simulator—a key aspect of this book. Therefore, the examples throughout this book use simplistic thermodynamic models to allow easy simulation. In any real problem, where the simulation will be used to design or troubleshoot a process, the proper choice of thermodynamic model is essential. This section focuses on the key issues in making that choice, in using experimental data, and in determining when additional data are needed.

It has been assumed that the reader understands the basics of chemical engineering thermodynamics as covered in standard textbooks [4–6]. As pointed out before, it is extremely important that the chemical engineer performing a process simulation understand the thermodynamics being used. In a course, the instructor can often provide guidance. The help facility of the process simulator provides a refresher on details of the model choices; however, these descriptions do not include the thermodynamics foundation required for complete understanding. If the descriptions in the help facility are more than a refresher, the standard thermodynamics textbooks should be consulted.

If the thermodynamic option used by the process simulator is a mystery, the meaning of the results obtained from the simulation will be equally mysterious.

13.4.1 Pure-Component Properties

Physical properties such as density, viscosity, thermal conductivity, and heat capacity are generally not difficult to predict accurately in a simulation. The group-contribution methods are reasonably good, and simulator databanks include experimental data for more than a thousand substances. Although these correlations have random and systematic errors of several percent, this is close enough for most purposes. (However, they are not sufficient when paying for a fluid crossing a boundary based on volumetric flowrate.) As noted in Section 13.2.2, it is important always to be aware of which properties are estimated and which are from experimental measurements.

13.4.2 Enthalpy

Although the pure-component heat capacities are calculated with acceptable accuracy, the enthalpies of phase changes often are not. Care should be taken in choosing the enthalpy model for a simulation. If the enthalpy of vaporization is an important part of a calculation, simple equations of state should be used with caution. In fact, the “latent heat” or “ideal” options often give more accurate results. If the substance is above or near its critical temperature, equations of state must be used, but the user must beware, especially if polar substances such as water are present.

13.4.3 Phase Equilibria

Extreme care must be exercised in choosing a model for phase equilibria (sometimes called the fugacity coefficient, K-factor, or fluid model). Whenever possible, phase-equilibrium data for the system should be used to regress the parameters in the model, and the deviation between the model predictions and the experimental data should be studied.

There are two general types of fugacity models: equations of state and liquid-state activity-coefficient models. An equation of state is an algebraic equation for the pressure of a mixture as a function of the composition, volume, and temperature. Through standard thermodynamic relationships, the fugacity, enthalpy, and so on for the mixture can be determined. These properties can be calculated for any density; therefore, both liquid and vapor properties, as well as supercritical phenomena, can be determined.

Activity-coefficient models, however, can only be used to calculate liquid-state fugacities and enthalpies of mixing. These models provide algebraic equations for the activity coefficient (γi) as a function of composition and temperature. Because the activity coefficient is merely a correction factor for the ideal-solution model (essentially Raoult’s Law), it cannot be used for supercritical or “noncondensable” components. (Modifications of these models for these types of systems have been developed, but they are not recommended for the process simulator user without consultation with a thermodynamics expert.)

Equations of state are recommended for simple systems (nonpolar, small molecules) and in regions (especially supercritical conditions for any component in a mixture) where activity-coefficient models are inappropriate. For complex liquid mixtures, activity-coefficient models are preferred, but only if all of the binary interaction parameters (BIPs) are available.

Equations of State. The default fugacity model is often either the SRK (Soave-Redlich-Kwong) or the PR (Peng-Robinson) equation. They (like most popular equations of state) normally use three pure-component parameters per substance and one binary-interaction parameter per binary pair. Although they give qualitatively correct results even in the supercritical region, they are known to be poor predictors of enthalpy changes, and (except for light hydrocarbons) they are not quantitatively accurate for phase equilibria.

The predicted phase equilibrium is a strong function of the binary interaction parameters (BIPs). Process simulators have regression options to determine these parameters from experimental phase-equilibrium data. The fit gives a first-order approximation for the accuracy of the equation of state. This information should always be considered in estimating the accuracy of the simulation. Additional simulations should be run with perturbed model parameters to get a feel for the uncertainty, and the user should realize that even this approach gives an optimistic approximation of the error introduced by the model. If BIPs are provided in the simulator and the user has no evidence that one equation of state is better than another, then a separate, complete simulation should be performed for each of these equations of state. The difference between the simulations is a crude measure of the uncertainty introduced into the simulation by the uncertainty in the models. Again, the inferred uncertainty will be on the low side.

Monte-Carlo simulations (see Section 10.7) can be done with the results of the regression; however, process simulators are not currently equipped to perform these directly. A simpler approach is to perform the simulation with a few different values of the BIPs for the equation of state. These values are typically 0.01 to 0.10. Larger values are rare, except in highly asymmetric systems. However, the difference between results calculated with values of, say, 0.01 and 0.02 can be large.

If BIPs are available for only a subset of the binary pairs, caution should be exercised. Assuming the unknown BIPs to be zero can be dangerous. Group-contribution models for estimating BIPs for equations of state can be used with caution.

There may be dozens of equation-of-state options, including different modifications of the same equation of state, plus a few mixing-rule choices. For polar or associating components or for heavy petroleum cuts, the help facility of the simulator should be consulted. Because different choices are available on the different simulators, they will not be covered here.

For most systems containing hydrocarbons and light gases, an equation of state is the best choice. Peng-Robinson or Soave-Redlich-Kwong are good initial choices. (Note that neither the van der Waals nor Redlich-Kwong equation is a standard choice in simulators. These two equations of state were tremendous breakthroughs in fluid property models, but they were long ago supplanted by other models that give better quantitative results.) VLE (vapor-liquid equilibrium) data for each binary system can then be used with the regression utility to calculate the BIPs for the binary pairs and to plot the resulting model predictions against the experimental data. This regression is done separately for each equation of state. The equation that gives a better fit in the (PTxy) region of operation of the unit operation of interest is then used. If phase-equilibrium data are available at different temperatures, the temperature-dependent BIP feature of the simulator can be used. In the simulator databank, many BIPs are already regressed and available.

If neither simple equation of state adequately reproduces the experimental data, one of the other equations of state or other mixing rules, or a temperature-dependent BIP, may be needed. These often work better for polar-nonpolar systems. However, running the simulation more than once with different BIPs and with different thermodynamic models to judge the uncertainty of the result is recommended, as shown in Example 13.3. If the difference between the simulations seriously affects the viability of the process, a detailed uncertainty analysis is essential [11]. This is beyond the scope of this book.

Use both the Peng-Robinson and the Soave-Redlich-Kwong equations of state to calculate the methane vapor molar flowrate from a flash at the following conditions:

Temperature: |

225 K |

|

Pressure: |

60.78 bar |

|

Feed flowrates: |

||

Carbon dioxide |

6 kmol/h |

|

Hydrogen sulfide |

24 kmol/h |

|

Methane |

66 kmol/h |

|

Ethane |

3 kmol/h |

|

Propane |

1 kmol/h |

|

Compare the results for BIPs from the process simulator databank and with the BIPs set to zero.

Solution

The following results were obtained using CHEMCAD 7.1.1:

Databank BIPs |

Zero BIPs |

|

Peng-Robinson |

51.9 kmol/h |

47.3 kmol/h |

Soave-Redlich-Kwong |

53.2 kmol/h |

35.2 kmol/h |

The two equations of state give different results, and the effect of setting the BIPs to zero is significant especially for SRK.

For most chemical systems below the critical region, a liquid-state activity-coefficient model is the better choice.

Liquid-State Activity-Coefficient Models. If the conditions of the unit operation are far from the critical region of the mixture or that of the major component, and if experimental data are available for the phase equilibrium of interest (VLE or LLE), then a liquid-state activity-coefficient model is a reasonable choice. Activity coefficients (γi) correct for deviations of the liquid phase from ideal solution behavior, as shown in Equation (13.1).

where ˆϕvi

The roles of the terms in Equation (13.1) are discussed in detail in standard thermodynamics texts. Here, it is sufficient to point out that the two terms closest to the equal sign (on either side of the equal sign) give Raoult’s Law and that the most important of the remaining correction terms is usually γi, the activity coefficient. Thus, use of an activity-coefficient model requires values for the pure-component vapor pressures at the temperature of the system. There are several important considerations in using activity-coefficient models:

If no BIPs are available for a given binary system, an activity-coefficient model will give results similar to, but not necessarily the same as, those for an ideal solution.

The standard version of the Wilson equation cannot predict liquid-liquid immiscibility.

The BIPs for various activity-coefficient models can be estimated by UNIFAC. However, caution must be exercised because increased uncertainty is inserted into the model with such estimation.

Some BIP estimation may be done automatically by the simulator.

There are no reliable rules for choosing an activity-coefficient model a priori. The standard procedure is to check the correlation of experimental data by several such models and then choose the model that gives the best correlation.

Parameters regressed from VLE data are often unreliable when used for LLE prediction (and vice versa). Therefore, some process simulators provide a choice between two sets of parameter sets.

Often ternary (and higher) data are not well predicted by activity-coefficient models and BIPs.

The BIPs are typically highly correlated. This and the empirical nature of these models lead to similar fits to experimental data with very different values of the BIPs.

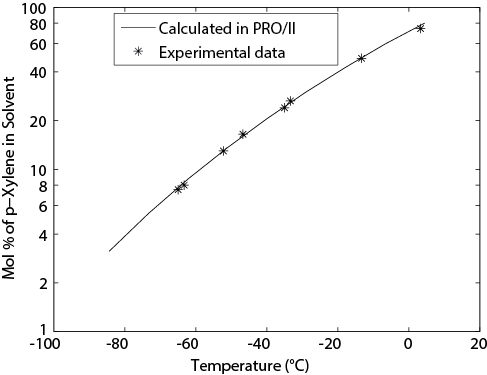

Some of these considerations are demonstrated in Examples 13.4 and 13.5.

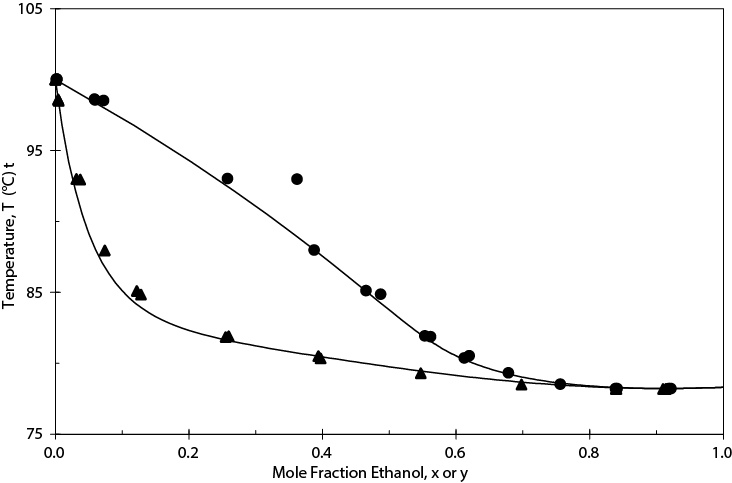

Use the simulator databank BIPs for NRTL to calculate the vapor-liquid equilibrium for ethanol/water at 1 atm. Compare the results for BIPs set to zero. Regress experimental VLE data [12] to determine NRTL BIPs.

Solution

Figure E13.4(a) shows the Txy diagrams using the NRTL BIPs from the CHEMCAD databank and for these BIPs set to zero. Note that the latter case results in an ideal solution; thus, the azeotrope is missed. Regressing the experimental data for this system with the simulator regression tool gives the results shown in Figure E13.4(b). Although the BIPs in the databank (−55.1581, 670.441, 0.3031) and those regressed from the data (−104.31, 807.10, 0.28675) are quite different, the VLE calculated is very similar and is close to the experimental data.

Calculate the LLE for the ternary di-isopropyl-ether/acetic-acid/water using NRTL and the BIPs available for the three binary pairs in the simulator databank. Compare the prediction with ternary LLE data for this system at 24.6°C [13].

Solution

See Figure E13.5. The experimental phase envelope (dotted lines) is twice the size of the predicted one (solid lines). This would lead to gross error in extraction calculations. Note that if all the BIPs are set to zero, there is no liquid-liquid immiscibility region. However, if the ternary LLE data were used to regress all of the BIPs simultaneously, the fit would be quite good.

The recommended strategy for choosing a liquid-state, activity-coefficient model is as follows:

The simulator databank is checked for BIPs for all the binary pairs in the system. If these are available, they are most often from the DECHEMA Data Series [12, 13], but sometimes they are from different sources. Some simulators provide the literature citation; others do not. Each of the three most common models (Wilson, NRTL, UNIQUAC) has different values for BIPs, and they are not correlated from one model to another. Although BIPs for Wilson may not be available for partially immiscible systems (see above), if a binary pair has BIPs for NRTL or for UNIQUAC, the BIPs for that pair should be available for both models. If they are not, the original data are found and the BIPs are fit for the other model.

If phase-equilibrium data can be found for the binary pairs with missing BIPs, a regression is done with the simulator to find the missing BIPs.

For binary pairs that have no measured phase equilibria (there are many!), the UNIFAC estimation option of the simulator is used to estimate the BIPs. There are two UNIFAC methods: one for VLE and one for LLE. The choice depends on the type of equilibrium for the unit operation of interest.

If the unit operation of interest is an extraction or other operation involving LLE or VLLE and ternary data are available, the predictions of the three activity-coefficient models are checked for the ternary LLE.

One of the three methods usually shows a significantly better fit than the others. This method, and the second-best method, are used for the simulation. Comparing the two results provides a rough sense of the uncertainty of the calculation. Note that the “true” result is certainly not guaranteed to be between the two results. It is possible that this strategy will give a false sense of low uncertainty if the two methods give similar predictions that are far from the experimental data. This uncertainty strategy is used in the same way as is any heuristic from Chapter 11. Although this strategy is an analogue of a long-practiced experimental strategy and the basis for numerical analysis error estimation, it does take considerable engineering judgment. Good judgment comes from experience.

If the predictions from the activity-coefficient model chosen do not fit the measured data, a more detailed uncertainty analysis is needed. Although the details of such an analysis are outside the scope of this book, the most important decision is that one is warranted. Calibration of the uncertainty of simulation results is obtained from simulations run with different estimates (high and low, when possible).

The UNIFAC model is never used if experimental data are available for the binary system. UNIFAC is a group-contribution model for determining the BIPs for the UNIQUAC model (and by extension for the NRTL and Wilson models and for equations of state). Only chemical structure data are needed, but the calculations are not very accurate. When determining the numbers of groups within a molecule, the starting point should always be the largest group. This strategy minimizes the assumptions (and therefore the errors) in the model. Group-contribution models should be used with caution.

For many systems, a model such as UNIFAC may be the only option. If so, even a very crude uncertainty estimate can be difficult. If only one phase-equilibrium datum for the system can be found, its deviation from the model prediction is at least some estimate of the uncertainty (as long as that datum was not used to regress parameters).

Using Scarce Data to Calibrate a Thermodynamic Model. Any experimental data on phase equilibria can be used to perform a crude calibration or verification of the model. It need not be the type of data that would be taken in the lab. If the recovery in a column for one set of conditions is known, for example, and if only one BIP is unknown, then the only value of the BIP that will reproduce that datum can be found. Such data are sometimes found in patents.

More Difficult Systems. The above discussions pertain to “easy” systems: (1) small, nonpolar or slightly polar molecules for equations of state and (2) nonelectrolyte, nonpolymeric substances considerably below their critical temperatures for liquid-state activity-coefficient models. Most simulators have some models for electrolytes and for polymers, but these are likely to be even more uncertain than for the easy systems. Again, the key is to find some data, even plant operating data, to verify and to calibrate the models. If the overall recovery from a multistage separation is known, for example, the column can be simulated using the best-known thermodynamic model, and the deviation between the plant datum and the simulator result is a crude (optimistic) estimate of the uncertainty.

Because most thermodynamic options are semitheoretical models for small, nonpolar molecules, the more difficult systems require another degree of freedom in the model. The most common such modification is to make the parameters temperature dependent. This requires additional data, but there is some theoretical justification for using effective model parameters that vary with temperature.

Hybrid Systems. Often a process includes components as wide ranging as solids at room temperature to supercritical gases. They can include water, strong acids, hydrocarbons, and polymers. Often, no single thermodynamic model can be used reliably to predict the fugacities of such a wide range of components. For these cases, simulators allow for hybrid thermodynamic models. The breadth of hybridization varies from one simulator to another, but all at least allow for some components to be considered immiscible with respect to others. For example, the NRTL model may be used for binary pairs for which both compounds are subcritical, while Henry’s Law is used for supercritical (so-called noncondensable) components. Each simulator allows for immiscibility of water and hydrocarbon liquid phases, with the compositions of hydrocarbons in the aqueous phase estimated with Henry’s Law and the liquid-liquid equilibrium for water calculated based on ideal solution in the aqueous phase and some chosen model in the hydrocarbon-rich phase. Each of these options should be checked so that it is clear what the simulator is doing. Although Henry’s Law does not necessarily mean that the phase is aqueous, the Henry’s Law model in a process simulator is often developed only for aqueous systems.

Another kind of hybridization is the choice of auxiliary models for liquid-state activity-coefficient models. The model to use for the vapor phase can be specified and whether to make the Poynting correction. The best choice is to use an equation of state (PR or SRK) for the vapor-phase correction and to use the Poynting correction. Both corrections go smoothly to zero in the low-pressure limit, and neither should add greatly to the computational time for most flowsheets.

The final type of hybridization is the use of different models for different unit operations. Although this appears to be inconsistent at first, it is reality that thermodynamic models are not perfect and that some work much better for LLE than for VLE, some work better for low pressures and others for high pressures, and some work for hydrocarbons but not for aqueous phases. Furthermore, simulators perform calculations for individual units and then pass only component flowrates, temperature, and pressure to the next unit. Thus, consistency is not a problem. Therefore, the possibility of using different models for different unit operations should always be considered. All of the simulators allow this, and it is essential for a complex flowsheet. An activity-coefficient model can be used for the liquid-liquid extractor and an equation of state for the flash unit. This hybridization can be extremely important when, for example, some units contain mainly complex organics and other units contain light hydrocarbons and nitrogen.

Other Models. Different simulators have a variety of additional models beyond those mentioned above. For example, some have nonideal electrolyte thermodynamic models that calculate species equilibria, some have polymer thermodynamic packages, and some allow petroleum cuts to be represented automatically by pseudocomponents. Presently, these packages are less consistent across simulators and are not discussed here. However, the range of models available for the simulator being used should always be investigated.

13.4.4 Using Thermodynamic Models

In summary, the assumed best thermodynamic model should be used, based on the rough guidelines above. However, a process should always be resimulated either with another model assumed to be equally good or with different model parameters (see Example 13.7). The appropriate perturbation to apply to the parameters is available from the experimental data regression or from comparison of calculated results with experimental or plant data. Such data should always be sought for the conditions closest to those in the simulation. If the application is liquid-liquid extraction, for example, liquid-liquid equilibrium data (rather than vapor-liquid equilibrium data) should be used in the parameter regression, even though the same activity-coefficient models are used for both liquid-liquid and vapor-liquid equilibria.

The availability of BIPs in the databank of a process simulator must never be interpreted as an indication that the model is of acceptable accuracy.

These parameter values are merely the “best” for some specific objective function, for some specific set of data. The model may not be able to correlate even these data very well with this optimum parameter set. And one should treat a decision to use a BIP equal to zero as equivalent to using an arbitrary value of the BIP. The decision to use zero is, in fact, a decision to use a specific value based on little or no data.