Chapter 2

Checking Out Common Components and Systems

IN THIS CHAPTER

![]() Identifying the major parts of a PV system

Identifying the major parts of a PV system

![]() Distinguishing between battery-based and battery-less systems

Distinguishing between battery-based and battery-less systems

![]() Helping your customers select the correct system for their needs

Helping your customers select the correct system for their needs

This chapter may seem trivial and worth skipping when all you want to do is dive into a new-to-you technology and design systems that’ll be the envy of your peers (not to mention major moneymakers). My advice to you? Remember that it’s all about the details. Before you can design and install that envy-inducing, moneymaking PV system, you need to have a grasp on exactly what goes into a PV system. Each component has a unique and important role in the whole system. You, the designer and installer, have to understand these components and their purpose, as well as how they fit together as a whole, in order to help your customers select the best system for their needs. This chapter gives you the knowledge base you need to start working with and recommending PV systems.

Introducing the Components That Make Up PV Systems

Even though you and I probably drive a different kind of vehicle, the major components inside each one are identical. Both vehicles have an engine, some wheels, and a steering wheel to help us navigate, although your vehicle may have a bigger engine than mine, and my vehicle may have bigger wheels and a smaller steering wheel than yours. You can look at PV systems in a similar manner. The basic components, such as the PV modules and the inverter, are the same even though the types of components differ based on the user’s needs and what the local regulations require. In the following sections, I take a look at the major components of a typical PV system and explain how each component relates to the others.

Note: The following information isn’t all-inclusive. Rather, it’s a primer designed to help you understand PV systems as a whole. Each of these components receives much more attention in later chapters, so please don’t feel overwhelmed with the descriptions I provide here.

PV modules and racking

PV modules are the source of power in a PV system. They produce DC electricity, which is easily stored in battery banks but needs to become AC power via an inverter for use in homes. (I present the features and limitations of different types of PV modules in Chapter 6.)

Racking components hold the PV array to the location where you choose to place the modules. One typical way to mount the entire array is on the roof of the structure you’re working with. Other options include building-integrated mounting (where the PV array becomes a substitute for the roofing or window materials) and mounting the array on a racking system down at ground level. Another common option is mounting the PV array on top of a pole rack. I give you the scoop on mounting methods and considerations in Chapter 16.

No matter where they’re mounted, PV modules are always connected to these particular components: disconnects, inverters, and charge controllers.

- A module is a single unit consisting of PV cells contained in an environmentally secure package.

- A panel is a group of modules fastened and wired together.

- An array is all the modules (and panels) and racking components used to produce DC electricity.

Battery bank

For systems that require energy storage (namely, any system that needs to operate without the utility grid; see the later “Battery-based systems” section for more information), a battery bank, multiple batteries wired together to achieve the specific voltage and energy capacity desired, is the best option.

The battery bank is typically housed in a container to keep the batteries safe. The PV array connects to it in order to provide charging, with a charge controller located somewhere in between. The battery bank is also connected to the inverter to provide power for the AC loads. If the system also uses DC loads, the battery bank is wired to a DC load center. (Don’t know what loads and load centers are? I cover both later in this chapter.)

I describe the different battery technologies in detail in Chapter 7, but the most common batteries used for the typical PV system are as follows:

- Sealed batteries: These come in a sealed container that requires a reduced amount of maintenance by the end user.

- Flooded batteries: These come in an open (or flooded) container that requires a higher level of user interaction.

Charge controller

A charge controller is a piece of electronics that’s placed between the PV array and the battery bank. As you can probably guess, its primary function in life is to control the charge coming into the battery bank from the PV array. Charge controllers can vary from a small unit intended to connect a single PV module to a single battery all the way to a controller designed to connect a multiple-kilowatt PV array to a large battery bank.

Flip to Chapter 8 for more information about charge controllers, including their features, technology, and sizing.

Inverter

Inverters turn the DC power produced by PV arrays or stored by battery banks (in battery-based systems) into the AC power used in homes and businesses. They come in many different shapes and sizes. An inverter can be as small as the 100-watt unit you plug into the DC plug in your car or as large as a megawatt unit installed in conjunction with a utility-scale PV project. (I delve into the details of inverter specifications in Chapter 9.)

The inverters in PV applications fall into two major categories:

- Utility-interactive: These inverters can connect to a utility and either supply power to the connected loads or send electricity back into the grid, essentially running the meter backward.

- Stand-alone: These inverters aren’t designed to interact with the utility and work by supplying power to loads.

Utility-interactive inverters come in two flavors:

- Grid-direct: These are primarily used in systems for homes and businesses with utility power present. They don’t provide the user with any energy storage, which means if the utility power isn’t present, the inverter can’t work. In grid-direct inverter systems, the PV array is connected to the inverter on the DC side, and the inverter is connected to the utility grid on the AC side.

- Battery-based: These require a stable voltage source of power, typically a battery bank, to keep the inverter running. A PV system using this inverter requires more components and is generally more complicated, but it allows the user to have backup power for times when the utility goes out. Battery-based inverters use a PV array and charge controller on the DC side and connect to the utility on the AC side.

Stand-alone inverters are quite similar to utility-interactive, battery-based inverters. The main difference is the source of AC power. In a typical stand-alone system you have an AC engine generator to supply power to the loads and allow for battery charging when the PV array can’t keep up with the user’s energy consumption. On the DC side, a stand-alone inverter is connected to the same components as its utility-interactive, battery-based counterpart, but on the AC side, the inverter sends power only to AC loads.

Loads

Loads are all the pieces of electrical equipment people want to use in their homes and offices. You can have DC loads or AC loads (and sometimes even both). You just have to make sure you supply the correct type of power to the load. For instance, you can’t use a DC light bulb when AC power is provided.

Loads are served differently depending on the system used (you can find out more about different systems later in this chapter).

- In grid-direct systems, loads are primarily served by the utility. The PV system can send power directly to the loads or back into the utility grid.

- In battery-based systems, the inverters are designed to directly run the loads connected to the inverter in the load center. This requires sizing the inverters differently based on the inverter technology used. Note: Occasionally, DC loads are present in battery-based systems; when they are, they receive their power from the battery bank via a DC load center.

Load centers

A load center is the place where electrical loads (see the preceding section) receive their power. In a typical scenario where the utility is present, the utility sends power to a building at a single location. The utility’s wires are connected to a meter; from that meter, a connection is made to the main distribution panel (MDP; also called a main load center). The individual wires running throughout the building are ultimately connected to the MDP via a circuit breaker.

When a number of electrical circuits are connected within a building, or if a detached structure is present, such as a garage, often an AC subpanel is used to help reduce the number of wires running all the way across the house. Figure 2-1 is an example of how a main panel and subpanel can be laid out in a residential setting. Usually, a circuit breaker in the MDP sends electricity to the subpanel. The subpanel then uses multiple circuit breakers to send electricity to loads and outlets that are physically close to the subpanel.

FIGURE 2-1: A main distribution panel and a subpanel in a residence.

Disconnects and overcurrent protection

A number of safety and servicing requirements exist for PV systems, including disconnects (the switches that can turn everything off, much like a big version of a light switch) and overcurrent protection devices (the pieces of equipment, typically a fuse or circuit breaker, that automatically turn a load off if it’s drawing too much current). The requirements for the exact components and their locations vary depending on the specifics of your installation and the requirements of the local utility and electrical inspector, but here are the main considerations:

- Disconnects are placed in locations for system maintenance and to isolate the PV array and inverter.

- Overcurrent protection is placed in the system to protect the conductors (wires) from becoming too hot and starting a fire.

Disconnects and overcurrent protection are commonly combined in a single enclosure in the form of a fusible disconnect.

Utility interconnection

The point at which a PV system interconnects with a utility grid is often referred to as the point of common connection (POCC). This is an electrical connection that can take various forms depending on the size of the PV system and the electrical equipment already located on-site.

The most straightforward way of making the POCC is to attach the inverter to a circuit breaker in the existing MDP on-site. Specific requirements for this type of connection need to be met, but that isn’t a difficult task in most cases.

Differentiating between PV System Types

You know the saying “the whole is greater than the sum of its parts”? It applies to PV systems too. After you have a picture of the major components of a PV system, you’re ready to focus on the two main types of systems: grid-direct and battery-based. The sections that follow help you create a mental picture of both systems; they also get you ready to differentiate between the two for scenarios you’re bound to encounter.

Grid-direct systems

For those folks with access to the utility grid, a grid-direct system is the most common type of PV system being installed today. A grid-direct (sometimes referred to as battery-less) PV system requires the least number of components and is typically the most efficient in converting the sun’s radiation into usable AC electricity for loads. These systems have the added benefit of requiring very little human interaction because the inverter is able to automatically control the flow of electricity from the PV array to the grid. In the following sections, I describe the configuration of a grid-direct system and explain its pros and cons.

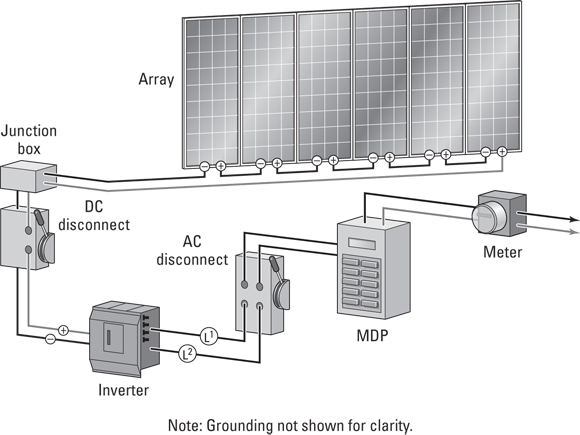

The configuration

- A PV array with racking

- A junction box to get the wires in the building

- A DC disconnect

- An inverter (or more than one, depending on the size of the PV array and/or whether you have multiple arrays)

- An AC disconnect

- A meter to record the energy produced by the PV array

- A utility interconnection across a circuit breaker inside the MDP

FIGURE 2-2: A typical grid-direct PV system.

As I explain in Chapter 17, the exact locations of all the equipment vary and are dependent on the specific system. However, Figure 2-2 is a good representation of the components most grid-direct systems use.

The pros and cons

Since 2001, the grid-direct system has been the most popular type of PV system installed in the United States. Why? Because 2001 is when manufacturers started selling reliable grid-direct inverters. It’s also when rebate programs came along.

- You have fewer components to work with.

- The design and installation are more simplistic (meaning less expensive).

- The system’s energy output is greater.

- The maintenance requirements are fewer.

- The inverter can be located outside the building.

Battery-based systems

The second major type of PV system (in addition to the grid-direct system described earlier in this chapter) is battery-based. A battery-based system can be utility-interactive or stand-alone. The two types are almost identical, but their differences are important to know:

- Utility-interactive, battery-based systems require an inverter that’s specifically listed as a utility-interactive inverter and has the same anti-islanding features as the grid-direct units. Although the stand-alone inverter requires safety listings, the anti-islanding portion doesn’t apply. (I provide basics on different types of inverters earlier in this chapter.)

- Utility-interactive, battery-based systems allow the user to back up certain loads but not the entire house. Yes, it’s possible to back up the entire house, but that’s pretty tough. Major energy-consuming appliances (think electric water heaters and clothes dryers) can’t be supported.

- Stand-alone, battery-based systems support all the loads in a home. The caveat, as I show you in Chapter 12, is that these loads must be very carefully considered and minimized as much as possible.

- In stand-alone, battery-based systems, the AC power source is an engine generator. Consequently, the inverter needs to be ready, willing, and able to accept power from the generator.

In the following sections, I fill you in on the basic configuration of a battery-based system and explain its pros and cons.

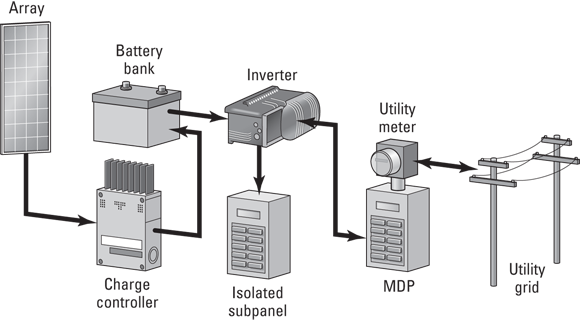

The configuration

- A PV array with racking

- A charge controller (or multiple charge controllers, depending on the size of the PV array in relation to the charge controller’s size)

- DC disconnects (specifically, two for every charge controller and one for every inverter so you can properly isolate all the equipment)

- A battery bank in a vented battery enclosure

- Battery metering

- An inverter (you may need more than one if the number of loads run at the same time will exceed the ability of a single inverter)

- An inverter bypass switch

- A backup load center (for utility-interactive systems only)

- AC disconnects

- An MDP with overcurrent protection (this is where the inverter is interconnected to the utility in a utility-interactive system)

FIGURE 2-3: A utility-interactive, battery-based PV system.

The optional components include

- A DC load panel (located near the battery bank and DC disconnects)

- A backup engine generator (located away from the rest of the equipment to keep the noise level down but wired into the inverter[s])

The pros and cons

Because battery-based systems can be used in utility-interactive and stand-alone scenarios, look at their pros and cons in light of where they’re used:

- The major pro of utility-interactive, battery-based systems is that you have power when the utility is out. (Depending on the user, this may be more than just a pro — it may be an absolute requirement!)

- Stand-alone, battery-based PV systems are typically compared to an electrical system with power supplied by an engine generator. The pro to the stand-alone system in this case is that the PV array provides silent, clean power with far less maintenance than an engine generator.

The biggest cons to utility-interactive, battery-based systems are the added costs and increased maintenance requirements. Because a battery-based system contains more components than a grid-direct system, the battery-based option is always going to cost more, especially over time. Also, the more components a system has, the more often you have to check and make sure that everything is working properly, hence the increased maintenance.

The main downside to stand-alone, battery-based systems is the extra work because battery banks take a lot of monitoring and maintaining. And if the system also features a backup engine generator, there’s even more to maintain. Fortunately, with a properly sized PV array and battery bank, the generator maintenance can be kept to a minimum.

Figuring Out the Right System Type for Any Situation

After you know about PV systems and their components, you’re better equipped to tackle the fun part — helping customers figure out which PV system is right for their situation. In the following sections, I separate the decision-making process into two main categories: when the customer is connected to the grid and when the customer is off the grid.

The customer is connected to the grid

For customers who want a PV system, and where utility power is available, the options are two-fold. They can have either a grid-direct system or a utility-interactive, battery-based system. Sometimes customers automatically assume they want the utility-interactive, battery-based system because when the power goes out, they’ll still have power for the television and cold food in the fridge. What they don’t consider are cost and maintenance.

- How often does the power go out?

- How long do the outages last?

- What activities (involving electricity) can’t be interrupted due to a power outage?

- How much money is realistic for you to spend on this feature?

- How much time are you willing to spend maintaining a battery bank?

- Will you be willing replace that battery bank in five to seven years?

After thinking about these questions, the reality of the situation quickly sets in for most urban and suburban PV-system-owners-to-be, and they give up on the idea of a battery-based system for the easier to maintain and less expensive grid-direct system. Of course, some individuals (like those rural dwellers who are at the end of the electrical line and see outages that last for days) still opt for the utility-interactive, battery-based system.

The customer isn’t connected to the grid

If a customer is constructing a remote home or isn’t connected to the grid in a current building but wants to make a change from her current system, the first type of PV system you should suggest is a stand-alone, battery-based one. This option makes the most sense for this type of customer because it offers an electrical supply that isn’t dependent on an engine generator.

Provided the customer is willing to bring utility power in, you can also suggest a grid-direct or utility-interactive, battery-based PV system. The deciding factor here is how far the utility has to bring its lines and how much that’s going to cost in addition to the cost of installing and operating a PV system. I’ve heard of utilities telling people it’d cost $40,000 to bring the utility a quarter of a mile to their residence — and then they get the pleasure of writing the utility a monthly check!

When working with a potential stand-alone client, you have to take some time with her early in the process to prepare her for the realities of living without the utility grid. Most of the time, making this commitment requires a major lifestyle change, at least as it relates to energy consumption. To help your client choose the right system for her, look at her life today as well as what her life will look like in the future and evaluate the different power sources that may apply for her.

- What’s your budget for the electrical system? (It’s nearly impossible to quote average costs with stand-alone PV systems due to the many variables involved.)

- Are you willing to maintain your battery bank one or two times a month?

- What are the electrical loads you want to run? (See Chapter 12 for more on this topic.)

- Where do you see your electrical demands in five to seven years?

- How much generator run time is acceptable for you?

- Do you have any other renewable energy resources (such as wind power or hydroelectric power) available to you?

The terms PV module and PV panel are often used interchangeably (I’ve been fighting myself for years on getting it straight when talking to people). You also see and hear PV array quite a bit. The fact is, different definitions describe these terms. If you’re discussing modules, panels, and arrays with someone, you need to make sure you’re both talking the same language.

The terms PV module and PV panel are often used interchangeably (I’ve been fighting myself for years on getting it straight when talking to people). You also see and hear PV array quite a bit. The fact is, different definitions describe these terms. If you’re discussing modules, panels, and arrays with someone, you need to make sure you’re both talking the same language.  Just like your car’s fuel gauge tells you when you need to fill up, a battery monitor tells you how full the battery is. In battery-based systems, a monitoring system is very important in keeping track of the battery level.

Just like your car’s fuel gauge tells you when you need to fill up, a battery monitor tells you how full the battery is. In battery-based systems, a monitoring system is very important in keeping track of the battery level. Sealed batteries are often referred to as “maintenance-free batteries.” Don’t believe the hype! Sealed batteries are indeed a reduced-maintenance option compared to flooded batteries, but they still need some attention. If you don’t advise your clients to monitor and properly maintain a battery bank, the batteries will die prematurely. Relatively simple battery monitoring can not only keep the system owner updated on the batteries’ status but it can also keep her from experiencing poor results when using the batteries. (

Sealed batteries are often referred to as “maintenance-free batteries.” Don’t believe the hype! Sealed batteries are indeed a reduced-maintenance option compared to flooded batteries, but they still need some attention. If you don’t advise your clients to monitor and properly maintain a battery bank, the batteries will die prematurely. Relatively simple battery monitoring can not only keep the system owner updated on the batteries’ status but it can also keep her from experiencing poor results when using the batteries. ( Battery-based systems can be used without an inverter to power DC-only loads, making them good for a PV array at a small remote cabin that needs only a few lights and a radio. Another possible location for such a system is a recreational vehicle that has a small PV array to recharge the house battery.

Battery-based systems can be used without an inverter to power DC-only loads, making them good for a PV array at a small remote cabin that needs only a few lights and a radio. Another possible location for such a system is a recreational vehicle that has a small PV array to recharge the house battery.