Law of Rare Events ◾ 191

CL = λ (12.8)

LCL = −λ λ3 (12.9)

In the previous example,

Upper control limit UCL 0.3 3 0.3

0.3 3 0.548

1.9

( ) = +

= + ×

= 443

is reasoning leads us to think of 1.943 defects per module as the statistical limit.

Poisson approximation thus allows us statistical control of defects. Any module with

more than 1.943 defects is a Poisson outlier. Poisson distribution here serves as a qual-

ity judge. (e use of this characteristic Poisson distribution is illustrated in Box 12.4.)

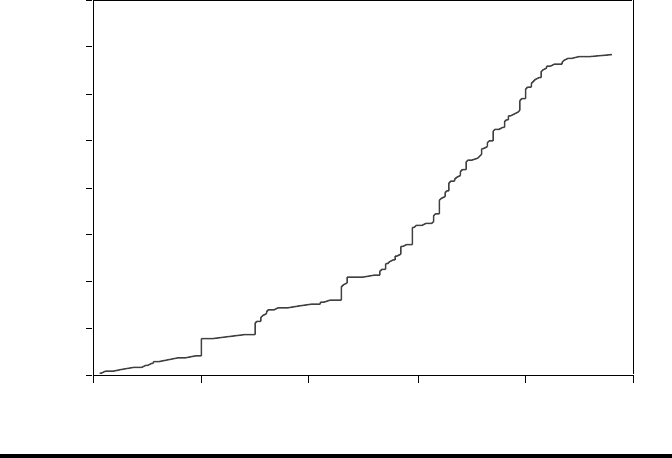

e CDF of the Poisson distribution, shown in Figure 12.9, is of special rel-

evance to software defect management.

It clearly shows only a few modules contain defects. e rest have zero defects.

is distribution helps to spot those defect intensive modules and subject them to

appropriate testing.

Another help from the Poisson distribution study is an objective estimate of the

right first-time index for the software product. is is the Poisson probability that

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

0 1 2

x, Module number

Poisson probability

3

Figure 12.8 Poisson distribution of module defects.

192 ◾ Simple Statistical Methods for Software Engineering

zero modules will have defects. For example, in the product described in Figure

12.7, the Poisson probability is 0.74 for x = 0. is is the right first-time index.

Study of Customer Complaint Arrival Rate

Based on Poisson Distribution

Customer complaints regarding field failure arrive at the Poisson rate. Let us con-

sider a case where the average number of failure complaints arriving per month is λ.

One question that comes to our mind is “Can we think about the maximum num-

ber of complaints that are likely to arrive?” Is there enough evidence in λ to predict

the maximum number of complaints? Poisson distribution is applied to such cases.

A c chart is plotted with the number of complaints arriving per month. e upper

limit in the chart is calculated by the same formula used above. We find that the

maximum number of complaints likely to arrive per month is

λ λ+ 3

is number could defy intuitive judgment of customer complaints; intuitive

judgment hovers around the average value. e predicted number may exceed the

maximum ever number of complaints received in any given month so far. e

Poisson boundary easily exceeds the trend forecast. e Poisson approximation to

customer complaint arrival is a very valuable aid.

An example of customer complaints arrival is shown in Figure 12.10.

1.2

1.0

0.8

0.6

0.4

0.2

0

0 2 4

x, Module number

Cumulative Poisson probability

6 8

Figure 12.9 Cumulative Poisson probability of module defects.

Law of Rare Events ◾ 193

e Poisson boundary is marked as an upper bound. A trend line is also included

in the figure to show how the Poisson boundary shows a complaint rate higher than

indicated by the trend.

In this context, the application of Poisson distribution to model baseball events

is illustrated in Box 12.5.

Applying Poisson Distribution to Software Maintenance

e arrival of service requests follows Poisson distribution. e interarrival time

follows exponential distribution. Both are memoryless. e time to repair a bug

does not depend on previous records. Mean time to fix bugs in a particular setup

controls dispersion of results. Month or week, teams may experience the same

Poisson curves. Sophisticated models for queues have been built, but the building

block is the exponential law.

Bathtub Curve of Reliability:

AUniversalModel of Rare Events

Failure of components is extensively used in reliability analysis because it is a Poisson

process. e bath tub curve of reliability has three zones. e first is characterized

by a rapidly decreasing failure rate. is region is known as the early failure period

(also called infant mortality period). Next, the failure rate levels off and remains

constant in the flat portion of the bathtub curve. Finally, the failure rate begins to

increase as materials wear out and degradation failures occur at an ever increasing

rate. is is the wear out failure period (see Figure 12.11).

0

2

4

6

8

10

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25

Trend

CL = λ

UCL = λ + 3√λ

Figure 12.10 Control chart for customer complaints.

194 ◾ Simple Statistical Methods for Software Engineering

e flat bottom is governed by a Poisson process that has a constant failure rate

(or hazard rate). To be more specific, this is called as the homogeneous Poisson process

(HPP). e term homogeneous is due to a constant failure rate or hazard rate. e

infant mortality period is also a period of growth in reliability. e failure rate in

this period is not constant but steadily reducing; hence, it is called nonhomogeneous.

is associated process is the nonhomogeneous Poisson process (NHPP). e wear

out period is also an NHPP, the difference being the fact that failure rate here

steadily increases until the system is discarded.

It may be noted that in the example of the bath tub curve shown in Figure 12.11,

◾ In the infant mortality period,

m(t) = λt

−β

, 0 < β < 1 (12.10)

defines a decreasing failure rate and an NHPP.

◾ In the middle region,

m(t) = λ, β = 0 (12.11)

defines a constant failure rate and an HPP.

◾ In the wear out period

m(t) = λt

–β

, β < 0 (12.12)

defines an increasing failure rate and an NHPP, in a reverse direction.

Constant failure rate (hazard rate)

Homogeneous Poisson process

Exponential distribution for interarrival time

Discrete Poisson distribution for events

Infant mortality

Decreasing failure rate

Nonhomogeneous Poisson process

Exponential NHPP

Power law NHPP

Etc.

Wearout

Increasing failure rate

Nonhomogeneous Poisson process

Software reliability is

in Region 1

Region 1

Region 2

Region 3

Time

Failure rate m(t)

(hazard rate)

m(t)

=

λ

m(t) = λt

–β

0 < β < 1

m(t) = λt

–β

β < 0

Figure 12.11 Bath tub curve.

Law of Rare Events ◾ 195

e HPP can be described only by exponential law, an oversimplification though.

Constant failure rate, a key assumption in HPP, is too ideal to be true even in the

case of mechanical systems. A bulb, under HPP, will have the same reliability after

burning through 400 hours or any time fixed by the analyst. Physically this is mean-

ingless. Similarly, the physical meaning of a failure rate in a situation shown in Figure

12.2 begs explanation. No software ever operates at a constant failure rate, although

the exponential representation produces such a parameter. It must be borne in mind

that Figure 12.2 has been obtained by numerical curve fitting rather than by using

physically reasonable reliability parameters such as failure rates or MTBF or MTTF.

e bath tub curve, in its entirety, is true for mechanical systems. In the case

of software, failures are constrained to Region 1, which records reliability growth.

Hence, software failure models are called reliability growth models. For both the

cases, we now need the help of NHPP modeling for a more accurate representation

of real world failure patterns.

Nonhomogeneous Poisson Process (NHPP)

Real-life software defect arrival is more complex than simple exponential curves, an

example available in Figure 12.12. It presents a typical defect arrival pattern during

system testing. Approximately 140 defects are discovered over a time span of about

three months. It is not a smooth exponential cumulative distribution. e curve is

0

20

40

60

80

100

120

140

160

0 20 40 60 80 100

Day of failure

Failure number

Figure 12.12 Defect arrival pattern—empirical model.

..................Content has been hidden....................

You can't read the all page of ebook, please click here login for view all page.