58 ◾ Advances in Communications-Based Train Control Systems

(Continued)

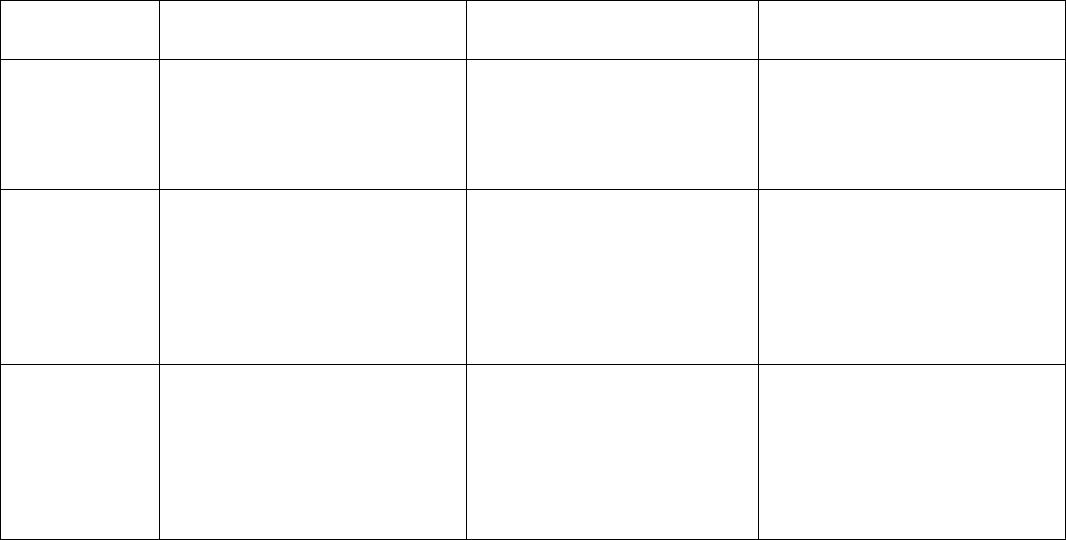

Table 3.1 Advantages and Disadvantages of NDT Methods for Rail and Fastening Parts Inspection

Inspection

Technique Advantages Disadvantages Detection Capability

Manual and

automated

visual

Simple, can be automated, fast,

inexpensive, defective ballast,

reliable in detecting corrugation

Provides information only

regarding the surface of the

component, missing parts,

nonquantitative

Surface breaking defects, rail head

prole missing parts

Liquid penetrant Simple, high resolution, accurate,

very sensitive to small surface-

breaking defects, appropriate for

weld inspection in rails,

applicable to any type of material

that is nonporous

Requires surface preparation,

access to the component’s

surface, qualitative, thorough

cleaning, no permanent record,

only surface-breaking defects

detectable

Small surface-breaking defects

such as fatigue cracks and

corrosion pits

Conventional

ultrasonic

Relatively inexpensive unless

phased arrays are used, capable of

detecting hidden defects and

quantifying both hidden and

surface-breaking defects, can be

applied to any type of material

Local inspection, at high speed

can miss surface defects

<4mmas well as internal

defects particularly at the rail

foot, affected by weather

conditions

Internal and surface defects

including fatigue cracks and

corrosion, no detectable rail foot

defects

Laser ultrasonic Reliable in detecting internal

defects, relatively fast

Can be affected by liftoff

variations of the sensors,

difcult to deploy at high

speeds, expensive

Internal and surface defects, rail

head, web and foot defects

Safe Rail Transport via Nondestructive Testing Inspection ◾ 59

(Continued)

Table 3.1 (Continued) Advantages and Disadvantages of NDT Methods for Rail and Fastening Parts Inspection

Inspection

Technique Advantages Disadvantages Detection Capability

Phased array

ultrasonic

Capable of detecting hidden

defects and quantifying, can be

applied to any type of material

Local inspection, at high speed

can miss smaller surface defects,

can be affected by liftoff

variations of the sensors, quite

expensive

Internal and surface defects

including fatigue cracks and

corrosion, rail head, web and foot

defects

Long-range

ultrasonics

Relatively fast, capable of detecting

large hidden and surface-breaking

defects, can be applied to any

type of material, can inspect long

sections up to several tens of

meters in one go

Only simple geometries can be

inspected, considerable dead

zone, defects need to be

relatively large to be detectable,

signal-to-noise ratio can be

affected by the inspection

conditions

Relatively severe corrosion and

transverse cracks, surface defects,

rail head, web and foot internal

defects

Magnetic ux

leakage

Fast, sensitive to transverse cracks

and corrosion, applicable for

surface and hidden defects

Only ferrous materials, defect

geometry inuences

quantication, parallel cracks

can be missed, requires good

magnetization to avoid

underestimation or missed

defects, bulky equipment

Surface and hidden corrosion and

fatigue cracks, inclusions

60 ◾ Advances in Communications-Based Train Control Systems

Table 3.1 (Continued) Advantages and Disadvantages of NDT Methods for Rail and Fastening Parts Inspection

Inspection

Technique Advantages Disadvantages Detection Capability

Eddy currents Inexpensive, sensitive to

microstructural, electric and

magnetic properties, sensitive to

small defects, applicable to any

conductive material, can operate

at signicant liftoffs

Very liftoff sensitive, inspection

penetration depth and

resolution dependent on

frequency, local inspection,

more efcient for surface and

near-surface inspection, low

resolution in high liftoffs

Surface and near-surface defects

(cracks and pitting corrosion),

general corrosion, microstructural

changes

Alternating

current eld

measurement

Mainly manual system,

inexpensive, sensitive to small

defects, capable of quantifying

depth and length of surface-

breaking defects, can be

automated, can operate at

signicant liftoffs

Only surface-breaking defects,

local inspection, quantication

only possible for fatigue cracks

Surface-breaking defects including

pitting corrosion and fatigue

cracks

Electromagnetic

acoustic

transducers

Inexpensive, noncontact, no

material limitation as long as it is

conductive, can detect both

hidden and surface-breaking

defect, can be local or long range,

can be applied at high

temperature, easy to produce

specic waves and modes

Low signal-to-noise ratio, sensor

requires cooling at high

temperatures, bulky sensors,

liftoff cannot exceed 2mm,

low-speed hi-rail vehicle

(<10km/h)

Surface and hidden defects

including corrosion and fatigue

cracks

Safe Rail Transport via Nondestructive Testing Inspection ◾ 61

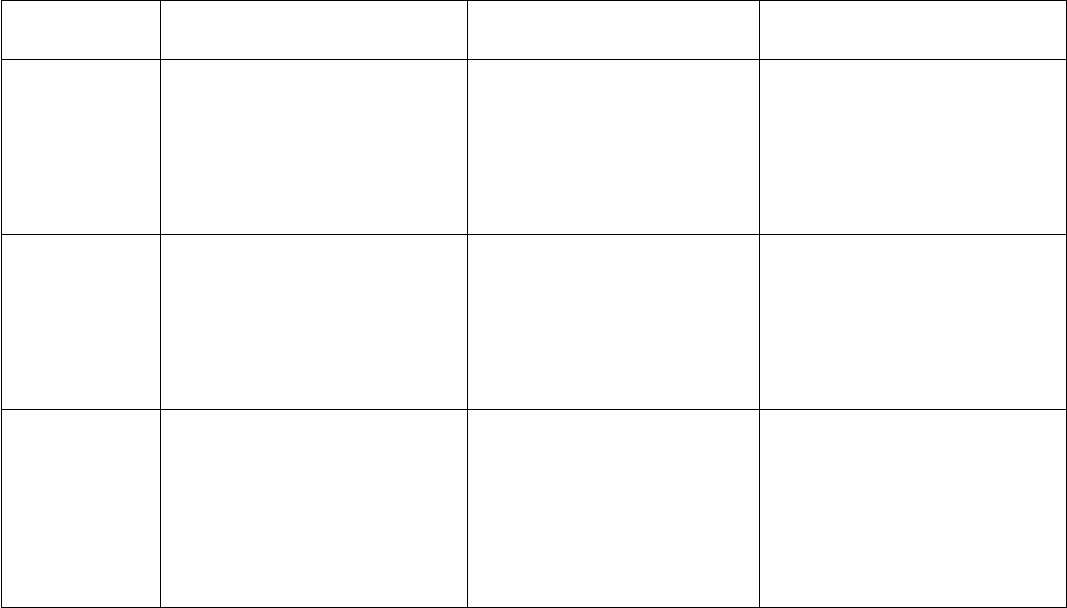

Table 3.2 Comparison of NDT Methods for Rail and Fastening Parts

Inspection

Characteristics

NDT Method

Manual and

Automated

Visual

Liquid

Penetrant

Conventional

Ultrasonic

Laser

Ultrasonic

Phased

Array

Ultrasonic

Long

Range

Ultrasonic

Magnetic

Flux

Leakage

Detection

capability

Limited

(surface

only)

High

(surface

only)

High High High

Average

(large

defects

only)

High

(ferrous

only)

High

(near

surface only)

High (surface

only)

High

Detection

resolution

Average High High High High Low Average High High Average

Depth estimation No No Yes Yes Yes Yes Yes Yes Yes Yes

Portability/access High High High

High

High High Low Average High High Average

Couplant

required/surface

treatment/surface

access

No Yes Yes Yes Yes Yes No

Average

(some surface

preparation

may be

required)

No No

Simplicity High High Low Low Average Average Average High Average

Inspection speed Average Average Average Average Average LowHigh High High High

Appropriate for

use in robotic

crawlers (internal

or external)

Yes (AVI)No Yes Yes Yes No Yes Yes Yes Yes

Level of training

required

Low Low High High High High Average High LowHigh

Cost Low Low Average High High High Average LowLow Average

Electromagnetic

Acoustic

Transducers

Alternating

Current Field

Measurement

Eddy

Current

62 ◾ Advances in Communications-Based Train Control Systems

References

1. Signals passed at danger, Oce of Rail Regulation, 2011.

2. Melago, C., and C. A. Catastrophic. Train wreck caused when metrolink engineer

failed to stop, say rail ocials. Daily News (New York City), September 13, 2008.

3. National Transportation Safety Board. Collision of union Pacic railroad train

MHOTU-25 with BNSF railway company train MEAP-TUL-126-D with subsequent

derailment and hazardous materials release, Macadona, TX, June 28, 2004. NTSB

#RAR-06/03, National Transportation Safety Board, Washington, DC, July2006.

4. Oce of Rail Regulation. Train derailment at Hateld: A nal report by the inde-

pendent investigation board, Oce of Rail Regulation, UK, 2006.

5. National Transportation Safety Board. Derailment of Canadian Pacic railway

freight train 292-16 and subsequent release of anhydrous ammonia near Minot,

North Dakota, January 18, 2002. Railroad Accident Report, RAR-04-01, National

Transportation Safety Board, Washington, DC, March 9, 2004.

6. Railway Association of Canada; Association of American Railroads. Algoma Central

Railway, British Columbia Railway, Burlington Northern Railroad, CN Rail, CP

Rail, Norfolk Southern, and Seaboard System Railroad: Advanced train control

systems operating requirements. Railway Association of Canada, Ottawa, Canada;

Association of American Railroads, Washington, DC, April 1984.

7. Detmold, P. J. New concepts in the control of train movement. In Transportation

Research Record 1029, TRB, National Research Council, Washington, DC, 1985,

pp.43–47.

8. FRA, U.S. Department of Transportation. Implementation of positive train control

systems. FRA, U.S. Department of Transportation, Washington, DC, 1999.

9. Moore Ede, W. J., A. Polivka, J. Brosseau, Y. Tse, and A. Reinschmidt. Improving

enforcement algorithms for communications-based train control using adaptive

methods. Proceedings of the 9th International Heavy Haul Conference—Heavy Haul

Innovation and Development, Shanghai, China, 2009.

10. FRA, U.S. Department of Transportation. Positive train control systems. 49

CFR Parts 229, 234, 235, and 236. FRA, U.S. Department of Transportation,

Washington, DC, January 15, 2010.

11. Lee, J.-D., J.-H. Lee, C.-H. Cho, P.-G. Jeong, K.-H. Kim, and Y.-J. Kim. Analysis of

moving and xed autoblock systems for Korean high speed railway. In Computer in

Railways VII, WIT Press, Southampton, MA, 2000, pp. 842–851.

12. Wendler, E. Inuence of ETCS on the capacity of lines. In Compendium on ERTMS,

Eurail Press, Hamburg, Germany, 2009, pp. 211–223.

13. Smith, M. E., R. R. Resor, and P. Patel. Train dispatching eectiveness with

respect to communication-based train control: quantication of the relationship. In

Transportation Research Record 1584, TRB, National Research Council, Washington,

DC, 1997, pp. 22–30.

14. Smith, M. E., and R. R. Resor. e use of train simulation as a tool to evaluate

the benets of the advanced railroad electronics system. Journal of the Transportation

Research Forum, Vol. 29, No. 1, 1989, pp. 163–168.

15. Smith, M. E., P. K. Patel, R. R. Resor, and S. Kondapalli. Quantication of expected

benets: Meet/pass planning and energy management subsystems of the advanced

railroad electronics system (ARES). Journal of the Transportation Research Forum,

Vol.30, No. 2, 1990, pp. 301–309.

..................Content has been hidden....................

You can't read the all page of ebook, please click here login for view all page.