3

Typical Manufacturing Industries

3.1 Introduction

Manufacturing covers a broad spectrum of activity ranging from large multinational companies employing thousands of people to very small enterprises comprised of a few individuals. If every type of manufacturing industry was to be covered in this text, many volumes would be necessary. Therefore, the purpose of this chapter is to simply provide a brief overview of some of them.

In Chapter 1, it was shown that industry can be considered as primary, secondary and tertiary, and that manufacturing constituted the secondary category. In fact, in modern manufacturing industries the boundary between manufacturing as a secondary industry often merges with service industry activities. For instance, research, development, design, marketing and selling would appear to be tertiary industries but they are often an integral part of large manufacturing companies.

Manufacturing processes themselves can also be considered as composed of three categories; primary, secondary and tertiary. For example, in primary processes raw material such as iron ore is processed with other raw materials to produce cast iron or steel and so on. Similarly, crude oil can be further processed to produce petroleum or plastics. In secondary processes the materials produced at the primary stage are formed into more easily worked shapes or components. For example, components can be created by forming steel into rods then machining and plastics can be further processed by moulding or extruding. Finally, tertiary processes take the previously created components from the secondary processes and assemble them into a completed product. Primary processes are more fully explained in Part 2 and secondary and tertiary processes in Part 3.

The classification of manufacturing industries is often done to aid analysis of different aspects of each industry including performance, contribution to the national economy and employment figures. Different countries use various classifications for these subdivisions, for example, the North American Industry Classification System (NAICS) has over 350 different types whereas the UK Office of National Statistics (ONS) lists 14 categories but then subdivides each of these much further. However, for our purposes we will adopt a simpler approach. Thus the following list describes some typical manufacturing industries that create wealth as previously discussed in the introductory chapter.

- Aerospace

- Automotive

- Shipbuilding and Marine Engineering

- Electronics and Electronic Products

- Household Appliances

- Pharmaceutical

- Food Processing

- Beverage Production

- Clothing

- Producer Goods

- Materials and Chemicals Production

It should be realised that the discipline of engineering is implied and inherent in each one of these. Specific manufacturing processes are examined later in the book.

An interesting aspect of manufacturing industries dealing with complex products and technology is systems engineering. The need for this is particularly acute in the aerospace, automotive and shipbuilding industries. Systems engineering is an interdisciplinary approach that addresses engineering and management aspects of an enterprise in an integrated manner. For example, in the case of an aircraft cockpit there are controls and displays that have to be designed. These controls may be interfaced with avionics systems for regulation of fuel supply to the engines and movement of the flight control surfaces, such as the ailerons and so on, also the displays will be connected to sensors to provide information on air speed and engine temperature and so on. As well as ensuring all of these subsystems work in harmony they will have to be suitably designed to enable the pilot to maintain situational awareness and understand the displays and operate the controls easily. Before all of this has occurred materials and components will have to be ordered, then assembled, installed and tested. It can therefore be seen that the disciplines of logistics, quality control, planning, product and engineering design and ergonomics are only some of the factors to be considered. Further, there is the need to consider the whole life cycle of the system including maintenance, repair and recycling. Therefore, systems engineering considers the entire system including design, hardware, software, human factors and management to ensure an optimum result is obtained for the final product. This is a very much simplified view of the discipline but it indicates not only the need for interdisciplinary cooperation but also the requirement for system engineers that are capable of grasping the holistic nature of modern complex product design and manufacture.

Important to all manufacturing industries is the supply of materials, components and services from sub‐contractors. For the supply chain see Chapter 1 and for quality control purposes see Chapter 26; it is common to categorise these suppliers into ‘tiers’. For example, a Tier 1 supplier will provide components direct to the producer of the finished product such as the seats for a commercial aircraft. A Tier 2 supplier will supply the seat manufacturer with the seat fabric and a Tier 3 supplier will provide the seat fabric manufacturer with the raw material to create the fabric. Industry today requires very tight control of quality and every supplier will require having their quality assurance procedures verified by the tier above it. This should ensure that the final product manufacturer can be confident of the quality of supplied parts.

3.2 Aerospace Industry

Aerospace is a very broad category and is an excellent example of a modern manufacturing engineering industry. Products are often highly complex, of very high added value and expensive to purchase. Typical products are commercial and military aircraft including unmanned aerial vehicles (UAVs), satellites, satellite launch vehicles and other space delivery systems, guided missiles and other defence equipment. The companies themselves are often big, multinational and large employers contributing significantly to the economies of the countries in which they are based.

The supply chains for these companies are also complex not only with many suppliers of components but also due to the distributed nature of the manufacture. For example, the Airbus series of aircraft have their components made in factories across the globe before they arrive at one of a number of final assembly plants. As noted in Chapter 1, the Airbus 380 has around four million manufactured components manufactured by around 1500 companies in 30 different countries.

The image in Figure 3.1 highlights the complexity of aerospace industry products. They are the result of a great deal of research, design, development and testing before the final manufacturing stages. This means that employees are usually well trained, very skilled and highly educated. These companies offer good apprenticeships for a broad spectrum of engineering careers as well as recruiting engineering graduates from universities and colleges. Product sales are usually to large airlines and governments rather than individuals. The aerospace industry additionally involves maintenance, repair and the supply of replacement and refurbished parts for existing products. Divisions of the companies will also be involved in sales and marketing of their products, thus exhibiting the blending of the secondary and tertiary industries noted earlier.

Figure 3.1 Engineers working on a Rolls Royce jet engine.

Source: Image courtesy of Rolls Royce.

3.3 Automotive Industry

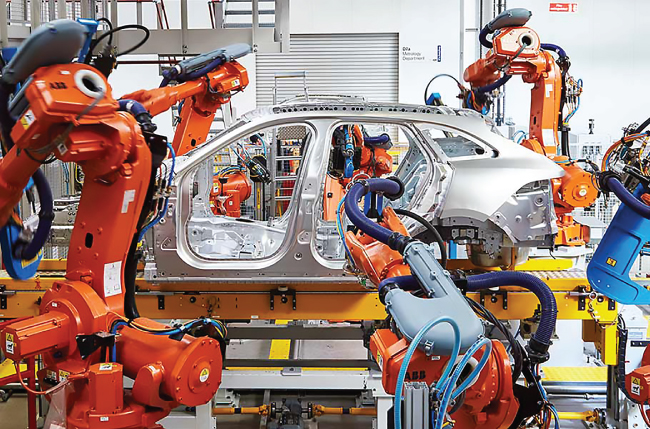

The automotive industry is another large employer producing complex products but this time for direct sale to the consumer. Cars, trucks and buses are examples of products, and car manufacture in particular epitomises modern mass production techniques. For example, the supply chain has been carefully analysed, established and managed, automation using industrial robots is widespread, lead times between the design and supply of products has been minimised and response to customer requirements is quick and efficient (Figure 3.2).

Figure 3.2 Car assembly by industrial robots.

Source: Image courtesy of Jaguar.

A modern car manufacturing factory is mostly an assembly plant. Using the tier system mentioned earlier, a series of sub‐contractors supply the plant with parts such fascia panels, electric window systems and seats. Subsidiary plants may produce complete engines. The car assembly plant itself will probably have presses for producing the car body elements from sheet steel and industrial robots for welding these together on a conveyor system. The welded body will then be surface finished with protective and cosmetic treatments including paint. The body will then join a conveyor system where the individual components from sub‐contractors and subsidiary plants will be added in a carefully ordered and balanced sequence.

The lead time between concept and design of a new car model has been continually reduced over the years to ensure emerging customer needs are met. Also, the use of reprogrammable automation means that individual customer requirements such as style and upholstery can be accommodated quickly into the production system.

3.4 Shipbuilding and Marine Engineering

This is an industry that demands a large amount of investment in space, materials and labour. Products created here include cruise, cargo and military ships, offshore oil platforms and submarines. Due to the large cost of manufacturing, these products' production is focused more and more in fewer and fewer countries. Currently more than 80% of the world's commercial shipbuilding occurs in China, South Korea and Japan. For security and employment purposes, military craft such as destroyers, aircraft carriers and submarines tend to be built in the countries that require them, providing the necessary expertise and manufacturing facilities have been retained.

In order to reduce costs and improve efficiency, large ships are often manufactured in a modular manner. For instance, an aircraft carrier like the one shown in Figure 3.3 was constructed in this way with prefabricated modules assembled in one location then transported to another where final assembly took place. The modules are often kitted out with all necessary services such as pipes and wiring in order to be easily connected to other modules at final assembly. Similarly, large cruise ships are also built in this way. Standardisation of the modules is adopted to reduce costs when building sister ships of similar design. The joining of the modules will be done by welding. Care has to be taken with the sequencing of the welds to prevent distortion, and the integrity of the welds has to be thoroughly checked to ensure metallurgical and mechanical properties are maintained. The lead time for a large aircraft carrier like the one shown from concept to placing contracts to design then manufacture and finally full service may be nearly 20 years. In contrast, the lead time for large cruise ships may be 5 years with attempts being made to reduce this to 3 years. For an aircraft carrier future strategic and political situations have to be considered as well as likely technological developments and this is extremely difficult since the ship may be expected to be in use for many decades, Whereas cruise ships need to be designed to cope with changing customer needs and demographics, these can change quite rapidly hence the requirement to reduce the time between design and service to a minimum.

Figure 3.3 Queen Elizabeth class aircraft carrier. (a) Hull module, (b) bridge module and (c) completed carrier. Source: Photos courtesy of BAE Systems.

3.5 Electronics and Electronic Products

The digital electronics industry has greatly contributed to the world's economic growth throughout the second half of the twentieth century and is continuing through the first decades of the twenty‐first century. Today's computers, industrial robots, autonomous cars, communication and entertainment hardware – like mobile phones or flat screen technology televisions – and the supporting digital infrastructure – such as the Internet and wireless communications – all rely on digital electronics.

The building blocks of electronic products are electronic components including resistors, capacitors, diodes, transistors and integrated circuits such as microprocessors. Since the inception of integrated circuits the number of transistors on a chip has increased according the ‘Moore's Law’ (actually an observation rather than a real law), which states that they will double roughly every year, although recently limits are being approached. This means that research, design and development in the industry is essential and competition is fierce. Chapter 15 describes the actual manufacturing processes involved in microprocessor production.

Electronic products are ubiquitous, the industry is global and competition is just as fierce as in the components industry. For example, each manufacturer of mobile phones will not only produce a variety of models at different prices but will also bring out new and improved models on at least a yearly basis. The product life cycle, as described in Chapter 4, is extremely short. In the assembly of electronic products industrial robots may be used, however, much assembly work is done by humans. This is because although the design of the product may be carried out in a high wage country, it is often useful to employ the labour of a low wage country for the actual manufacture and assembly.

3.6 Household Appliances

Included in this category are what is often termed ‘white goods’ such as domestic kitchen washing machines, refrigerators, microwave ovens and cookers. This industry mostly involves assembly of individual components from other manufacturers. Taking a clothes washing machine as an example, the basic design will be a frame structure to which the other parts are fixed or hung. An electric motor, a pump, a rotating barrel for holding the washing, heating elements and an electronic module for wash timing and sequencing. Also, sheet metal parts to form the frame and the cosmetic panels that encase the whole appliance.

The structure of the washing machine means that it is not designed for automated assembly. This is because parts are being fitted within the frame from different angles and using flexible items like hoses and transmission belts. Therefore, assembly of large electrical appliances like this usually uses human labour although industrial robots can be used at the packing stages once assembly is complete. This type of manufacture, therefore, can employ relatively large numbers of people and the skill level required for the assembly work is not high.

3.7 Pharmaceutical Industry

In contrast to the household appliances industry, the pharmaceuticals industry is highly automated. However, in a similar manner to the electronics industry research and development is extremely important and occupies a large proportion of company expenditure. Globally, the cost of research into pharmaceuticals is in the order of many tens of billions of dollars and the expenditure on prescription pharmaceuticals is around a thousand billion dollars. It is a highly regulated industry and even after a new drug is developed it can take years before it can be approved and released for public use.

Pharmaceuticals are produced in various forms such as powders, capsules and tablets. The powder compounds use to create these delivery methods may be blended and they will be manufactured by milling to achieve a specific particle size, or by binding the small particles together into granules to aid flow and ensure the proper compound mix is maintained.

After the compounds have been pressed into tablets or filled into capsules they can then be packaged. This is often done in highly automated systems in clean environments. Various types of automation are used including vibratory bowl feeders, mechanical handling devices including industrial robots and conveyor systems; these are explained more fully in Part 4 of this book.

3.8 Food Processing

Food is available in most countries now as either fresh produce or as food that has been processed in some manner, it is this latter type that concerns us here in a manufacturing context. Products such as sausages, bacon, many cold meats such as corned beef, canned fruit, confectionary and convenience foods, like ready to eat meals for cooking in microwave ovens, are all processed. Baked products such as cakes and biscuits are also part of the food manufacturing industry. In this industry, the size of the companies and manufacturing facilities covers a broad spectrum. There are very small independent units comprising a few individuals engaged, say, in personalised wedding cakes, through to large multinational corporations employing thousands of employees.

The factories themselves vary in size and production methods. Some are very labour intensive with hundreds of workers carrying out operations analogous to those found on assembly lines, and some are highly automated using special purpose machines and industrial robots. The industrial robots are normally the very high speed types such as those described in Chapter 20. The use of machine vision is particularly important where automation is used to verify the quality of the product and this is covered in Chapter 21.

3.9 Beverage Industry

Bottled water, soft drinks, energy drinks, milk products and alcoholic drinks are all examples of beverage industry products. Water and milk are not as such manufactured but manufacturing industry is required to process them into a marketable form by bottling them or putting them into cartons. Tea, coffee and drinking chocolate are beverages but they are usually supplied to the customer in a dry form and the customer adds water, milk and heat to their personal taste.

A large proportion of soft drinks are sodas. These are comprised of syrups, also called concentrates, for flavouring and sweetening and they are usually supplied to the final bottling plant from a primary manufacturer. At the bottling factory they are mixed with filtered water in appropriate proportions and carbon dioxide gas is injected before pouring the mix into bottles or cans. Alcoholic drinks contain methanol obtained from fermentation and they come in a wide range of types such as wines, beers, ciders and spirits. The spirits have a higher content of alcohol obtained by distillation and maturation and they include whisky, gin, brandy and vodka. Once again the major manufacturing aspect occurs at the bottling and canning stages with highly automated high speed production lines.

3.10 Clothing Industry

The clothing industry, and in particular the fashion industry, is responsible for a large proportion of world economic output. Apart from bespoke haute couture almost all clothing is mass produced. Manufacturing facilities use not only the ‘factory system’ (see Chapter 2) employing large numbers of people, but they also use the latest computer controlled high speed automation technology such as computer controlled knives or lasers for cutting through thick stacks of material. Less commonly, reprogrammable automation can also be used to produce unique items to individual specifications.

Clothing manufacture is a large global industry that employs millions particularly in countries where wage levels are low. The movement of information and material through the supply chain in this industry is very fast. For example, fashion forecasters in one country may input ideas to garment range designers in another country who will be using computer‐aided design technologies. The fabric required may then be produced in a third country, this material is then sent to a fourth for manufacture into the garments themselves, then shipped to the warehouse of a fifth for distribution to retail outlets around the world.

Also by automatically monitoring sales and stock levels in a large department store a particular fashion range and style can be recognised to be popular and stock running low identified. This will be noted by the system and an order triggered immediately to the manufacturing country to make and dispatch more stock.

The materials used may be natural such as wool, cotton and silk; or they may be synthetic such as polyester, nylon or acrylic. Much research goes into creating materials that can provide specialised properties for different applications. For example, moisture wicking for sport and active leisure wear, effective insulation for cold weather and material that protects the skin from the sun's rays.

Footwear can also be considered under this heading as many aspects of it are similar to that of clothing. For example, fashion changes and innovations occur frequently in the sports shoe industry. Synthetic materials are popular and rubber and leather are also used although natural leather is becoming increasingly expensive. The supply chain involved will again be similar to that of clothing from computer‐aided design through to mass production in factories employing large labour forces with high speed automation also used where appropriate. Analogous to the bespoke fashion mentioned earlier it is also possible to produce unique footwear using additive manufacturing techniques as described in Chapter 13, but this is uncommon and expensive.

3.11 Producer Goods

Generally, any piece of equipment used to create components and products in the manufacturing industry is termed a producer good. For example, in the aerospace industry metal cutting tools are required to achieve high tolerances on machined parts; in the automotive industry industrial robots are widely used for spot welding; in the electronics industry, high speed machines for populating printed circuit boards are used; in the household appliances industry press tools will be needed to produce sheet metal parts; in the pharmaceuticals industry pills are blister packed using high speed machinery; in food processing ovens are required for baking; in the beverage industry complex automated conveyor systems are needed in bottling plants and in the clothing industry special purpose machinery is used for cutting cloth. The producer goods that manipulate material in some way such as by cutting or deforming are termed machine tools and the machine tool industry is often used as a manufacturing industry classification. However, there are other producer goods that are important such as the ovens and conveyors already mentioned, as well as machine vision systems for inspection and large scale items such as the equipment required for materials and chemical production.

This industry does not have such a high profile as others but is an essential one contributing significantly to the economic output and employment of countries where a producer goods industry exists. The design and manufacture of machine tools and other producer goods requires well‐educated engineers, technicians and skilled craft workers. The need to continually improve the design of this type of equipment in a very competitive and sophisticated market is a good stimulant for research and development, much of which is carried out in technological universities and research establishments in collaboration with industry.

3.12 Materials and Chemicals Production

Finally, we briefly consider the industries that provide the raw materials for all of the other industries. Materials production is covered in Chapter 7 and this short section is simply indicating that there is an industry that produces the basic materials for creating all subsequent artefacts from producer goods through to finished products.

Production of materials and chemicals is usually carried out in very large, expensive and complex plants covering many square kilometres. The equipment is highly automated with the movement and processing of the raw materials within the plant monitored and controlled through sensors and actuators such as valves and manipulators. The plants are often located close to rivers or railway lines where bulk materials can be easily transported to the processing areas (Figure 3.4).

Figure 3.4 A massive oil refinery complex in Texas. Source: Reproduced with permission of Pixabay.

This industry employs large numbers of skilled and well‐educated technicians and engineers responsible for maintenance, repair, health and safety, quality control and process control within the plants. Environmental concerns are also addressed carefully as the processes are energy hungry and often are capable of producing high levels of pollution if not carefully monitored and controlled. They are also important producers of wealth for both the global and local economies.

Review Questions

- 1 Describe what you understand by the terms primary, secondary and tertiary as applied to manufacturing processes.

- 2 Explain what is meant by the term systems engineering.

- 3 Name 10 broad categories of manufacturing industry and, for five of these, describe the typical products manufactured and activities undertaken.