Chapter 7

Fulfilling Expectations and Orders

IN THIS CHAPTER

![]() Planning the logistics of your operation

Planning the logistics of your operation

![]() Setting up an in-house fulfillment system

Setting up an in-house fulfillment system

![]() Outsourcing your shipping area to someone else

Outsourcing your shipping area to someone else

![]() Learning the rules of shipping and handling

Learning the rules of shipping and handling

![]() Maintaining your information as you pack up and ship out

Maintaining your information as you pack up and ship out

Setting up your online business can be full of excitement and milestones. The true payoff, though, is best realized when that first payment rolls in for something you sold. Seeing a paper check or an electronic deposit right in front of you helps cement the idea of what you’re doing and provides validation of the business you created. Even though you may feel satisfied when you see the money, don’t think you’re done.

After the order is completed and the payment has cleared, you still need to handle one area of the sale. Fulfillment, or filling the order, is simply the practice of delivering the product to the buyer after payment has been received. In a retail store, fulfillment is easy: You hand your customers a shopping bag with the purchase and the sales receipt, and they walk out the door. In an online business, you need to perform a few steps to make order fulfillment happen. Thankfully, with all the advances in Internet technology and shipping services, achieving this goal is easier than ever.

Of course, planning for order fulfillment doesn’t start when the money comes through your door. In this chapter, we talk about the elements that can affect fulfillment, starting with how you set up your business. We talk about strategies you can implement to handle your product storage and organization, and how to pack and ship your items. In some cases, the best step you can take is to turn shipping over to another company and pay it to deliver your products to the right customers.

Figuring Out the Logistics of Shipping

How do you set up the entire flow of your business? Start by thinking about the operations and daily tasks that make your business work. Then lay out everything and decide how the business can best operate. To help you plan all these tasks, ask yourself these questions:

- Does my online business operate from my home or a dedicated office space?

- Should I buy products for resale or have someone else ship the goods?

- Does a physical store or presence have to work with my online business?

- How many employees need access to the merchandise and system?

Track the flow of one of your items for sale from beginning to end:

- Receive the product from your supplier.

- Prepare the product for sale.

- Store the product while it’s up for sale.

- Pack the product after it’s sold.

- Ship the product after it’s packaged.

Think about when and where these events take place, so you can plan the logistics of your business. Logistics simply refers to how you manage the operations of your business. You might need to dedicate a room in your house, or you might need to coordinate products and shipments through a warehouse that has different vendors and manufacturers.

The key is to set up a model that fits your business. You have no reason to buy an expensive software inventory program if you sell 10 or 20 items per month. Likewise, don’t expect to run a multimillion-dollar venture with a pencil and pad of paper. Choose a system that lets you know at any given time where your inventory is in the process, whether it’s receiving, photographing, listing, packing, or shipping.

Developing an In-House Fulfillment Model

Many small businesses take care of their own fulfillment, which means that they pack and ship their own products and send them out the door. Doing so allows these businesses to control the quality of their shipments so that they know that their customers are being served. Typically, doing so makes sense: Because the inventory is on-site, orders can be packed at the source and sent out rather than relayed to some far-flung warehouse.

Setting up an in-house fulfillment model requires first having enough inventory on hand and available at your location. In the beginning, you need to estimate orders and decide how many different products to carry in your store. Be sure to have enough on hand to fill initial orders. After you’re in business a while, you’ll know from your average order level how much inventory to have. After you know how much inventory you need to have in stock, you can plan for the space required to hold this inventory.

Your relationships with your vendors help determine the amount of space that’s required. If you receive shipments in batches, make sure that you have enough space available to take in a shipment and hold it until sales for that order come in. If you have a responsive vendor that can ship items in a just-in-time approach, your space requirement can be much lower.

If the space you require is more than the available space at your location, either look at temporary storage, such as a storage locker, or rent dedicated industrial or warehouse space for your inventory. If you acquire additional storage away from your location, make sure that you keep at least one sample of each product close at hand, so you can take photographs, write descriptions for your website, and refer to the item when necessary to answer customers’ questions.

After your space requirement is resolved, think about labor: Who will pack and ship your products? The number of orders to be packed and shipped can help determine the number of fulfillment workers required. If you’re packing only a few orders a day, you or one of your employees might handle the task. As the number of orders continues to grow, consider hiring a dedicated employee to perform the fulfillment or reassign someone to focus only on fulfillment.

Deciding to Outsource Fulfillment

Most people have a passion for the businesses they want to create. Whether someone is turning her knowledge of, and experience with, a hobby into a business or solving a need and providing a product that people want, a business owner dreams of turning a business idea into a reality. A business owner usually doesn’t dream, however, of a massive shipping-and-warehouse operation (unless that person is in charge of UPS or FedEx). Therefore, many business owners choose to outsource their fulfillment operations to someone else so that they can focus on the most important element: their businesses. After all, just because you’re good at selling widgets doesn’t mean that you’re good at packing and shipping them.

Contrary to popular belief, you don’t need to have a Fortune 500 corporation to outsource fulfillment. Small businesses around the world outsource this process. This action not only reduces the amount of space you require but also frees you and your employees to work on other aspects of your business.

Enter the fulfillment house, a business whose sole job is to handle the packing and shipping of other people’s goods. By grouping multiple clients’ shipping operations, a fulfillment house can employ fewer people to handle the volume of goods than individual companies who hire their own staffs. These fulfillment companies create state-of-the-art, computerized inventory-management systems and train their employees to be efficient in this process.

Outsourcing companies also offer specialized and enhanced service in these other areas that affect your business:

- Customer service: Every time a customer calls to ask a question about an order, make a special request, or have a product returned, someone has to handle the call. Fulfillment houses typically employ their own customer service teams to manage these calls. The houses worry about hiring, training, and maintaining the calls and about handling the request so that you don’t have to.

- Reporting: As your business grows, you need to keep track of how many orders go out for each product line and then analyze that data. Most fulfillment houses have some sort of tracking and reporting capability built into their systems so that they can deliver reports and let you know what’s going on, to help you plan for your next phase.

- Scalability: Suppose that you operate a seasonal business, such as stocking Christmas gift items, and you have to quickly grow and expand your inventory space to meet demand. Doing it yourself means worrying about reserving temporary space in September that you need to give up in early January. If you use a fulfillment service, you can draw on its resources and let it worry about finding the space. If your business grows quickly, a good fulfillment partner accommodates that growth easily.

Finding an outsourcing partner

When you’re ready to outsource the fulfillment process, you’re probably wondering what the first step is. Your first inclination may be to open a Google search window and type in “outsourcing,” but then what do you do when you see millions of search results? Every business magazine and talk show discusses the effect of outsourcing for bigger corporations, but what about small businesses? Some outsourcing companies are targeted to small-business accounts, especially online businesses.

After all, these companies know that if they can pool several inventories of small businesses, they can manage those accounts with a smaller team of trained personnel and one warehouse. In other cases, your outsourcing partner can be a similar business that has its fulfillment process down to a science and has decided to use that expertise to make money for other companies by solving their fulfillment headaches.

As you look for a fulfillment partner, keep a few guidelines in mind:

- Know your budget. Some companies can complete a part of your fulfillment process, and others assume control of your entire shipping department. Know how much you can afford to spend, to guide yourself to a partner that’s right for you. Understand that you’re saving employee labor time and salary when you’re outsourcing your fulfillment, so factor those into your budget.

- Shop around. Just like shopping for any other type of service professional for your business, get two or three estimates. Develop a feel for the service levels each offers, and see whether one company is willing to match another’s price.

- Factor in all the costs. You can easily see a price quote from a company and think that it shows the total cost. Before you sign anything, make sure that you understand all the requirements you will have to provide to the fulfillment partner and factor in all the costs. One quote might be cheaper because your company is still handling part of the fulfillment process, for example.

When you’re ready to look for a partner, start by asking around: Ask your vendors, manufacturing partners, and even fellow business owners in places such as Chamber of Commerce get-togethers, small-business workshops, and online forums. Internet searches on Google and Yahoo! will turn up lots of leads, so do your research. See what other business owners say on message boards and in forums.

Here are some Internet companies to get you started:

- eFulfillment Service:

www.efulfillmentservice.com - Fulfillment Works:

www.fulfillmentworks.com - Strategic Fulfillment Group (SFG):

http://www.sfgnetwork.com/business-solutions/ecommerce-fulfillment - Rakuten Super Logistics (formerly Webgistix):

www.rakutensl.com

Look for a company that specializes in your area (such as SFG for e-commerce, as shown in Figure 7-1) or provides the reporting features you need, such as eFulfillment Services’ Fulfillment Control Panel system.

FIGURE 7-1: SFG helps you fulfill your inventory.

Establishing your outsourcing relationship

After you find the outsourcing partner you want, it’s time to create an agreement and determine the terms of your relationship. You have to agree on terms such as service level and the rate of customer response. You need to know how quickly the company ships your products, what materials it uses to pack them, and how quickly it responds to customer requests.

Here are the factors in this relationship that should concern you:

- Reputation and service level: Even though the outsourcing company is doing the work, your name and reputation are on the line with your customers. If something goes wrong, guess who gets blamed? Yep, you do! Make sure that your partner is willing to commit to a service level that doesn’t embarrass you or annoy your customers.

- Scalability: As you grow, your outsourcing partner must be able to grow with you. After all, you’re turning to your partner to smoothly handle a part of your business so that you can expand the operation. If the company is struggling to keep up the pace of your business, you run the risk of your whole operation falling apart.

- Experience: Your outsourcing partner’s management team needs to have the right experience in the right areas to lead that company. You’re paying for experience, so make sure that team members are well versed in controlling

- Back-end computer systems

- Customer service

- Inventory management

- Logistics

- Subject matter knowledge: A product is a product is a product. It helps, though, to find a partner that can understand your specific product line, whether it’s computer chips or dried fruit. See whether this partner has ever handled an account similar to yours and understands some of the nuances of your product line, to better anticipate any problems or questions that might arise.

Operating with an outsourced fulfillment house

When you’re ready to start working with a fulfillment house, don’t just sign the lowest-price contract and begin transferring inventory to it. You need to talk about how your relationship will work, what expectations you have for the company, and — believe it or not — what expectations it has of you. After all, even though you might have hired the fulfillment house to do “all the work,” you, as the client, still need to provide these items:

- Inventory: Most fulfillment houses take on your inventory and warehouse it at their locations. Decide how much inventory to transfer, when to do it, and when and how replacement inventory should funnel in. Make sure that you carefully assess your inventory before it leaves your business, and double-check the inventory list when it arrives. Some fulfillment companies provide the trucks and labor to move inventory; others need you to make the arrangements.

-

Order information: When orders come in, find a reliable and automated way to move that order information over to your fulfillment house. Depending on how you capture orders and which computer systems your fulfillment house uses, you can transfer orders as they occur or as a group of orders every day (in a daily batch). In some cases, you can have the fulfillment company operate the order-collection part of your business so that the order goes directly from the customers’ computer screens to the company’s databases.

If the fulfillment house is taking your orders, make sure that you receive a detailed report containing all customer data and order information. After all, customer orders are the building blocks for a customer list that helps your business thrive.

If the fulfillment house is taking your orders, make sure that you receive a detailed report containing all customer data and order information. After all, customer orders are the building blocks for a customer list that helps your business thrive. - Payment: Fulfillment houses don’t pack and ship your orders out of the goodness of their hearts, so they need to get paid. You have several options for handling this cost:

- Build the extra cost into the shipping amount of your orders, and have that money transferred each time the company fills an order.

- Instead of transferring money each time an order is filled, have the company invoice you for a couple of months’ worth of orders as a reserve or retainer. (You may be required to pay a reserve amount anyway to cover initial orders.) As you see the costs accumulate, you should begin to estimate the monthly cost better and can arrange payments that better fit the cash flow of your company.

- If the company is taking your orders and payment, it can keep its portion of the shipping amount and pay you for the goods it ships out.

After a certain length of time, you should receive a report detailing the activity your fulfillment house has performed. Never just file the report without looking it over. This report gives you a revealing look at the flow of your business and shows you how products are moving out the door. If you’re concerned about the quality of the fulfillment house’s work, compare the ship dates of those orders to the times you received them, and calculate how quickly this company is processing your business orders.

As your inventory level goes down at the fulfillment house, you need to have an event that triggers the transfer of more inventory. This inventory replenishment level is the point at which the inventory on hand is projected to drop to zero before the next delivery from your business would usually occur. Many fulfillment houses can help you calculate this number because they use sophisticated computer tracking systems that monitor shipment levels and predict how long it takes to ship all inventory in their possession. They usually factor in some time to cover unexpected delays in inventory transfers or unusual bumps in your orders. When you negotiate this cushion of products with your fulfillment house, choose a level that keeps orders flowing but doesn’t back up the warehouse.

Assessing the quality of the fulfillment work

When you get a sense of the quantity of work that your fulfillment partner is performing, look at the quality of its work also. Most important, determine whether your customers are happy with the packages they receive. Were the items well packed? Did packaging materials withstand the pressures of being shipped cross-country? Did your customers receive their orders in a reasonable amount of time?

The easiest way to find this information is to provide a phone number that your customers can call to report any problems. In some cases, the fulfillment house can also be your customer service partner. This way, if a problem with a customer’s order occurs, a fulfillment person can go into your inventory on-site, pull a replacement set of products, ship it immediately, and let the customer know that the replacement is on its way. Make sure that you receive a monthly report of any customer service calls, and see whether that number goes up or down.

You can also go one step further: Rather than wait to hear whether a problem has occurred, reach out and ask your customers in the form of a survey. You don’t want to bother them too much, but sometimes a simple survey packaged into each order can elicit some helpful feedback. Give prizes (such as gift certificates) or guaranteed discounts (such as free shipping on future orders) to customers who respond. You can partner with a company such as BizRate Insights (www.bizrateinsights.com) that coordinates online surveys of customers and gives you the results. (See Figure 7-2.) This way, you can uncover any problems before they get out of control.

FIGURE 7-2: Hire a company such as BizRate to coordinate surveys of your customers.

If you notice a problem, talk to your fulfillment partner. Be direct, not confrontational. Find out the cause of the problem, see whether it can be fixed, and inquire about how your partner will ensure that it doesn’t happen again. You can never prevent all problems, but you can help make sure that they don’t happen as often.

Shaping Up and Shipping Out

The immediate gratification that customers feel when they order something from your business applies also to the fulfillment of those orders. Customers want to hold a product in their hands as soon as possible, and some customers are willing to pay even more to receive their order faster. Customers often have a favorite shipping carrier, or a carrier that they don’t want you to use.

When those same people hear the term shipping and handling, they usually envision you performing these basic steps:

- Pull an item off the shelf.

- Put that item and a packing slip or invoice in the box.

- Add packing material to fill up any empty space in the box.

- Seal the box with tape.

- Put the customer’s name and address and your business return address, on top of the box.

- Ship the box.

Even though these steps demonstrate the basic flow of the shipping process, you can make it happen in many ways. If you’re handling the shipment of your business orders, you can take advantage of some existing systems to make your life easier.

Giving your customers shipping options

In the end, the best way to satisfy both your business goals and the customer’s shopping goals is to offer multiple shipping options to your customers.

Giving customers options can mean that you offer a variety in

- Shipping carriers: You’re willing to ship something by using FedEx, UPS, or the U.S. Postal Service.

- Shipping methods: If your only carrier is FedEx, for example, customers can pay for Next Day Air, 2-Day Air, or Ground (with an average delivery time of one or two weeks).

- Order mixing: A customer who orders multiple items can choose which items get which type of shipping. For example, a customer who orders a heavy computer system and a light book about computers can have the book delivered to start reading the next day, and have the heavy computer system delivered by ground in two weeks.

When you offer customers these options, you (as either an in-house or outsourced business) have to be ready to use each service whenever it’s needed. You have to know the common rates and link to their websites to find updated pricing quotes based on different weights and sizes. You also have to update your shopping cart with these different options so that customers can pick and choose.

The best example of the power of multiple shipping options is Amazon. To spur sales, it offers free shipping if you spend at least $35 on an order, and it ships items by U.S. Postal Service Ground Mail. However, customers can specify all or part of their orders to be sent a certain way, and they can pay the appropriate rate for faster shipping, such as Next Day Air or 2nd Day Air.

Setting up accounts with carriers

Two truths apply to shipping companies:

- They always seem to break even the most carefully packed items.

- They’re always competing for your business.

The amount of gross revenue generated by shipping online orders has become a primary means of producing revenue. Therefore, carriers are fighting to keep customers by virtue of their service — and adding new features and adjusting prices whenever necessary to succeed.

Because the shipping companies’ goal is to maximize revenue, they cater to higher-volume customers. They’re usually online businesses, like yours, that have a number of orders to be shipped each day, week, or month. Online businesses that are setting up accounts with one or more carriers are finding, therefore, that they have some negotiating power for better rates or more services.

To sign up for a business account, choose one of these methods:

- Contact the company by phone and work with a sales representative to set up your account.

- Go to a shipping company’s website and look for a Business Accounts link for the appropriate forms to fill out.

- Go directly to a shipping company’s office and ask to speak to a representative to set up an account.

When you start to talk to these companies, they ask you a number of questions to gauge your level of shipping. Determine your answers to the following questions before you start calling:

- How many packages do you expect to ship in a month? How many do you send in an average week? What are your high and low numbers for a week?

- What size and weight are the packages you typically send?

- Are your customers mostly in the United States, or do you send a mix of domestic and international packages?

- What percentage of orders do you ship by using an air option, such as Next Day, 2nd Day, or 3 Day? What percentage do you send by ground?

When you start reviewing these details with the company, ask about rates and price breaks for certain shipping levels. Find out whether your current level is close to a certain price tier for shipping, and see whether you can raise your order shipments to meet that new level to save money for your business. Meeting a goal is easier if you can aim for a measurable number.

An account with a shipping company is typically free of monthly charges, unless you add a special service. The company keeps a payment method on file so that you can accrue shipping charges and make one monthly payment. That way, you’re not always paying out when you want to ship a package. Your shipping department then runs much more smoothly and you qualify for corporate rates.

Creating online postage and labels

One of the best developments in Internet technology over the years (especially if you’re in the fulfillment field) is being able to print postage from your computer and create your own shipping labels. Although you can still stand in line at the post office, now you can prepare packages at home or at your business and drop off addressed packages with your carrier.

If you need to buy postage for various sizes of letters or packages, you can print postage by the package or join a service such as Endicia (see Figure 7-3) and pay a monthly fee to print all the postage you need. You sign up for an account and provide a credit card number. When you print postage, these services charge your account and send to your printer a special coded label that acts as your stamp. Every month, you pay for only the stamps you print.

FIGURE 7-3: Endicia helps you print your own postage and labels.

Here are some of these services:

- Endicia:

www.endicia.com - Pitney Bowes:

www.pb.com - Stamps.com:

www.stamps.com - USPS Click-N-Ship:

cns.usps.com/labelInformation.shtml

For example, rather than print the stamps for a customer’s order, you print a prepaid label that has all the customer’s address information, your return address, and the postage paid. You stick this label at the top of the package and hand off the package to the shipping company. Every month, your account is charged for the shipping costs of all the labels you prepared.

Virtually every big shipping company can now generate these shipping labels from their websites, including FedEx, UPS, and the U.S. Postal Service. You simply log in to a company’s website with your account number and then start specifying customer addresses and the weights and dimensions of each order.

Having items picked up for delivery

After you do all the work to prepare your packages, they still have to move from you to your shipping company. In the past, you had to load your car or company van, drive down to the shipping company’s office, fight for parking, and then stand in line to unload your vehicle.

Almost all the big shipping companies now come to you to get your items:

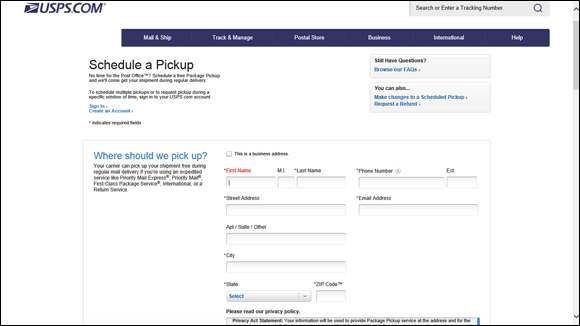

- U.S. Postal Service: If you print your shipping labels in advance and pay for your postage online, a postal employee can pick up the item on her normal route. When you schedule a pickup (shown in Figure 7-4), someone picks up all your Express Mail and Priority Mail packages in a 2-hour period that you specify.

- Other carriers: Carriers such as UPS and FedEx work more on demand. If you’re receiving a package from one of these carriers, you can hand off your completed packages when the driver arrives, but you have to know that the shipment is coming. For business accounts, these carriers typically offer weekly or daily pickup, based on the needs of your business. If you have a low-volume account, you’re charged for this feature, and the rates vary. Depending on how many orders per month you can guarantee, however, one item you can request during your account setup is a free daily pickup. Ask your shipping company for more details.

FIGURE 7-4: Schedule your mail carrier to pick up your packages whenever you want.

Shipping international orders

Customers around the world are communicating with each other instantaneously by using the Internet, fax and data lines, and cellphones. These methods have allowed online businesses to reach millions of new potential customers. Shipping companies have responded by beefing up their international shipping options, which gives you more options for servicing your customers.

The only shipper that reaches most countries in the world is the U.S. Postal Service. The U.S. Postal Service offers air-mail service, which can take at least a week to reach its destination country. Although the USPS offers insurance for packages to most countries, it typically doesn’t provide any tracking capability. The only service it offers that guarantees a tracking number and insurance is its Priority Mail Express International service, which is expensive.

If you want to use UPS, FedEx, or other carriers such as DHL to ship packages, you have to send them by some form of air mail, which can be quite expensive for heavy items. Although these services automatically issue tracking numbers, in some cases their tracking capabilities end when the packages enter their destination countries. Each country also places specific limits on package weight and dimensions. Consult each company’s website for specific information about country-specific limits.

In all cases, you’re required to fill out a customs form to document the following information about an item:

- The country of origin

- The quantity

- An item description

- The value of each product in the package

Shippers such as UPS and FedEx incorporate the customs form information into the label-creation process so that when you create your label, the appropriate shipping documents are created alongside it. The USPS uses two customs forms:

- CN 22/Form 2976: For packages that weigh less than 4 pounds (see Figure 7-5) and have no insurance

- Form 2976-A: For packages that weigh more than 4 pounds or have insurance

FIGURE 7-5: Use this customs form to send small packages.

In some cases, the destination country requires you to complete a certificate of origin or a signed affidavit that certifies the origin country of an exported item. Some countries also require that you

- Have your goods inspected by an independent, third-party organization

- Include a certificate of inspection with your label and customs forms

For more detailed information on how to send large shipments overseas, consult the International Chamber of Commerce website (www.iccwbo.org).

For smaller shipments that you send directly to customers, you typically need to classify your shipment in one of four categories:

- Commercial sample: Samples or free product trials

- Documents: Catalogs and paperwork

- Gift: Products that customers didn’t pay for

- Other: Most other types of shipments

Maintaining the Back End

As you expand your business, keep track of how your fulfillment operation works so that it can grow with your business. Investing in good recordkeeping enables you to not only provide customers with tracking numbers and copies of invoices but also see what’s working and what’s not so that you can make necessary improvements.

Deciding on a database

You have several choices for storing your business information. Many online businesses create one or more databases to store these types of data:

- Customer information

- Order information

- Payment information

- Product information

Sometimes a business owner chooses a database solely because it can “talk to” the shopping cart or website software that the business uses. At other times, the database was installed first and the business owner wants to ensure that all other products can communicate with it. Other small-business owners organize their information by using spreadsheets in a financial program such as Microsoft Excel.

The key for you is that your database — in whatever form — needs to be accessible and searchable. You and your employees need to be able to see your data easily. You use your database to answer questions about your business (such as “How many customers do we have?” or “Which orders are ready for shipment?” or “Who still owes us money?”) and to store information about how your business is doing financially.

- Carrier name

- Internet link, if possible, to monitor the shipment

- Invoice number

- Order-packing date

- Shipment date

- Tracking number

As you’re setting up your business, here are some questions to help you determine which database program to use:

- Is a database program in your budget?

- Which programs work well with your other software systems, such as your web server or electronic shopping cart?

- How many people need access to the database? Are all the people in one building (or on one internal computer network), or are they spread out around the world?

- Which software programs do you have access to?

Using handheld scanners and bar codes

Inventory tracking is a process that even a small online business can afford to implement. You don’t have to be Wal-Mart or Home Depot to use technology to help organize your inventory. You just have to spend some time setting up the equipment and codes to make it work. You can use handheld scanners (or newer smartphones that support the RedLaser app, such as the Apple iPhone) to read bar codes identified on your products to help keep track of your overall product inventory.

Here’s how inventory tracking works:

-

Make sure that each individual product for resale has some sort of bar code on its box.

The bar code can be either the Universal Product Code (UPC) that comes with the product or one you provide by using an inventory-management program.

- Decide where in your warehouse or inventory area you want to store the product.

-

Scan a special bar code that represents the shelf or rack number.

Use a handheld scanner (like the ones used in grocery stores or by delivery personnel) or a smartphone equipped with the RedLaser app and an inventory app.

- Scan the bar code of the product.

- Sync your scanner and inventory-management software.

Developing a shelving inventory system

Many online businesses buy industrial-strength racks and shelving systems for organizing their products. You can find these systems at most hardware stores, such as Home Depot and Lowes, for a couple of hundred dollars apiece (with some assembly required). After you buy and set up these racks, label each shelf properly and start storing your products on these shelves. Then, whenever you need a product, you can just walk over to your shelves and look to find the product you need. If you keep similar items together, locating and retrieving the product you need is that much easier.

Feeding orders into the shipping department

You might think that when you receive an online order, red lights should start flashing and sirens should sound to announce its arrival. Although that level of drama isn’t necessary, you need to make sure that your orders are being properly funneled to your shipping area so that they’re packaged and sent in a reasonable length of time. You can

- Print orders from a printer automatically. Then, whoever is in charge of fulfillment can grab the printout and start pulling the inventory.

- Print manifests or invoices (known as pick-and-pull sheets) from the preceding day’s orders. Items are picked off the shelves in your warehouse area and pulled into the packing area.

If you’re outsourcing your fulfillment operation, you can specify that customers receive an e-mail every time they place an order. A duplicate of that e-mail is sent to a specific e-mail account for new orders at the fulfillment house, and the employees monitor and print an order every time an e-mail is received or print a batch of e-mail at certain times during the day.

After an order is prepared and packed, the last pieces of information to capture on the back end are the package shipment date and tracking number. If you’re using online postage creation tools, that information is already captured. If you’re creating your own postage and labels, be sure to keep a copy of every tracking number and shipping date and then feed that information into your order database.

In just-in-time inventory management, vendors deliver their products to you just before you need them for listing or shipping out. If you’re receiving shipments just in time, you don’t need to have a big warehouse to store upcoming orders. However, if your just-in-time vendor is late with a shipment, you have nothing to sell or send out to your customers.

In just-in-time inventory management, vendors deliver their products to you just before you need them for listing or shipping out. If you’re receiving shipments just in time, you don’t need to have a big warehouse to store upcoming orders. However, if your just-in-time vendor is late with a shipment, you have nothing to sell or send out to your customers. If you rent a storage locker to hold inventory, ask the management team whether it can accept packages for you and place them in your unit. This way, you don’t have to be present when your shipments come in or worry about sending them to storage from your home.

If you rent a storage locker to hold inventory, ask the management team whether it can accept packages for you and place them in your unit. This way, you don’t have to be present when your shipments come in or worry about sending them to storage from your home. An international customer might ask you to classify a package as a gift and specify a lower amount for the value. Be aware that you can insure a package for only the value you state and that falsifying a customs document can result in fines and penalties levied against you and your customer.

An international customer might ask you to classify a package as a gift and specify a lower amount for the value. Be aware that you can insure a package for only the value you state and that falsifying a customs document can result in fines and penalties levied against you and your customer.