Photovoltaic System Conversion

Nimrod Vázquez Technological Institute of Celaya, Celaya, Mexico

Jeziel Vázquez Superior Technological Institute of South Guanajuato, Uriangato, Mexico

Abstract

This chapter highlights in brief how solar cells produce electricity and will discuss in detail the various techniques available to track the sun in order to maximize the output power generated by the PV array. Moreover, not only the grid-connected and stand-alone converters required to operate PV systems efficiently will be described, but also the PV system design is discussed.

Keywords

Solar cells; PV panels; MPPT; Grid-connected converters; Stand-alone converters; PV system design

24.1 Introduction

For many years, fossil fuels have been the primary source of energy. However, due to the limited supply, the rate of deployment of fossil fuels is more rapid than their rate of production, and hence, fossil fuels will eventually run out. Moreover, the threat of global climate change caused by carbon dioxide (CO2) emissions from fossil fuels is one of the main reasons for the increasing consensus to reduce the consumption of such fuels. This reduction can be achieved by switching to renewable energy for many energy-requiring applications since it is “clean” and “green.” Today, the global trend is to use a nondepletable clean source of energy for a healthier and greener environment to save the future generation. The most efficient and harmless energy source is probably solar energy, which is so technically straightforward to use in many applications. Almost, all renewable energy sources, except nuclear and geothermal, are the energy forms originating from the solar energy.

Solar energy is considered one of the most promising energy sources due to its infinite power. Thus, modern solar technologies have been penetrating the market at faster rates, and photovoltaic (PV) technology that has the greatest impact, not because of the amount of electricity it produces but because photovoltaic cells—working silently, not polluting—can generate electricity wherever the sun shines, even in places where no other form of electricity can be obtained. PV is a combination of the Greek word for light and the name of the physicist Alessandro Volta. PV is the direct conversion of sunlight into electricity by means of solar cells.

This chapter will highlight in brief how solar cells produce electricity and will discuss in detail the various techniques available to track the sun in order to maximize the output power generated by the PV array. Moreover, the components required to operate grid-connected and stand-alone PV systems will be described. Additionally, the affecting factors and design issues of PV systems will be presented.

24.2 Solar Cell Characteristics

Solar cells are composed of various semiconductor materials that become electrically conductive when supplied with heat or light. The majority of the first-generation solar cells produced are composed of silicon (Si), which exists in sufficient quantities. However, more than 95% of these cells have power conversion efficiency about 17%, whereas solar cells that developed over the last decade in laboratory environment have efficiency as high as 31%. All technologies related to capturing solar energy to be used as direct electricity generator are described as photovoltaic technology, which is subdivided into crystalline, thin film, and nanotechnology.

Doping technique is used to obtain an excess of positive charge carriers (p-type) or a surplus of negative charge carriers (n-type). When two layers of different doping are in contact, then a p-n junction is formed on the boundary.

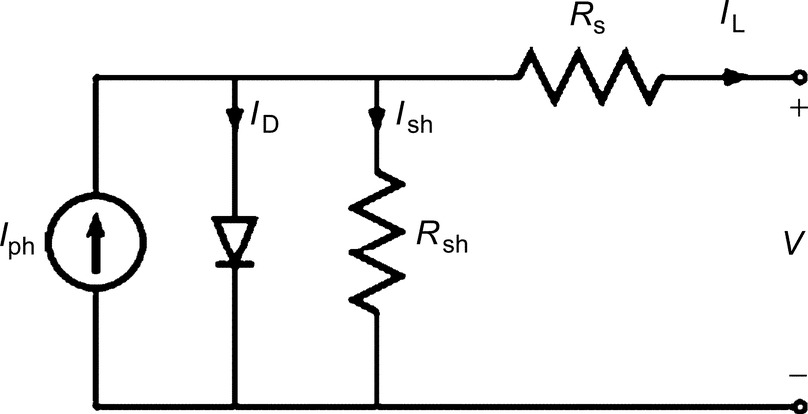

An internal electric field is built up causing the separation of charge carriers released by light, freeing electrons within the electric field proximity, which then pull the electrons from the p-side to the n-side (Fig. 24.1). The primary solar cell equivalent circuit (Fig. 24.2) contains a current source with a parallel diode, in addition to parasitic series (Rs, normally small) and shunt (Rsh) resistances (relatively large). Rs is mainly affected by the factors such as the bulk resistance of the semiconductor material, metallic contacts, and interconnections, whereas Rsh is affected mainly by the p-n junction nonidealities and impurities near the junction.

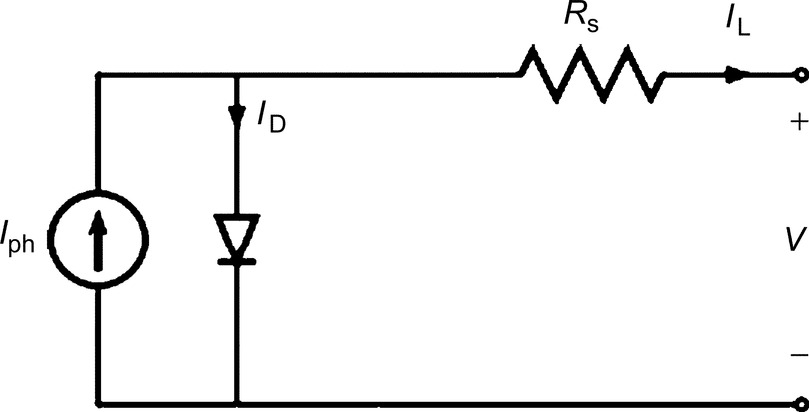

A simplified equivalent circuit is shown in Fig. 24.3.

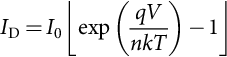

The diode current is given by the Shockley equation:

where I0 is the reverse saturation current, q is the charge carrier, k is the Boltzmann constant, T is the cell temperature, and n is the ideality factor.

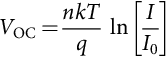

The PV module has two limiting components (Fig. 24.3): open-circuit voltage (VOC) and short-circuit current (Isc). To determine Isc, set ![]() and

and ![]() , and this value changes proportionally to the cell irradiance. To determine VOC, set the cell current

, and this value changes proportionally to the cell irradiance. To determine VOC, set the cell current ![]() ; hence,

; hence,

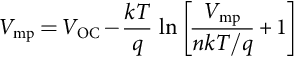

The PV module can also be characterized by the maximum point when the product (Vmp (voltage, where power is maximum) ![]() (current, where power is maximum)) is at its maximum value. The maximum power output is derived by

(current, where power is maximum)) is at its maximum value. The maximum power output is derived by

and

A PV module is normally rated using its Wp, which is normally 1 kW/m2 under standard test conditions (STC), which defines the PV performance at an incident sunlight of 1000 W/m2, a cell temperature of ![]() (

(![]() ), and an air mass (AM) of 1.5. The product (

), and an air mass (AM) of 1.5. The product (![]() is related to the product generated by (

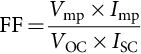

is related to the product generated by (![]() ) by a fill factor (FF) that is a measure of the junction quality and series resistance, and it is given by

) by a fill factor (FF) that is a measure of the junction quality and series resistance, and it is given by

The closer the FF is to unity, the higher the quality of the PV module.

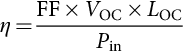

Finally, the last and most important factor of merit for a PV module is its efficiency (η), which is defined as

Pin represents the incident power depending on the light spectrum incident on the PV cell.

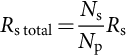

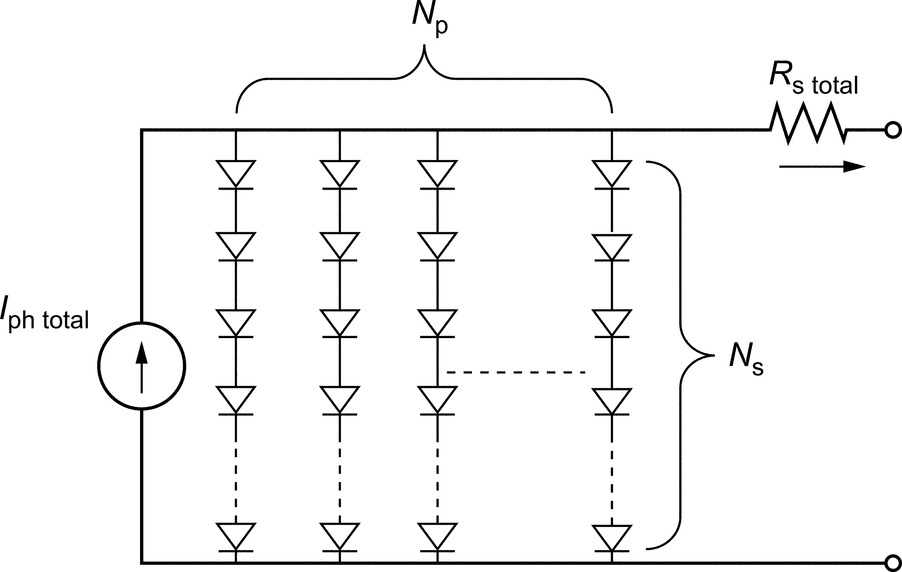

To achieve the desired voltage and current levels, solar cells are connected in series (Ns) and parallel (Np) combinations forming a PV module. The PV parameters are then affected as shown below:

This model is shown in Fig. 24.4.

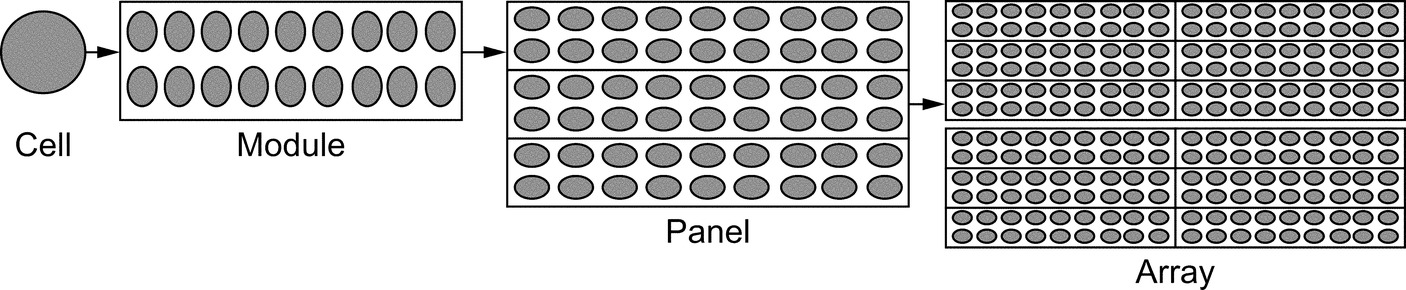

In order to obtain the appropriate voltages and outputs for different applications, single solar cells are interconnected in series (for larger voltage) and in parallel (for larger current) to form the photovoltaic module. Then, several of these modules are connected to each other to form the photovoltaic array. This array is then fitted with aluminum or stainless steel frame and covered with transparent glass on the front side (Fig. 24.5).

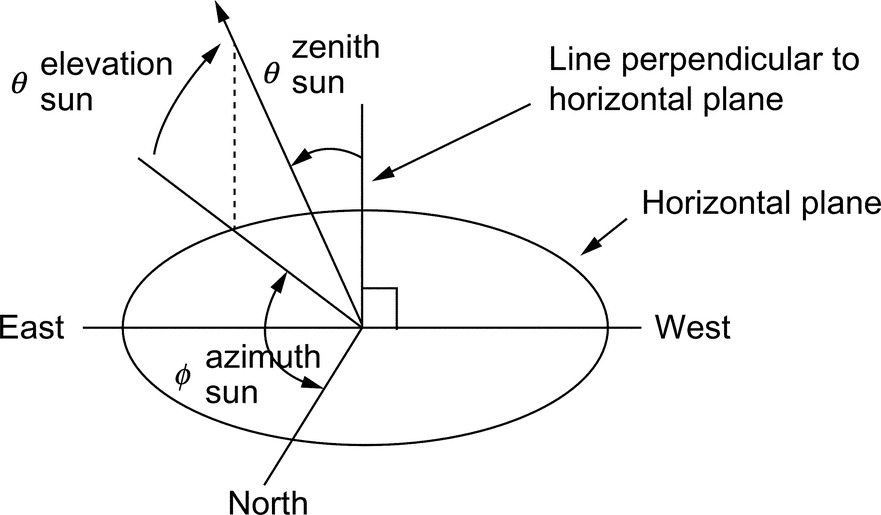

The voltage generated by the array depends primarily on the design and materials of the cell, whereas the electric current depends primarily on the incident solar irradiance and the cell area. This current fluctuates since the path of the sun varies dramatically over the year, with winter and summer seasons being the two extreme excursions. The elevation angle of the sun (θsunelevation) is expressed in degrees above the horizon. Azimuth angle (ϕsunazimuth) of the sun is expressed in degrees from true north. Zenith angle (θsunzenith) of the sun equals 90 degrees less than the elevation angle of the sun, or

Azimuth, zenith, and elevation angles are illustrated in Fig. 24.6.

The output from a typical solar cell that is exposed to the sun, therefore, increases from zero at sunrise to a maximum at midday and then falls again to zero at dusk. The radiation of the sun varies when reaching the surface of the earth due to absorption and scattering effect in the earth's atmosphere. PV system designers require the estimate of the insolation expected to fall on a randomly tilted surface and hence need a good evaluation of global radiation on a horizontal surface, horizontal direct, and diffuse components, in order to estimate the amount of irradiation striking a tilted plane.

24.3 Photovoltaic Technology Operation

Photovoltaic technology is used to produce electricity in areas where power lines do not reach. In developing countries, it helps improving living conditions in rural areas, especially in health care, education, and agriculture. In industrialized countries, such technology has been used extensively and integrated with the utility grid.

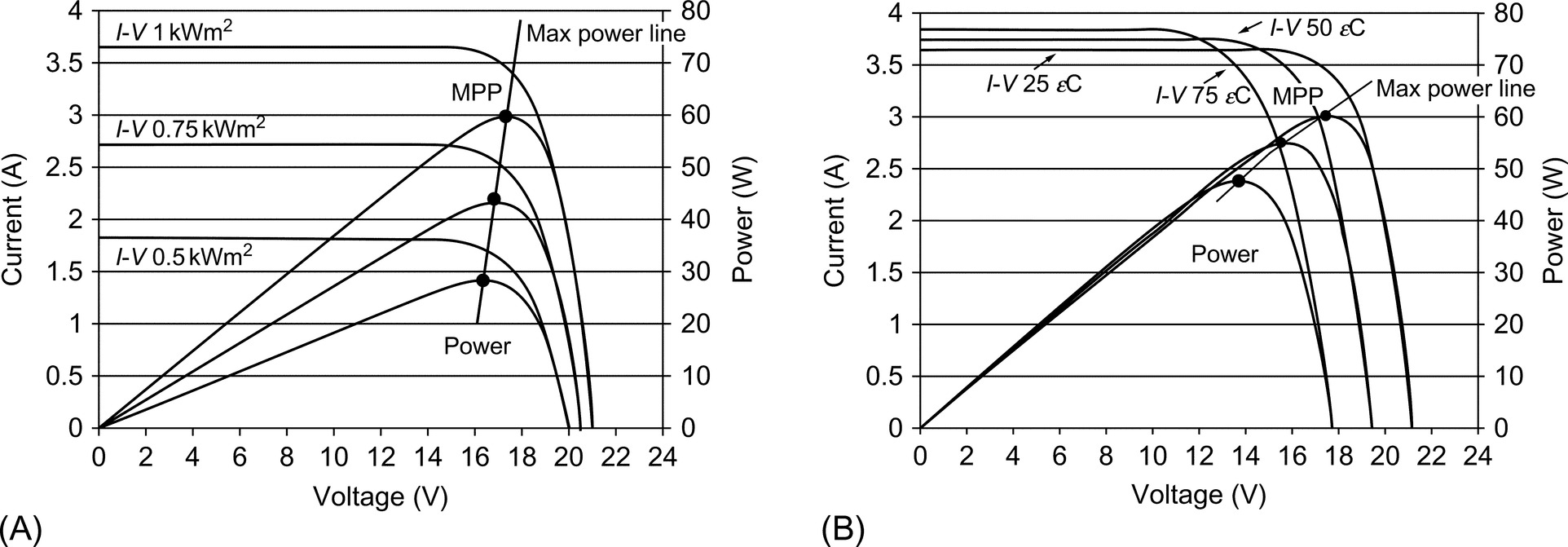

Photovoltaic arrays are usually mounted in a fixed position and tilted toward the south to optimize the noontime and the daily energy production. The orientation of fixed panel should be carefully chosen to capture the most energy for the season or for a year. Photovoltaic arrays have an optimum operating point called the maximum power point (MPP) as shown in Fig. 24.7.

It is noted that power increases as voltage increases, reaching a peak value and decreases as the resistance increases to a point where current drops off. According to the maximum power transfer theory, this is the point where the load is matched to the solar panel's resistance at a certain level of temperature and insolation. The I-V curve changes as the temperature and insolation levels change as shown in Fig. 24.8, and thus, the MPP will vary accordingly.

It is shown that the open-circuit voltage increases logarithmically, while the short-circuit current increases linearly as the isolation level increases. Moreover, increasing the temperature of the cell decreases the open-circuit voltage and increases slightly the short-circuit current, causing a reduction in the efficiency of the cell.

The PV panels, usually mounted on the roof or at a near open area, are fixed to face the sun at an angle matching the country's latitude. If possible, seasonal adjustment of the module's direction toward the sun is done manually. Since solar power technology is relatively expensive, it is important to operate panels at their maximum power conditions. However, to collect as much solar radiation as possible, it is more convenient and efficient to use a sun tracking mechanism causing the module's surface to track the sun throughout the day.

The tracking can be along either one axis or two axes, whereby double axis tracking provides a higher power output. The energy yield can be thus increased by about 20%–30% depending on the seasonal climate and geographic location. Although some claim that a fixed system costs less and requires almost no maintenance, different tracking mechanisms that utilized to control the orientation of the PV panels have proved their superiority over fixed systems in terms of converted power efficiency.

To get maximum power from the PV panel at the prevailing temperature and insolation conditions, either the operating voltage or current should be controlled by a maximum power point tracker (MPPT) that should meet the following conditions:

• Operate the PV system close to the MPP irrespective of the atmospheric changes.

• Have low-cost and high-conversion efficiency.

• Provide an output interface compatible with the battery charging requirement.

24.4 Maximum Power Point Tracking Components

The MPPT increases the energy that can be transferred from the array to an electric system. The main function is to adjust the panel's output voltage to supply the maximum energy to the load. Most current designs consist of three basic components: switch-mode DC-DC converter, control system, and tracking component.

The switch-mode converter is the core of the entire supply because the energy drawn, stored as magnetic energy, is released at different potential levels. By setting up the switch-mode section in various topologies such as buck or boost converter, voltage converters are designed providing a fixed input voltage or current, which correspond to the maximum power point, allowing the output resistance to match the battery. To achieve the above-stated mechanism, a controller is essential to continuously monitor the PV system and ensure its operation at the PV maximum power point by tracking this MPP. The controller's aim is to continuously measure the voltage and current values generated from the PV and compare them with certain threshold values in order to apply either voltage controlled method or power feedback control.

24.4.1 Voltage Feedback Control

With the PV array terminal voltage being the controlled variable, voltage feedback controller forces the PV array to operate at its MPP by changing the array terminal voltage and neglecting the variation in the temperature and insolation level.

24.4.2 Power Feedback Control

In this method, the power delivered to the load is the controlled variable. To achieve maximum power, dp/dv should be zero. This control scheme is not affected by the characteristics of the PV array, yet it increases power to the load and not power from the PV array. Factors such as fast shadows may cause trackers to lose the MPP momentarily. It is very critical to ensure that the time lost in seeking MPP again, which equates the energy lost while the array is off power point, is very short. On the other hand, if lighting conditions do change, the tracker needs to respond within a short amount of time to the change avoiding energy loss. Therefore, the controller's most important feature is its capability to quickly adjust the system to operate back at the MPPT.

24.5 MPPT Controlling Algorithms

Several proposed algorithms to accomplish MPPT are described in the following sections.

24.5.1 Perturb and Observe

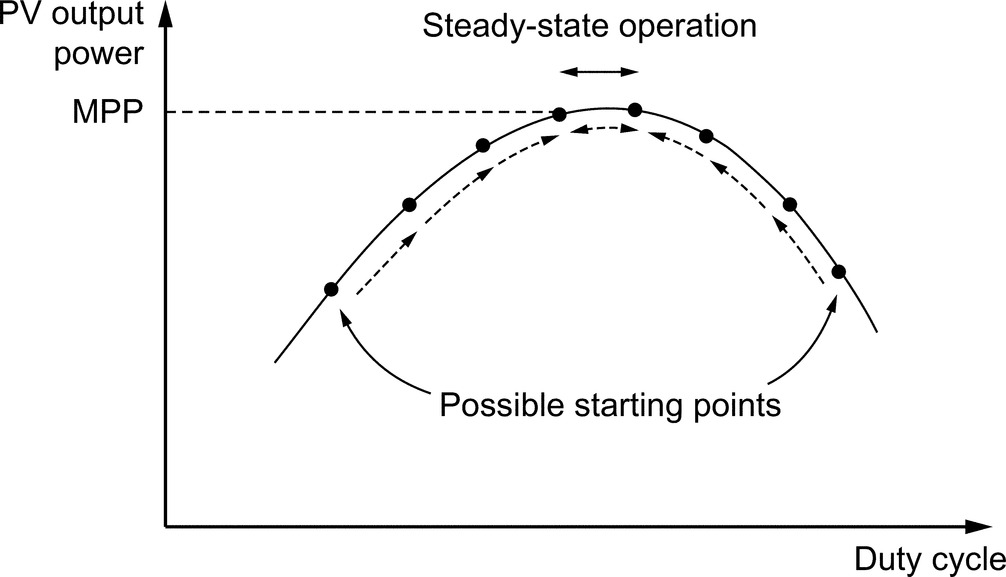

The perturb and observe (PAO) method has a simple feedback structure and few measured parameters. It operates by periodically perturbing (i.e., incrementing or decrementing) the duty cycle while controlling the array current as shown in Fig. 24.9 and comparing the PV output power with that of the previous perturbation cycle. It measures the derivative of power Δp and the derivative of voltage Δv to determine the movement of the operating point. If the perturbation leads to an increase (or decrease) in array power, the subsequent perturbation is made in the same (or opposite) direction. This cost-effective technique can be easily implemented and is characterized by continuously tracking and very efficiently extracting the maximum power from PV. However, such method may fail under rapidly changing atmospheric conditions due to its slow tracking speed.

24.5.2 Incremental Conductance Technique

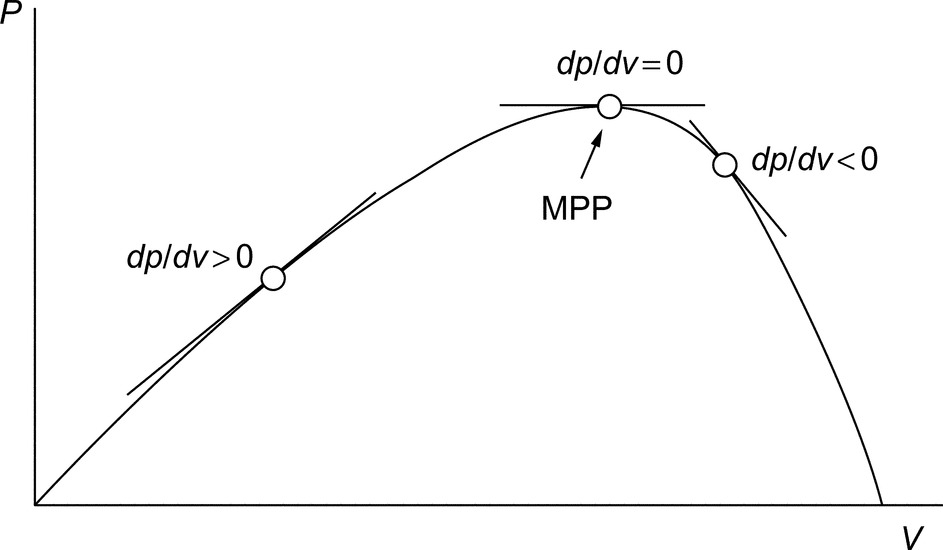

The incremental conductance technique (ICT) process based on the fact that the derivative of the power with respect to the voltage (dp/dv) vanishes at the MPP because it is the maximum point on the curve as shown in Fig. 24.10.

The ICT algorithm detects the MPP by comparing di/dv with ![]() till it attains the voltage operating point at which the incremental conductance is equal to the source conductance. The algorithm starts by measuring the present values of the I and V and then uses the corresponding stored value (Ib and Vb) measured during the preceding cycle to calculate the incremental changes as

till it attains the voltage operating point at which the incremental conductance is equal to the source conductance. The algorithm starts by measuring the present values of the I and V and then uses the corresponding stored value (Ib and Vb) measured during the preceding cycle to calculate the incremental changes as ![]() and

and ![]() . Based on the result obtained, the control reference signal Vref will be adjusted in order to move the array voltage toward the MPP voltage. At the MPP,

. Based on the result obtained, the control reference signal Vref will be adjusted in order to move the array voltage toward the MPP voltage. At the MPP, ![]() , no control action is needed; therefore, the adjustment stage will be bypassed, and the algorithm will update the stored parameters at the end of the cycle. In order to detect any changes in weather conditions, the algorithm detects whether a control action took place when the array was operating at the previous cycle MPP (

, no control action is needed; therefore, the adjustment stage will be bypassed, and the algorithm will update the stored parameters at the end of the cycle. In order to detect any changes in weather conditions, the algorithm detects whether a control action took place when the array was operating at the previous cycle MPP (![]() ). This technique is accurate and well suited for rapid changes in atmospheric conditions; however, because the increment size approach is used to determine how fast the system is responding, ICT requires precise calculations of both instantaneous and increasing conductance.

). This technique is accurate and well suited for rapid changes in atmospheric conditions; however, because the increment size approach is used to determine how fast the system is responding, ICT requires precise calculations of both instantaneous and increasing conductance.

24.5.3 Constant Reference

One very common MPPT technique is to compare the PV array voltage (or current) with a constant reference voltage (or current), which corresponds to the PV voltage (or current) at the maximum power point, under specific atmospheric conditions. The resulting difference signal (error signal) is used to drive a power conditioner, which interfaces the PV array to the load. Although the implementation of this method is simple, the method itself is not very accurate because it does not consider the effects of temperature and irradiation variations in addition to the difficulty in choosing the optimum point.

24.5.4 Current-Based Maximum Power Point Tracker

Current-based maximum power point tracker (CMPPT) is another MPPT technique that exists. Employed numerical methods show a linear dependence between the “cell currents corresponding to maximum power” and the “cell short-circuit currents.” The current IMPP operating at the MPP is calculated using the following equation:

where MC is the “current factor” that differs from one panel to another and is affected by the panel surface conditions, especially if partial shading covers the panel. Although this method is easy to implement, an additional switch is added to the power converter to periodically short the PV array, increase the cost, and reduce the output power. This method also suffers from a major drawback due to periodic tuning requirement.

24.5.5 Voltage-Based Maximum Power Point Tracker

Similar to the above-mentioned method, voltage-based maximum power tracking (VMPPT) technique can also be applied. The MPP operating voltage is calculated directly from VOC:

where MV is the “voltage factor.” The open-circuit voltage VOC is sampled by an analog sampler, and then, VMPP is calculated by Eq. (24.13). This operating VMPP voltage is the reference voltage for the voltage control loop as shown in Fig. 24.11. This method always “results in a considerable power error because the output voltage of the PV module only follows the unchanged reference voltage during one sampling period” [2]. Albeit the implementation of this procedure is simple, it endures several disadvantages such as momentarily power converter shutdown causing power loss. Furthermore, such process depends greatly on the I-V characteristics and requires periodic tuning.

Other researchers argue that these two practices are considered to be “fast, practical, and powerful methods for MPP estimation of PV generators under all insolation and temperature conditions” [3].

24.5.6 Other Methods

Automated techniques such as Fibonacci line search, ripple correlation control method, neural network, and fuzzy logic have also been introduced for MPPT. In order to generate a clear understanding in determining the advantages and disadvantages of each algorithm, a comprehensive experimental comparison between different MPPT algorithms was made and run for the same PV setup at South Dakota State University, and results showed that the ICT method has the highest efficiency of 98% in terms of power extracted from the PV array, the PAO technique has the efficiency of 96.5%, and finally, the constant voltage method has the efficiency of 88%.

The ICT method provided good performance under rapidly changing weather conditions and provided the highest tracking efficiency, although four sensors were required to perform the measurements for computations and decision-making. If the system required more conversion time in tracking the MPP, a large amount of power loss would occur. On the contrary, under perturb and observe method, losses are reduced if the sampling and execution speed were increased. The main benefit of this procedure is that only two sensors are required, which resulted in the reduction of hardware requirements and cost.

24.6 Grid-Connected Photovoltaic System

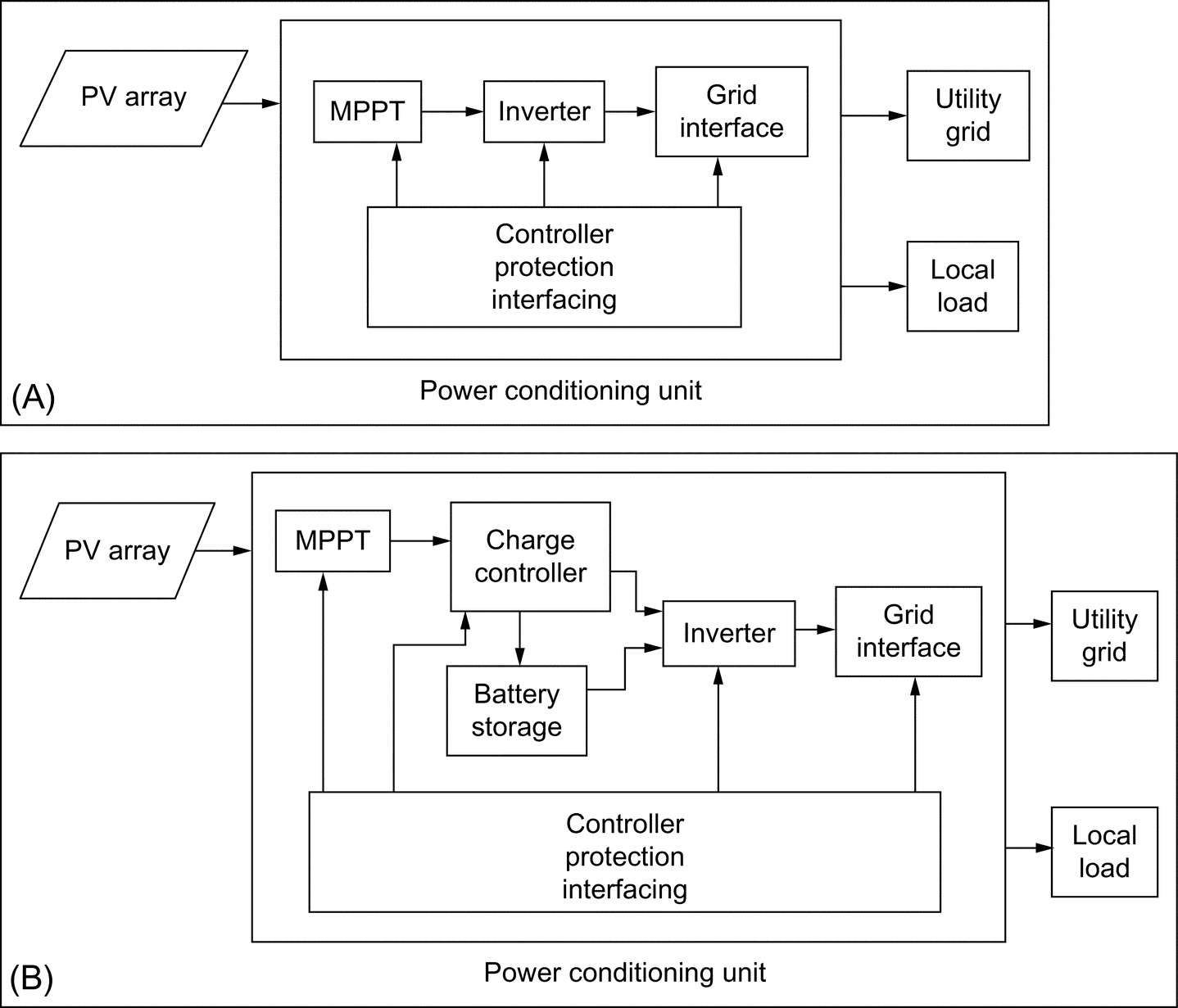

Grid-connected photovoltaic systems are composed of PV arrays connected to the grid through a power conditioning unit (PCU) and are designed to operate in parallel with the electric utility grid. The power conditioning unit may include the MPPT, the inverter, the grid interface, and the control system needed for efficient system performance. There are two general types of electric designs for PV power systems: systems that interact with the utility power grid as shown in Fig. 24.12A and have no battery backup capability and systems that interact and include battery backup as well as shown in Fig. 24.12B. The latter type of system incorporates energy storage in the form of a battery to keep “critical load” circuits operating during utility outage. When an outage occurs, the unit disconnects from the utility and powers specific circuits of the load. If the outage occurs in daylight, the PV array is able to assist the load in supplying the loads.

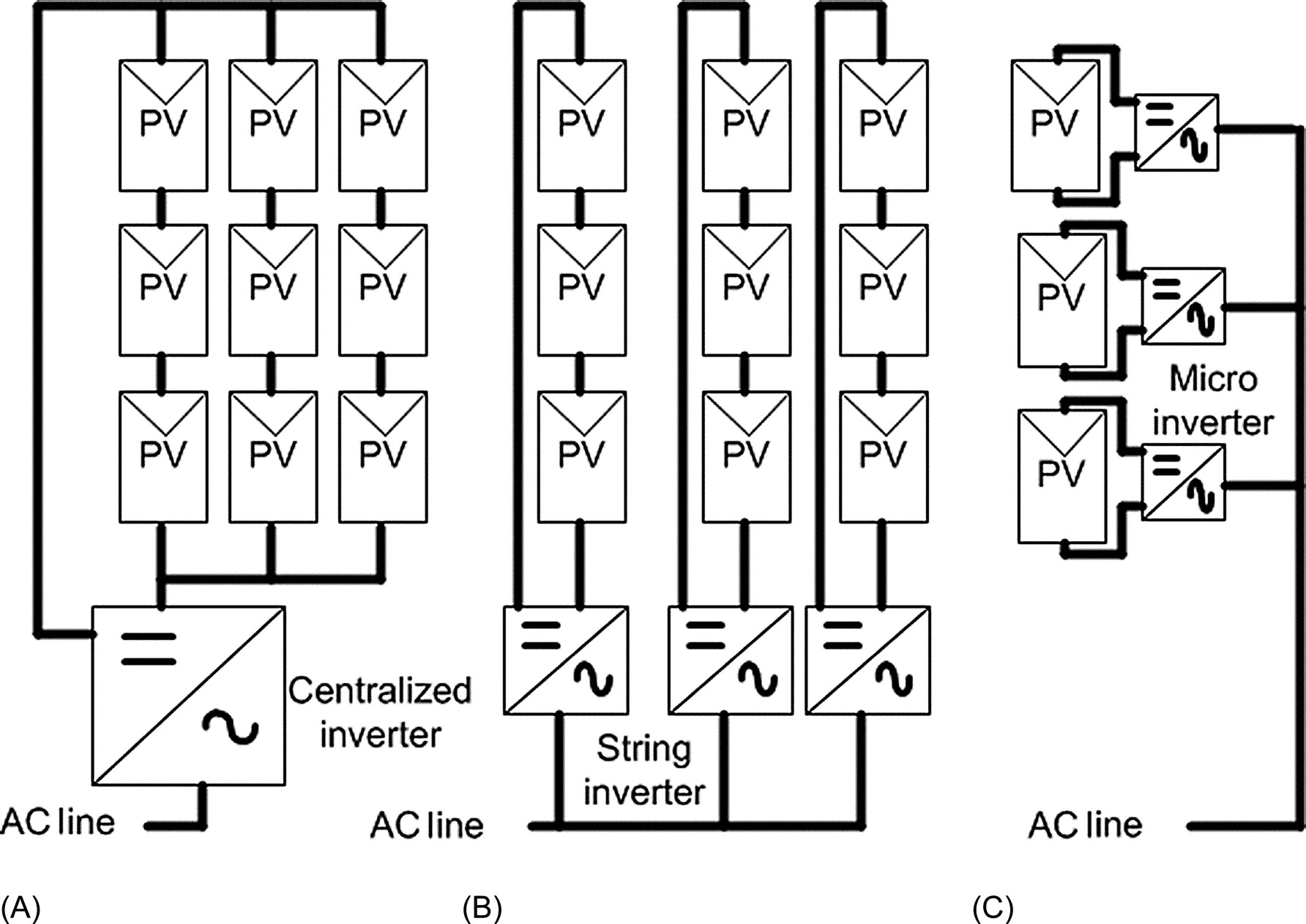

The major component in both systems is the DC-AC inverter or also called the power conditioning unit (PCU). The inverter is the key to the successful operation of the system, but it is also the most complex hardware. The inverter requirements include operation over a wide range of voltages and currents and regulated output voltage and frequency while providing AC power with good power quality that includes low total harmonic distortion and high power factor, in addition to highest possible efficiency for all solar irradiance levels. Inverters can be used in a centralized connection (Fig. 24.13A) for the whole array of PV, each PV module string is connected to a single inverter (Fig. 24.13B), and a single PV module is connected to a named microinverter (Fig. 24.13C).

The first circuit handled all the power, and the maximum power point is difficult to follow if there is voltage/current mismatching at the PV modules. The second option is more efficient than the first one since it minimizes the losses due to voltage/current mismatching and it enhances its modularity capability. The last circuit may perform a good tracking since each PV module is controlled independently; however, more stages and components are required.

For the last years, researchers have been working on developing different inverter topologies. The evolution of solid-state devices such as metal-oxide-semiconductor field-effect transistors (MOSFETs), insulated-gate bipolar transistors (IGBTs), microprocessors, and PWM-integrated circuits has allowed improvements on the inverter. Some research is being carried to ensure quality control, reliability, high efficiency, and lower cost since inverters are the key for a sustainable photovoltaic market.

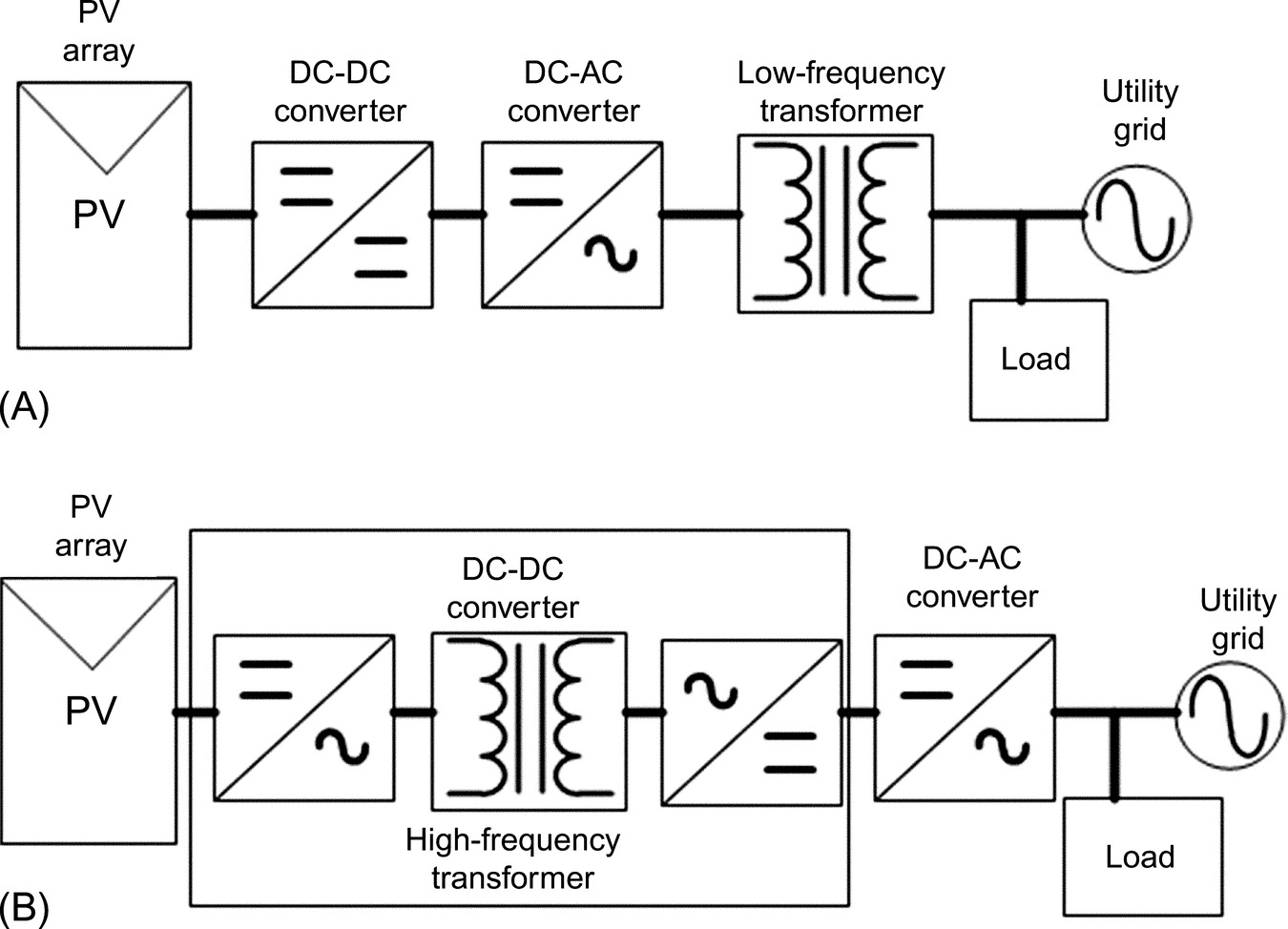

24.6.1 Isolated Converters

For safety reasons, not only both the grid neutral line and the chassis of the PV modules must be grounded, but also the PCU may provide galvanic isolation. The first option is to place the isolation on the grid side, by using an AC low-frequency transformer (Fig. 24.14A), which makes the system big, heavy, and bulky. The second option is to include the isolation on the DC side, after the PV array, by using a high-frequency transformer (Fig. 24.14B), which is smaller and costs less than an AC transformer.

These options have different drawbacks: low efficiency, the size and weight are compromised, and the cost should be high due to the inclusion of the isolation. Therefore, researchers are developing the PCUs without isolation.

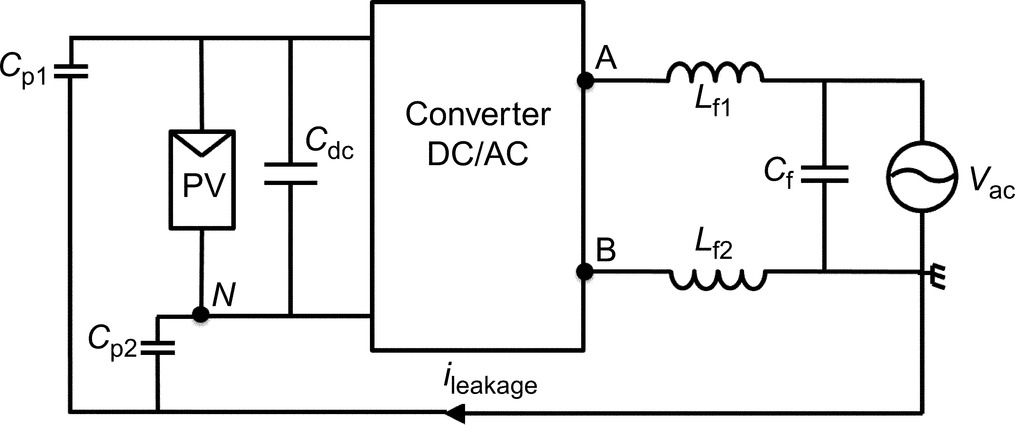

24.6.2 Transformerless Converters

A costless PCU is obtained if the isolation is removed, but then, a common-mode resonant circuit appears due to the grounding cable, which includes the filter, the inverter, the grid impedance, and the PV parasitic capacitance. This common mode generates a leakage current (ileakage) that circulates through parasitic capacitances in PV array to the ground, as shown in Fig. 24.15. The common-mode voltage, the modulation strategy, and the value of the parasitic capacitance greatly affect the value of the leakage current.

The parasitic capacitance value depends on many factors such as the PV panel and frame structure, the surface of cells, the distance between cells, the weather conditions, and the type of EMC filter. In order to reduce this parasitic current, different PCUs have been reported: H-5, HERIC, and common-mode inverters, among others.

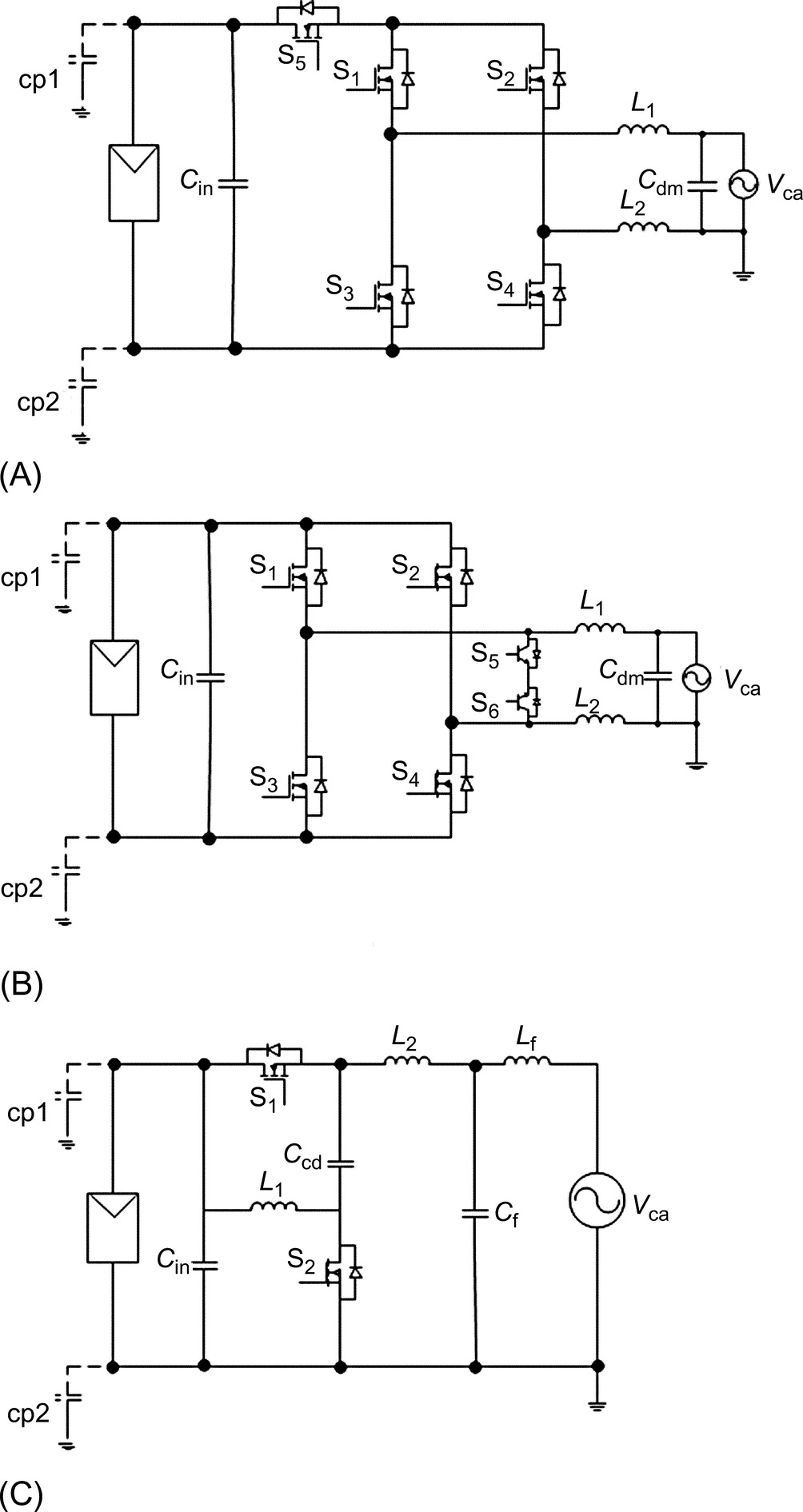

A. H-5 inverter

This DC/AC converter is similar to the traditional full-bridge inverter topology, where the upper switches operate at grid frequency and the lower ones work at a high frequency. It has incorporated an extra switch S5 on the DC side that operates in both semicycles at a high frequency (Fig. 24.16A). The main characteristic of this configuration is that the PV array is decoupled from the grid when this extra switch is turned off.

Normally during active states, the current flows during freewheeling modes through two switches, but in active vectors, the current flows through three switches causing conduction losses, which become a disadvantage.

B. Heric inverter

This topology combines advantages from two alternatives: the three-level output voltage of the unipolar PWM, besides the reduced common-mode voltage as in the case of bipolar PWM. It consists of a full-bridge inverter plus two additional switches, as illustrated in Fig. 24.16B. Each group of diagonal switches of the full bridge operates at a high frequency during the half wave of the grid. One of the two additional switches is turned on during the half wave of the grid. S5 or S6 is used when the disconnection occurs between the grid and PV array, which reduces the leakage current. The main drawback of this topology is the pair of additional semiconductors.

C. Common mode converter

There are different schemes for this configuration; the main idea is that the neutral terminal of the grid is connected straight to the negative of the PV array. Shown in Fig. 24.16C is an alternative; this topology is composed of two power MOSFETs (S1 and S2), and just a single device is conducting in each switching state. The converter includes two capacitors and three inductors (Cf, Cdc and L1, L2, Lf).

Since the negative of the PV array is connected straight to the neutral line of the grid, the ground leakage current is very low, while the applied voltage to the parasitic capacitance is maintained almost constant.

24.6.3 Grid Synchronization

PV grid-connected converters need a phase and frequency tracking system to provide a reference signal in order to synchronize it with the grid voltage. It is critical in a synchronization system with a high degree of immunity to harmonics, unbalances, and power system disturbances as sags and swells.

There are several state-of-the-art techniques in detecting the phase angle of the grid voltages. A particular easy and simple to implement is the voltage zero-crossing technique. However, voltage sags and harmonics can disturb greatly the output signal. Digital schemes have improved zero-crossing method using filtering techniques: extended Kalman filters, low-pass filters, space vector, and recursive weighted least-square estimation.

Phase-locked-loop (PLL)-based algorithms can successfully reject harmonics, notches, voltage sags, and swells. At the same time, PLL algorithms provide the estimation of time-varying fundamental parameters from the distorted grid voltage waveform. Another representative technique in grid synchronization is the second-order generalized integrator frequency-locked loop (SOGI-FLL). SOGI-FLL-based techniques estimate important grid parameters for single- and three-phase systems, reducing undesirable frequency swing during phase-angle jumps.

24.6.4 Islanding Mode

For security reasons, the PV grid-connected inverters must be disconnected from the grid when the utility is disabled or out of operation. Once the grid is out, the PV system is operating in islanding mode, and this mode must be detected in order to shut off the system and separate it from the utility.

The islanding mode detector may be classified in local or remote techniques. The local techniques are based on the measurements of physical parameters at the common point of coupling, like voltage and current. The remote techniques are based on communication infrastructure between the electricity provider and the PV system. The local techniques may be subclassified in passive and active methods. These methods are briefly described as follows.

A. Passive methods

The passive method is based on not only the measurement of variables as voltage and current at common point of coupling but also obtaining parameters like rms voltage, rms current, frequency, phase, and total harmonic distortion. It established the range for the normal operation, and once the system is out of the specified range, the PV system is considered that is operating in islanding mode.

B. Active methods

The active methods also are based on the measurements of voltage and current, but additionally, these methods inject perturbations in order to accelerate the fastness of the detection. There are many methods.

One method is called the shift active frequency, during a small time, the injected current is zero (no sinusoidal current), and when the system is in islanding mode, the output frequency is naturally changed, and this will be detected fast.

A second method is called sandia voltage shift; in this scheme, a positive feedback is considered in the current loop; this loop tries to produce an instability at the output voltage. If the system is operated normally, this loop will not cause a major trouble since the stability is determined by the grid. However, when the islanding mode occurs, this loop will produce an instability at the output voltage, and this is detected fast as an under or overvoltage.

24.7 Stand-Alone Photovoltaic System

The main advantage of PV systems is their flexibility to be implemented in remote locations where grid connection is either impossible or very expensive to execute. Such systems are called stand-alone PV systems and are described in this section.

Stand-alone photovoltaic systems are usually a utility power alternative. They generally include solar charging modules, storage batteries, and controls or regulators as shown in Fig. 24.17. Ground- or roof-mounted systems will require a mounting structure, and if AC power is desired, an inverter is also required. In many stand-alone PV systems, batteries are used for energy storage as they may account for up to 40% of the overall stand-alone PV system cost over its lifetime.

These batteries cause losses in the PV system due to limited availability of time and energy to recharge the battery in addition to the insufficient battery maintenance. Hence, a charge controller is then used to control the system and prevent the battery from overcharging and overdischarging. Overcharging shortens the battery life and may cause gassing, while undercharging may lead to sulfation and stratification, which result in the reduction in battery effectiveness and lifetime.

Batteries are often used in PV systems for storing energy produced by the PV array during daytime and supplying it to electric loads as needed (during nighttime or cloudy weather). Moreover, batteries are also needed in the tracker systems to operate at MPP in order to provide electric loads with stable voltages. Nearly, most of the batteries used in PV systems are deep-cycle lead-acid batteries. These batteries have thicker lead plates that make them tolerate deep discharges. The thicker the lead plates, the longer the lifespan of the batteries. The heavier the battery for a given group size, the thicker the plates and the better the battery will tolerate deep discharges.

All deep-cycle batteries are rated in ampere-hour (AH) capacity, a quantity of the amount of usable energy it can store at nominal voltage. A good charge rate is approximately 10% of the total capacity of the battery per hour. This will reduce the electrolyte losses and the damage to the plates. A PV system may have to be sized to store a sufficient amount of power in the batteries to meet power demand during several days of cloudy weather, known as “days of autonomy.” The Institute of Electrical and Electronics Engineers (IEEE) has set several guidelines and standards for sizing lead-acid batteries (IEEE Std 1013–1990), for selecting, charging, and testing in stand-alone PV systems (IEEE Std 1361–2003), and for installing and maintaining them (IEEE Std 937–2007).

Nickel-cadmium batteries are also used for PV stand-alone systems but are often expensive. However, their main advantage is they are not affected by temperature as other battery types, hence mostly recommended for industrial or commercial applications in cold locations. IEEE has also drafted some guidelines for installation and maintenance (IEEE Std 1145–1999).

To extend battery's lifetime and for efficient system's operation, a charge controller is needed to regulate the flow of electricity from the PV modules to the battery and the load. The controller keeps the battery fully charged without overcharging it. Many controllers have the ability to sense the excess of electricity drawn from batteries to the load and stop the flow until sufficient charge is restored to the batteries. The latter can greatly extend the battery's lifetime. However, controllers in the stand-alone photovoltaic system are more complex devices that depend on battery state of charge, which in turn depends on many factors and is difficult to measure. The controller must be sized to handle the maximum current produced. Several characteristics should be considered before selecting a controller such as adjustable set points including high-voltage and low-voltage disconnects, temperature compensation, low-voltage warning, and reverse current protection. Moreover, the controller should ensure that no current flows from the battery to the array at night.

24.7.1 Power Converters

There are different power converters for stand-alone systems, and they have different operating modes. They may be summarized as described below:

• Power delivered from the main voltage source

The power converter may be able to deliver energy directly to the load form the main voltage source, without the use of the battery set. This mode in some converters is not considered, and the load is just fed by the battery set.

• Not energy available from the main voltage source

It is possible to not have energy due to weather conditions, and then, the battery will deliver the energy to the load. This may be through a direct connection or by considering a power converter.

• Power delivered from main source and battery set

When the photovoltaic system cannot provide all required energy by the load, but still there is available energy, then the system could be operated to demand energy from both sources: the photovoltaic system and the battery set. Not all the power converters may operate in this form.

• Charging the battery set

Once the battery is empty, a charging mode must be considered. The battery is fed by the photovoltaic system through a power converter. This mode occurs if there is energy available from the renewable source.

• No energy available from any source

It is possible to not have energy due to weather conditions and also when the battery is discharged; then, the system is turned off, until the system has the energy to operate.

For stand-alone applications, it is possible to consider more than one solar panel, besides the battery set. Then, power converter with multiple inputs should be considered. One of the most important issues in these converters is the power administration, that is, to determine when each source should be used, in order to have the best operation of the system.

24.8 Factors Affecting PV Output

PV systems produce power in proportion to the intensity of sunlight striking the solar array surface. Thus, there are some factors that affect the overall output of the PV system and are discussed below.

24.8.1 Temperature

The output power of a PV system decreases as the module temperature increases. An increasing cell temperature at constant irradiance causes a reduction in VOC at a rate approximately of 2–2.5 mV/C. The short-circuit current, on the other hand, remains nearly constant. Since Vmp is normally about 80% of VOC and the cells are series connected, it is important the combined effect on cell performance merit careful consideration. The temperature effect on monocrystalline solar cells is higher than polycrystalline silicon and thin-film solar cells; operating at temperatures higher than 25°C may reduce maximum output power by 15% in monocrystalline solar cells and by 5% in thin-film solar cells.

24.8.2 Dirt and Dust

Dirt and dust can accumulate on the solar module surface, also known as soiling. The soil layer blocks the sunlight and reduces the output power. Estimation of soiling loss is difficult due to the variations in the soil type, geographic locations, and climatic conditions. In general, there are two types of soil shading on PV modules, namely, hard shading and soft shading. Hard shading occurs when a solid such as accumulated dust blocks the sunlight in a clear and definable shape. On the other hand, soft shading takes place when some particles such as smog or some dust reduce the overall intensity of the solar irradiance.

For hard shading, the performance of the PV module depends on the portions shaded of the PV module. Soft shading affects the current of the PV module, but the voltage remains the same. To get better performance, the solar module surface must be clean. Manually hand cleaning element by water with detergent is suggested one time per week on the panel.

24.8.3 DC-AC Conversion

Because the power from the PV array is converted back to AC as shown earlier, some power is being lost in the conversion process, in addition to losses in the wiring. Common inverters used have peak efficiencies of about 90%–98%. Recently, the new devices based on gallium nitride (GaN) and silicon carbide (SiC) are recommended for these power converters.

24.9 PV System Design

The goal for a solar direct electricity generation system or photovoltaic system is to provide high-quality, reliable, and green electric power. Then, some suggestions may be followed.

24.9.1 Criteria for a Quality PV System

The criteria for quality PV system are as follows:

• Be properly sized and oriented to provide electric power and energy

• Good control circuit to reduce electric losses, overcurrent protection, switches, and inverters

• Good charge controller and battery management system, if the system contains batteries

24.9.2 Design Procedures

The first task in designing a PV system is to estimate the system's load. This is achieved by defining the power demand of all loads, the number of hours used per day, and the operating voltage. From the load ampere-hours and the given operating voltage for each load, the power demand is calculated. For a stand-alone system, the system voltage is the potential required by the largest load. When AC loads dominate, the DC system voltage should be chosen to be compatible with the inverter input.

24.9.3 Power-Conditioning Unit

The choice of the PCU has a great impact on the performance and economics of the system. It depends on the type of waveform produced, which in turn depends on the method used for conversion and the filtering techniques of unwanted frequencies. Several factors must be considered when selecting or designing the inverter:

• The power conversion efficiency

• Rated power

• Duty rating, the amount of time the inverter can supply maximum load

• Input voltage

• Voltage regulation

• Voltage protection

• Frequency requirement

• Power factor

• Islanding detection

24.9.4 Battery Sizing

PV system parameters need to be defined with the battery in mind. The amount of battery storage needed depends on the load energy demand and on weather patterns at the site. There is always a trade-off between keeping cost low and meeting energy demand. There are a number of basic battery characteristics that can have a significant impact on PV system performance.

Among the most important characteristics are temperature effects, recharge efficiency, charge voltage, and the number of days a PV battery will carry the load without energy from the PV array. It is important to clearly define battery charging requirements and meet those charging requirements with proper charge control voltage and array sizing.